High-strength car-stop door

A high-strength, door technology, applied in the field of gates, can solve problems such as troublesome door repairs and delays in passing vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

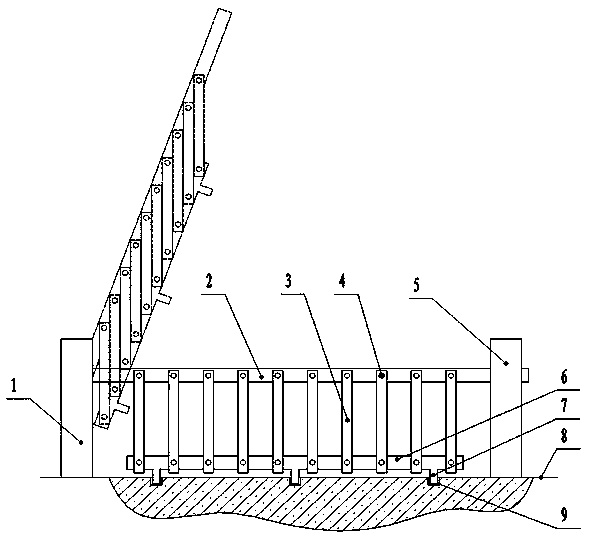

[0008] figure 1 In, is the structure and installation drawing of the barrier gate. The left side of the barrier gate is the left gatepost 1, and the right side is the right gatepost 5, and in the two gateposts, an upper railing rotating device is installed in one of the gateposts. For convenience of description, the doorpost installed with the upper railing rotating device is called the left doorpost below. Both the upper railing 2 and the lower railing 6 are hinged with retaining bars 3 correspondingly with connecting pins 4 at intervals. Upper railing 2, lower railing 6, and retaining bar 3 are all made of strong steel with impact resistance. The lower side of the lower railing is welded to at least two plug-in blocks 7, and what is drawn in the figure is three plug-in blocks. What the solid line draws among the figure is that the upper and lower railings of the stop gate are put down, and the gate is closed. The dotted line in the figure shows the state where the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com