Piezoelectric ceramic jacquard comb

A piezoelectric ceramic and jacquard comb technology, applied in the field of accessories in the field of warp knitting machinery, can solve the problems of increasing comb pieces, broken needles, collisions, etc., to avoid excessive vibration, improve the ability to resist collision and deformation, Improve the effect of the limit function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

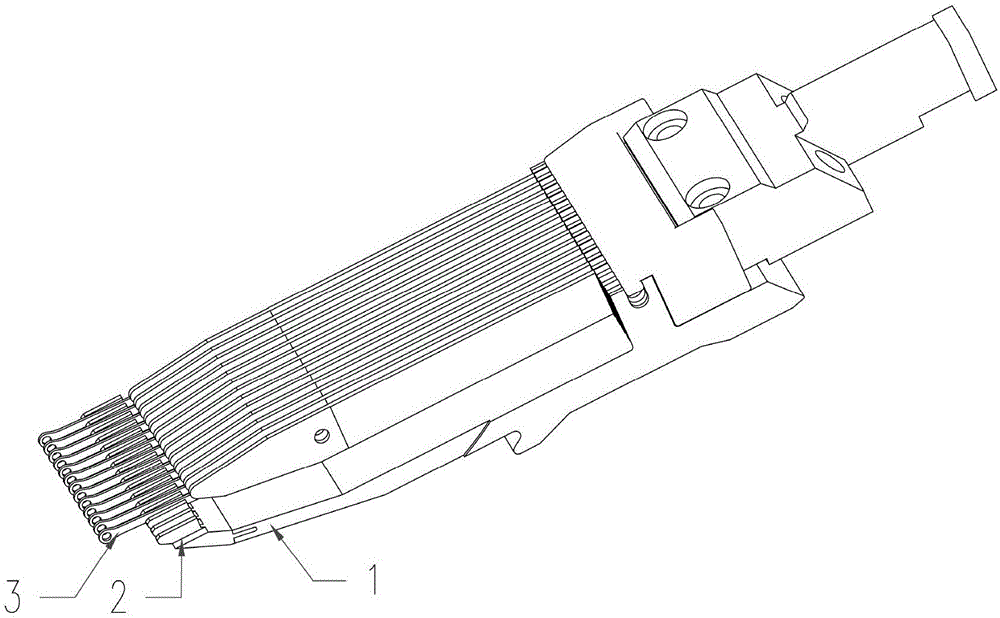

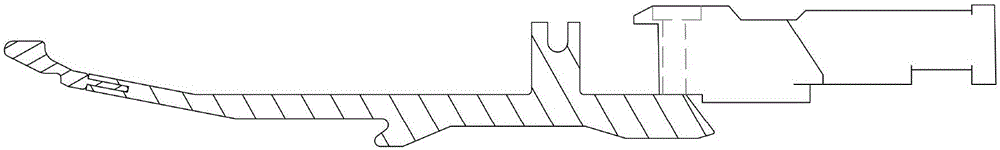

[0012] Such as Figure 1 to Figure 2 As shown, a piezoelectric ceramic jacquard comb, the piezoelectric ceramic jacquard comb includes a main body and a jacquard needle, the main body includes a base and a comb head, and the comb head is provided with a plurality of comb pieces, the base There is a groove on the top, and correspondingly, a protrusion is provided on the comb head, and a weight-reducing groove is also provided at the lower end of the comb head. The lower end of the comb head is also provided with a weight-reducing groove, and the comb head is made of high-strength alloy material. Since the aluminum alloy material is lighter than other alloy materials, the lower end of the comb head made of high-strength alloy material will increase the overall weight, and the weight-reducing groove can make the improved structure completely equal in weight, and the appearance is similar to the existing one. The consistency of the jacquard comb can also avoid the excessive swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com