Lens edge grinding machine

A technology of edging machine and lens, which is applied in the field of grinding or polishing to achieve the effect of improving the quality of grinding and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

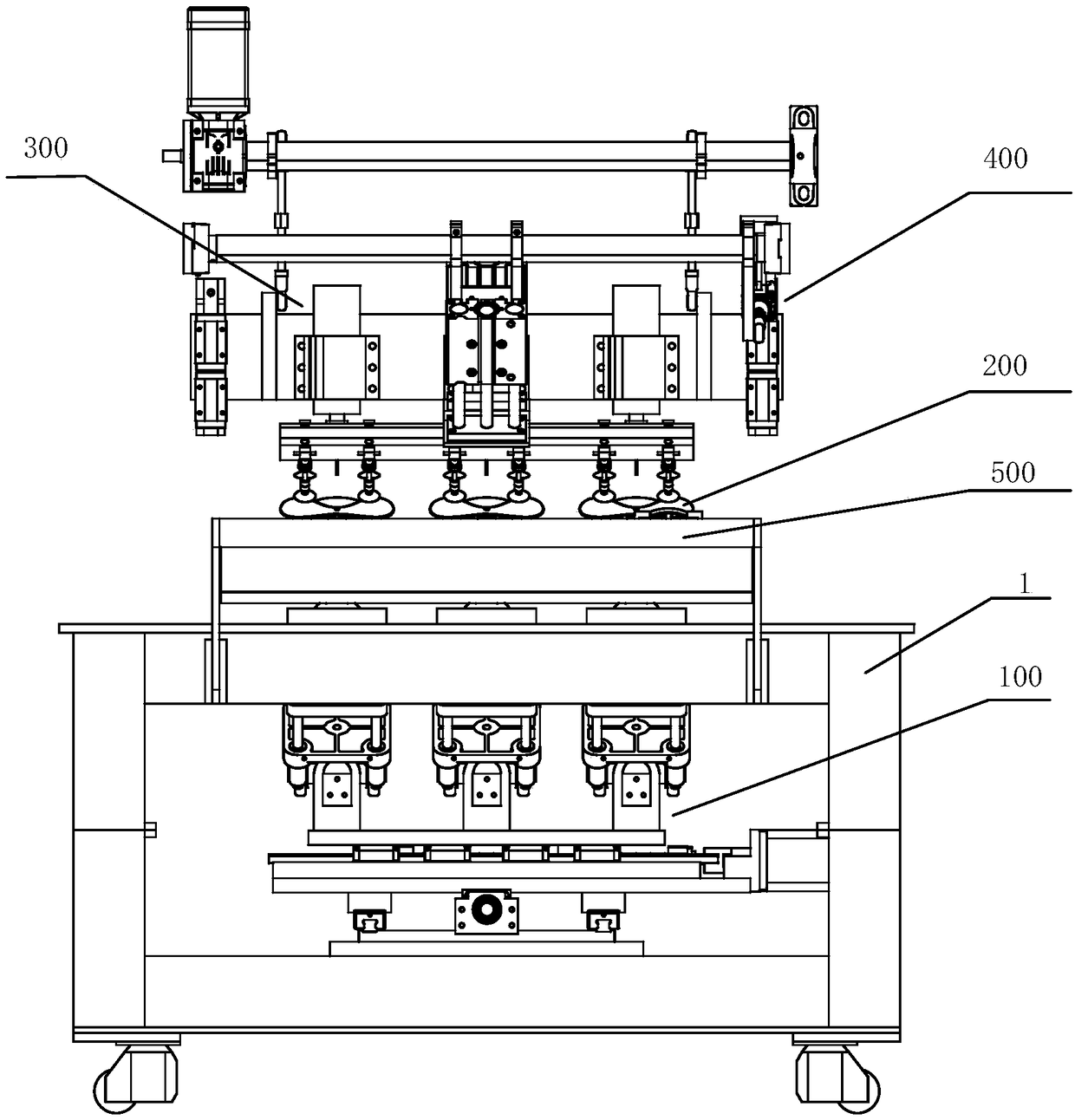

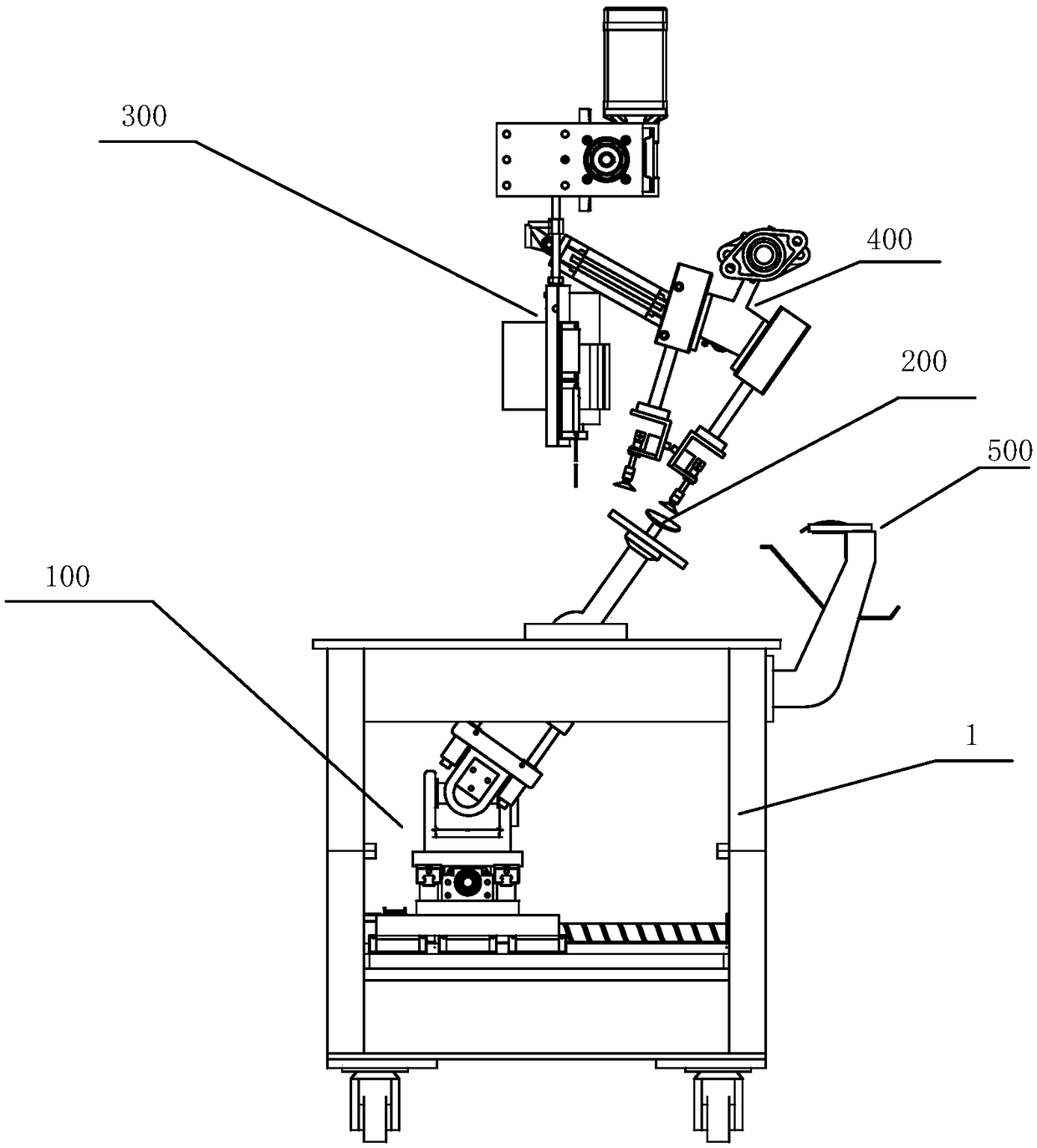

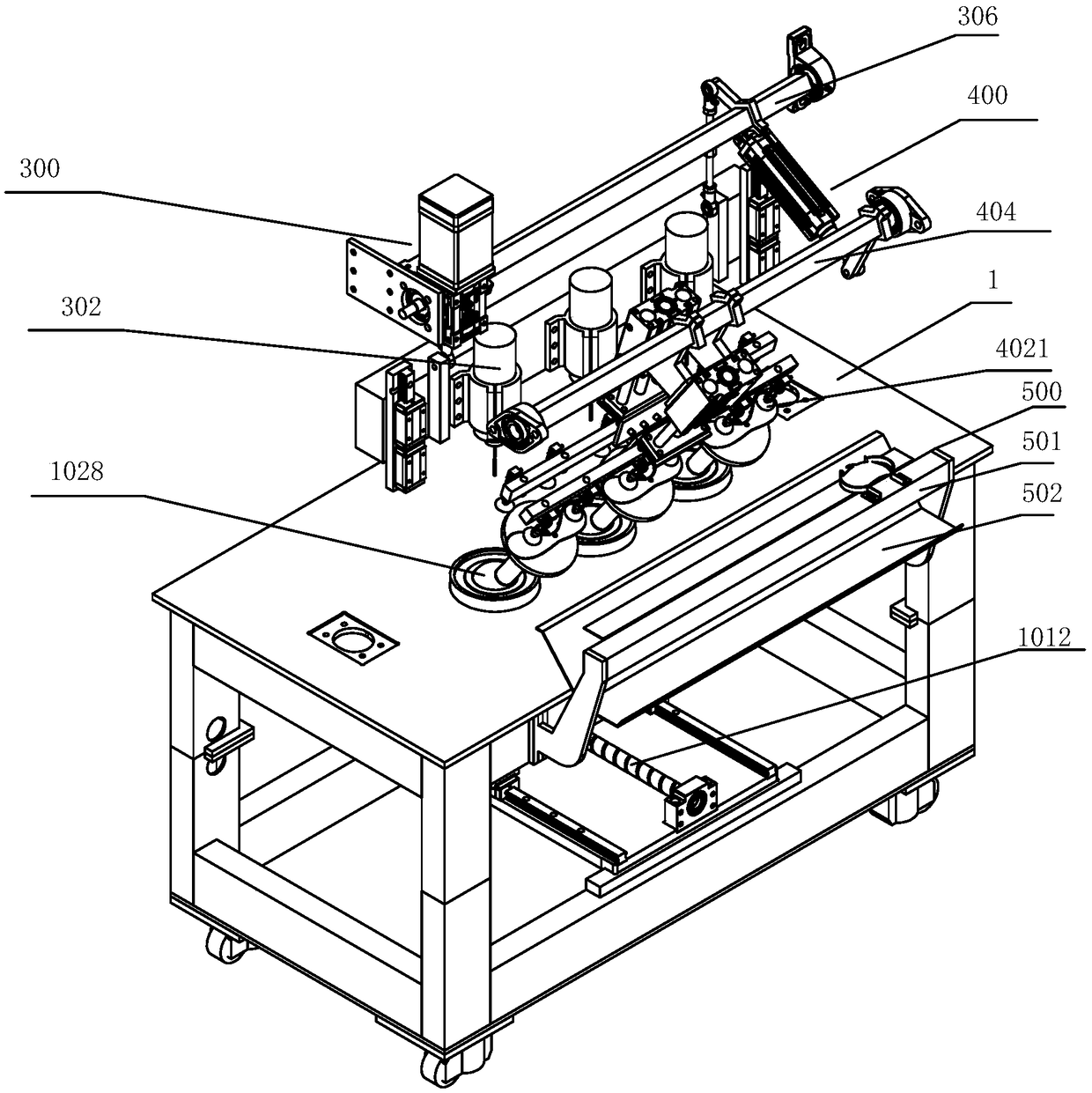

[0029] Such as Figure 1 to Figure 7 The shown lens edger includes a frame 1 and a PLC control unit arranged on the frame 1, an adjusting device 100 for adjusting the rotation angle of the lens fixing device 200 is arranged on the frame 1, and the adjusting device 100 A lens fixing device 200 is arranged on the frame 1 for fixing the lens. A grinding device 300 for grinding the edge of the lens and a delivery device 400 for transporting the lens are also arranged on the frame 1. The grinding device 300 is arranged on the side of the lens fixing device 200. Above, the conveying device 400 is arranged on one side of the polishing device 300, and the material rack 500 for placing the lens is arranged on the frame 1; the adjusting device 100 includes a driving mechanism one 101, an adjuster 102 and a rotating rod 103, and the adjuster 102 is fixed On the first driving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com