A Method for Determining the Size of Hydraulic Oscillator Valve Disc

A technology of hydraulic oscillator and determination method, which is applied in the direction of earth square drilling, vibration drilling, rotary combined drilling drive device, etc., which can solve the problem of not being able to take into account the needs of equipment and downhole well, the accuracy is not high, and there is no theory Basis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

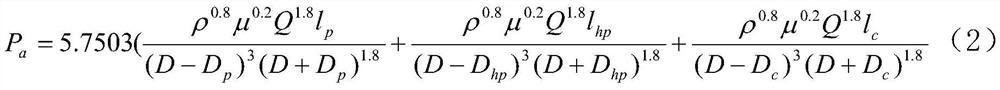

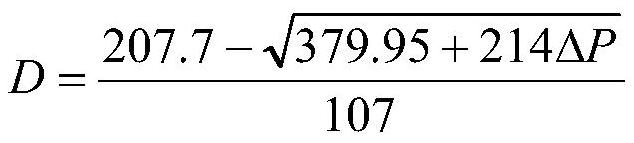

Method used

Image

Examples

Embodiment

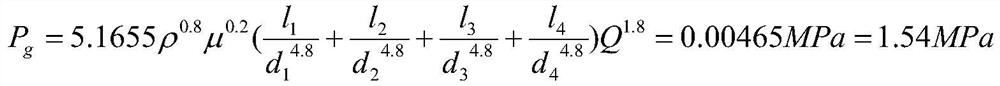

[0038] Well A is designed to have a well depth of 4000m, and the drilling tool assemblies used in the drilling process are: 30m drill collars with an outer diameter of 17.78cm and an inner diameter of 5.7cm, 180m of heavy drill pipe with an outer diameter of 12.7cm and an inner diameter of cm drill pipe 3790m, the nozzle equivalent area of the drill bit is 12.02cm 2 .

[0039] Drilling fluid properties used: Drilling fluid density 1.25g / cm 3 , The plastic viscosity of the drilling fluid is 45Pa·s.

[0040] The drilling fluid displacement used in the drilling process is 1.8m 3 / min.

[0041] The equipment of the drilling team responsible for Drilling A: 3NB-1000C drilling pump (the rated working pressure of the new pump is 26.6MPa), which has been in service for 3 years; the length of the surface high-pressure pipeline is 20m, and the inner diameter is 8.0cm; the length of the high-pressure riser is 40m, the inner diameter is 8.0cm ; The length of the hose is 35m and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com