Engine hood of construction machinery

A technology for engine hood and construction machinery, which is applied to the power unit, the arrangement of the cooling combination of the power unit, the superstructure sub-assembly, etc. Avoid the effect of ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

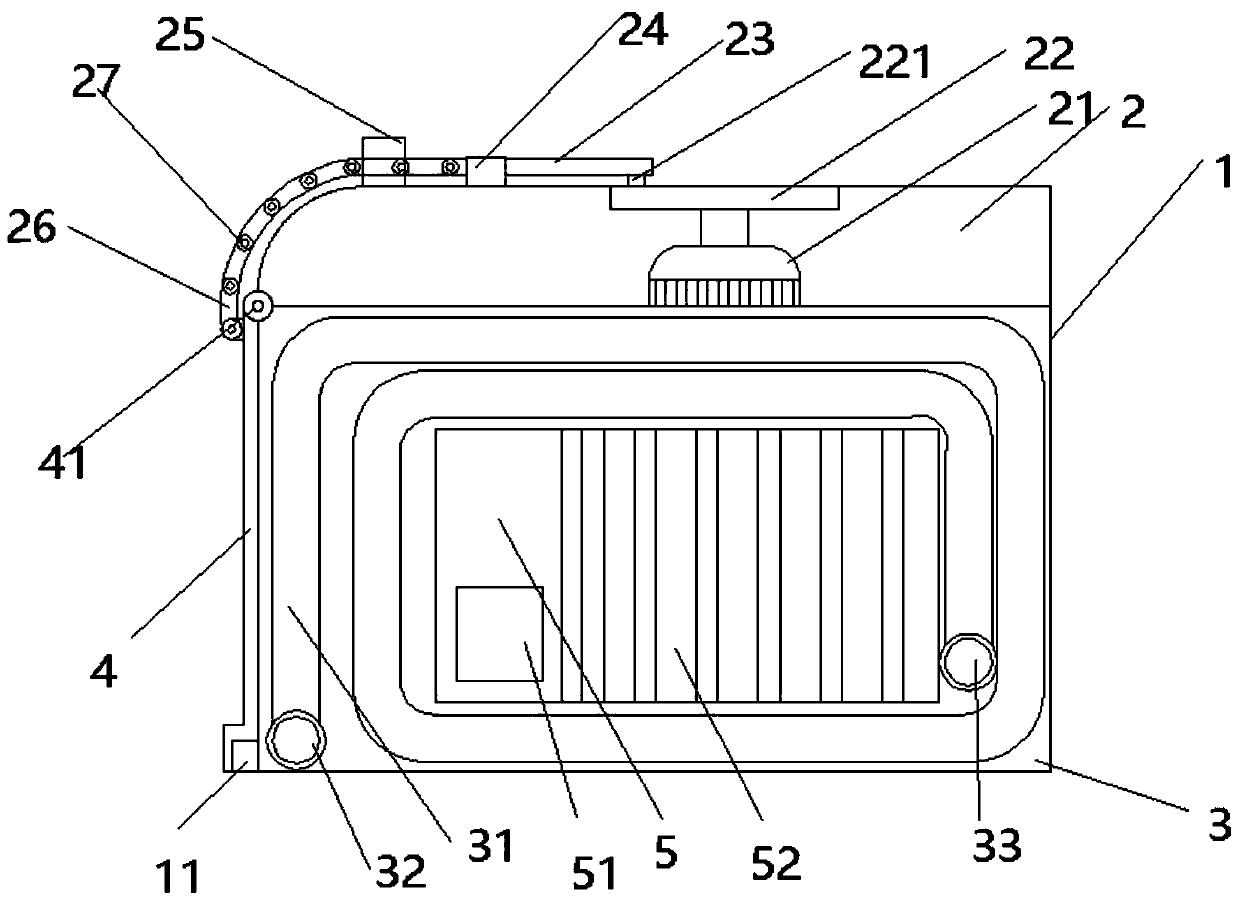

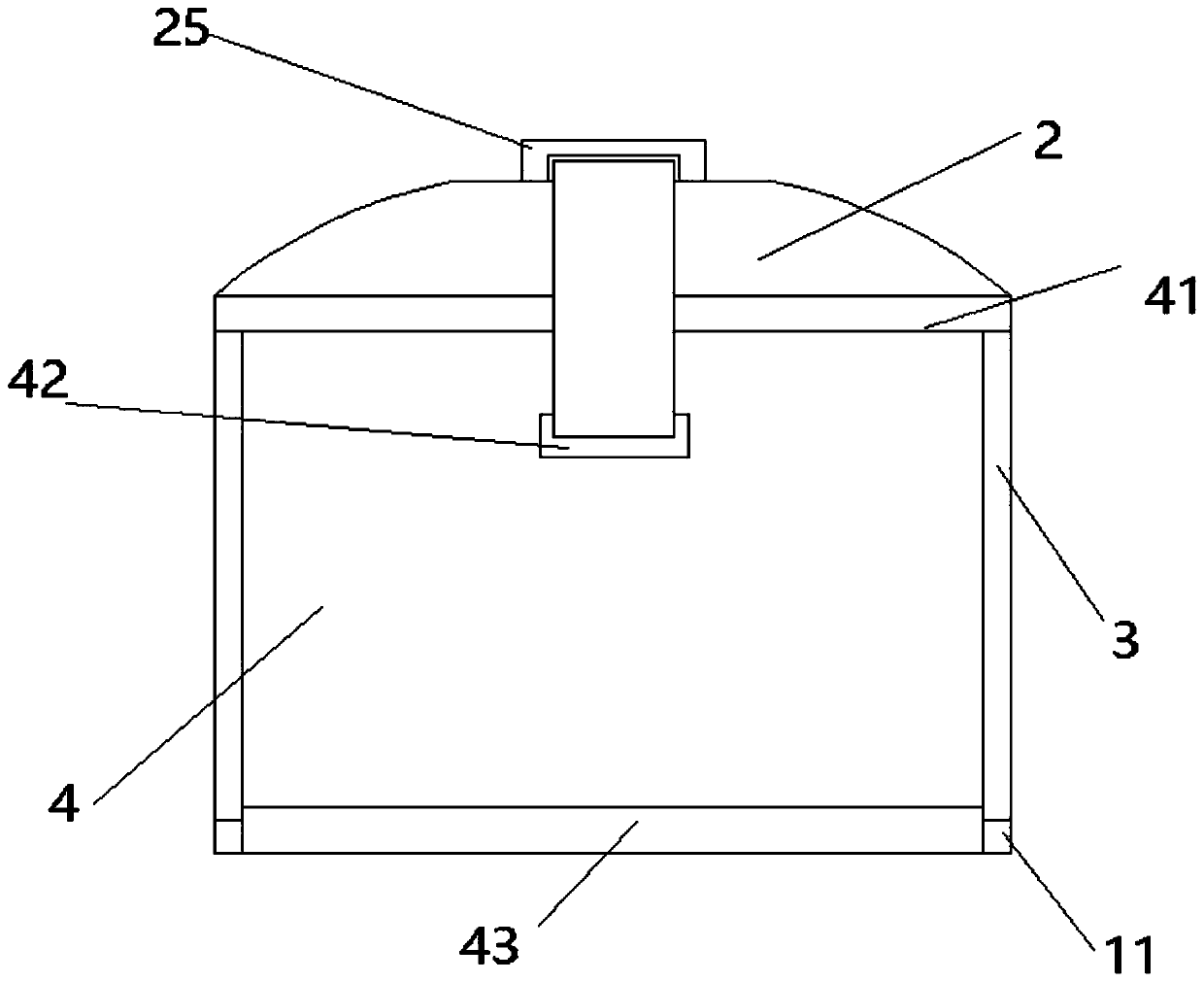

[0022] An engine cover of construction machinery, comprising: a housing 1, a power chamber 2, a cooling plate 3 and a sliding door 4, such as figure 1 As shown, the upper end of the housing 1 is a power chamber, the lower end is a cooling plate 3, a motor 21 is arranged in the power chamber 2, a turntable 22 is arranged at the upper end of the motor 21, and a turntable connection block 221 is arranged on the turntable 22, and the turntable connection block 221 passes through The connecting column 23 is rotationally connected with the connecting column 23, and the left side of the connecting column 23 passes through the first-level limiting groove 24 and is rotatably connected with the lock block 26. The left side of the first-level limiting groove 24 is provided with a second-level limiting groove 25 and the power chamber 2 Fixedly connected, the lock blocks 26 are rotatably connected by the lock ring 27, the lower end of the lock block 26 is rotatably connected with the slidin...

Embodiment 2

[0024] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the lower end of the connecting column 23 is connected to the rotating shaft 28, and the lower end of the rotating shaft 28 is fixedly connected with the locking block 26. The primary limiting column 24 and the secondary limiting groove 25 are provided with sliding holes, and the connecting column 23, the rotating shaft 28 and the locking block 26 Pass through the sliding hole in the primary limiting frame 24.

Embodiment 3

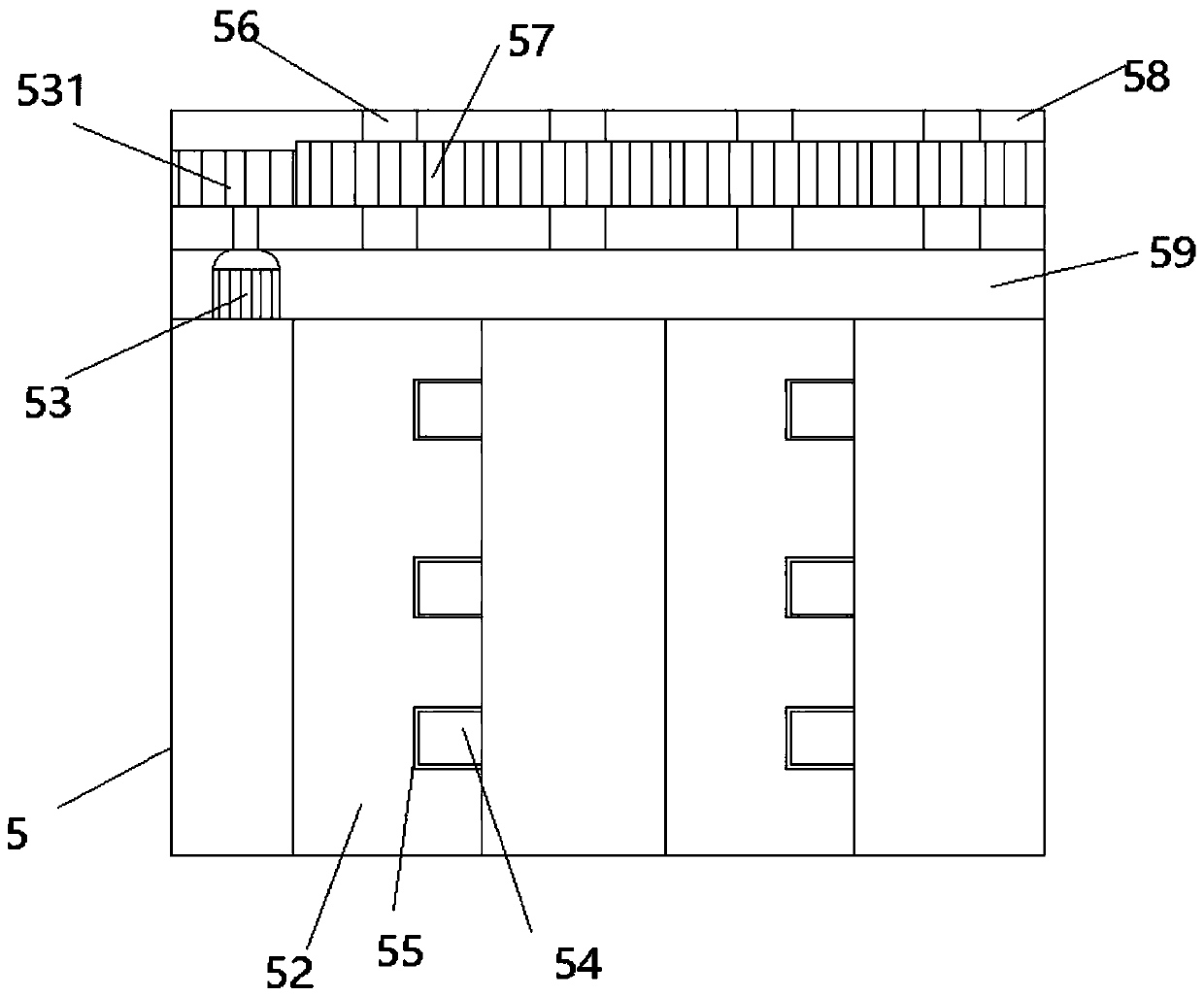

[0026] The difference between this embodiment and Embodiment 1 is that the upper end of the ventilation device 5 is provided with a power layer 58, and the power layer 58 is provided with a number of blade columns 56, and the blade column 56 is provided with a fan impeller 57, and the lower end of the power layer 58 is The motor layer 59 is provided with a fan blade motor 53 inside the motor layer 59, the upper end of the fan blade motor 53 is connected to the motor wheel 531, the fan blade motor wheel 531 is fitted with the fan blade wheel 57, and the lower end of the fan blade column 56 is fixedly connected with the fan blade 52, The right end of the left fan blade 52 is provided with a fan blade locking slot 55 , and the left side of the right fan blade 52 is provided with a fan blade locking block 54 .

[0027] During use, the blade motor 53 rotates the blade motor wheel 531, the blade motor wheel 531 drives the fan wheel 57 to rotate, and the fan wheel 57 drives the fan bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com