A three-dimensional coiling machine for welded coiled tubes

A coiling machine and three-dimensional technology, applied in the field of metal product processing, can solve problems such as unsafety and pressure, and achieve the effects of increasing service life, improving working environment, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

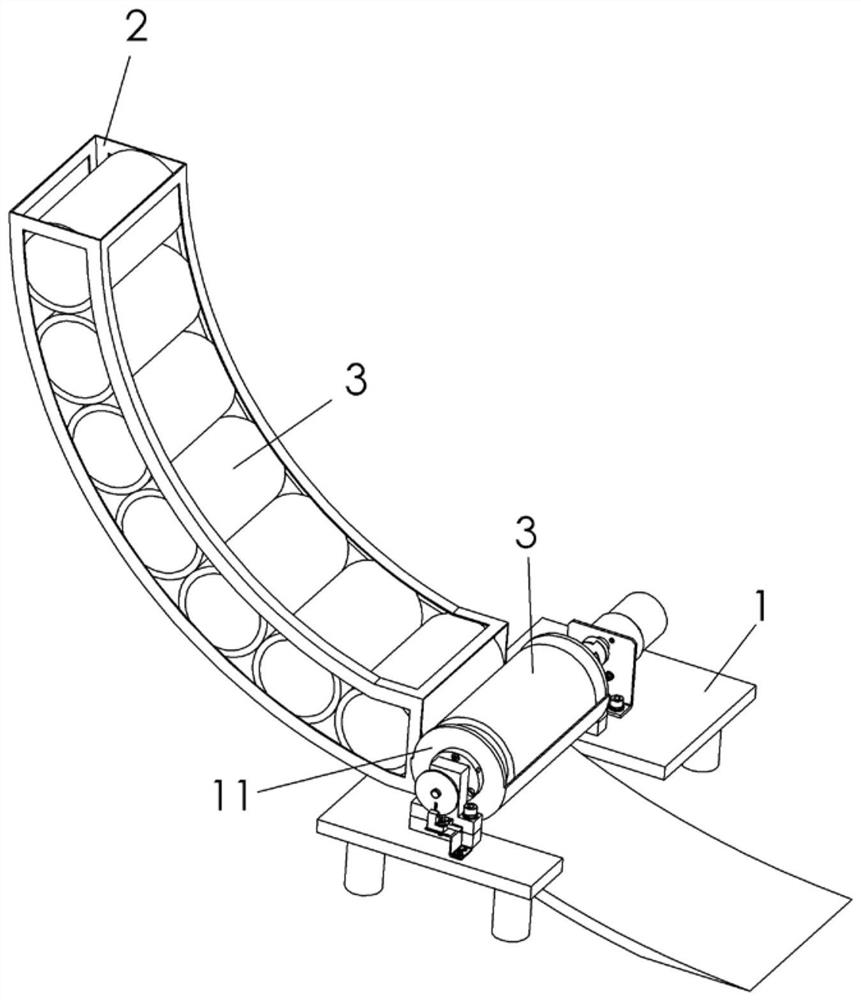

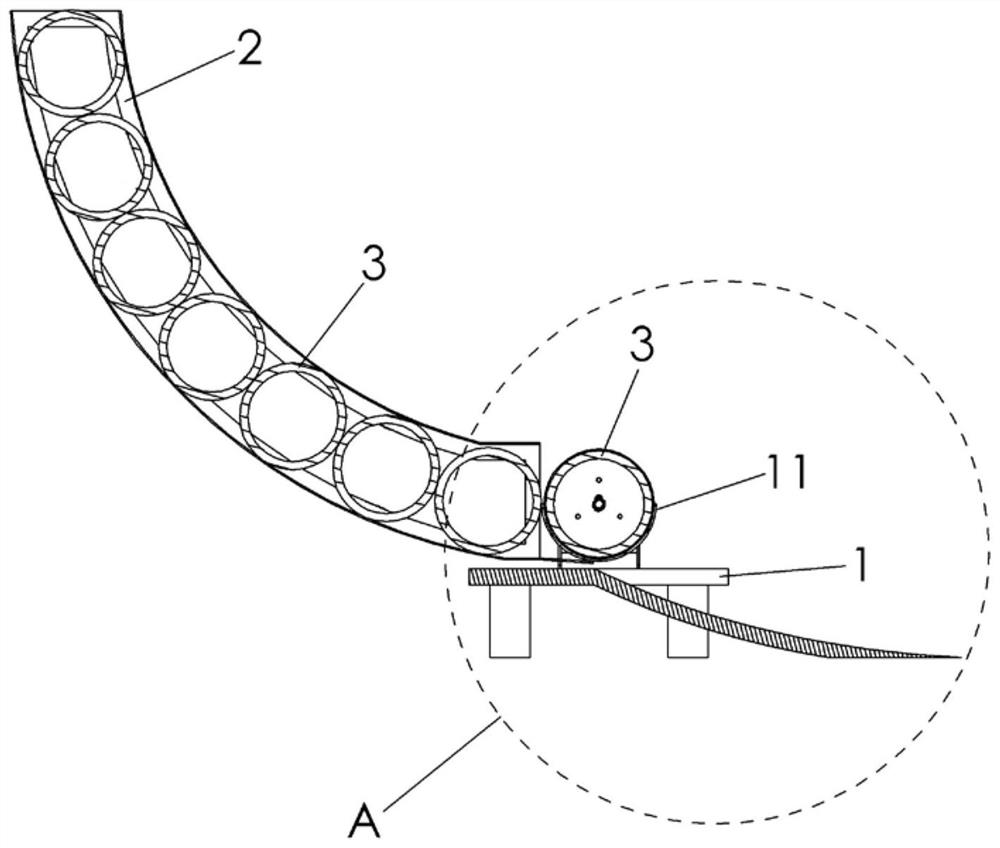

[0022] see Figure 1-Figure 5 , the present invention is a three-dimensional coiling machine for welded coiled tubes, which includes a coiling unit 1 and a conveying unit 2 .

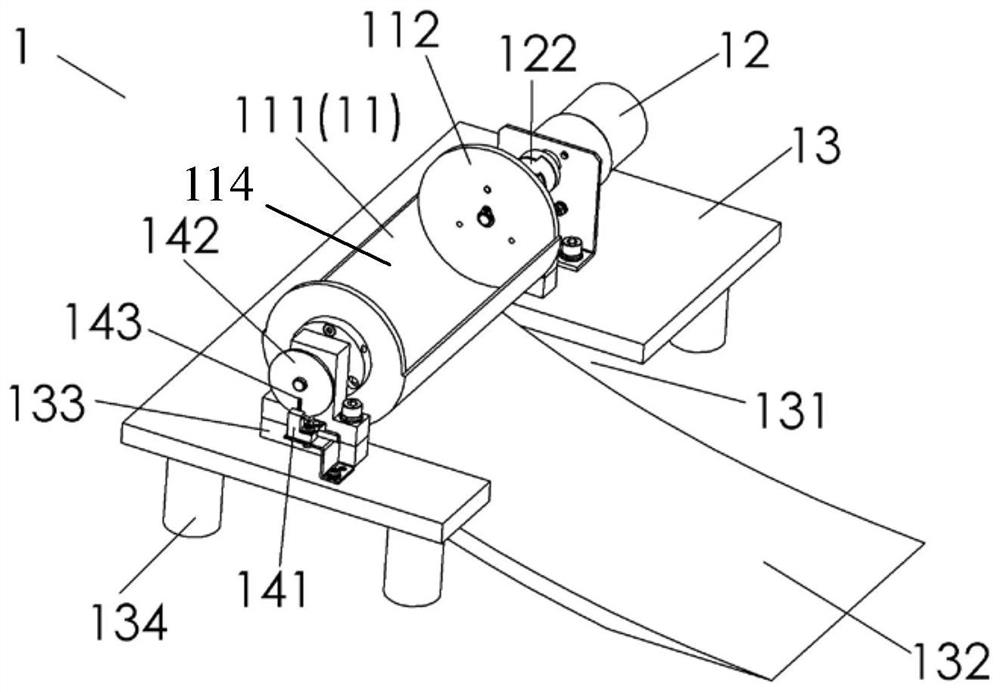

[0023] The sub-roll section 1 includes a sub-drum 11 , a power unit 12 and a frame 13 .

[0024] The sub-reel 11 is connected to the power device 12 , and the frame 13 is provided with a discharge port 131 , and the sub-reel 11 is hinged on the frame 13 and faces the discharge port 131 .

[0025] The sub-roller 11 includes a sub-volume arc plate 111, and the two ends of the sub-volume arc plate 111 are fixedly provided with end plates 112, and the sub-volume arc plate 111 is a semi-open structure, such as image 3 As shown, the sub-volume arc-shaped plate 111 is a receiving groove 114 formed by recessing from the surface of the cylinder, and the two sides of the notch surface of the receiving groove 114 form an angle of 180-90 degrees with the axis of the cylinder, preferably 180 degrees. The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com