Sewage recovery recycling device for glass production

A technology for producing sewage and recycling equipment, which is applied in water/sewage treatment, water/sewage treatment equipment, multi-stage water/sewage treatment, etc. It can solve the problems of low removal efficiency, unsatisfactory production and use, and increased water loss, etc., to achieve The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further describe the present invention, a specific embodiment of a glass production sewage recovery and recycling device will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

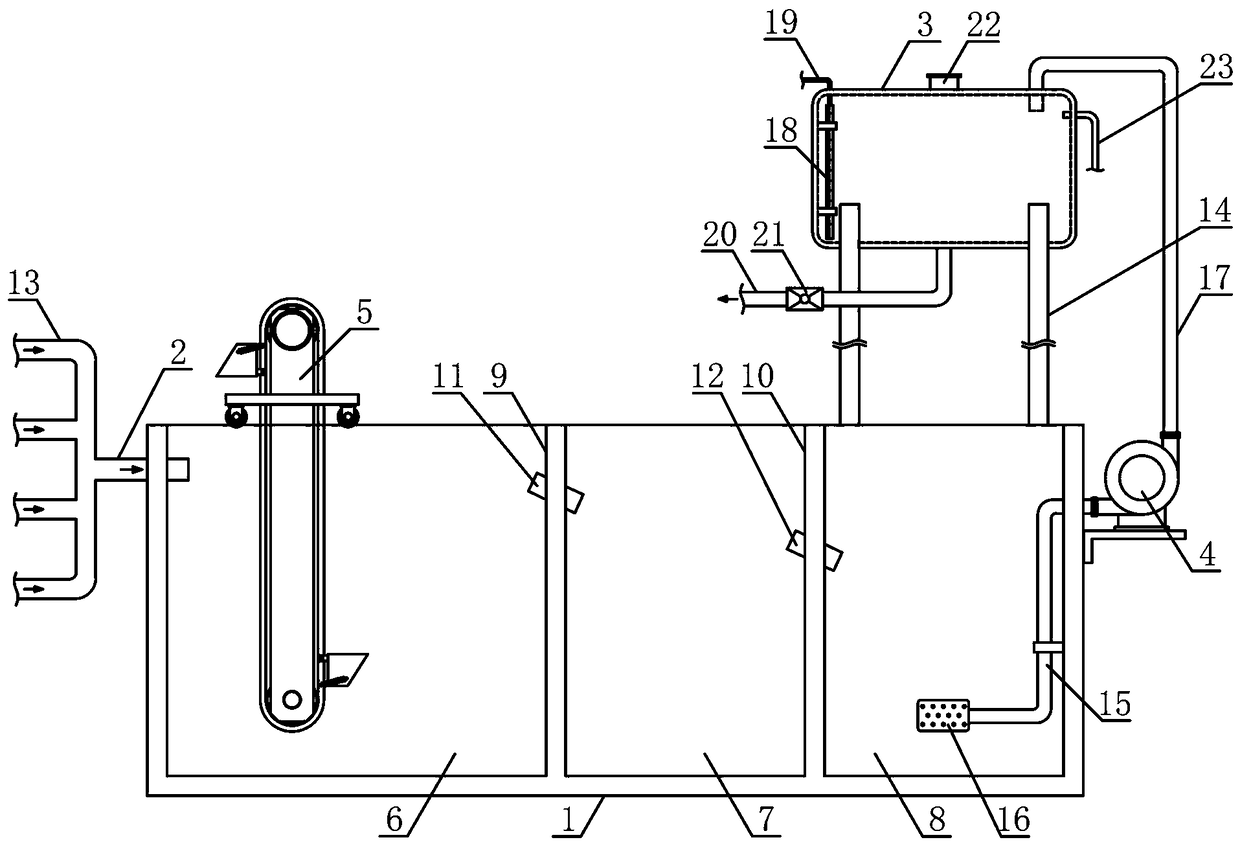

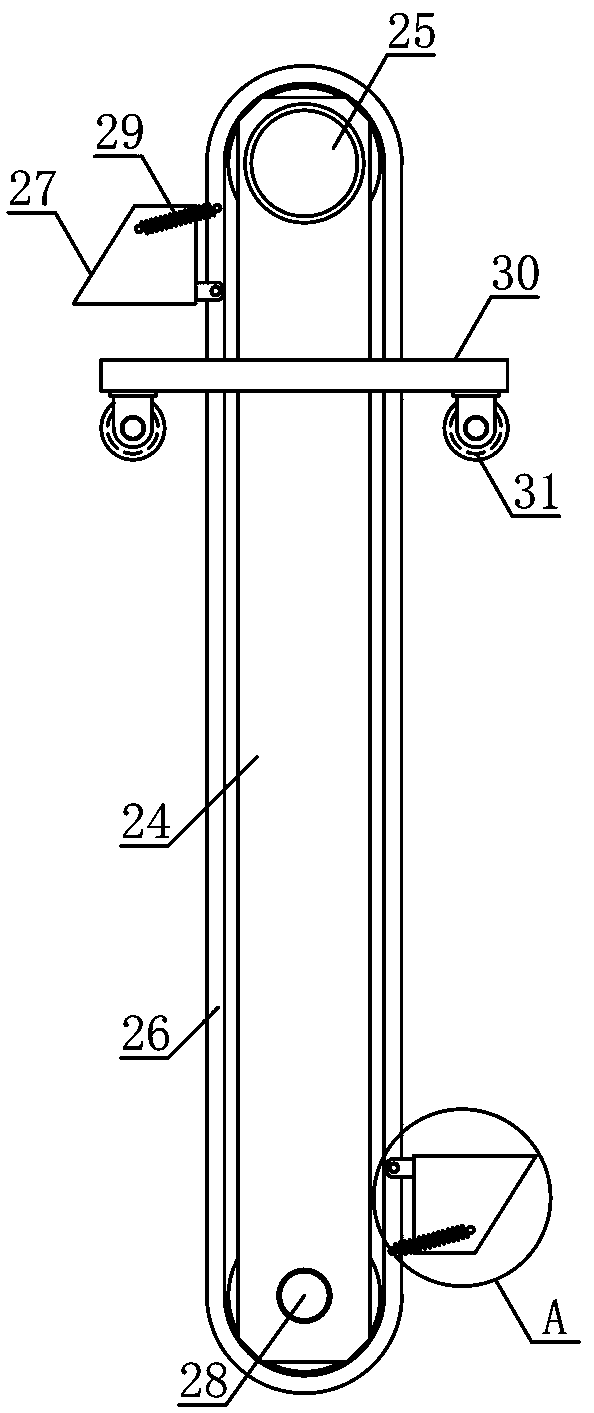

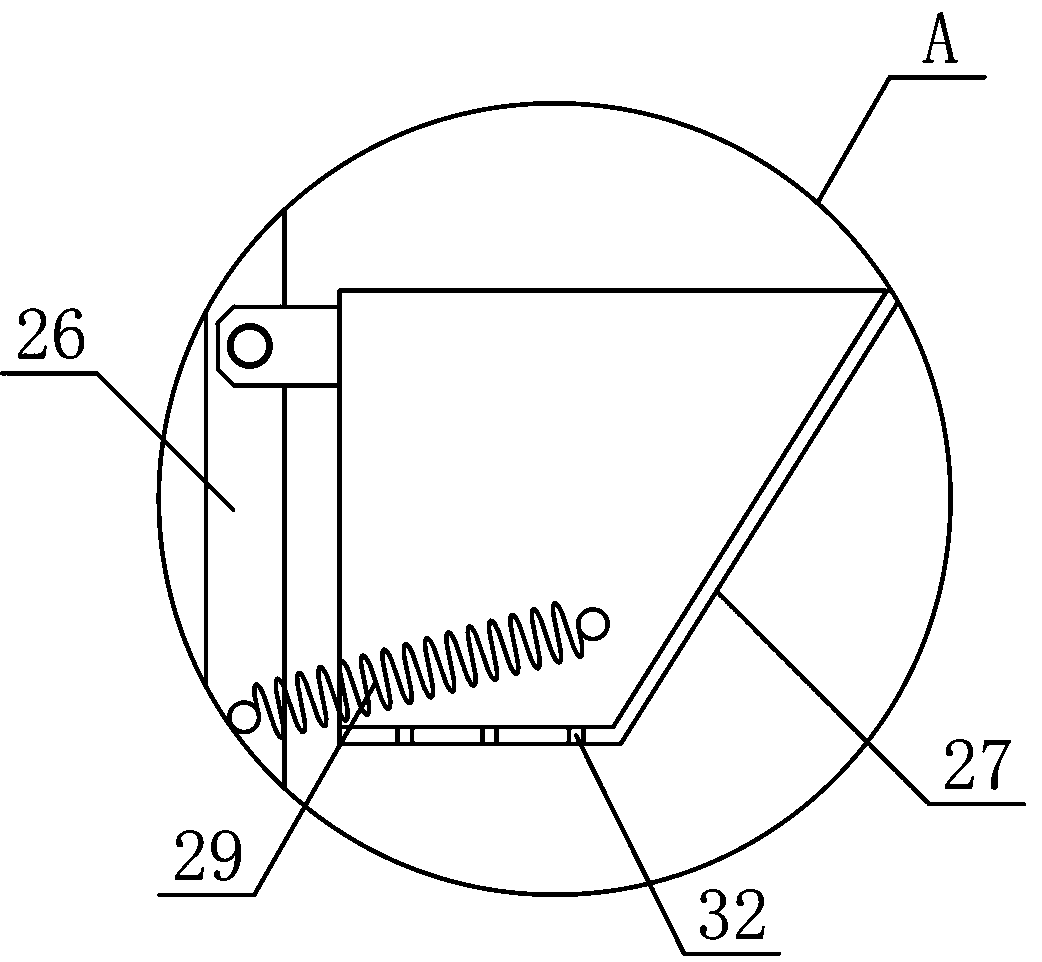

[0014] Such asfigure 1 As shown, the waste water recycling device for glass production of the present invention includes a waste water recovery tank 1, a sewage water inlet pipe 2, a water storage round tank 3, a pumping motor 4 and a desilting mechanism 5, and the sewage recovery tank 1 includes a first sedimentation chamber 6 , the second settling chamber 7 and recovery water storage chamber 8, between the first settling chamber 6 and the second settling chamber 7, a front isolation baffle plate 9 is vertically fixed, the second settling chamber 7 and recovery water storage chamber 8 A rear isolation baffle 10 is fixed verticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com