Mounting structure of front auxiliary frame of new energy vehicle

A front subframe and mounting structure technology, applied in the substructure, vehicle components, transportation and packaging, etc., can solve the problems of many fixtures, high manufacturing costs, complex structures, etc., and achieve the effect of increasing absorption and improving anti-collision ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objects, technical solutions, and advantages of the present invention, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

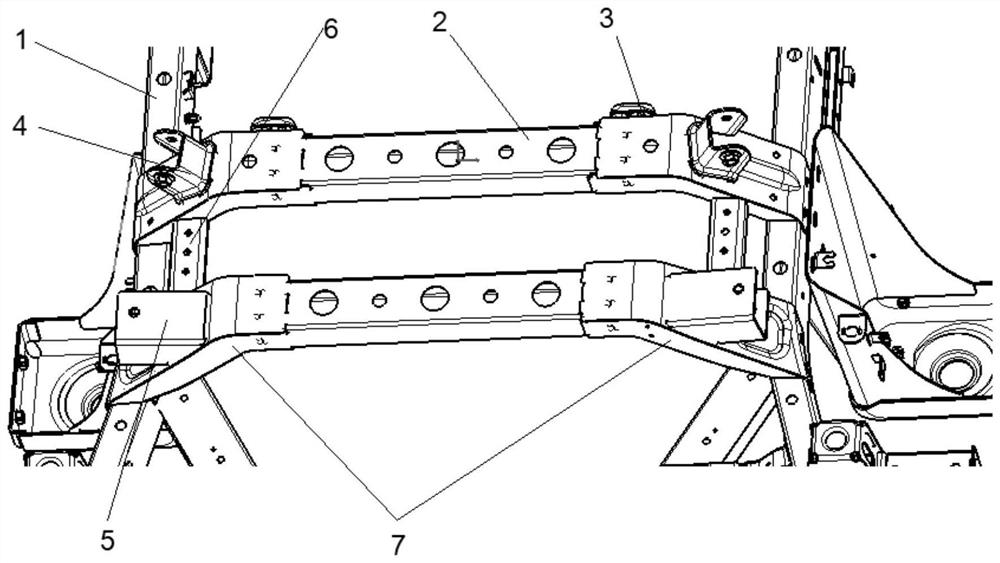

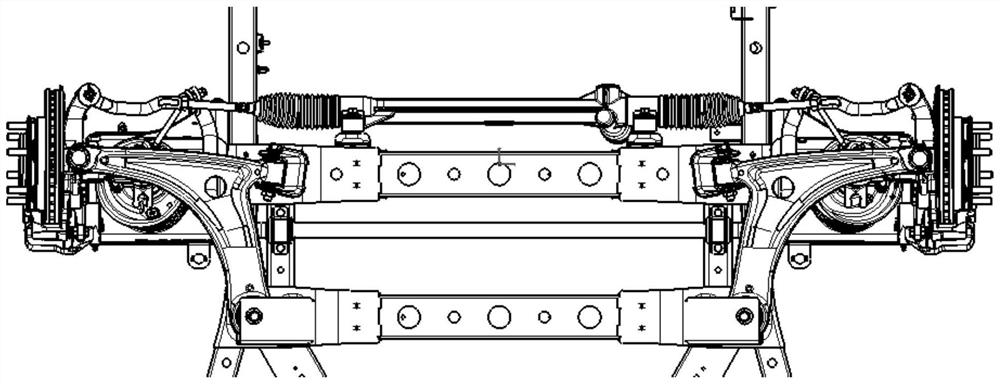

[0024] See Figure 1-2 , Install front subframe structure of a new energy vehicles, it has:

[0025] Frame rail;

[0026] Front subframe cross member, mounted on both ends of the frame rails; front cross member comprises a first sub-frame before the sub-beam and the second sub-frame front cross member;

[0027] Under the arm front bracket, mounted on the front ends of the first sub-frame cross member;

[0028] Diverter fixing bracket mounted on the front ends of the first sub-frame cross member;

[0029] Lower rear arm bracket, mounted on both ends of the second sub-frame front cross member;

[0030] Stabilizer bar fixed bracket, a first end portion connected to the front cross member and the second sub-frame before the sub-beam.

[0031] The front ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com