Even discharging building sand screening device

A constructional and uniform technology, applied in mixers with rotary stirring devices, transportation and packaging, dissolving, etc., can solve the problems of ununiform feeding, uncontrollable feeding, no crushing and agglomeration, avoiding sieving and agglomeration. The effect of sand waste, controllable speed, reduction of feeding difficulty and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

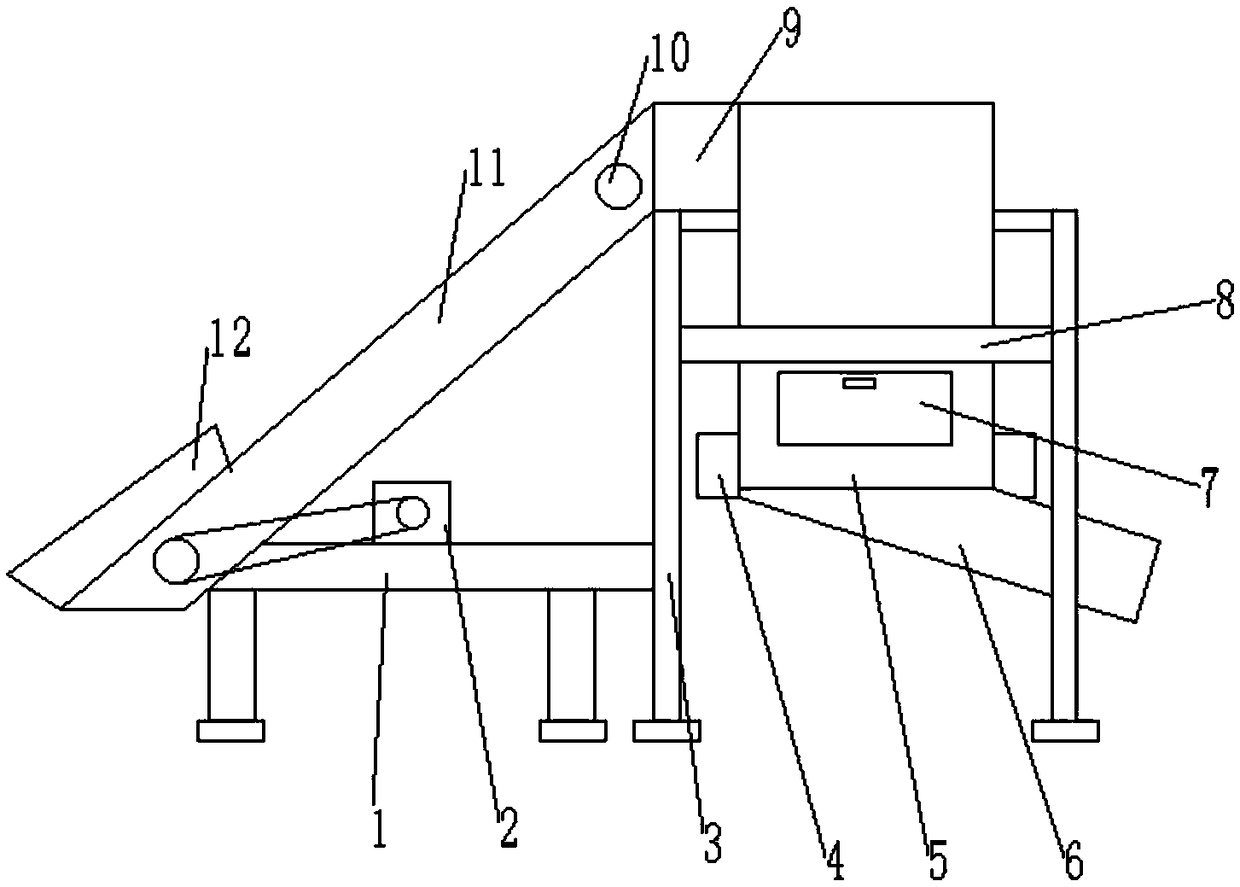

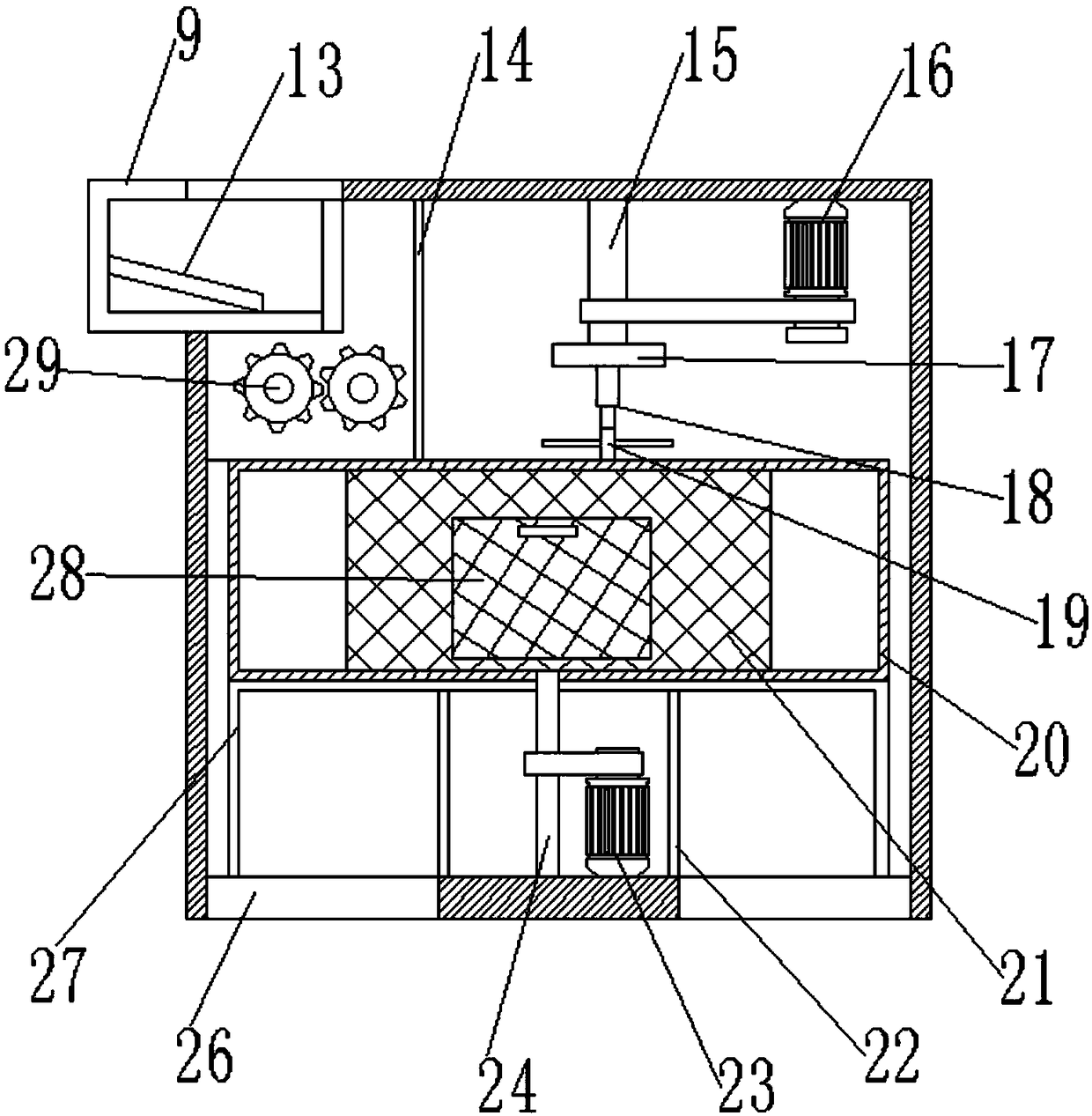

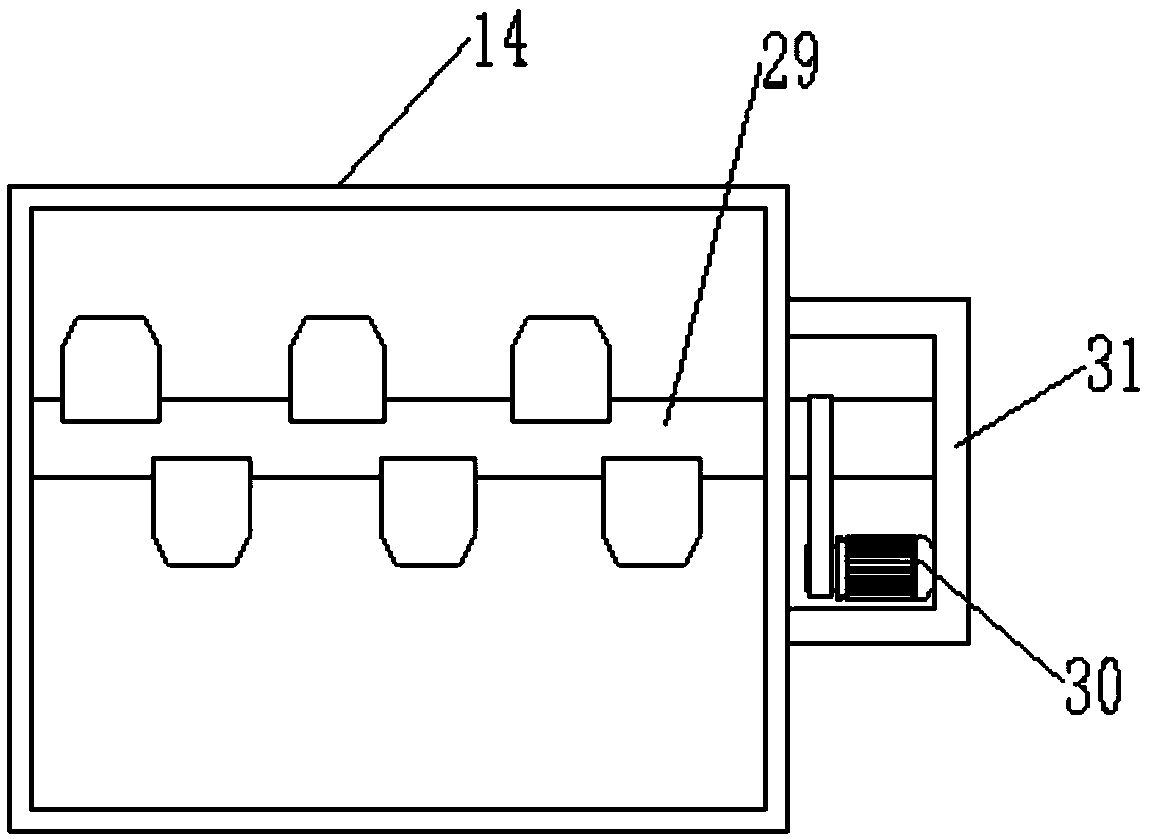

[0027] Reference Figure 1-5 , A uniformly discharging sand screening device for construction, including a tank body 5, the outer walls of both sides of the tank body 5 are welded with reinforcement frames 8, and the outer walls of both sides of the reinforcement frame 8 are welded with support columns 3, reinforcement frames 8 The tank body 5 is supported together with the support column 3, which improves the stability of the tank body 5. One side of the outer wall of the two support columns 3 is welded with the same connecting platform 1, and the four corners of the bottom outer wall of the connecting platform 1 are all welded with support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com