Method of Strengthening Beams with Prestressed Carbon Fiber Plates

A carbon fiber board, reinforcing beam technology, used in building maintenance, construction, building construction, etc., can solve problems such as difficult to control bolt force changes, poor anchoring performance, disconnection, etc., to achieve long-term effectiveness of prestress and improve prestress efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

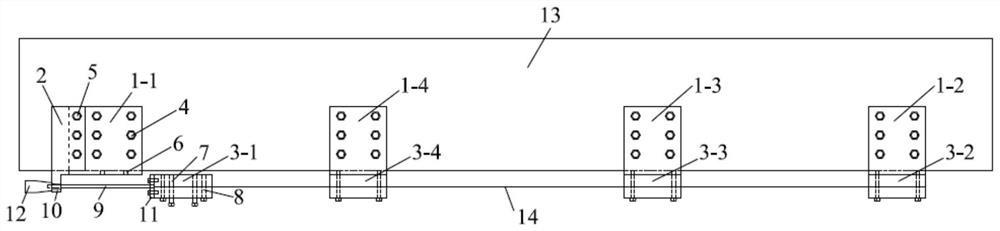

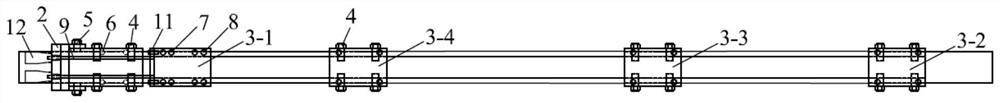

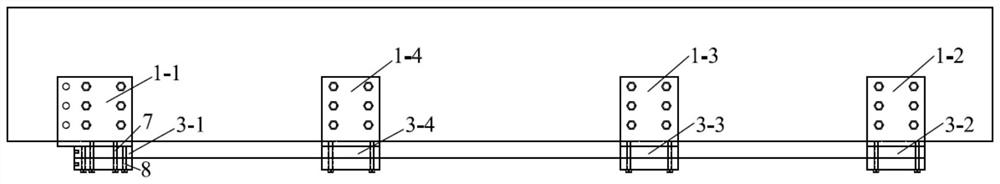

[0057] Such as Figure 1-6 Shown, according to an embodiment of the method for the prestressed carbon fiber plate strengthening beam of the present invention, it comprises the following steps in sequence:

[0058] Step 1: Calculate the length of the carbon fiber plate for reinforcement according to the length of the beam to be strengthened, the material properties of the carbon fiber plate, and the magnitude of the tension control stress, number the material and intercept it;

[0059] Step 2: mark the side of the beam 13 to be reinforced according to the design positions of tension end anchor plate 1-1, fixed end anchor plate 1-2, intermediate anchor plate I1-3, and intermediate anchor plate II1-4 Hole position, the marked punching position and the expansion bolt 4 on the tension end anchor plate 1-1, the fixed end anchor plate 1-2, the middle anchor plate I1-3, and the middle anchor plate II1-4 Corresponding to the hole, insert the expansion tube after drilling, and fill the...

Embodiment 2

[0079] According to another embodiment of the method for strengthening a beam with a prestressed carbon fiber plate of the present invention, its process steps, the structure of the carbon fiber plate anchor, the connection relationship between each component, the working principle, the beneficial effect, etc. are all the same as the first embodiment, The difference is: in the carbon fiber plate inner surface clamping anchorage, the length of the upper splint and the lower splint is 55 times the thickness of the carbon fiber plate; the two ends of the upper splint and the lower splint along the longitudinal direction The thickness of the plywood is 4cm; the difference between the thickness of the middle position of the upper splint and the lower splint in the longitudinal direction and the thickness of the two ends is 11% of the thickness of the carbon fiber plate; the compression of the carbon fiber plate at the central position of the through hole The amount is 11%.

Embodiment 3

[0081] According to another embodiment of the method for strengthening a beam with a prestressed carbon fiber plate of the present invention, its process steps, the structure of the carbon fiber plate anchor, the connection relationship between each component, the working principle, the beneficial effect, etc. are all the same as the first embodiment, The difference is: in the carbon fiber plate inner surface clamping anchorage, the length of the upper splint and the lower splint is 60 times the thickness of the carbon fiber plate; the two ends of the upper splint and the lower splint along the longitudinal direction The thickness of the plywood is 5cm; the difference between the thickness of the middle position of the upper splint and the lower splint in the longitudinal direction and the thickness of the two ends is 12% of the thickness of the carbon fiber plate; the compression of the carbon fiber plate at the central position of the through hole The amount is 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com