Retroreflective filament slide fastener

A fibril and reflective technology, applied in the field of fibril zippers, can solve the problems that zippers cannot reflect light, do not have reflective functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] best practice

[0035] The following describes the best embodiment of the reflective thread slide fastener according to the present invention with reference to the accompanying drawings.

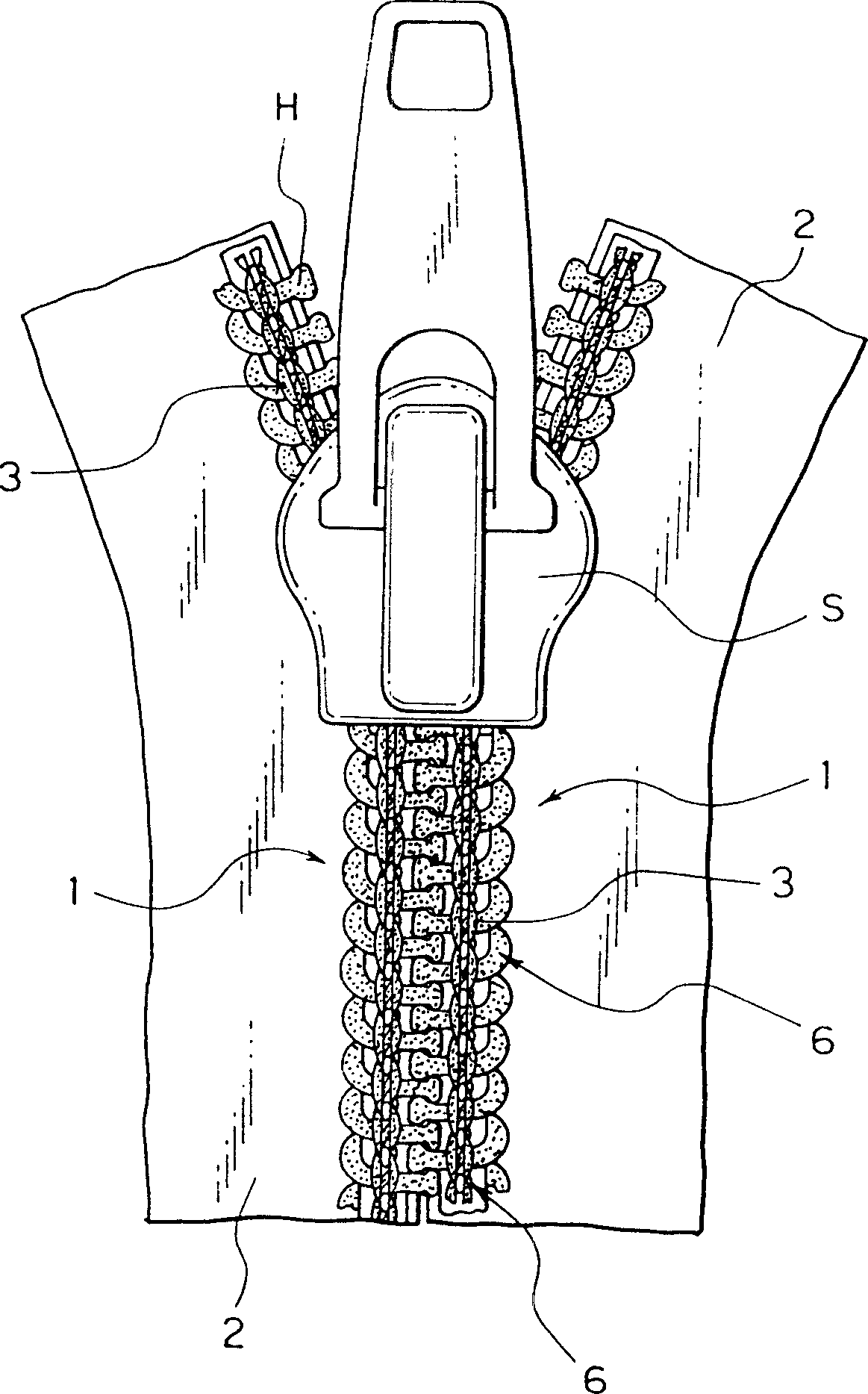

[0036] Such as figure 1 As shown, the structure of the reflective silk zipper of the present invention comprises a zipper chain, which is to sew a coil-shaped silk zipper member belt 1 made of monofilament thermoplastic synthetic fiber of polyamide, polyester or the like to a synthetic fiber. The fixed thread 3 made of the thread 10 is formed on the longitudinal edge of the zipper strip 2 through the multi-thread chain stitch of single needle and double thread. figure 1 The marked character S represents the slider of the zipper.

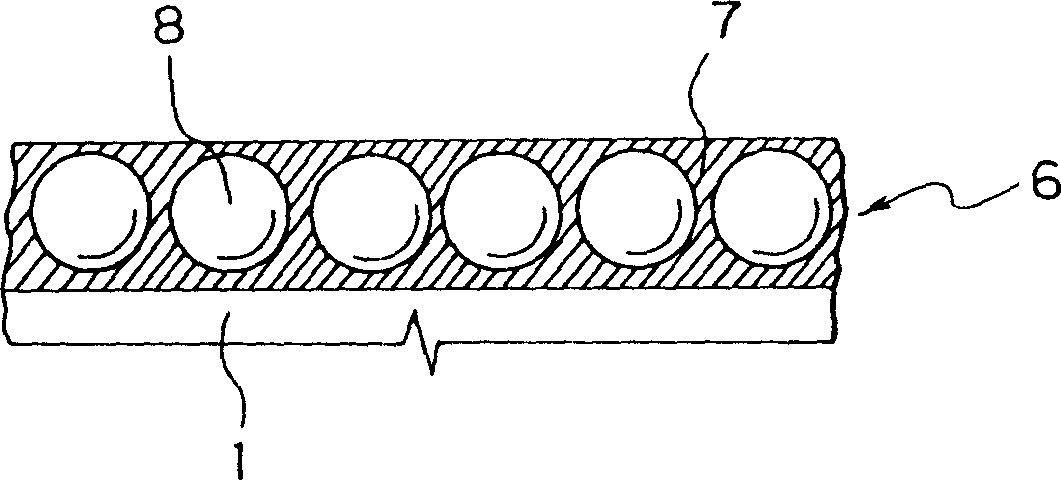

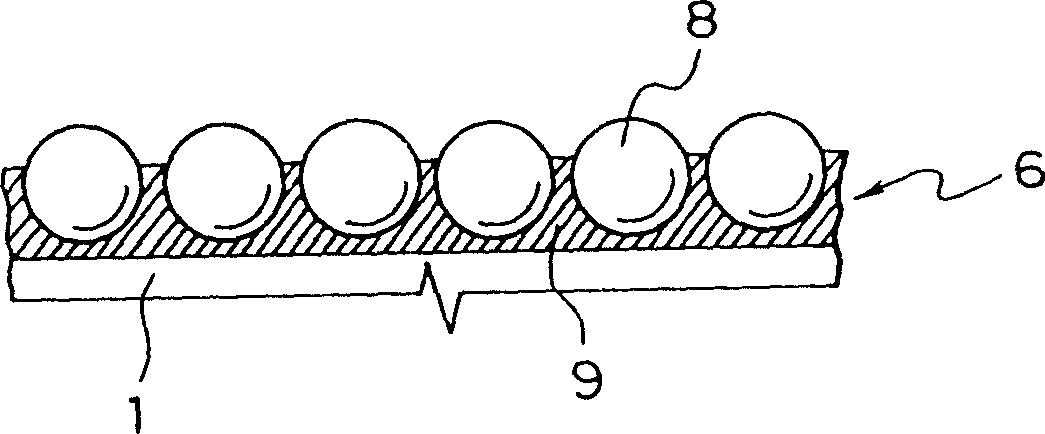

[0037] Such as figure 2 As shown, the reflective layer 6 is formed by covering the surface of the coil-shaped stripe fastener member tape 1 with a reflective paint 7 containing glass beads 8 or microbeads made of insoluble resin. First, the monofilament...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com