Wall brick tiling device for building

A construction and wall-attaching technology, which is applied in the direction of construction and building construction, can solve the problems of easy displacement, increased deviation of grid lines, uneven thickness, etc., to ensure position accuracy, simple and reasonable structure, and wall-attachment tidy brick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

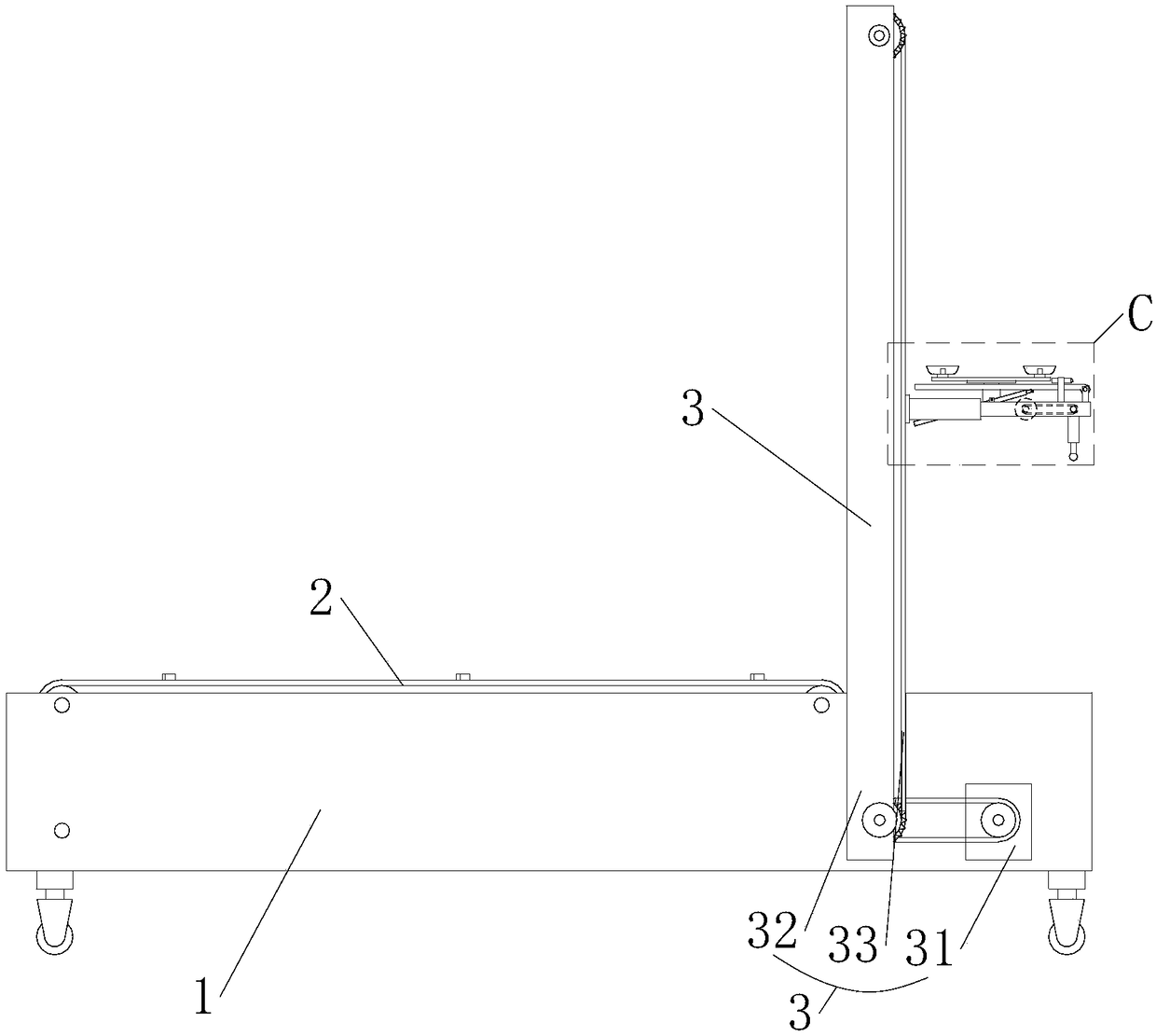

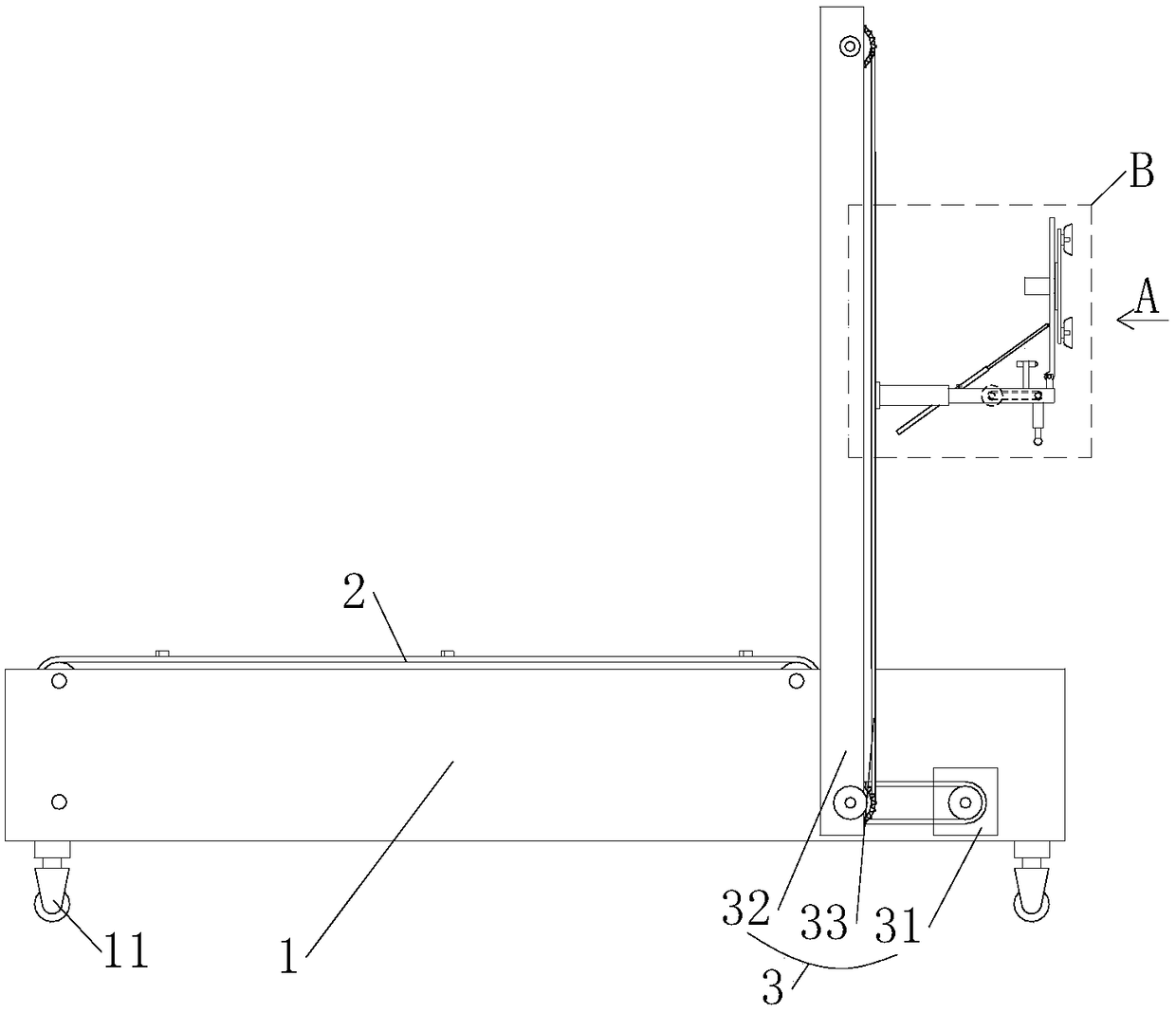

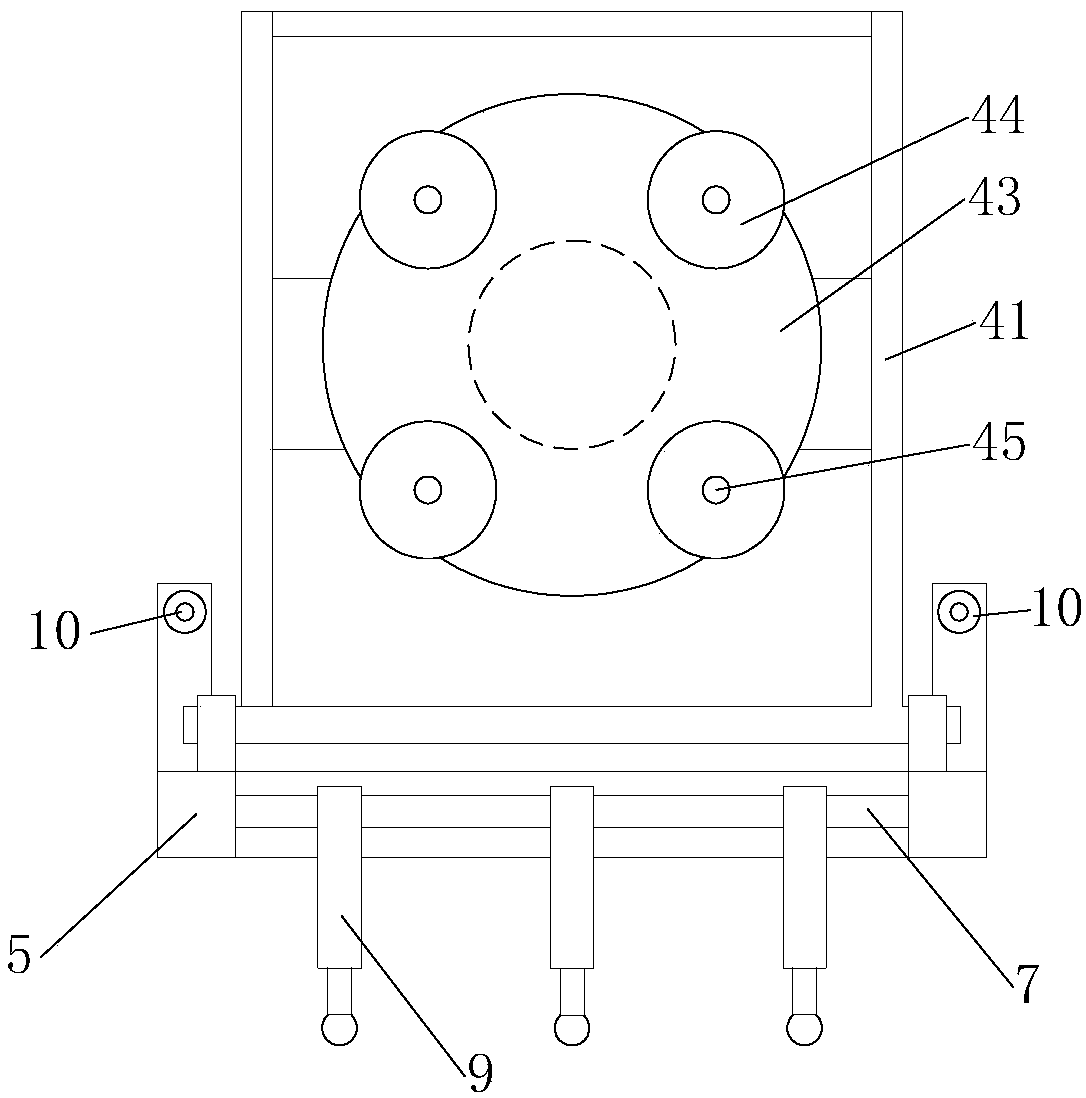

[0036] A device for sticking wall tiles for construction, as shown in the figure, includes a support frame 1, a feeding component 2, a material conveying component 3 and a material sticking component 4;

[0037] The feeding assembly 2 includes two material conveyor belts 21 and a motor one 22, the two material transmission belts are respectively fixedly connected to both sides of the support frame 1, the motor one 22 is fixedly connected to the bottom surface of the support frame 1, the motor one 22 is driven by a pulley and The material transmission belt is connected, and the transmission grid 23 is arranged at equal intervals on the material transmission belt. The transmission grid 23 can position the wall tiles and place them on the material transmission belt for transmission.

[0038] The material transmission assembly 3 comprises a motor two 31, a support plate 32 and a lifting chain 33, the support plate 32 is vertically connected to the outside of the support frame 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com