A hydrogen refueling station hydrogen energy supply method and system

A hydrogen energy and hydrogen refueling station technology, applied in the field of hydrogen energy applications, can solve the problems of low transportation efficiency and large recycling residual pressure, and achieve the effects of improving transportation efficiency, reducing recycling residual pressure, and reducing recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

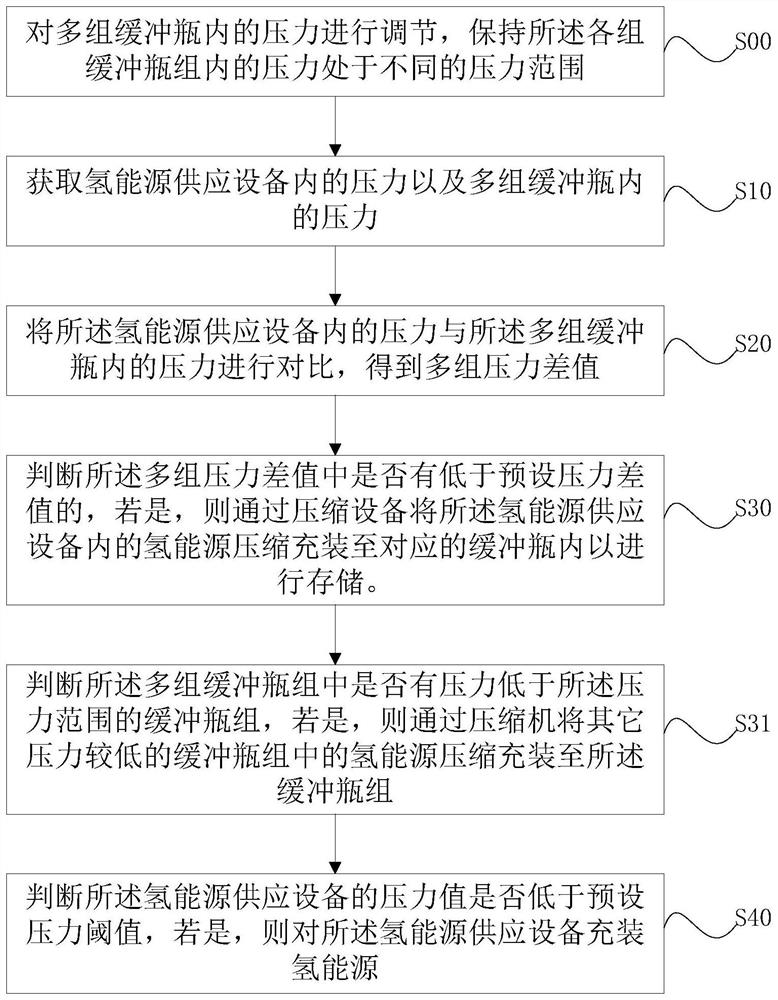

[0034] refer to figure 1 , this embodiment provides a hydrogen refueling station hydrogen energy supply method, including steps:

[0035] S10: Obtain the pressure in the hydrogen energy supply equipment and the pressure in multiple sets of buffer bottles;

[0036] S20: Comparing the pressure in the hydrogen energy supply equipment with the pressure in the multiple sets of buffer bottles to obtain multiple sets of pressure difference ratios;

[0037] S30: Determine whether any of the multiple sets of differential pressure ratios is lower than the preset differential pressure ratio, and if so, adjust the control logic of the compression equipment to compress and fill the hydrogen energy in the hydrogen energy supply equipment to the corresponding buffer bottle for storage.

[0038] In this embodiment, the hydrogen refueling station is equipped with a single-stage compressor and a buffer bottle for buffering hydrogen energy. The pressure capacity of the single-stage compressor ...

Embodiment 2

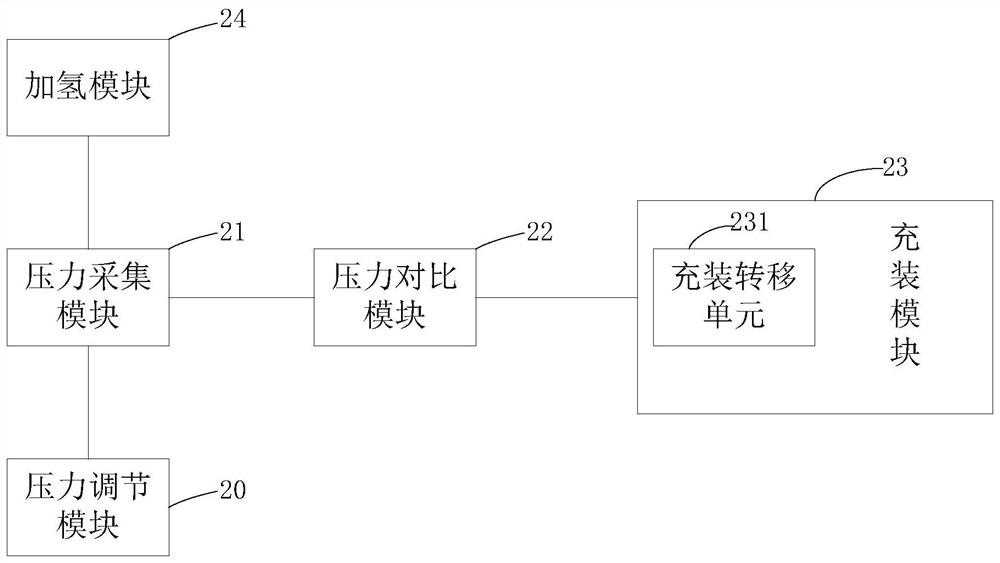

[0058] refer to figure 2 , this embodiment provides a hydrogen energy supply system for a hydrogen refueling station, including:

[0059] Pressure acquisition module 21: used to acquire the pressure in the hydrogen energy supply equipment and the pressure in multiple sets of buffer bottles;

[0060] Pressure comparison module 22: used to compare the pressure in the hydrogen energy supply equipment with the pressure in the multiple sets of buffer bottles to obtain multiple sets of pressure difference ratios;

[0061] Filling module 23: used to judge whether any of the multiple sets of differential pressure ratios is lower than the preset differential pressure ratio, and if so, compress and charge the hydrogen energy in the hydrogen energy supply equipment by adjusting the control logic of the compression equipment. Fill into corresponding buffer bottles for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com