Environment-friendly mechanical seal cavity structure for pump and method for controlling temperature of cooling medium

A mechanical seal and environmentally friendly technology, applied in mechanical equipment, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of time-consuming and labor-intensive, complicated replacement process, and inability to intuitively grasp the cooling and lubricating medium in real time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

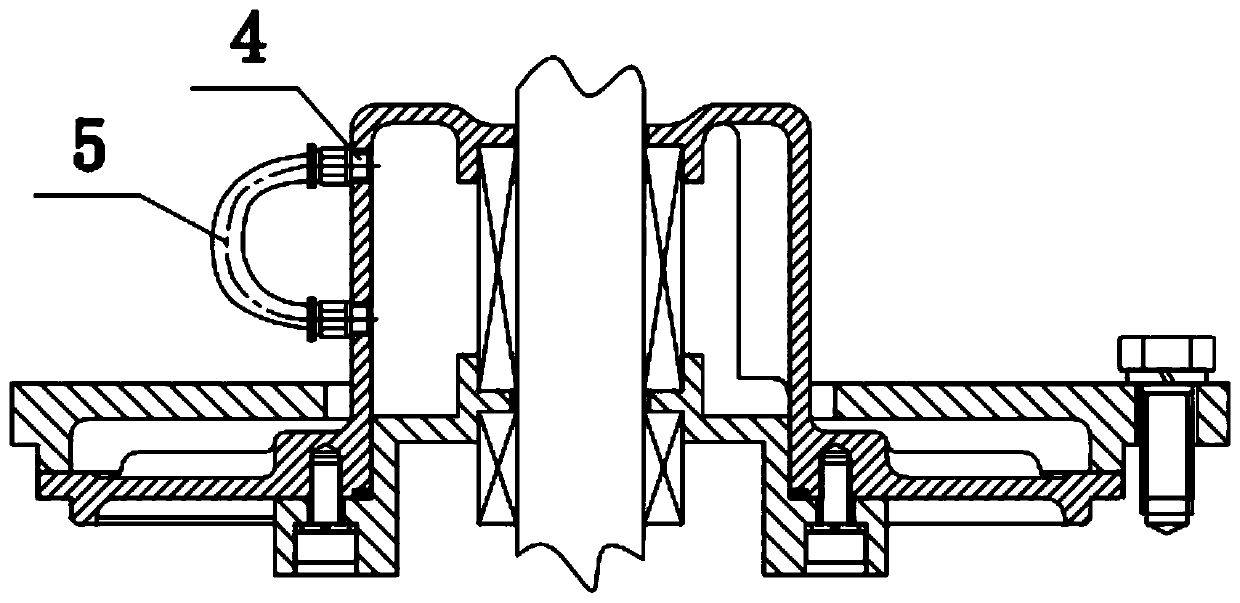

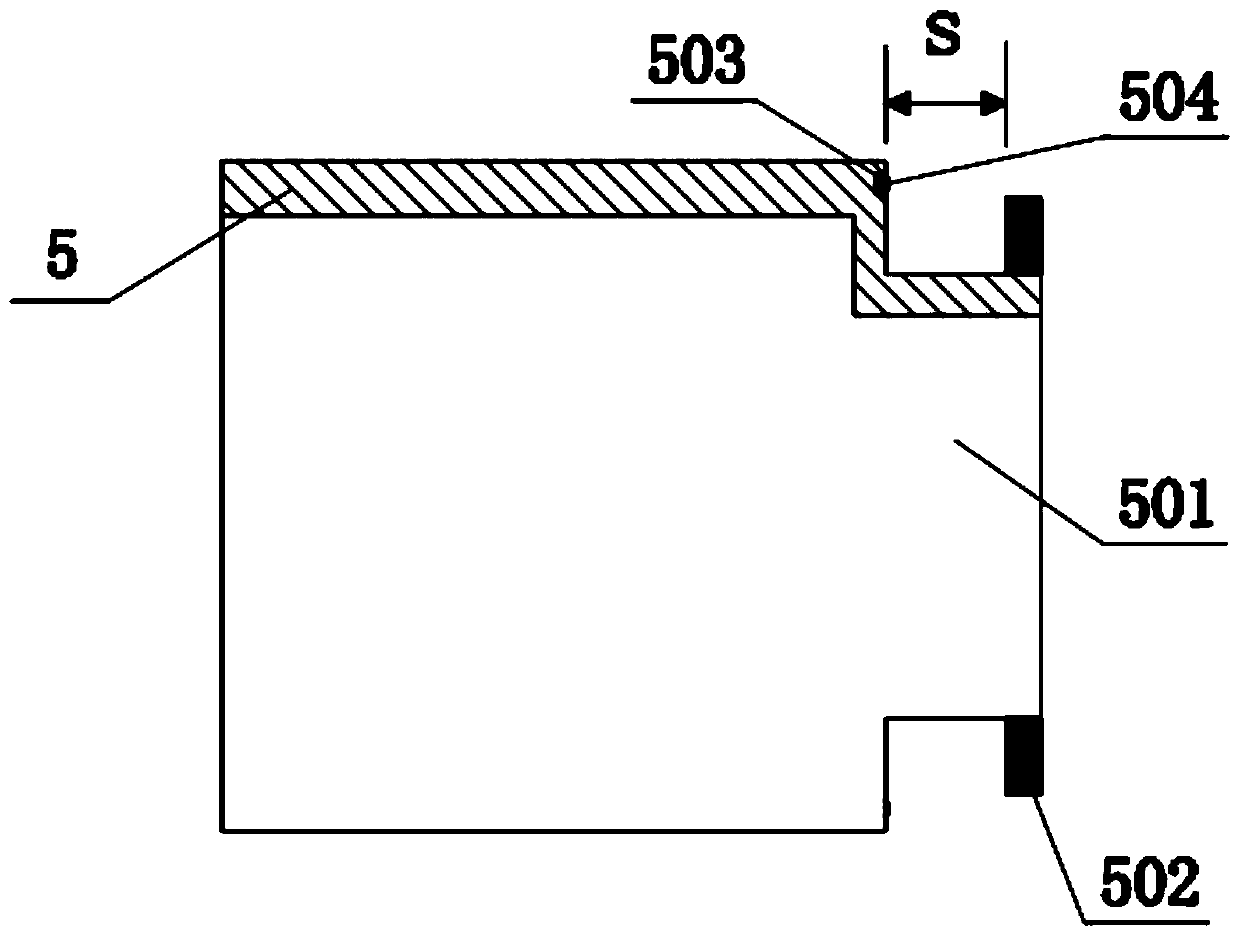

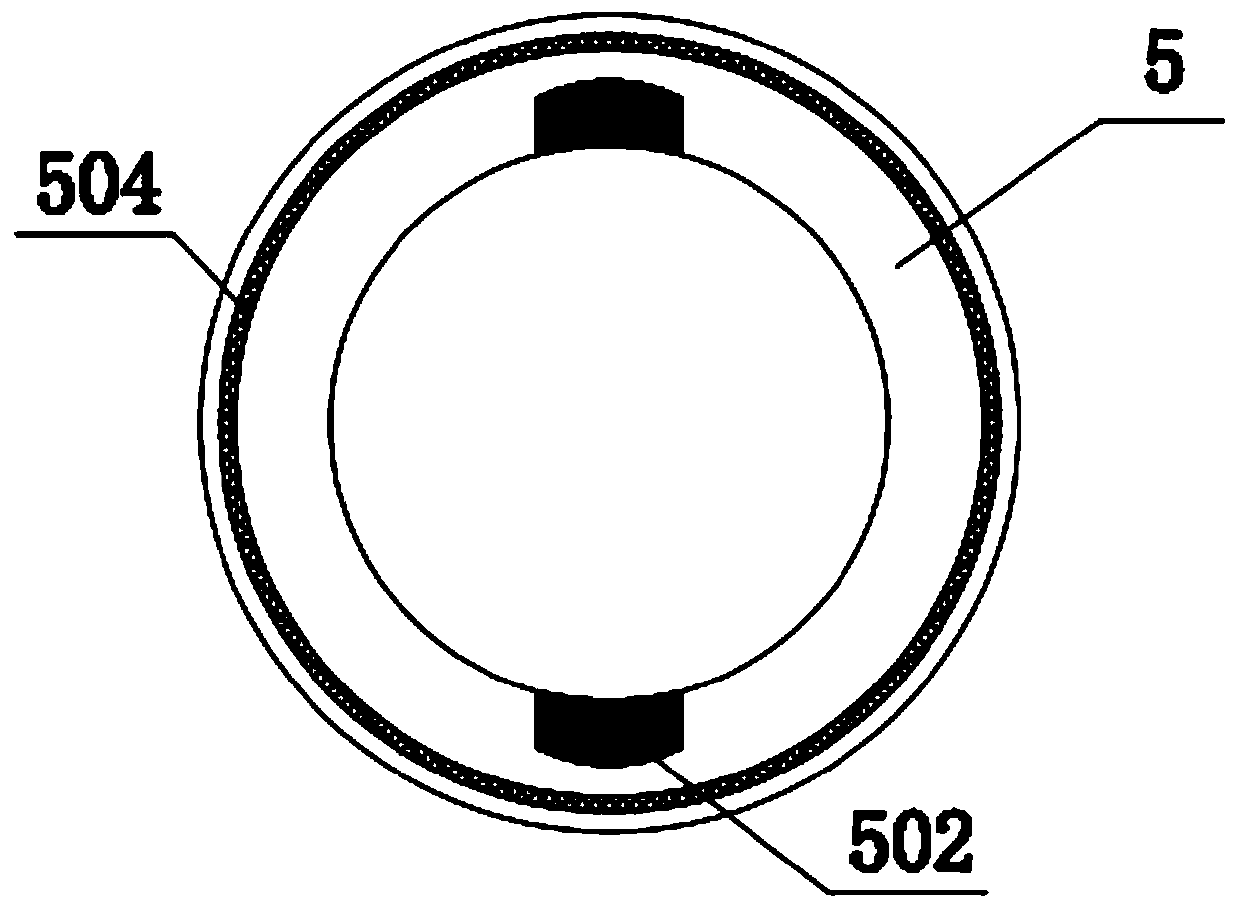

[0054] as attached figure 1 As shown, there is an environment-friendly mechanical seal cavity structure for a pump, and two liquid injection holes 4 communicating with the outside are arranged on the side wall of the seal cavity structure along the axial direction of the pump shaft. The two liquid injection holes 4 communicate through an observation device 5 located outside the sealed chamber structure. Wherein, one liquid injection hole 4 is arranged close to the motor of the pump body, and the other liquid injection hole 4 is arranged close to the impeller. The two injection holes 4 can be coaxially opened up and down, and can also be staggered up and down. For the convenience of connection and observation, in this solution, the two liquid injection holes 4 are coaxially arranged up and down. Managers can intuitively and real-time grasp the state of the cooling and lubricating medium in the sealing cavity through the observation device 5, for example, they can judge whethe...

Embodiment 2

[0057] Such as figure 1 As shown, the observation device 5 includes a transparent rubber tube, and the transparent rubber tube can be a transparent silicone tube with high transparency and moderate hardness. The two ports of the transparent rubber tube are respectively connected with the two liquid injection holes 4, so that the transparent rubber tube communicates with the sealing cavity, and at the same time, the cooling lubricating medium enters the transparent rubber tube. By directly observing the cooling and lubricating medium in the transparent hose, you can easily grasp the real-time status of the cooling and lubricating medium, and then judge whether the pump body is working abnormally.

[0058] In this technical solution, the transparent rubber tube is connected to the liquid injection hole 4 on the sealed cavity structure by quick connection, so as to realize the quick docking and disengagement of the transparent rubber tube and the sealed cavity structure.

[0059...

Embodiment 3

[0067] When the pipeline pump transports hot water and other high-temperature flow media, and the cooling and lubricating medium in the sealed cavity needs to be circulated, preferably, the observation device 5 is also connected with a cooling and lubricating medium storage device (not shown in the figure) located outside the sealed cavity structure. show). A detachable transparent rubber hose can be selected, for example, the transparent rubber hose is in two sections, which are connected as a whole by threads. If an external cooling and lubricating medium storage device is required, the transparent rubber tube can be separated along the middle, and then the two free ends are respectively connected to the cooling and lubricating medium storage device. At this time, the cooling and lubricating medium storage device communicates with the sealing cavity through the transparent rubber tube. Since the liquid injection hole 4 is set high and low, the temperature difference of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com