Dual Push Static Push-Back Rotary Steerable Tool

A rotary-steering, double-push technology, applied in directional drilling and other directions, can solve problems such as increasing the slope, achieve the effect of reducing requirements, reducing internal cavities, and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] It should be noted that, in the case of no conflict, the embodiments of the present invention and the technical features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

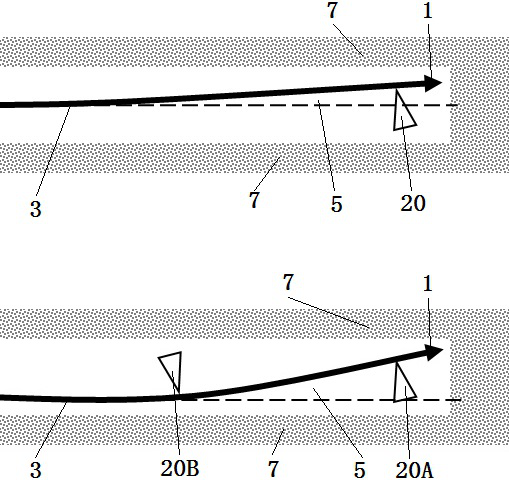

[0037] Combine below Figure 1 to Figure 6 , the preferred embodiments of the present invention will be described in further detail.

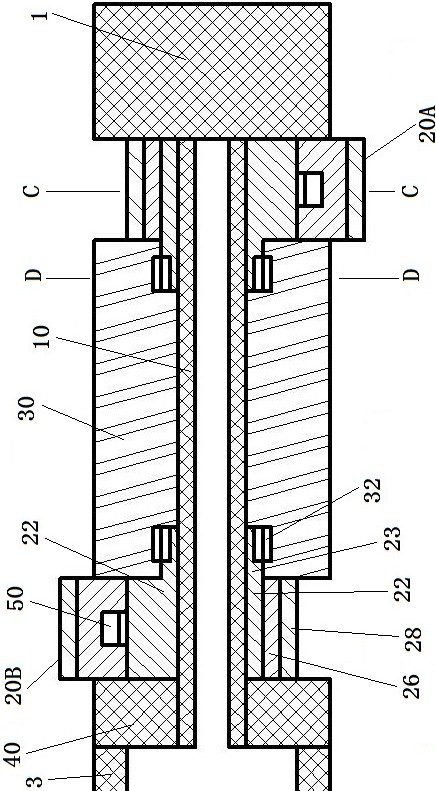

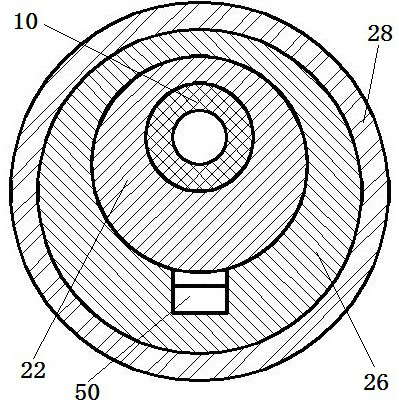

[0038] Such as figure 1 As shown, it is the cross-section of the double-push type static push-back type rotary steering tool passing the axis of the mandrel 10 in the ramp-up state.

[0039] The rear end of the base 40 is fixedly connected to the drill string 3 , and is used for connecting the double-push static push-to-rest rotary steering tool to the drill string 3 .

[0040] The rear end of the mandrel 10 is fixedly connected to the base 40, and the front end of the mandrel 10 is fixedly connected to the drill bit 1; it is used to transmit the torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com