Gradually unpacked washable well packer

A well-washing type and packer technology, which is applied in the directions of sealing/isolation, flushing wellbore, wellbore/well parts, etc., can solve the problems of affecting the normal operation of equipment, inability to separate and lift, and danger of equipment on the well, and meet the requirements of Ground equipment requirements, operation time saving, and effect of improving oil production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

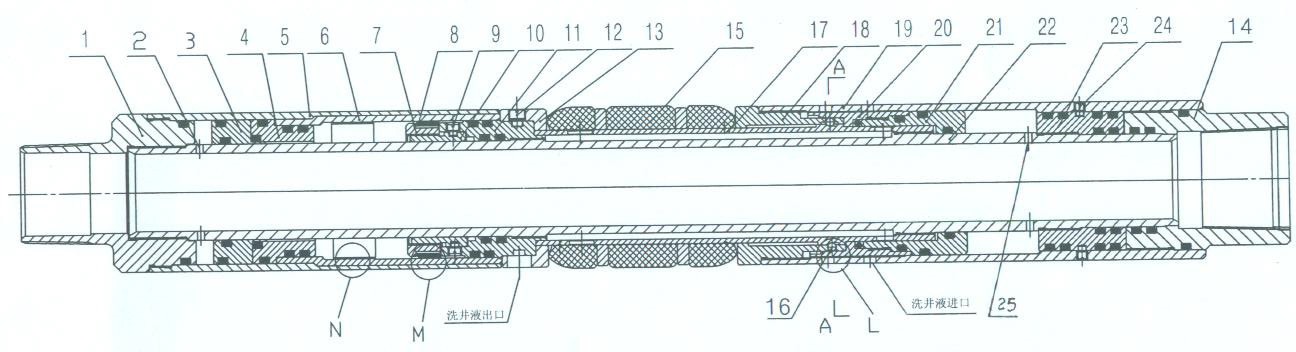

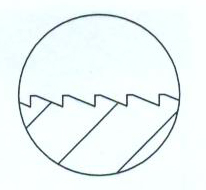

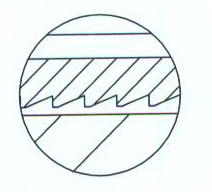

[0013] See figure 1 -3, the specific structure is as follows: the lower end of the lower joint 1 is an outer tapered pipe thread, the upper end is connected with the outer working cylinder 5 through the outer thread, and is connected with the central pipe 22 through the inner thread. The upper and lower ends of the central tube 22 are respectively provided with pressure inlet holes 25 and 2. The lower outer peripheral surface of the central tube 22 is sleeved with a release piston 3 and a screwed connection release piston 4. The two pistons form a release piston assembly; There is a release cylinder 6 , and the upper end of the release cylinder 6 is in contact with the well flushing ring 13 . See Figure 4 , 5 , the release cylinder 6 is provided with one-way serrated teeth, which mesh with the C-shaped circlip 8 with one-way teeth (as the prior art). The well flushing ring 13 is connected with the fixed piston 11 through the release pins 12, and the fixed piston 11 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com