Self-locking connector and realizing method thereof

A connector and self-locking technology, which is applied in the direction of contact parts, parts of connecting devices, connections, etc., can solve the problems of requiring operating space, high structural cost, poor connection, etc., and achieves small operating space, simple process, and easy contact. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

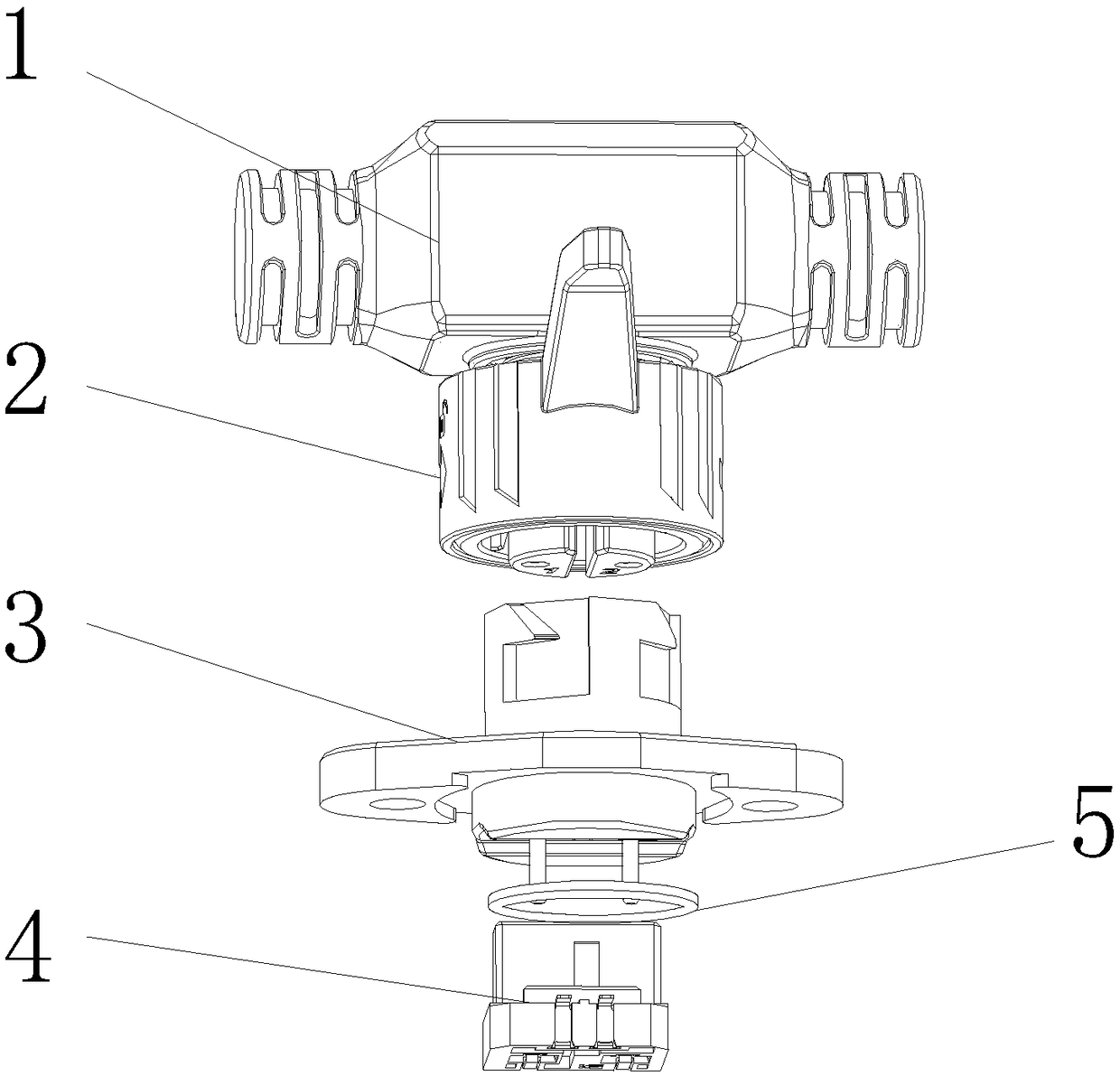

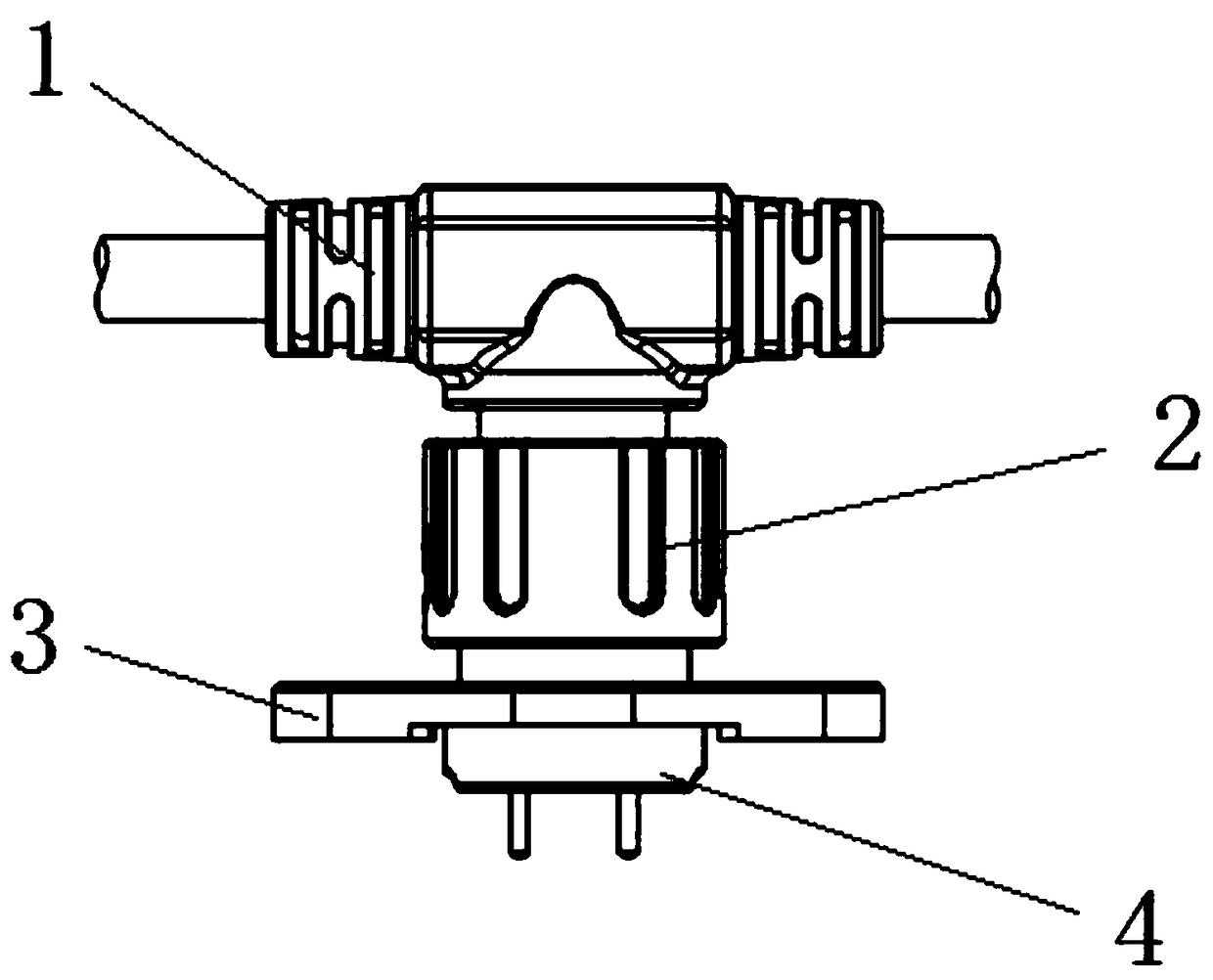

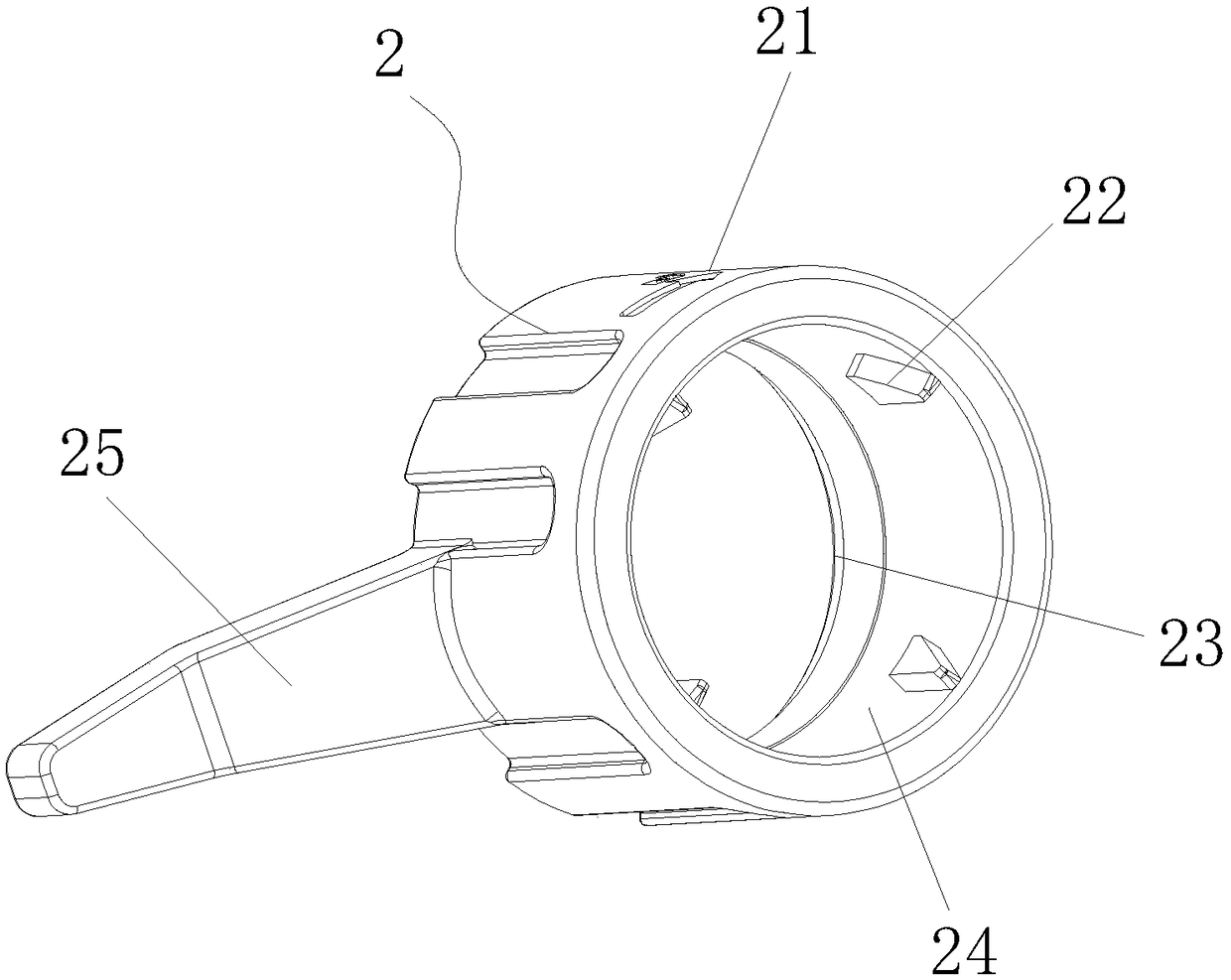

[0032] see Figure 1-5 , the present invention provides the following technical solutions: a self-locking connector, including a cable connection injection head 1, a rotary nut 2, a flange head 3 and a female end of the connector 4, wherein the rotary nut 2 is nested in-line The cable is connected to the connection end of the injection molding head 1, and the cable is connected to the injection molding head 1 and the rotary nut 2 is rotationally connected. The female end 4 of the connector is snap-connected.

[0033] Further, the cable connection injection molding head 1 includes a limit groove 101, a connection head 102, a return spring 103 and a small sealing ring 104, wherein the connection end of the cable connection injection molding head 1 is integrally formed with two connection heads 102, and the wire The limit groove 101 is integrally formed on the circumference of the connection end of the cable connection injection molding head 1 , the lower end of the limit groove...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap