Slow-closing swing type non-return valve

A check valve, swing-type technology, applied in the direction of valve details, control valves, valve devices, etc., can solve the problems of valve damage, fast closing speed, easy damage, etc., to prolong service life, reduce impact force, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

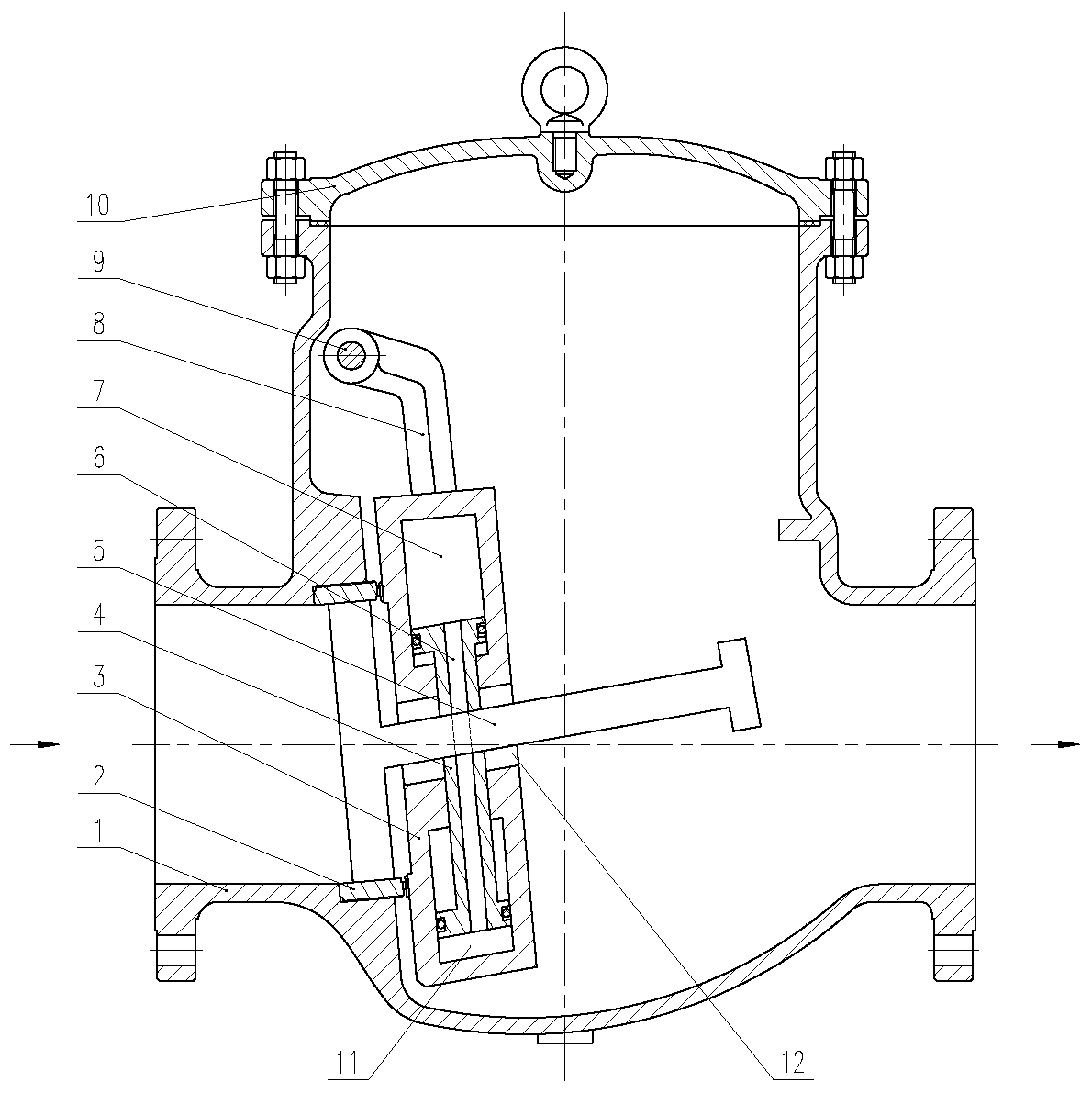

[0012] according to figure 1 It can be seen that this kind of slow-closing swing check valve includes: valve body 1, valve seat 2, check valve disc 3, rocker 8, pin shaft 9 and valve cover 10, and the valve cover 10 is installed on the valve The top of the body 1, the middle part of the inner cavity of the valve body 1 is provided with a chamber, the two ends of the inner cavity of the valve body 1 are respectively provided with inlet and outlet channels for medium circulation, and the valve seat 2 is provided with a valve seat sealing surface, and is installed on the In the inlet channel, the pin shaft 9 is fixedly installed on the upper part of the chamber, and the front of the check valve disc 3 is provided with a check valve disc sealing surface that can form a seal with the valve seat sealing surface, and the upper end of the rocker 8 is hingedly connected with the pin shaft 9 , characterized in that: the lower end of the rocker 8 is fixedly connected to the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com