Concrete pouring formwork bracket

A concrete and formwork technology, applied in the field of concrete pouring, can solve the problems of exceeding the tensile strength of the spring, affecting the service life, insufficient strength, etc., and achieving the effects of avoiding the troweling process, facilitating assembly, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through specific implementations:

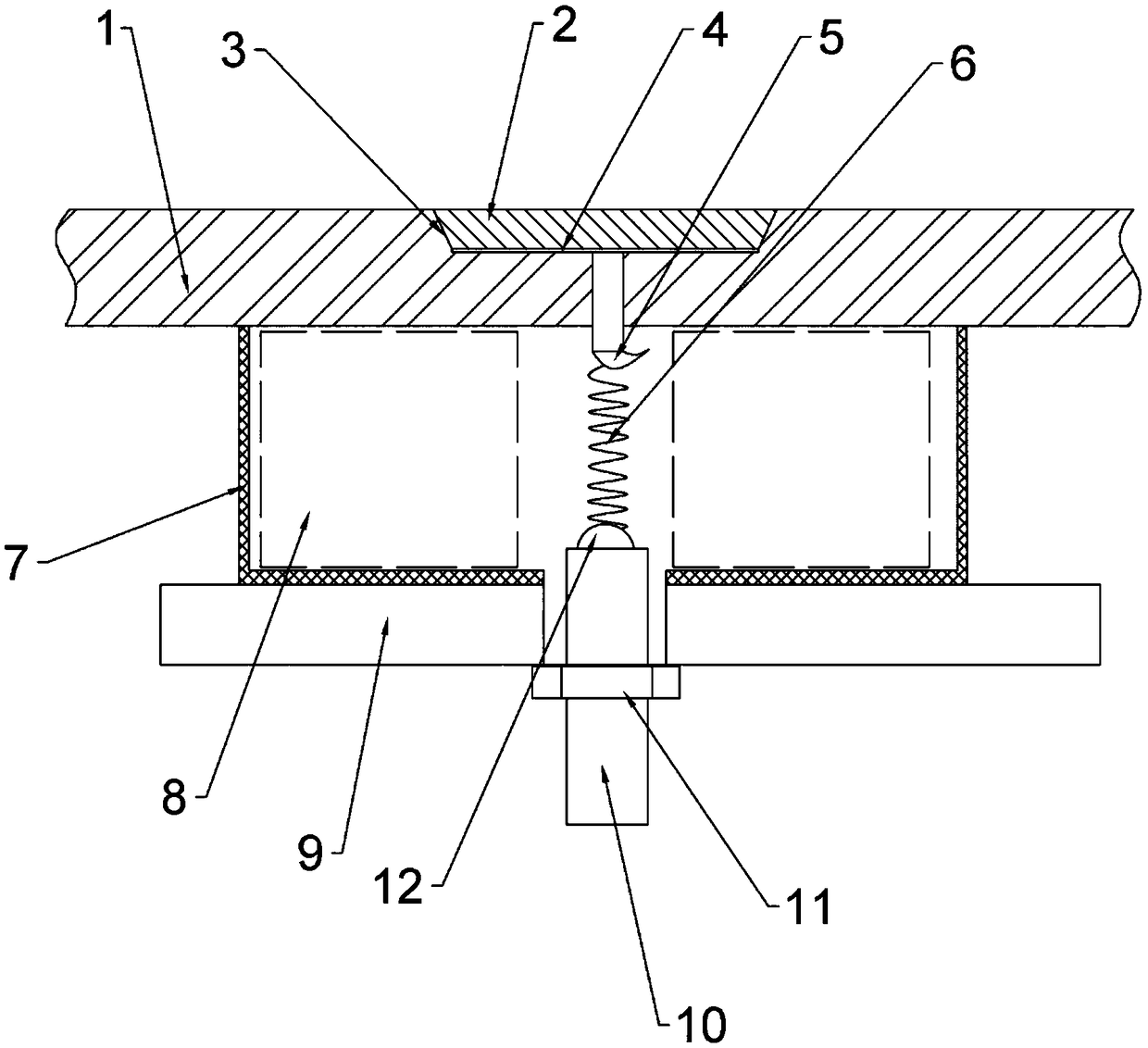

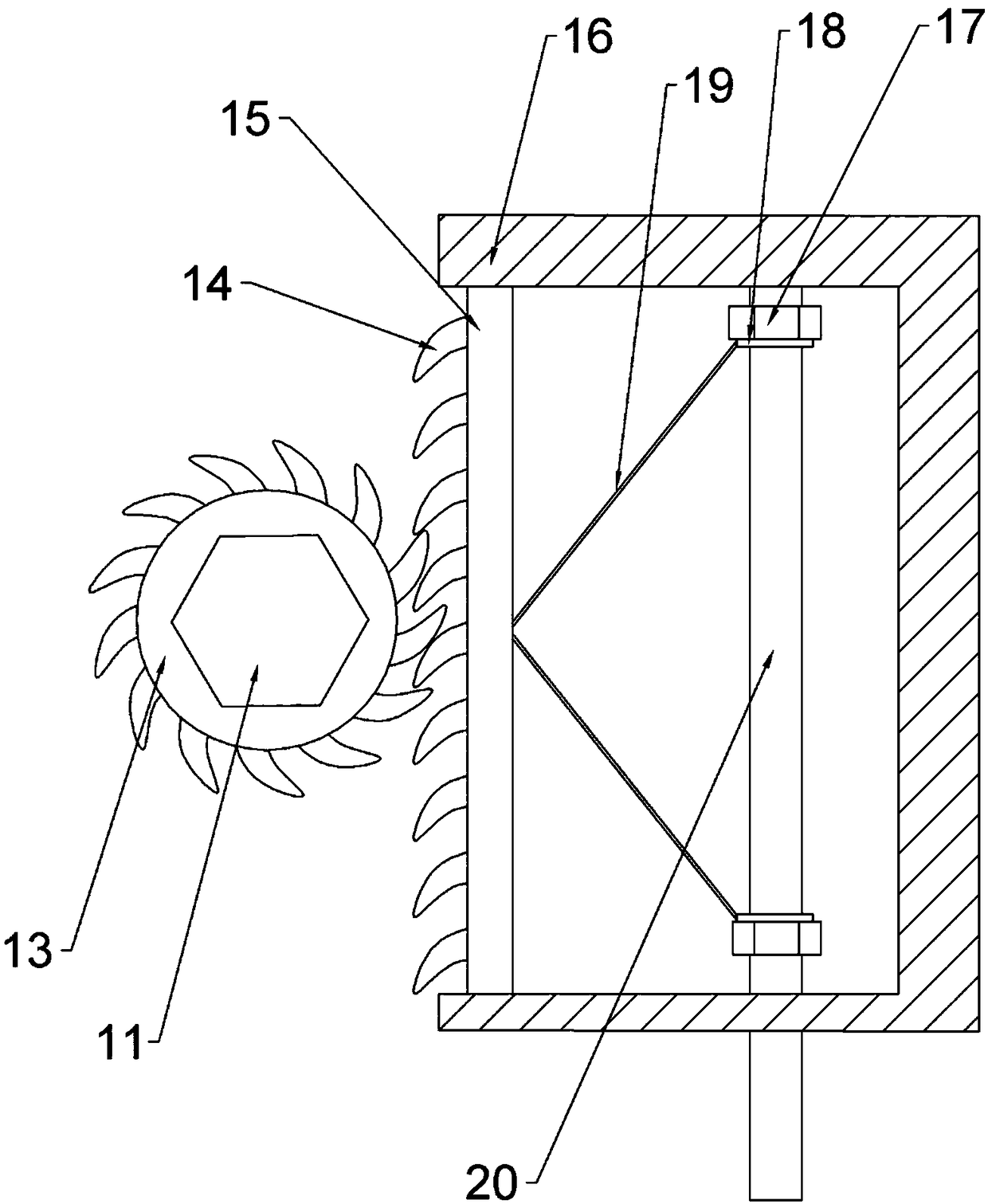

[0014] The reference signs in the drawings of the specification include: template 1, connecting piece 2, sinking groove 3, rubber pad 4, first hook 5, spring 6, clamping piece 7, cushion strip 8, bracket 9, screw 10, nut 11. The second hook 12, the ratchet gear 13, the ratchet teeth 14, the connecting plate 15, the fixing plate 16, the fixing nut 17, the ring 18, the connecting rod 19, and the two-way screw 20.

[0015] The embodiment is basically as attached figure 1 Shown: concrete pouring formwork support, including formwork 1, cushion strip 8, connecting piece 2, spring 6, fixed part and bracket 9. The connecting piece 2 is a connecting piece 2 made of metal material, and the connecting piece 2 made of metal material has better strength and better connection effect. The support 9 is built into a frame shape, the top of the support 9 is provided with a plurality of mat str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com