Process and equipment for manufacturing spray water belt

A manufacturing method and technology of water spray belts, which are applied in the field of irrigation, can solve the problems of high price and difficulty in application, and achieve the effects of improving compressive strength, satisfying belt running speed, and regular hole shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

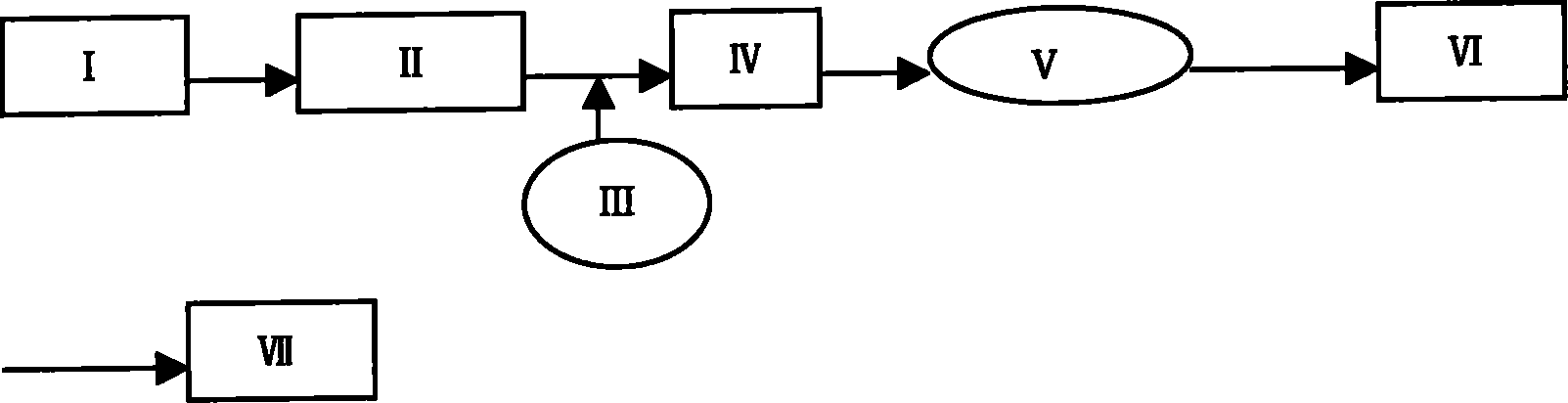

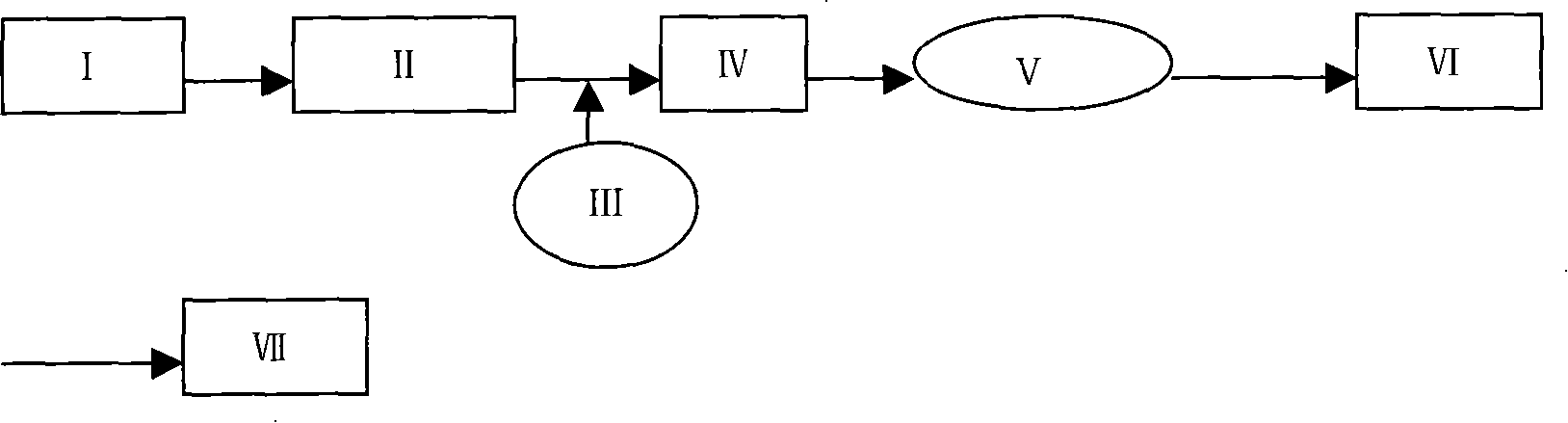

[0052] This invention adopts the process of cutting and welding into tubes after pressing the sheet. The difference from the water spray belt formed by blowpipe is that after the water spray belt is filled with water, its two sides are bonded to form wings, so it is also called "double-wing water spray belt". , see Figure 2. In the production process, after the tape is extruded, it is divided from the center, and then the upper side is turned over and translated to align the lower tape, and then the upper and lower tapes are bonded into a tube. Its main production process is as follows:

[0053] I. Extrusion

[0054]The plastic (polyethylene) pellets are extruded after being heated by the extruder. The extrusion port is sheet-shaped, with a width of about 200-250mm. The extruded plastic is strip-shaped, with a width of 150-200mm and a thickness of 0.25-1mm. At this time, the plastic It is still hot and melted, and it enters the tablet press after extrusion. The extruder tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com