Tube ultrasonic brackish water desalination equipment and method

A brackish water desalination and ultrasonic technology, applied in chemical instruments and methods, water/sewage treatment equipment, water/sewage treatment, etc., can solve the problems of high cost, high energy consumption of desalination equipment, complicated maintenance, etc., and achieve extremely easy Effect of replacement, long service life, and improvement of desalination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

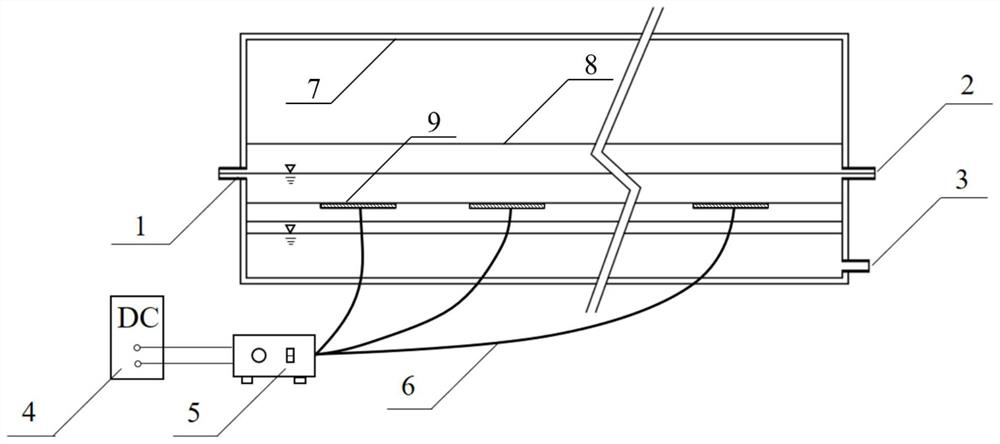

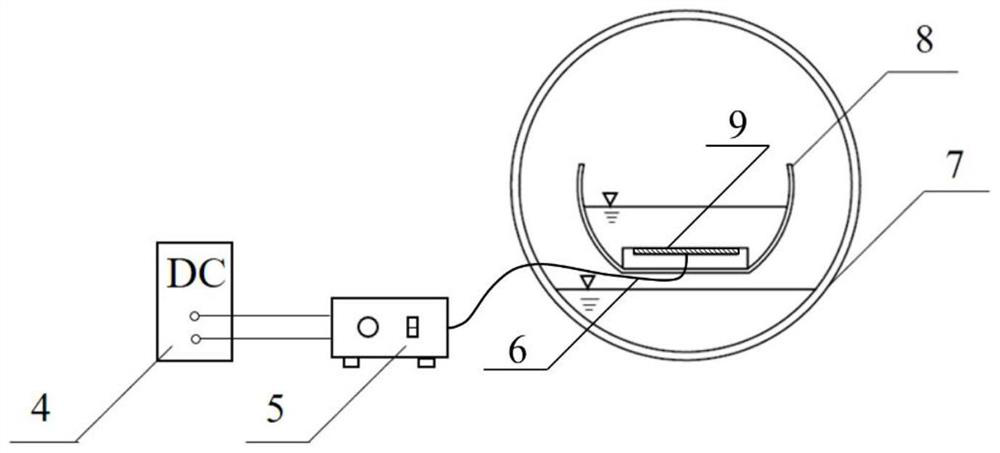

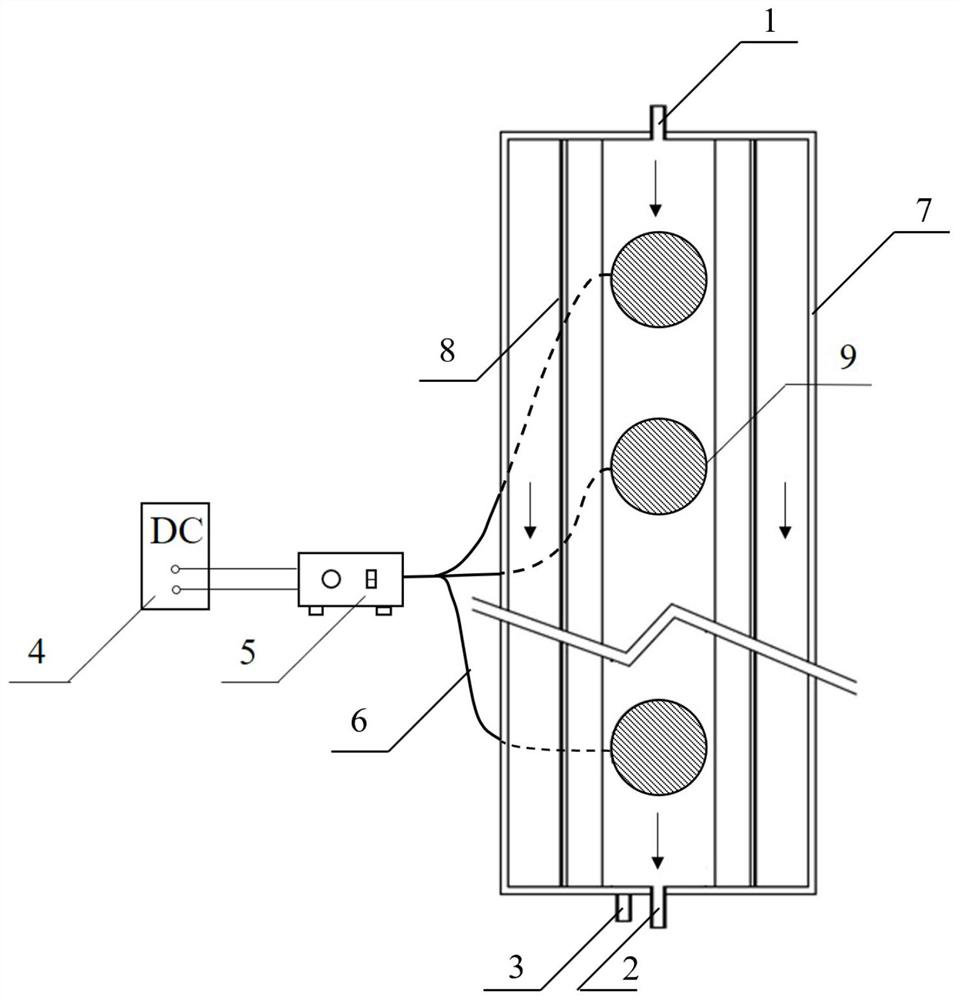

[0032]Example 1: A tube type ultrasonic brackish water desalination equipment

[0033]byFigure 1 ~ Figure 3As shown, the tube-type ultrasonic brackish water desalination equipment of the present invention includes: a stabilized current power supply 4, a controller 5, an electric wire 6, a condensation outer tube 7, an atomizing inner tube 8 and an ultrasonic atomizing sheet 9; The pressure current power supply 4 is placed outside the tube type ultrasonic brackish water desalination equipment; the controller 5 is placed outside the tube type ultrasonic brackish water desalination equipment and is connected to the constant voltage current power supply 4; The wire 6 is connected to the ultrasonic atomization sheet 9 and the controller 5; the condensation outer tube 7 is a closed cylindrical shape, and the atomization inner tube 8 and the ultrasonic atomization sheet 9 are enclosed in it, and the bottom end of the condensation outer tube 7 It is clean water after treatment; the inner atomi...

Embodiment 2

[0042]Example 2: A method for desalination of brackish water

[0043]Combinefigure 1 ——image 3 , The brackish water desalination method is described. The desalination method includes: brackish water enters the tubular ultrasonic brackish water desalination device from the water inlet 1 and flows in the atomization inner tube 8; the ultrasonic atomization sheet 9 passes through the wire 6 It forms a positive feedback resonant circuit with the triode, capacitor, and resistance in the controller 5. Under the action of the stabilized current power supply 4, the ultrasonic atomizing sheet 9 produces high-frequency oscillations to atomize the brackish water in the atomizing inner tube 8 , Becomes water mist; the water mist contacts the outer condenser tube 7 and condenses again during the process of floating, and the condensed clear water is discharged from the clear water outlet 3 through the inner wall of the outer condenser tube 7; discharge.

Embodiment 3

[0044]Example 3: Brackish water desalination experiment

[0045](1) Artificially prepared brackish water: By adding NaCl to distilled water to prepare simulated brackish water, the salt content of brackish water is about 2000mg / L and the pH is 6.8.

[0046](2) Brackish water desalination experiment: The influent flow rate of the brackish water prepared above was controlled at 4.5 L / h, and the tubular ultrasonic brackish water desalination device described in Example 1 was continuously operated for 48 hours.

[0047](3) Experimental results: A total of about 200L of clean water after desalination was produced, the salt content of the obtained clean water was 50±10mg / L, the pH was 7.2±0.1, and the salt content of about 15L was 27.7±0.15g / L. Salt wastewater, the treatment efficiency is: 200 / (200+15)*100%=93.02%; the equipment only needs about 48kWh / m3Energy consumption, while the commonly used heating distillation desalination method requires about 800kWh / m3Energy consumption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com