Railway Freight Car Axlebox Suspension Swing Bogie

A railway wagon, swing-type technology, applied in the field of railway wagons, can solve the problem that it is difficult to improve the lateral performance and vertical performance at the same time, achieve the effect of easy replacement and repair, reduce maintenance and management costs, and improve the horizontal performance and vertical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

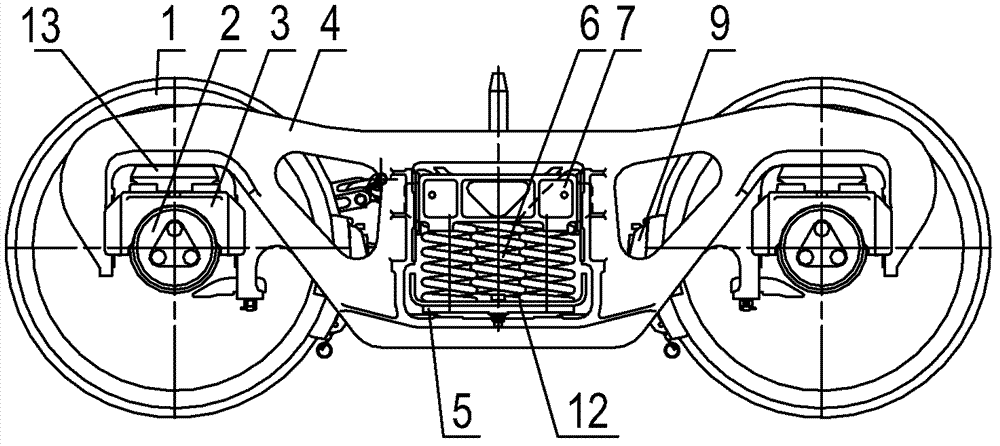

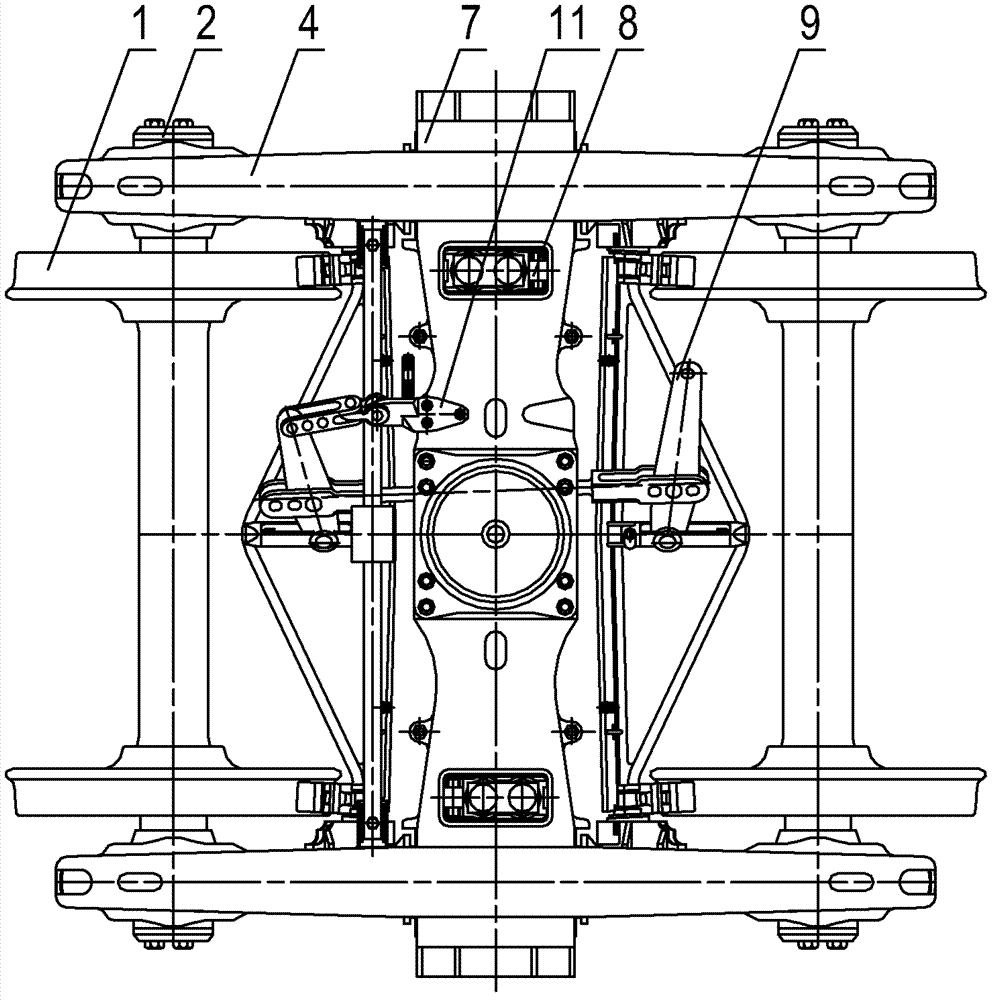

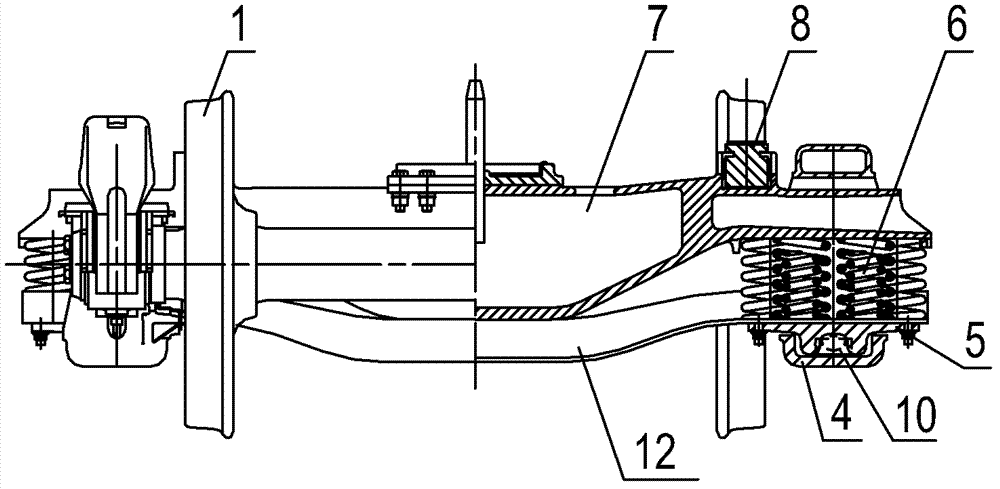

[0021] Such as Figure 1 to Figure 3 As shown, the railway freight car axle box suspension swing type bogie of the present invention comprises wheel set 1, axle box 2, side frame 4, bolster 7, side bearing 8 and foundation braking device 9, the connection between axle box 2 and side frame 4 A bearing saddle 3 is arranged between them, a central suspension device 6 is arranged under the two ends of the bolster 7, and a fixed lever fulcrum seat 11 is arranged on the bolster 7 . One side of the fulcrum seat body 11a of the fixed lever fulcrum seat 11 is provided with a brake rod support 11b, and the fulcrum seat body 11a is provided with three riveting holes 11c arranged in an isosceles triangle, as Figure 4 shown. The brake lever support 11b and the fulcrum seat body 11a are cast as one, that is, the original two parts are combined i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com