A turning mechanism for corrugated paper printing

A technology of corrugated paper and paper turning, which is applied in the direction of turning over objects, pile separation, thin material processing, etc. It can solve the problems of poor fixing effect, achieve the effects of preventing scattering, speeding up efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

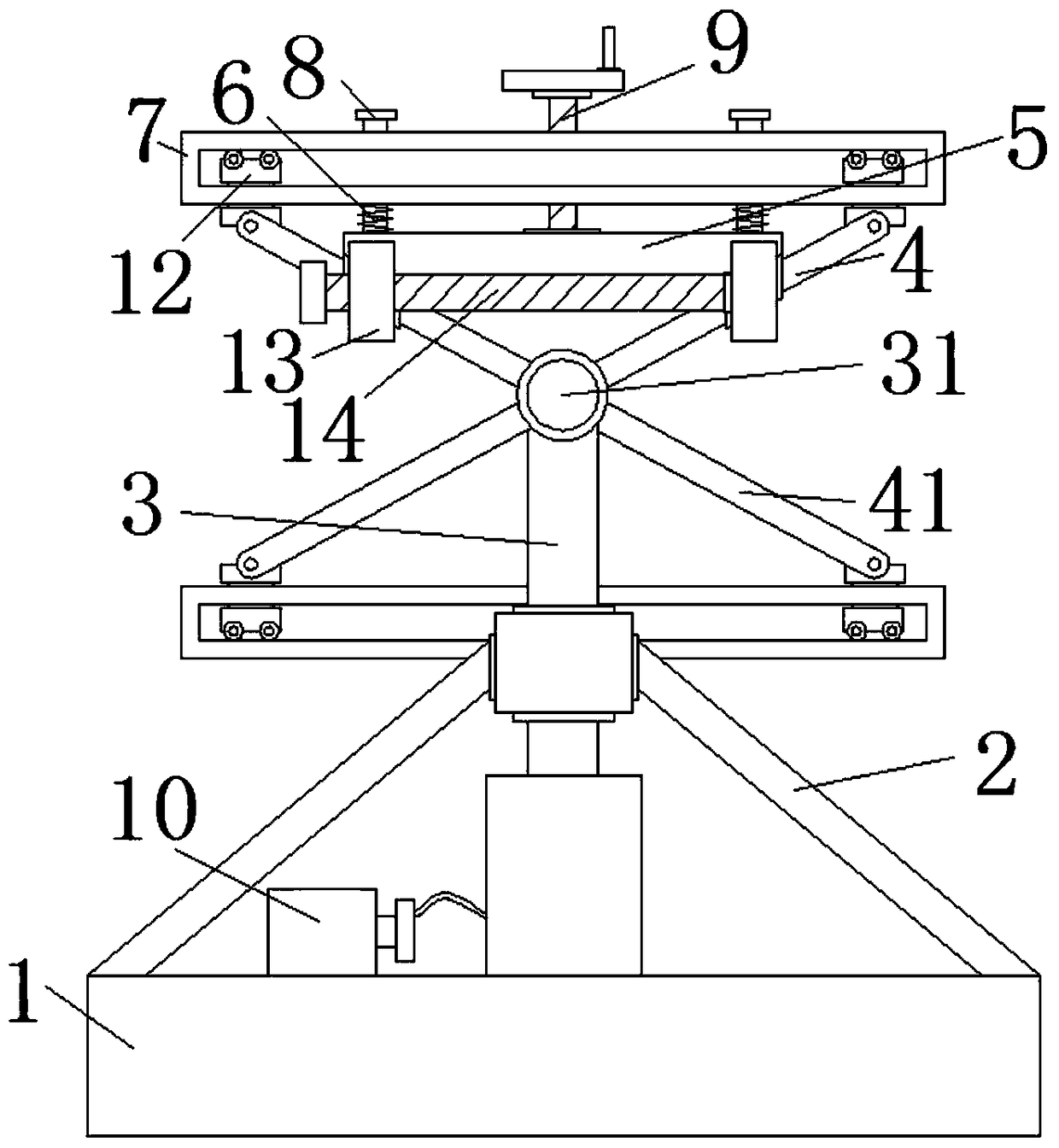

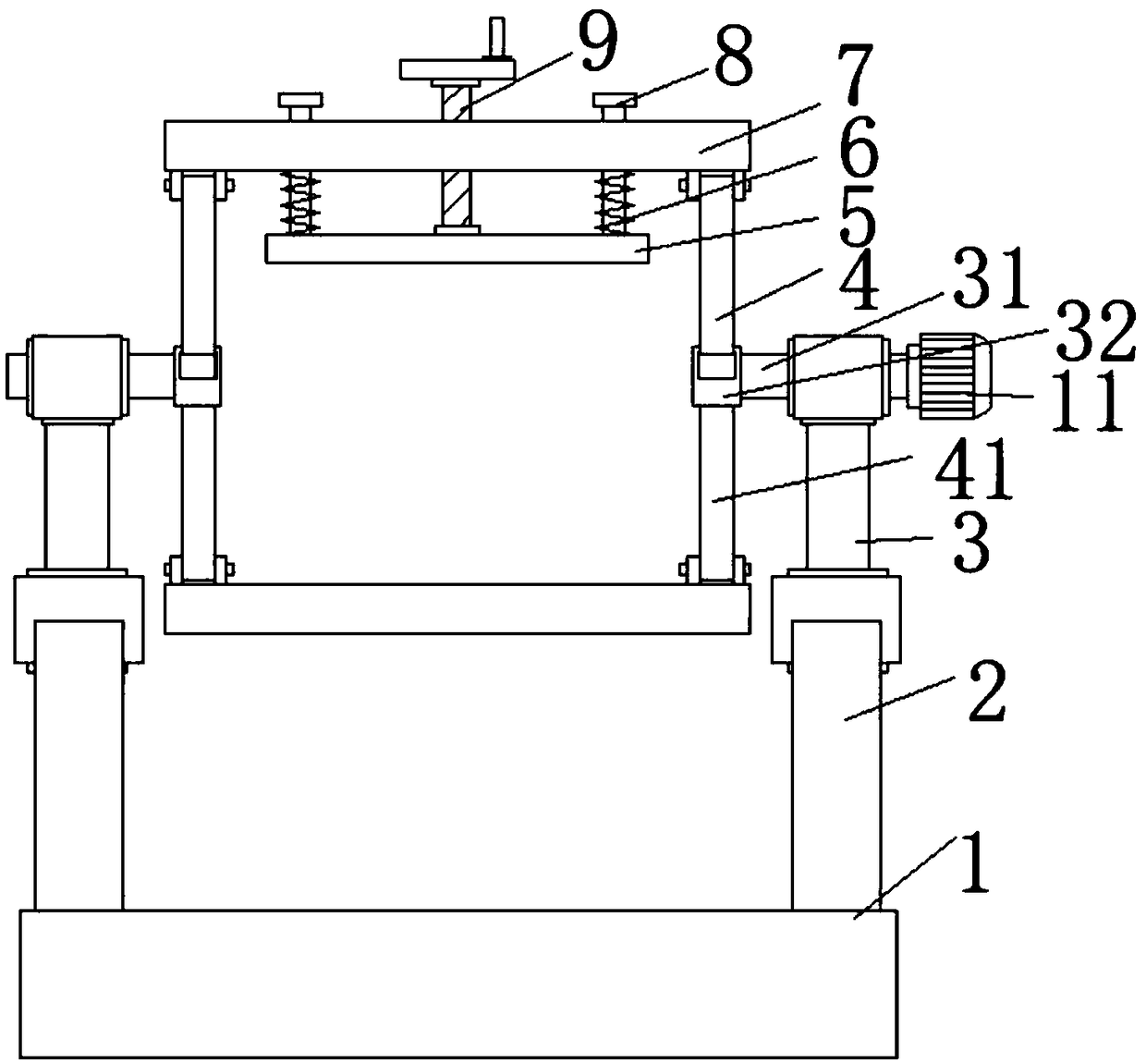

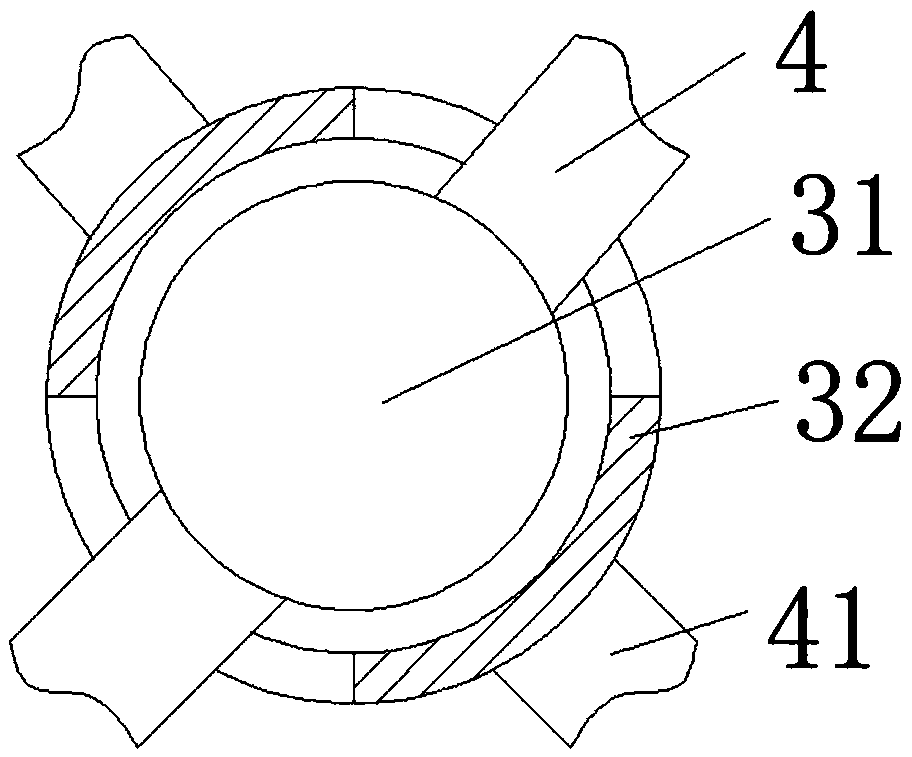

[0019] see Figure 1-3 , this embodiment provides a paper-turning mechanism for corrugated paper printing, including a base 1, a support frame 2 and a hydraulic lifting rod 3 are fixedly connected to the top of the base 1, and the top end of the hydraulic lifting rod 3 penetrates the supporting frame 2 and slides with the supporting frame 2 Connection, the inner side of the top of the hydraulic lifting rod 3 is connected with a rotating shaft 31, the outer side of the rotating shaft 31 away from the hydraulic lifting rod 3 is rotatably connected with a movable sleeve 32, and the outer side of the movable sleeve 32 is fixedly connected with a second support rod 41, the rotating shaft 31 is fixedly connected with the first support rod 4 at one end away from the hydraulic lifting rod 3, the first support rod 4 runs through the movable sleeve 32, the first support rod 4 and the second support rod 41 are in the same plane, the first support rod 4 and the second The outer sides of t...

Embodiment 2

[0022] see Figure 1-3 , on the basis of Embodiment 1, a further improvement is made: a chute is provided on the inside of the movable plate 7, and the slider 12 is connected to the inner wall of the chute by rolling on the rollers. The sliding on the inner side is smoother, which speeds up the working efficiency of the paper turning mechanism.

[0023] In the embodiment of the present invention, the inner sides of the fixed plate 5 and the movable plate 7 are provided with sponge pads, and placing the fixed plate 5 and the movable plate 7 too hard will cause damage to the corrugated paper, thereby better protecting the corrugated paper. Wherein, the threaded rod 14 and the threaded rod 9 are provided with a handle and a hand rocker respectively, which facilitates the adjustment of the distance between the movable plates 7 and the fixing of the corrugated paper, and accelerates the working efficiency of the paper turning mechanism. The hydraulic pump 10 passes through the infu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com