A self-cleaning landing gear

A landing rod, self-cleaning technology, applied in the directions of roads, buildings, road signs, etc., can solve the problems of landing rod cleaning, damage to the landing rod, loss, etc., to improve the cleaning effect and avoid the effect of reflective signs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

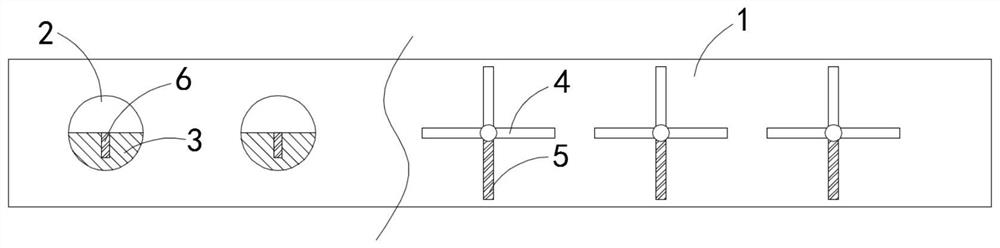

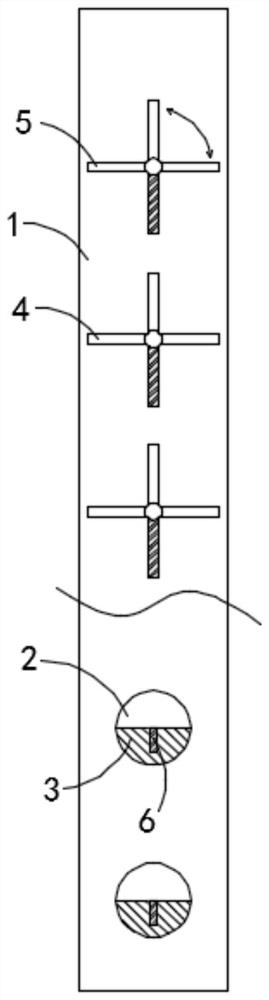

[0022] Such as Figure 1-2 As shown, a self-cleaning landing rod includes a rod body 1 made of non-magnetic material. The rod body 1 is provided with a plurality of spherical cavities 2, and the spherical cavities 2 are rotatably connected with hemispheres that can rotate in a vertical plane. body 3, and a cleaning mechanism corresponding to the hemispherical body 3 is provided outside the rod body 1.

[0023] In this embodiment, the cleaning mechanism includes a first rotating brush 4 that is rotatably connected to the side walls on both sides of the rod body 1. The first rotating brush 4 is composed of at least four brush rods 5. Since the rotation angle of the brush rods 5 is 90 degrees, So at least four brush rods 5 are needed to complete the cleaning of the surface of the rod body 1, and one of the brush rods 5 is made of a permanent magnet. The produced brush rod 5 attracts opposite poles. It should be noted that the actual size of the brush rod 5 is relatively small, s...

Embodiment 2

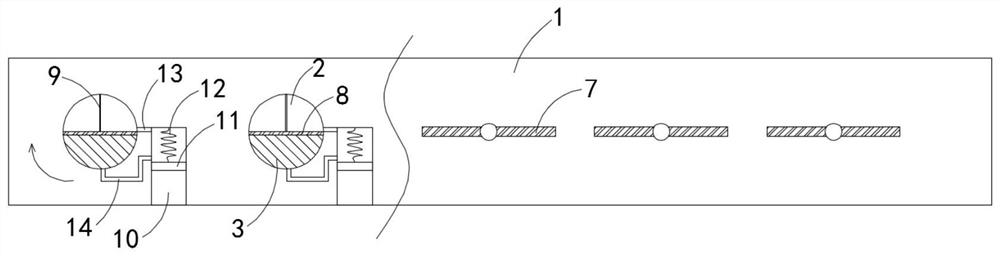

[0026] Such as Figure 3-8 As shown, the difference between this embodiment and Embodiment 1 is that the cleaning mechanism includes a second rotating brush 7 that is rotatably connected to the side walls on both sides of the rod body 1, the second rotating brush 7 is elongated, and the second rotating brush 7 is The brush 7 is made of a magnet, and the flat end surface of the hemisphere 3 is fixedly connected with a permanent magnet 8. The permanent magnet 8 attracts the second rotating brush 7 with different poles made of a permanent magnet, and the middle part of the permanent magnet 8 is fixed. It is connected with a partition 9 arranged vertically, and the end of the partition 9 away from the permanent magnet sheet 8 is in sliding and sealing connection with the side wall of the spherical cavity 2, and one side of the spherical cavity 2 is provided with a groove communicating with the outside. 10. A piston block 11 is slidingly sealed in the groove 10. The piston block 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com