A double-taper work roll and its roll shape design method

A double-taper work roll and work roll technology, applied in the field of strip rolling, can solve the problems of inability to adapt to the changing range of plate width and large limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

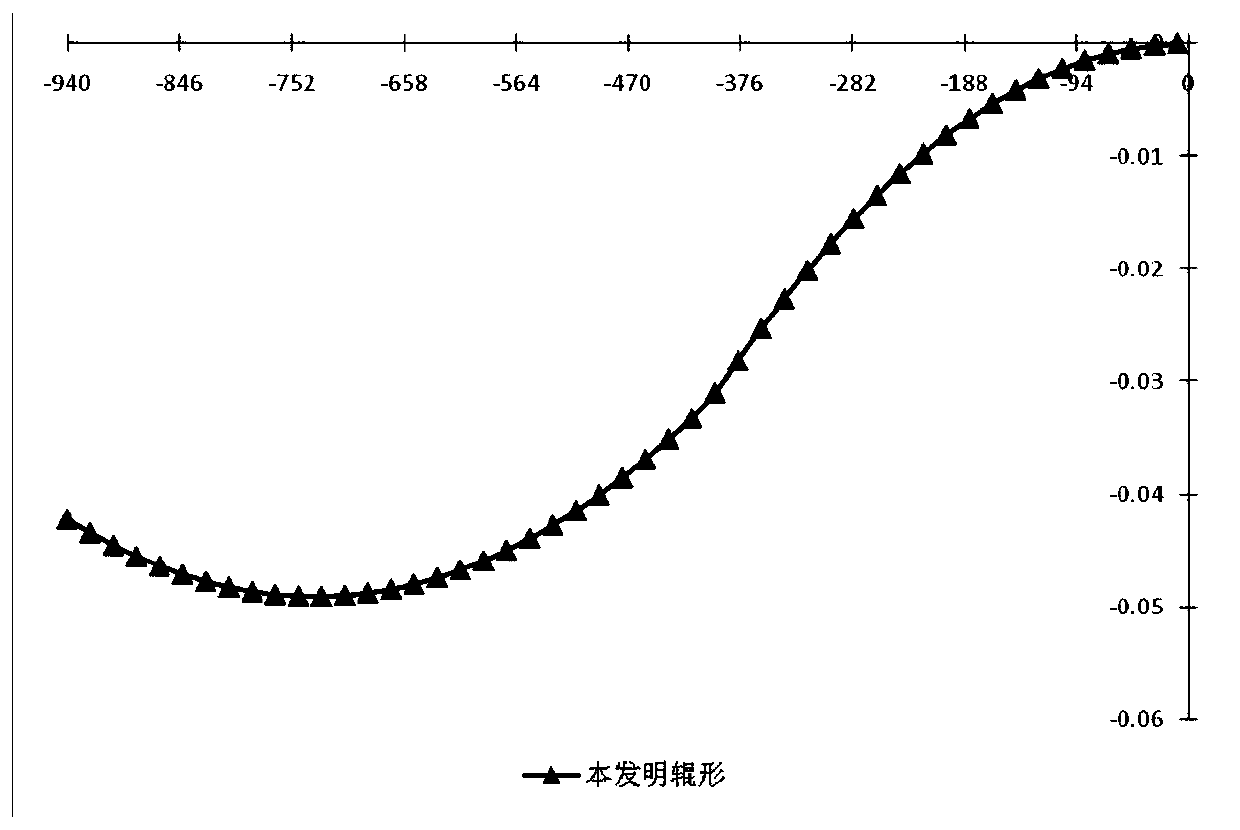

Examples

Embodiment Construction

[0077] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

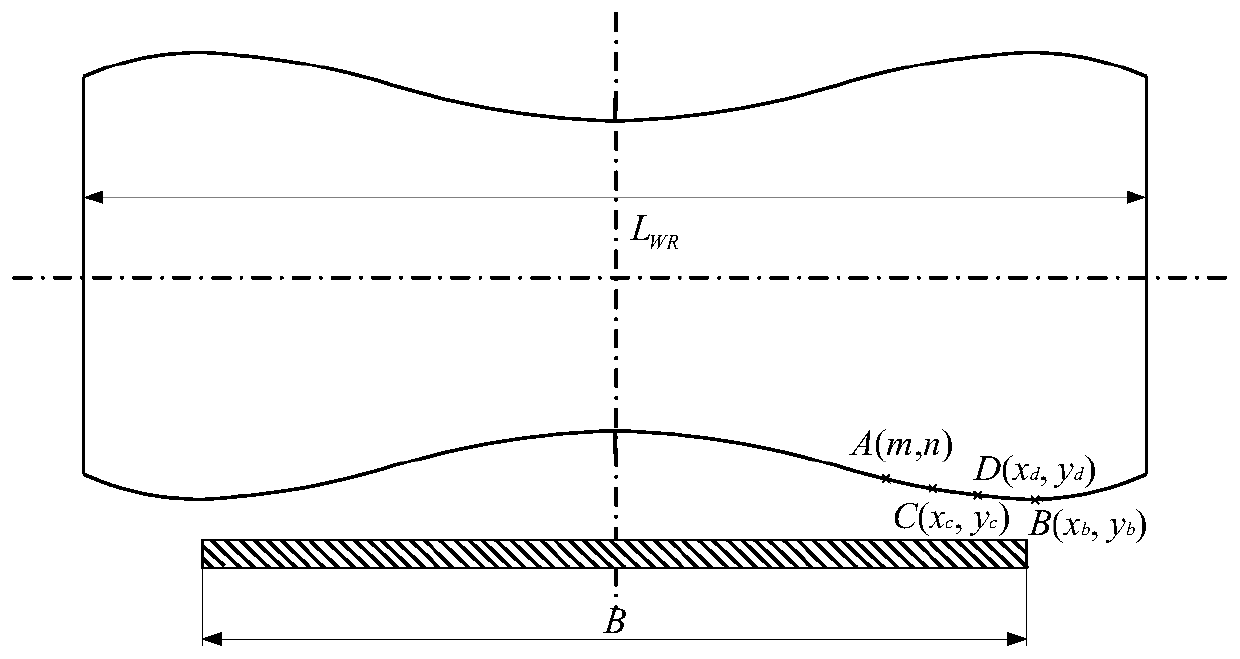

[0078] The invention provides a double taper work roll and a roll shape design method thereof.

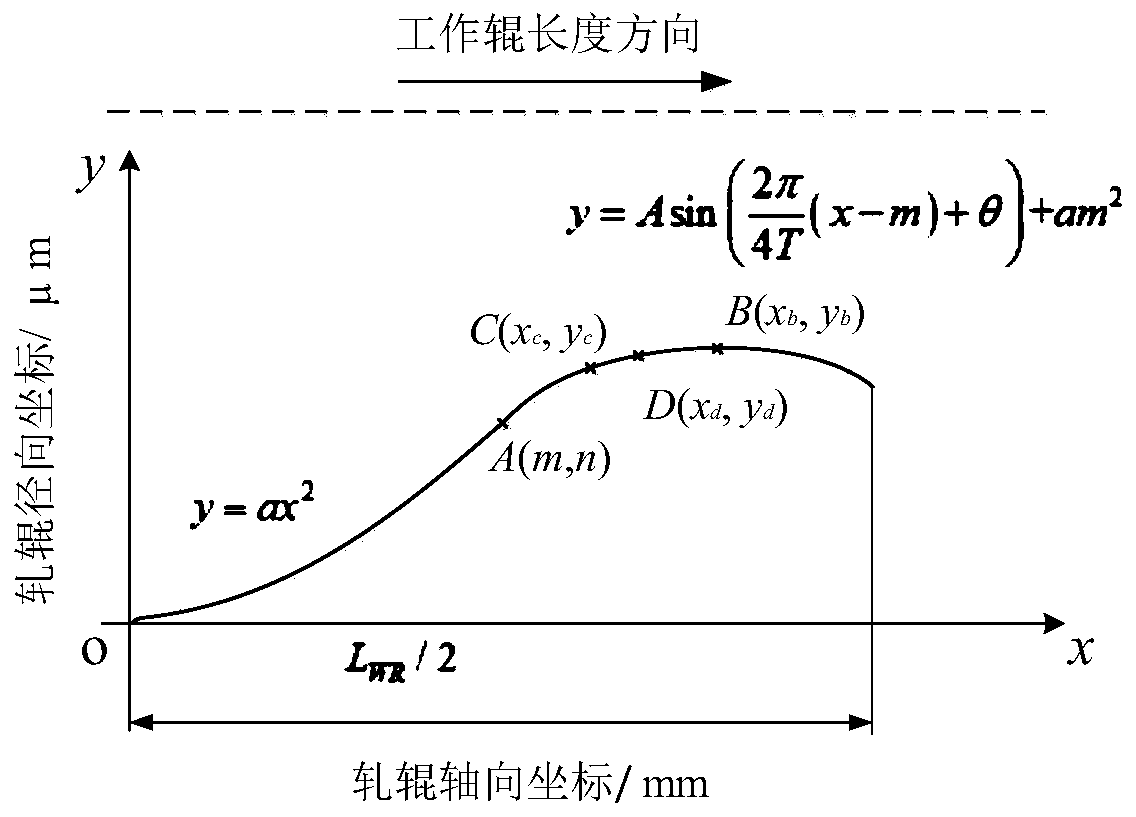

[0079] Such as figure 1 , in the two-dimensional coordinate system in the figure, a double-tapered work roll used for hot-rolled strip edge drop control, the roll shape curve equation of the work roll is:

[0080]

[0081] In the formula, x is the coordinate of the roll body, in mm; y(x) is the roll shape curve equation, in mm.

[0082] see figure 1 According to an embodiment of the present invention, a double-tapered work roll profile design method with hot-rolled strip edge drop control capability includes the following steps:

[0083] Step 1: Determine the quadratic curve y=ax 2 .

[0084] Select the production data of non-oriented silicon steel at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com