Valve axial force testing device and testing method thereof

A testing device, valve device technology, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problems of waste, lack of actual data of valve axial force, restricting technological progress and quality improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

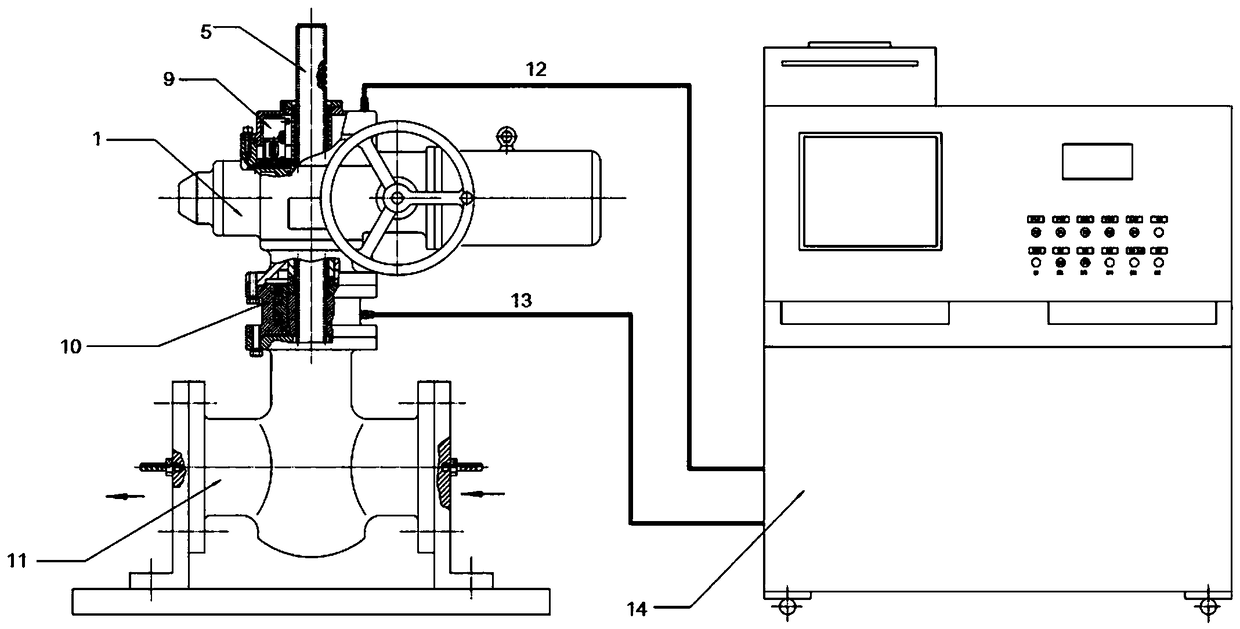

[0043] see Figure 1-5 , a valve axial force testing device, having:

[0044] The valve to be tested;

[0045] A driving device, the output shaft of the driving device is connected to the valve stem of the valve to be tested;

[0046] A connector, the first end of which is connected to the driving device, and the second end is connected to the valve stem;

[0047] An axial force sensor is arranged on the joint;

[0048] The encoder is arranged in the driving device and can measure the rotation angle of the output shaft of the driving device;

[0049] Control cabinet;

[0050] Axial force sensor signal cable, connecting the axial force sensor and the control cabinet;

[0051] The drive unit cable connects the drive unit to the control cabinet, and the drive unit cable is also connected to the encoder.

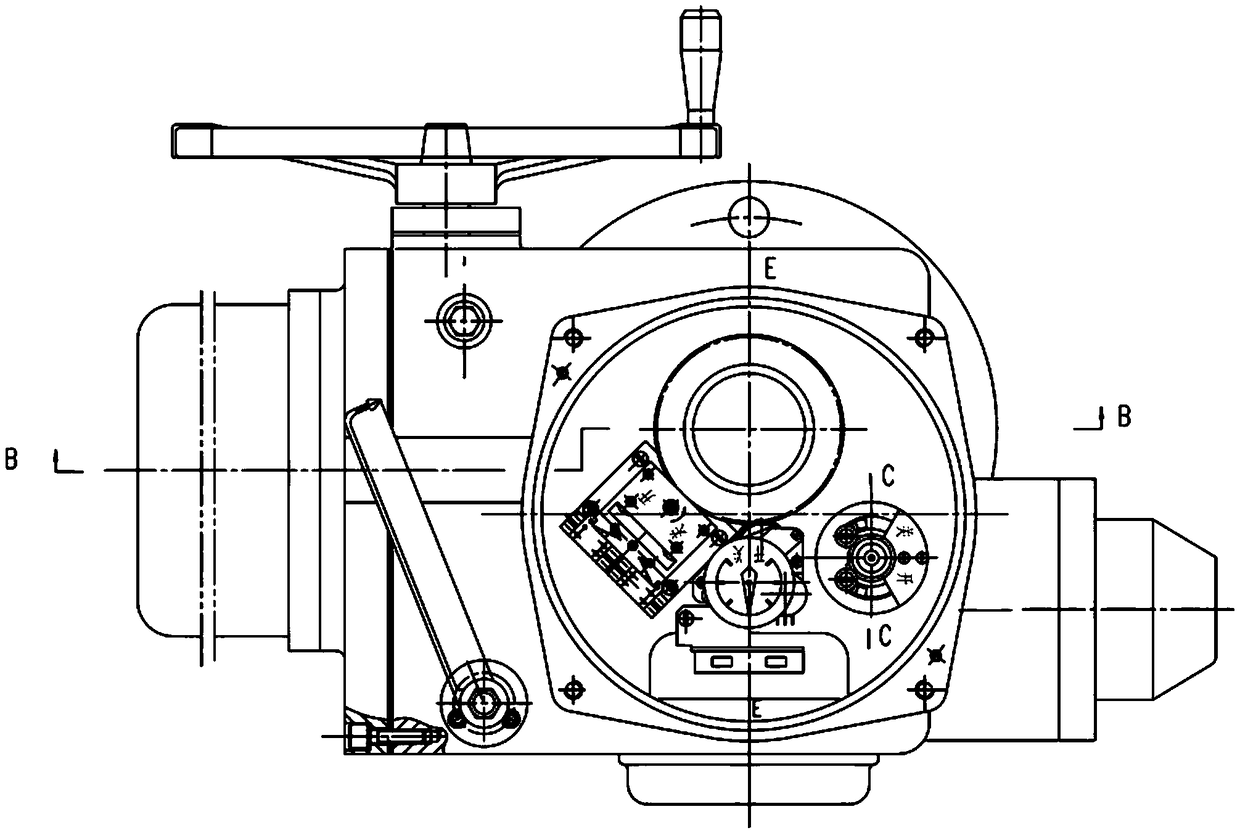

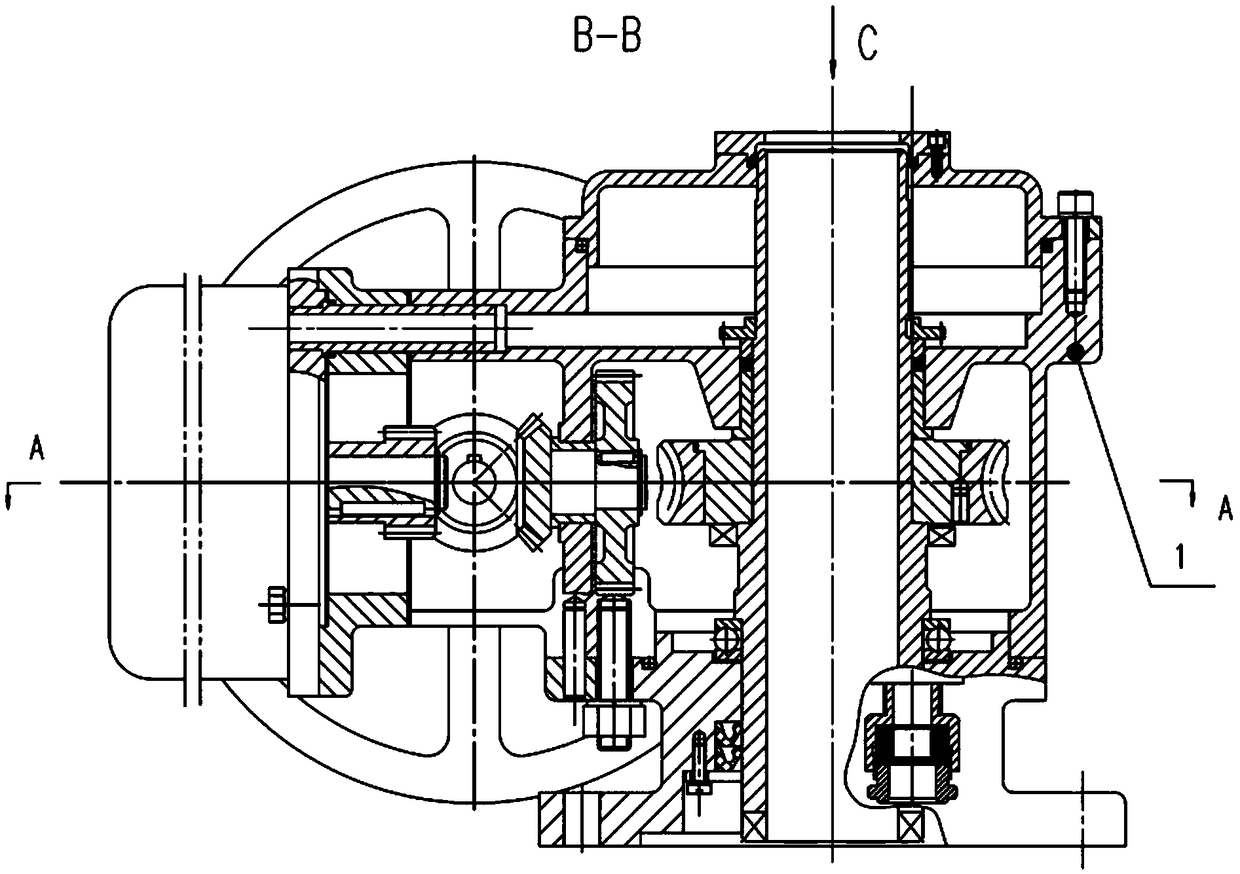

[0052] The driving device is a valve device; the valve device includes:

[0053] box;

[0054] The intermediate shaft is rotatably installed in the box;

[0055] The wo...

Embodiment 2

[0075] A test method of the valve axial force testing device described above, the upper bolt of the axial force sensor is connected to the driving device, the lower bolt is connected to the valve to be tested, and the encoder is arranged in the electric box cover of the driving device. When measuring, the valve to be tested must be in the pressure test condition, that is, there is a load;

[0076] The driving device runs, drives the encoder to rotate, outputs pulses to the control cabinet for counting, and the data enters the control cabinet for recording and processing;

[0077] The output shaft rotates to drive the valve stem up and down, causing axial force to appear at both ends of the axial force sensor, and the resistance value of the strain gauge in it changes, which is converted into analog data and converted into digital signal by A / D to enter the control cabinet;

[0078] After all the data signals are processed by the control cabinet, they are output through the bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com