Fan and cleaner

A technology of air supply device and stationary blade, which is applied in the directions of vacuum cleaners, pump devices, and components of pumping devices for elastic fluids, etc., can solve the problem of reduced air supply efficiency, inability to reduce the circumferential gap between adjacent blades, and the number of blades. Less problems, etc., to achieve the effect of improving air supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

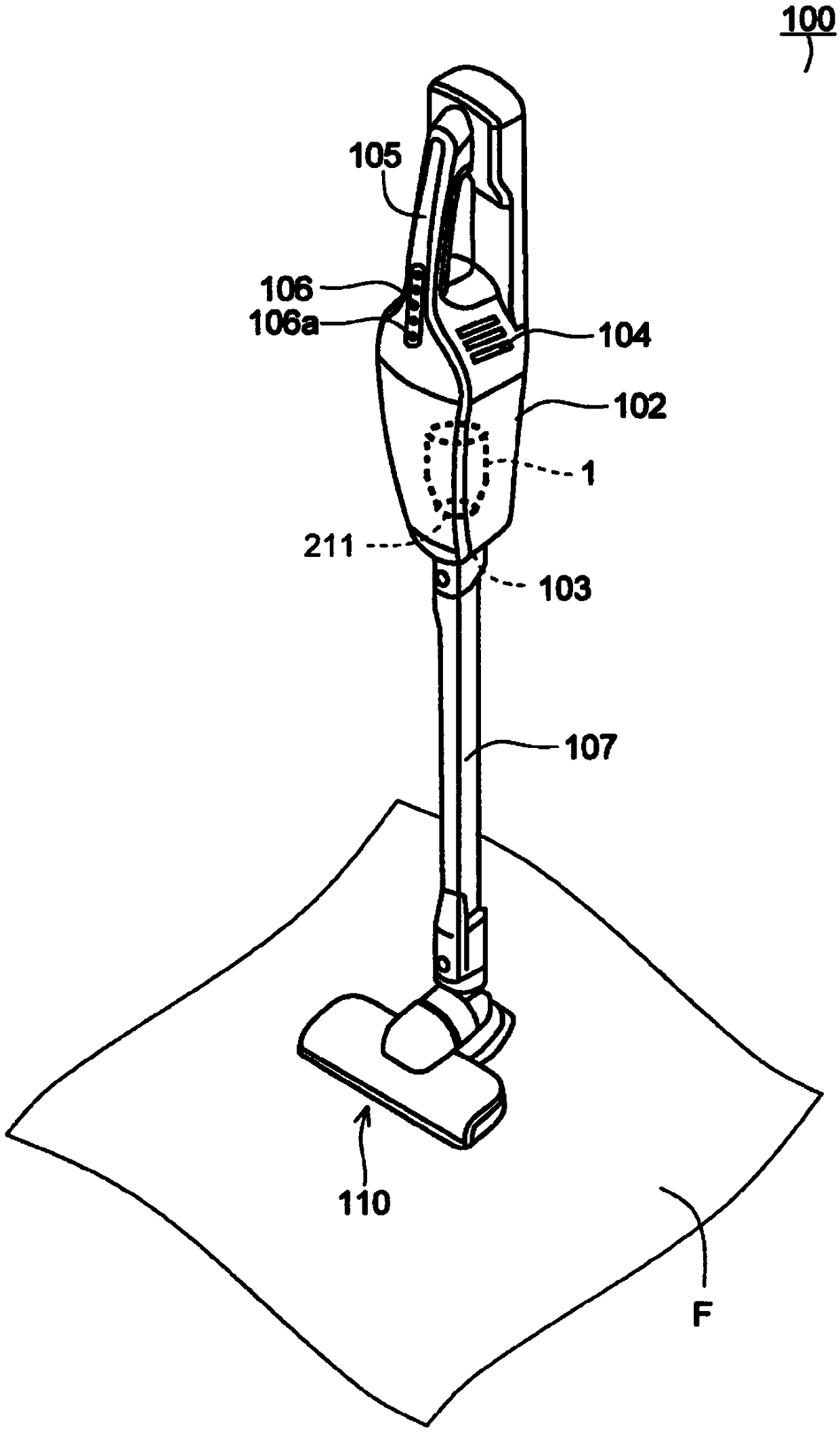

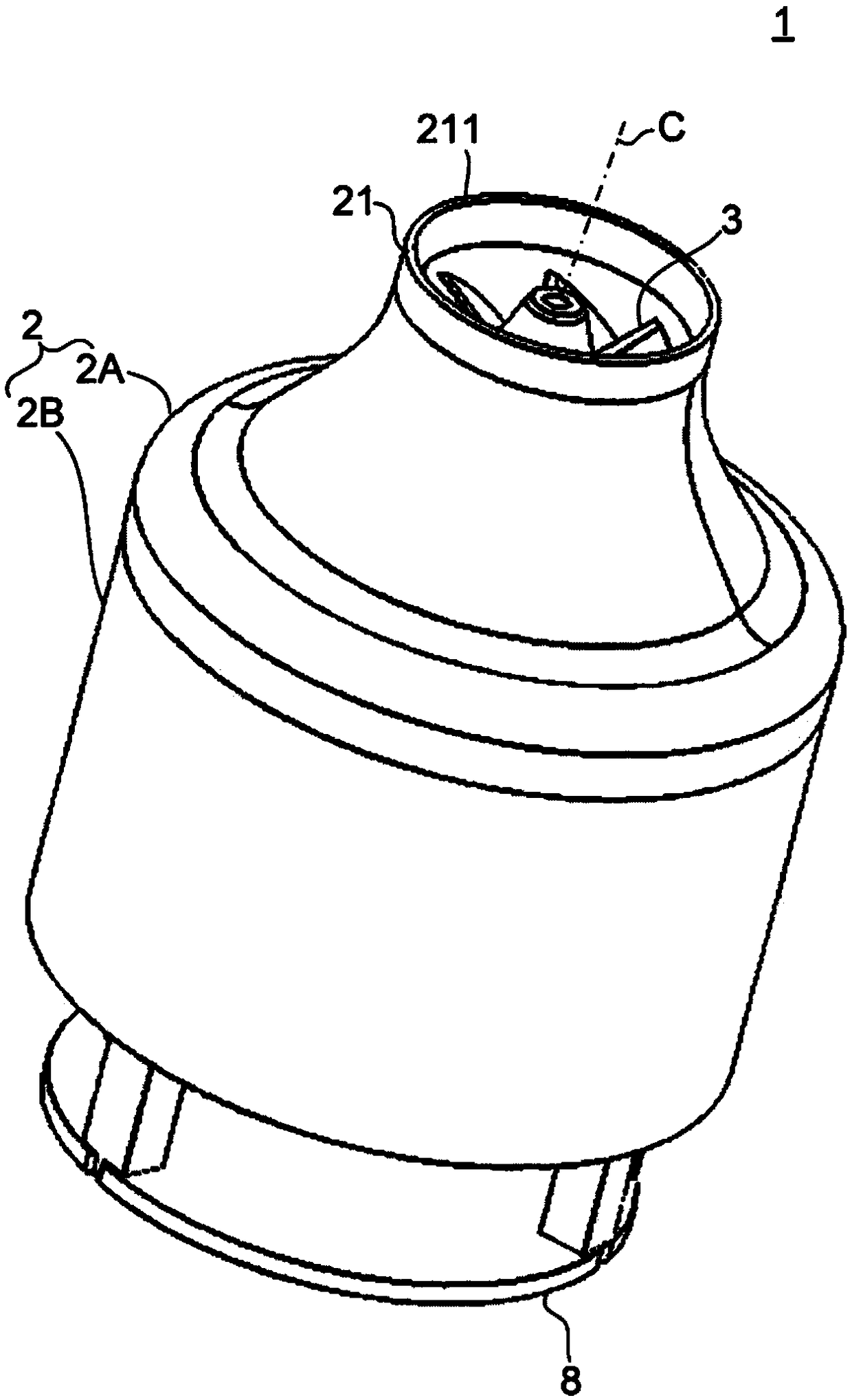

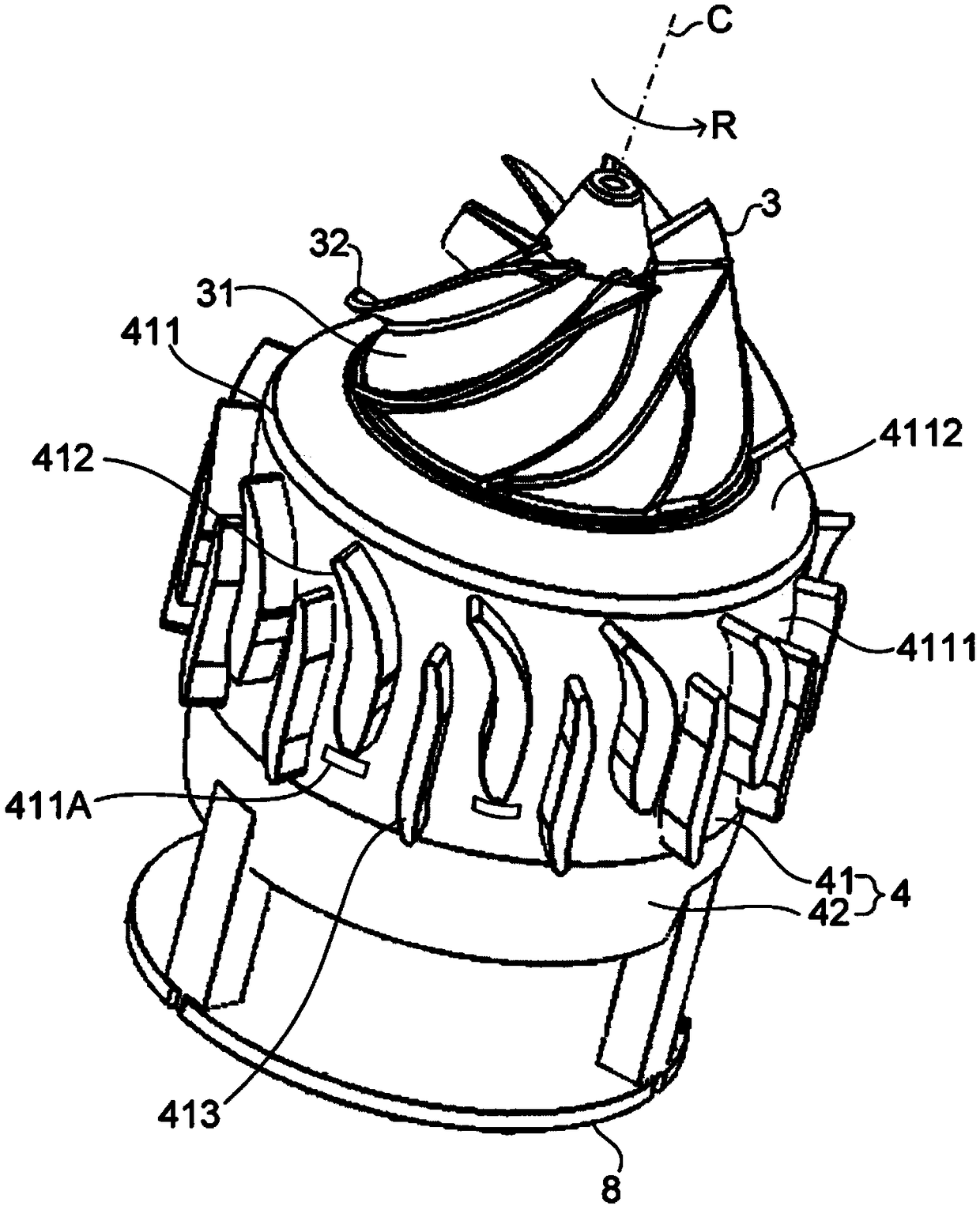

[0016] Hereinafter, exemplary embodiments of the present invention will be described with reference to the drawings. In addition, in this specification, the direction in which the central axis of the air blower extends is called "axial direction", and the direction perpendicular to the central axis of the air blower is called "radial". The direction of the circular arc centered on the central axis is called "circumferential direction". In addition, the above-mentioned central axis extends along the "upper and lower direction", and in this specification, the shape and positional relationship of each part will be described with respect to the impeller with the suction side being referred to as the "upper side". However, the above-mentioned "up and down direction" does not limit the actual positional relationship and direction when it is installed in the device. In addition, "upstream" and "downstream" mean upstream and downstream, respectively, in the flow direction of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com