Device and method for quantitatively detecting defects of self-compacting concrete filling layer of ballastless track

A self-compacting concrete, quantitative detection technology, applied in the direction of measuring devices, material inspection products, mechanical area measurement, etc., can solve the problem of inability to quantitatively evaluate the pouring quality of self-compacting concrete, achieve remarkable rationality and scientificity, and low learning cost , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

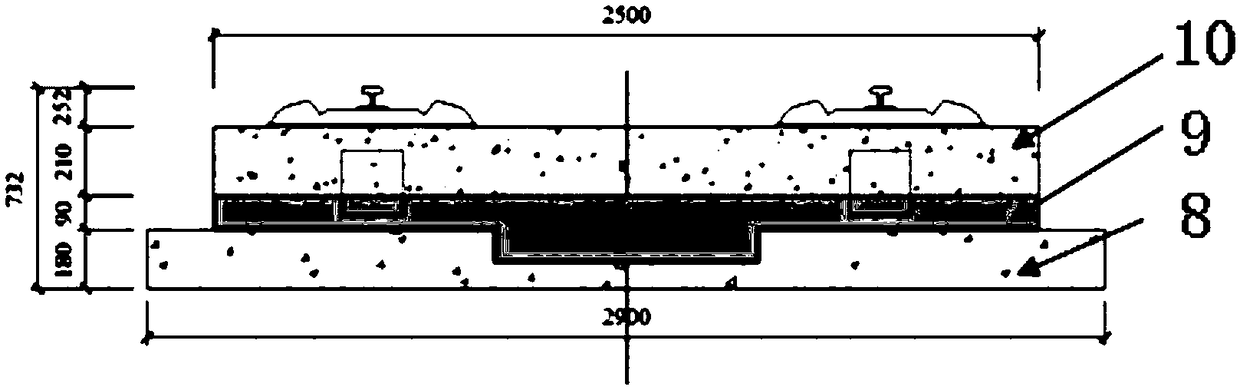

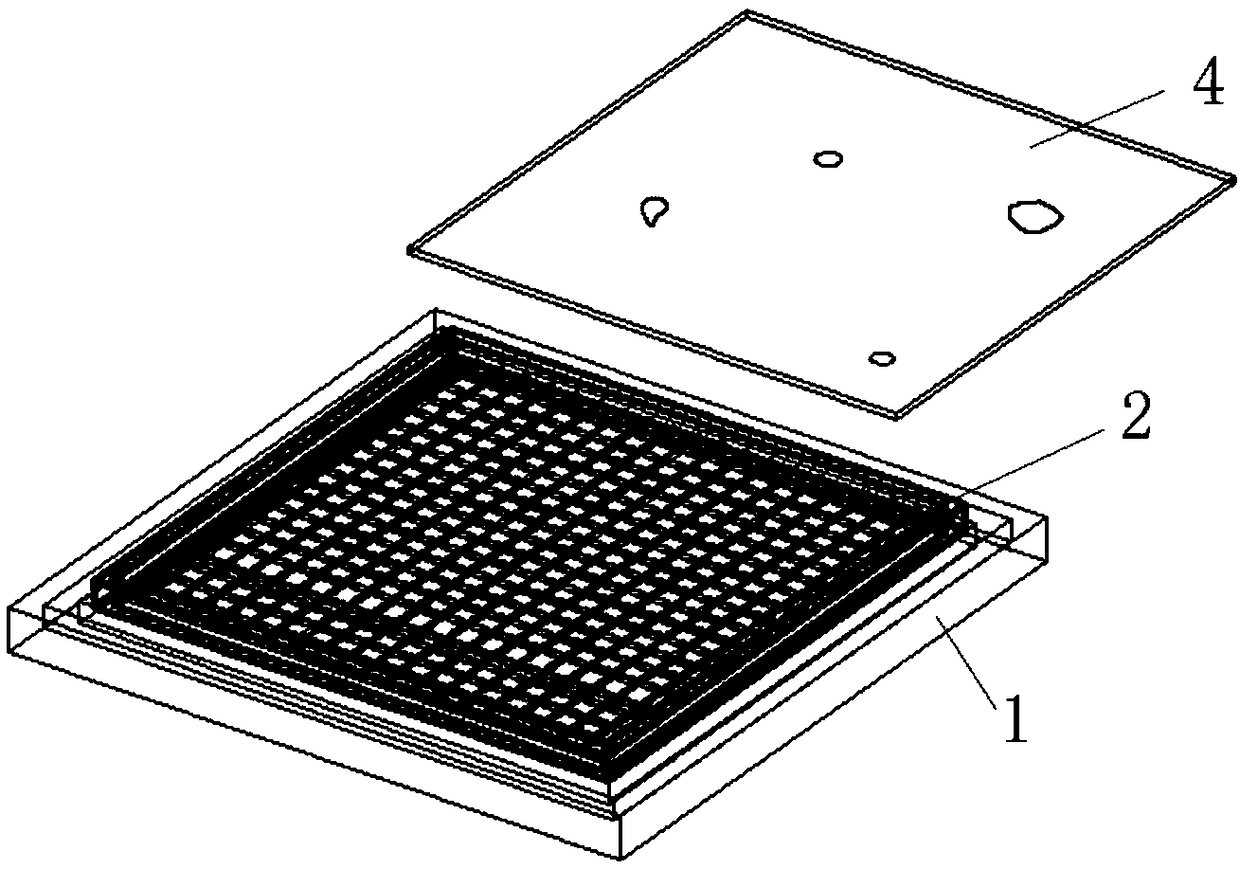

[0048] See attached Figure 3-8 , a ballastless track self-compacting concrete filling layer defect quantitative detection device, said device includes a base plate (1), a metal grid (2), filling particles (3), sampling paper (4), said sampling paper ( 4) Cover the area to be tested on the surface of the self-compacting concrete, and obtain the defect contour of the self-compacting concrete filling layer in the area to be tested; the metal grid (2) is placed on the bottom plate (1), and the obtained self-compacting concrete filling The sampling paper (4) of the layer defect contour is covered on the surface of the metal grid (2), and the filling particles (3) are filled into the metal grid (2) in the area of the defect contour marked on the sampling paper (4); The filling particles (3) in the defect contour area are counted by the counting device to calculate the defect area of the defect contour area; the counting device includes a funnel (5), a counter (7), and a support...

Embodiment 2

[0053] See attached Figure 1-8 , a method for quantitative testing of defects in self-compacting concrete filling layers of ballastless track, comprising the following steps:

[0054] In this example, the area of the self-compacting concrete filling layer is: 1400cm 2 , the concrete label is: SCC1;

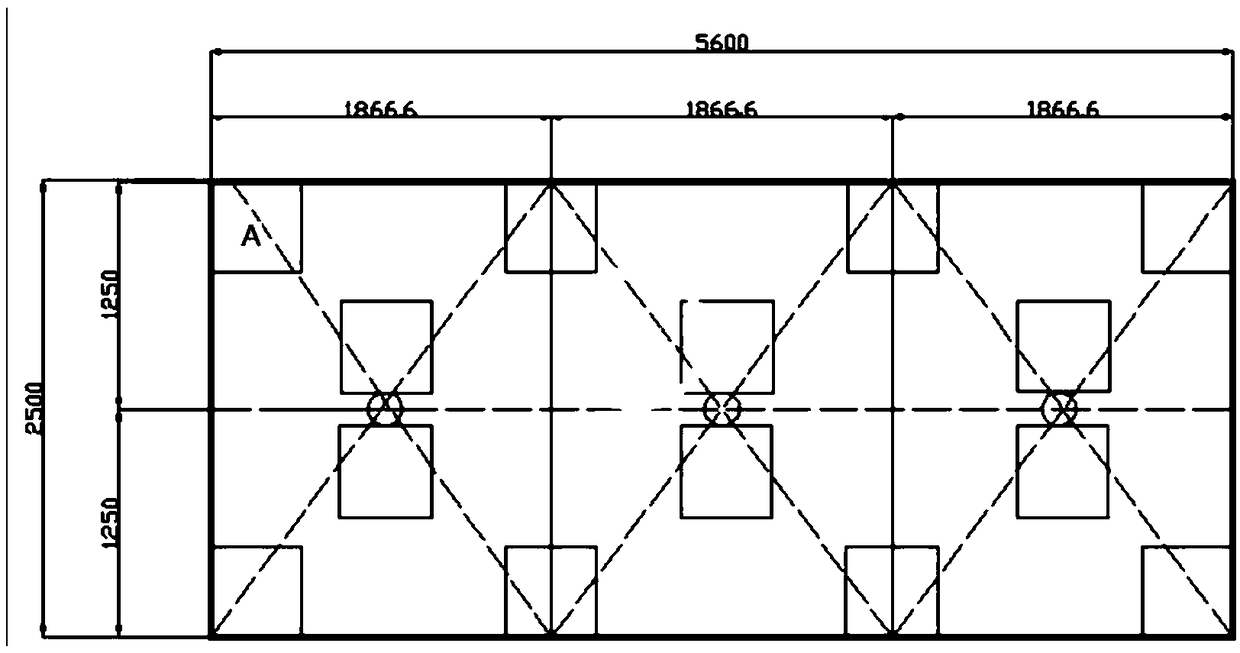

[0055] Step 1: Select the measurement area

[0056] According to the representative sampling principle, the self-compacting concrete slab surface of the filled layer is divided into 3 rectangles, and a measurement area is set at the inner corner of each rectangle, and the 2 measurement areas at the adjacent inner corners of adjacent rectangles are combined into one , evenly arranged in two adjacent rectangles; one measurement area is set on each side of the diagonal intersection point of each rectangle, and 14 measurement areas are arranged on the self-compacting concrete slab surface of the filling layer, and each measurement area is a square , with a side length of 50mm an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com