Cylinder barrel with reduced weight

A cylinder and weight technology, applied to cylinders, engine components, mechanical equipment, etc., can solve the problems of increasing cylinder weight, increasing cylinder cost, cylinder explosion, etc., to reduce production costs, reduce weight, and reduce cylinders. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

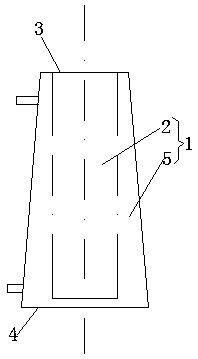

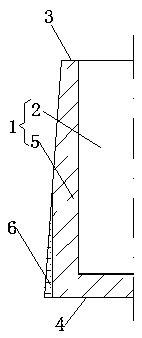

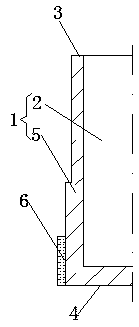

[0016] Such as figure 1 , 2 . As shown in 3, a cylinder with reduced weight includes a cylinder body 1, the cylinder body is a cylindrical structure with an internal cavity 2, the cavity is the place where the piston runs, and the surrounding of the cavity It is a side wall; the cylinder body has an upper end 3 and a lower end 4, the piston moves downwards to compress the air in the cavity, and the piston moves upwards to reduce the pressure in the cavity; it is characterized in that: The side wall 5 of the cylinder body has a thin upper surface and a thicker lower surface.

[0017] The cylinder is set in this way. When the piston moves to the bottom, the side wall below the cylinder body will bear a large expansion strength, but the upper part of the cylinder body does not bear the expansion force, and the side wall of the cylinder body will bear the expansion force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com