A kind of electrochemical treatment liquid and its application

An electrochemical and treatment liquid technology, applied in the field of chemical electroplating, can solve the problems of surface temperature rise, rapid oxidation of workpiece surface, easy corrosion of workpiece, etc., to achieve the effect of increasing brightness

Active Publication Date: 2020-07-21

HESHAN SEIKO PLATEMAKING CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

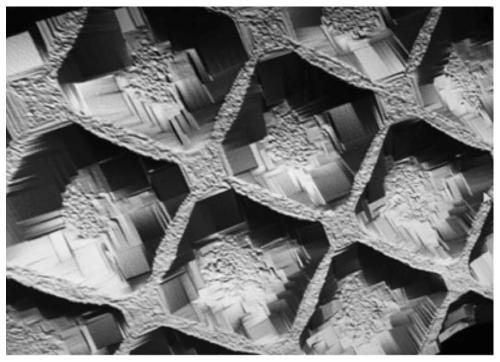

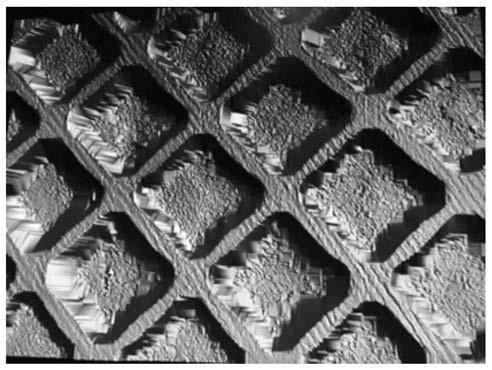

The existing electrochemical treatment liquid is mainly composed of phosphoric acid, glycerin, thiourea, etc. The workpiece after treatment has the following disadvantages: (1) After the workpiece is treated at high current and for a long time, the surface temperature of the workpiece rises sharply, and the surface of the workpiece oxidizes rapidly , which is not conducive to observing the change of dot shape; (2) After electrochemical treatment, a thick white film (additive decomposition residue) is formed on the surface of the workpiece, which is not conducive to reprocessing in subsequent processes; (3) The workpiece is easy to corrode after long-term treatment ; (4) After removing the oxide layer at the bottom of the dot, the top of the dot is seriously deformed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

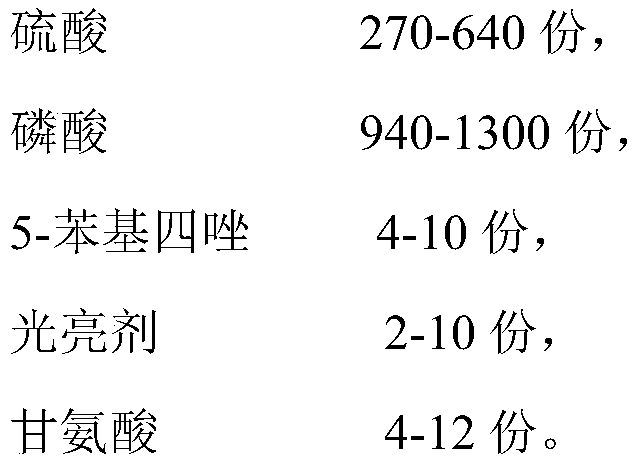

[0024] A kind of electrochemical treatment liquid, comprises the following components by weight parts:

[0025]

Embodiment 2

[0027] A kind of electrochemical treatment liquid, comprises the following components by weight parts:

[0028]

Embodiment 3

[0030] A kind of electrochemical treatment liquid, comprises the following components by weight parts:

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to view more

Abstract

The invention belongs to the field of chemical electroplating, and particularly relates to electrochemical treatment liquid and an application thereof, in particular to the electrochemical treatment liquid for processing a workpiece after laser engraving. The electrochemical treatment liquid of the present invention comprises the following components in parts by weight: 270-640 parts of sulfuric acid, 940-1300 parts of phosphoric acid, 4-10 parts of 5-phenyltetrazole, 2-10 parts of a brightener, and 4-12 parts of glycine. When the laser-engraved workpiece is treated with the electrochemical treatment liquid of the present invention, an oxide layer formed on the workpiece can be removed, and re-oxidation of the workpiece is not generated; when the laser-engraved workpiece is treated by theelectrochemical treatment liquid of the invention, the workpiece body is not affected, and the pattern structure of the workpiece is not deformed; when the laser-engraved workpiece is treated with theelectrochemical treatment liquid of the present invention, the brightness of the surface of the workpiece can be increased, and thereby the requirement of subsequent processes is satisfied.

Description

technical field [0001] The invention belongs to the field of chemical electroplating, and in particular relates to an electrochemical treatment liquid and application thereof, in particular to an electrochemical treatment liquid for electrochemically treating laser engraved workpieces. Background technique [0002] Laser engraving is a processing technology with laser as the processing medium. The physical denaturation of the instantaneous melting and gasification of the processing material under laser irradiation can make laser engraving achieve the purpose of processing. Laser processing is characterized by no contact with the material surface and is not affected by mechanical movement. [0003] In the electroplating industry, laser engraving is the high temperature generated by laser to burn the copper layer and white oil on the surface of the workpiece. Laser engraving will form a thick oxide layer on the copper surface. When using ordinary phosphoric acid treatment liq...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): C25F3/22

CPCC25F3/22

Inventor 黄春霞张鹏华李福恩

Owner HESHAN SEIKO PLATEMAKING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap