Laminar flow purifying unit for modular ceiling of clean room

A modularized, top-lifting technology, applied in mechanical equipment, airflow control components, household heating, etc., can solve the problems of complex structure of central air-conditioning units and purification systems, affecting the directional flow of airflow, cross-infection in operating rooms, etc. Fast and convenient, eliminate noise, save the effect of multiple air supply pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

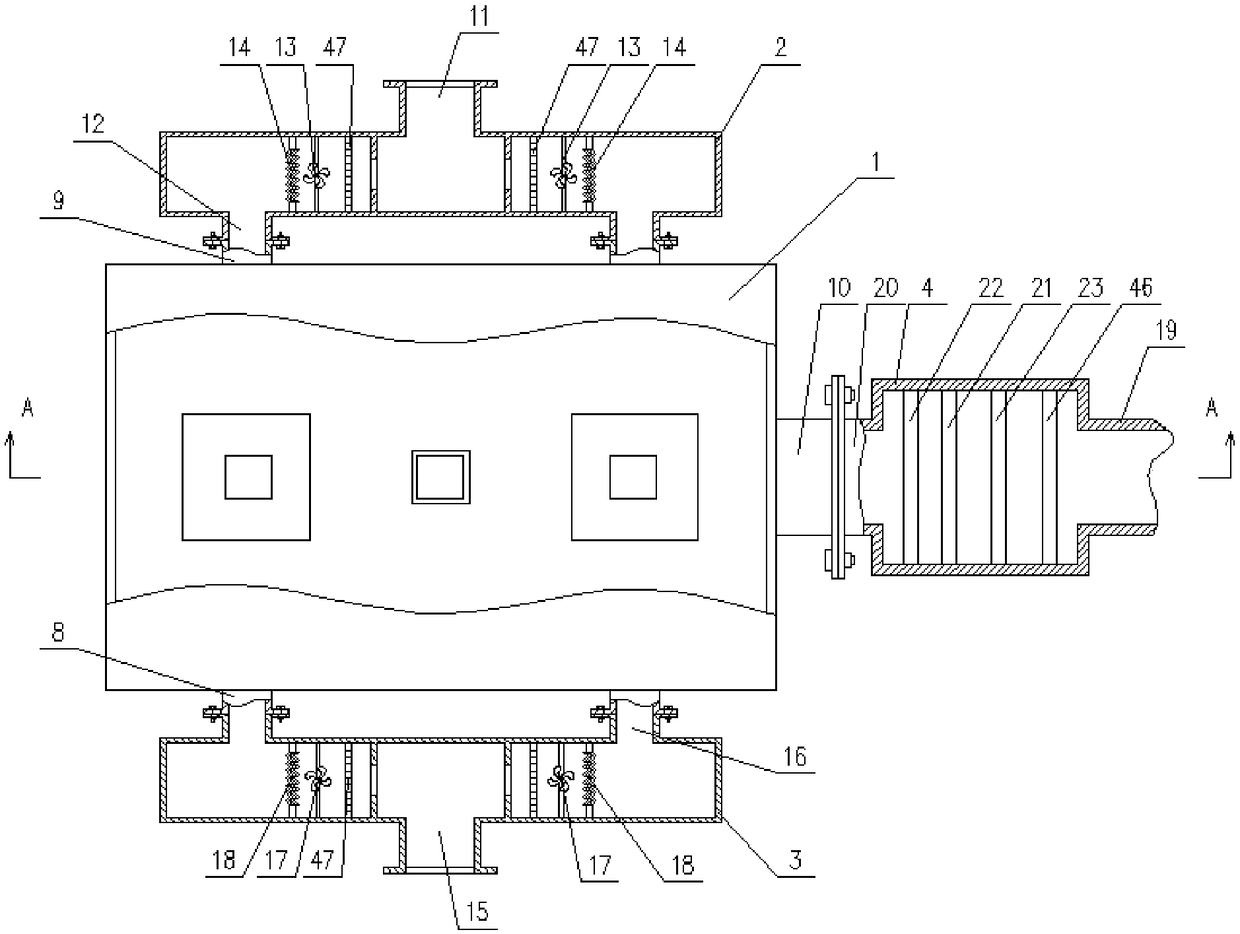

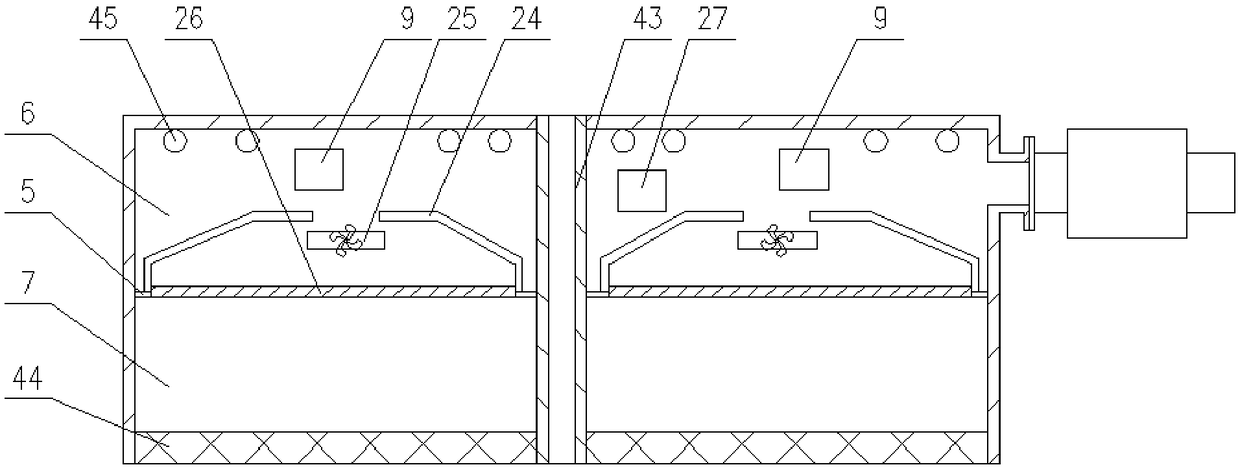

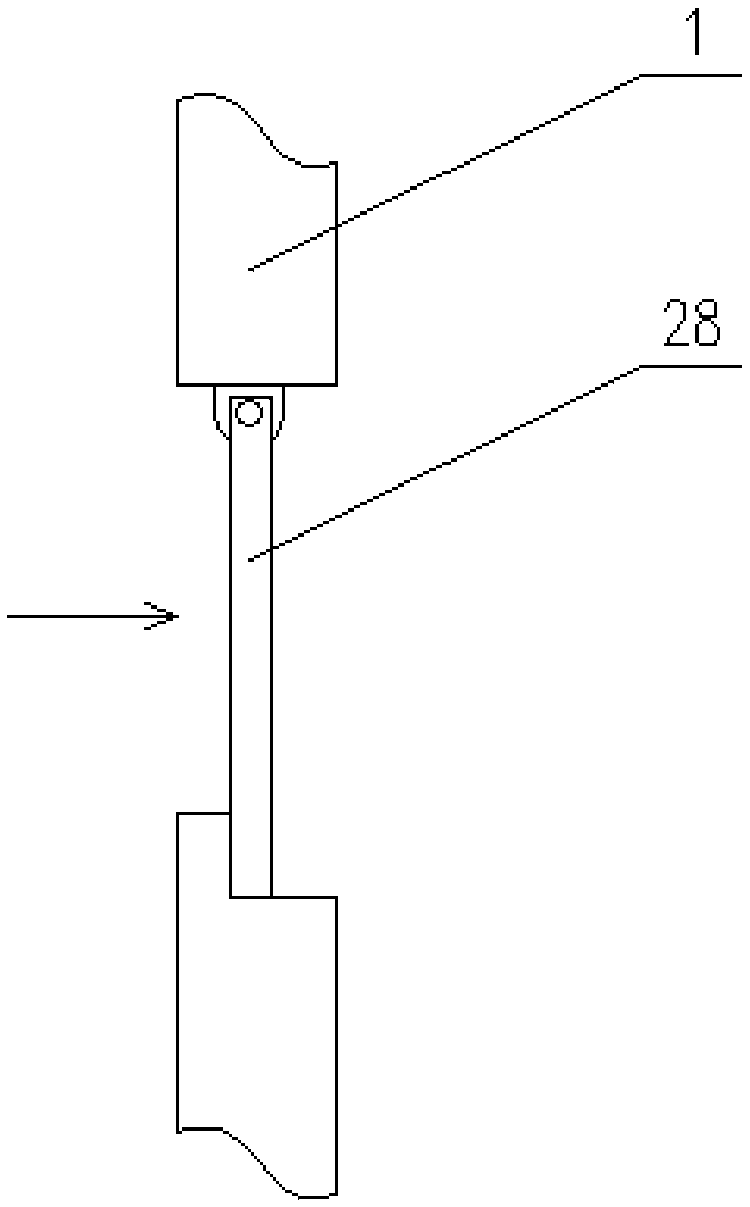

[0032] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, the clean room modular ceiling laminar flow purification unit of this embodiment includes a main chassis 1, a refrigeration chassis 2, a heating chassis 3 and a humidifying fresh air preheating chassis 4, the main chassis 1 is a rectangular parallelepiped chassis, the main chassis 1 has a separation layer 5 inside. The separation layer 5 divides the interior of the main chassis 1 into upper and lower chambers. The upper chamber is an air mixing layer 6, and the lower chamber is an air equalization layer 7. The main chassis 1 The front and rear side walls of the main chassis 1 are prefabricated with a connecting port 8 for a heating cabinet and a connecting port 9 for a cooling cabinet. The chassis communication port 9 communicates with the main chassis 1, the heating chassis 3 communicates with the main chassis 1 through the heating chassis communication port 8, and the humidified fre...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination Figure 1-Figure 5Describe this embodiment, the clean room modular ceiling laminar flow purification unit of this embodiment, the preset heating cabinet communication port 8 on the side wall of the main cabinet 1, the refrigeration cabinet communication port 9 communicate with the humidifying fresh air preheating cabinet The ports 10 are all in communication with the air mixing layer 6 . In this way, the preset connecting port 8 of the heating cabinet, the connecting port 9 of the cooling cabinet and the connecting port 10 of the humidifying fresh air preheating cabinet on the side wall of the main cabinet 1 are all used to supplement the air volume of the clean room. This air supply system is a clean room The room provides a sufficient amount of air intake to ensure that the indoor constant temperature and constant humidity are effectively adjusted.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination Figure 1-Figure 5 Describe this embodiment, the clean room modular ceiling laminar flow purification unit of this embodiment, the refrigerator cabinet 2 is a rectangular closed cavity, the center of the upper side wall of the refrigerator cabinet 2 is provided with a first air return port 11, the refrigerator cabinet The lower side wall of 2 has a first cooling air outlet 12, and a return air filter 47, a first return fan 13 and a surface cooler 14 are respectively installed in the refrigeration cabinet 2. In such a setting, the first air return port 11 provided at the center of the upper side wall of the refrigerating chassis 2 communicates with the return air duct of the clean room. 11 into the refrigeration cabinet 2, when a certain amount of cold air is needed in the clean room, the surface cooler 14 installed in the refrigeration cabinet 2 realizes the air cooling operation, and the return air filter 47 can filter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com