Efficient airtightness faucet for engineering driller

An engineering drilling rig and sealing technology, applied in the direction of engine sealing, earthwork drilling, mechanical equipment, etc., can solve the problems of poor sealing performance, low work efficiency, high labor intensity of workers, etc., to solve the problems of poor sealing performance and reliability. And the effect of long life, quick and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

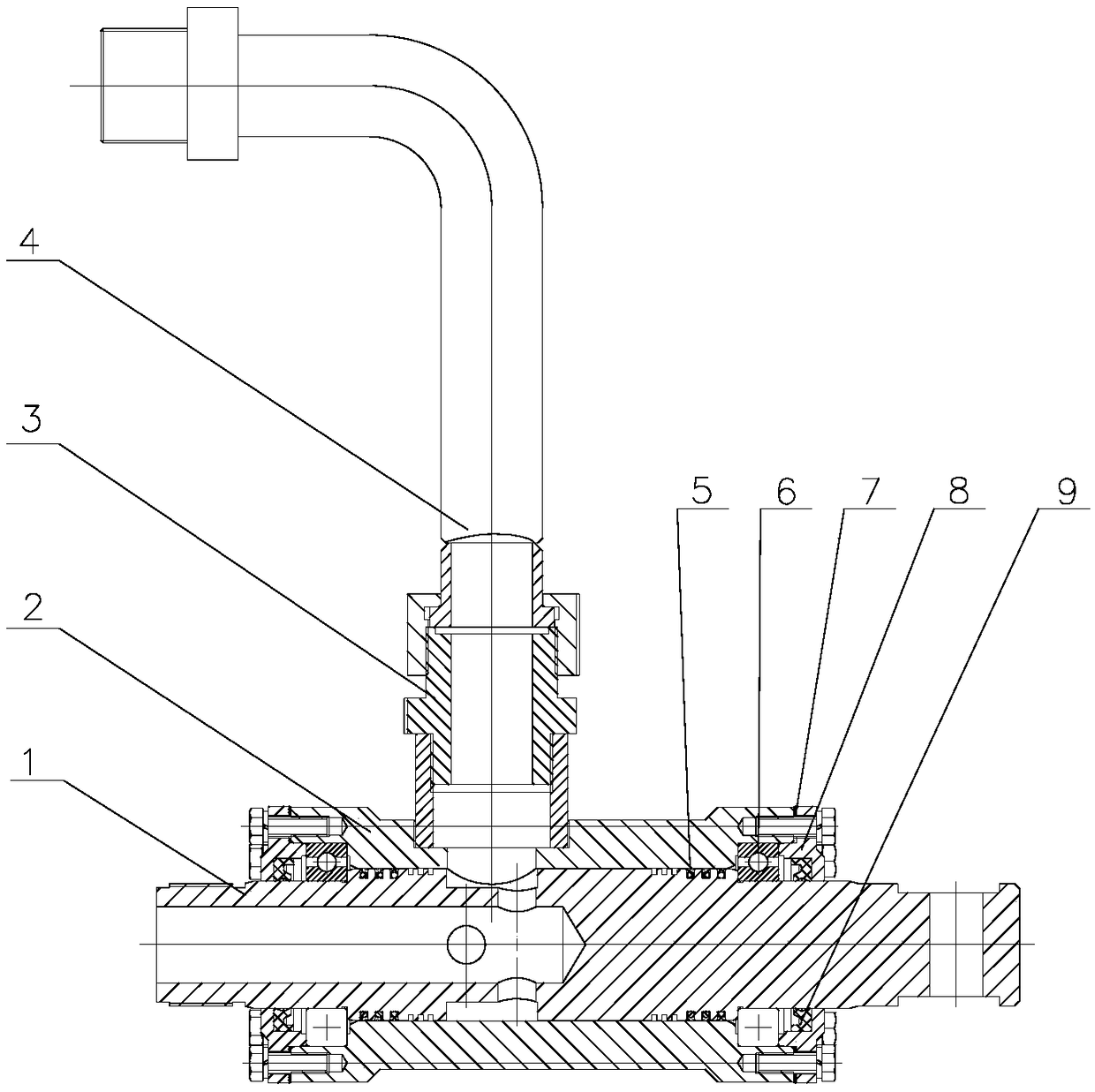

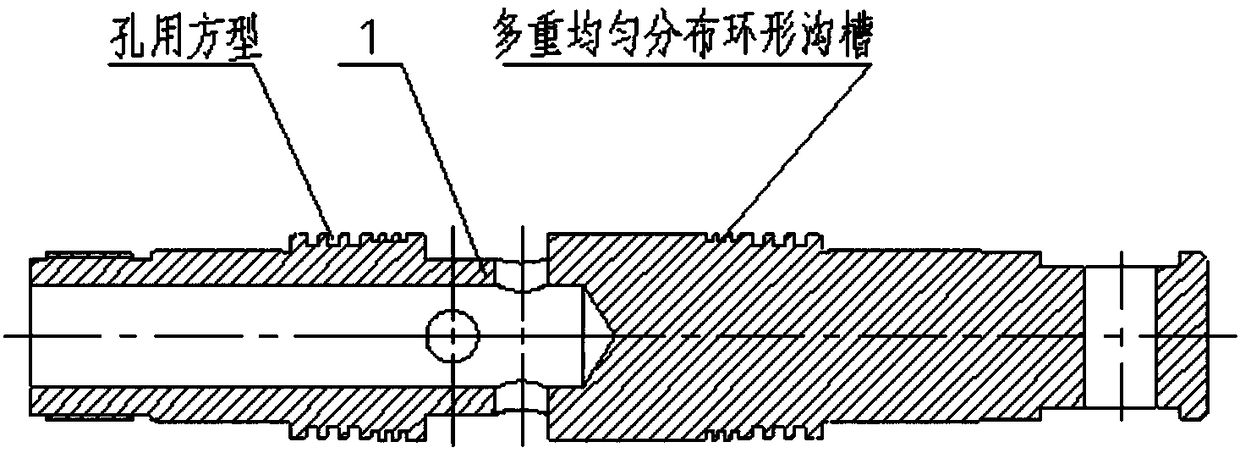

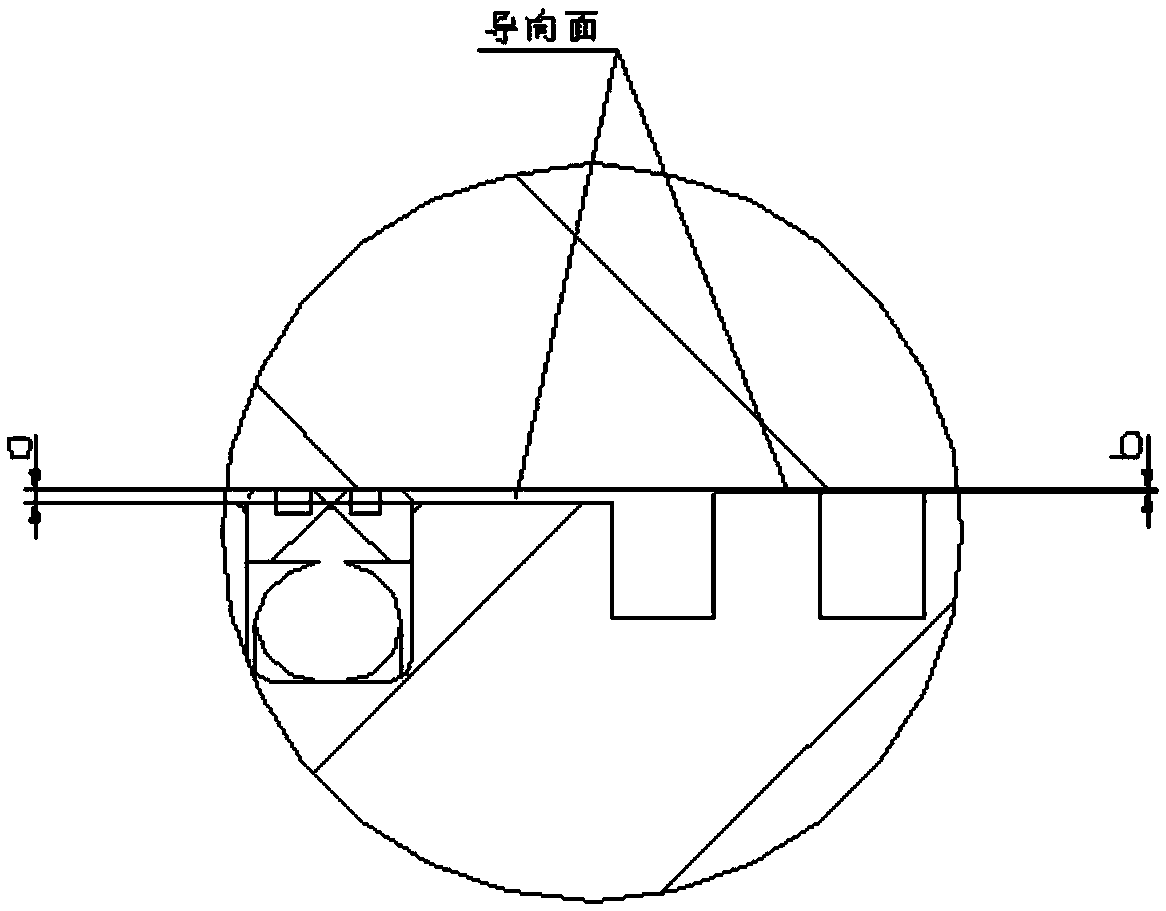

[0022] Such as figure 1 As shown, a high-efficiency airtight faucet for engineering drilling rigs includes a rotary core tube 1 and a rotary housing 2; bearings 6 are installed at both ends of the rotary core tube 1, and the rotary housing 2 passes through 6 sets of bearings. Connected to the outside of the rotary core tube 1; a rotary seal 5 is installed on one side of the bearing 6, and a bearing end cover 8 is provided on the other side; an end cover seal 9 is provided inside the bearing end cover 8, and the end cover seal 9 is connected with the The bearing 6 is connected, and a soft steel backing plate 7 is provided on one side of the bearing 6 and the bearing end cover 8; the middle part of the rotary housing 2 is provided with a gooseneck 4.

[0023] A triple rotary seal 5 is arranged between the bearings 6; the highly reli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com