A Film sensor ITO pattern and a manufacturing method thereof

A manufacturing method and graphic technology, applied in the field of ITO thin film sensor, can solve the problems of ITO damage, poor function, poor appearance, etc., and achieve the effect of avoiding appearance and reducing electrostatic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

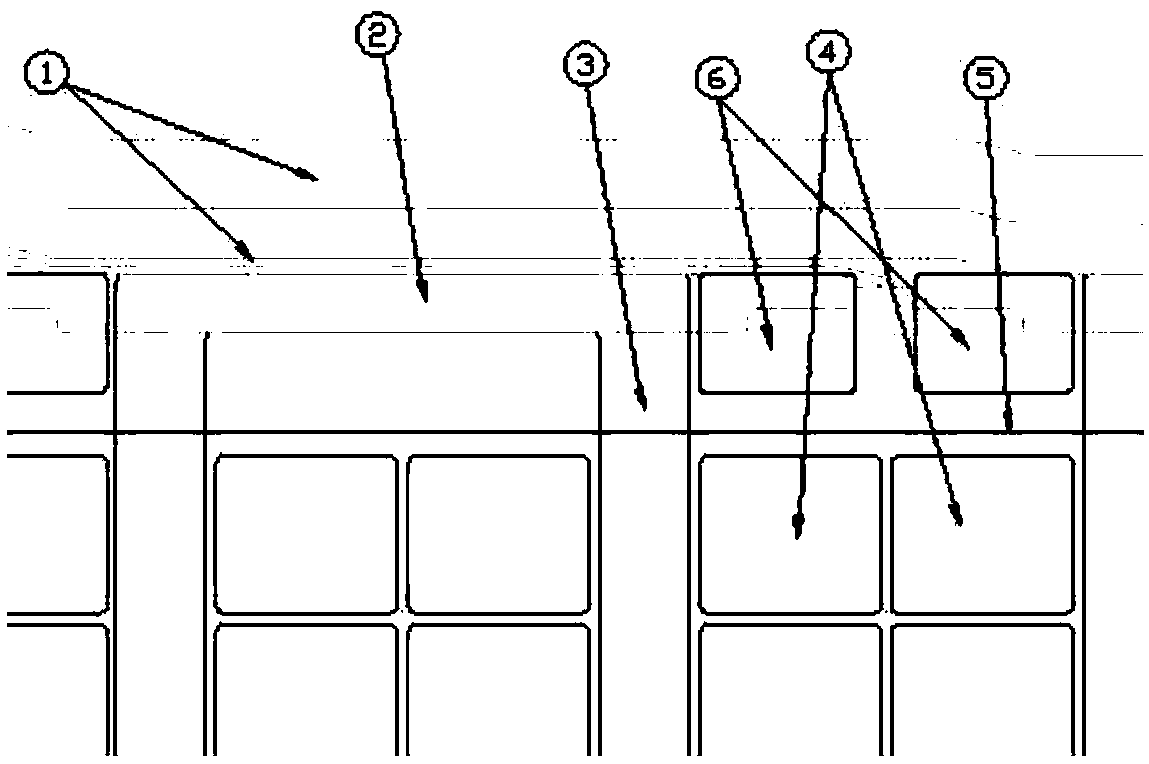

[0028] Example 1, such as figure 1 As shown, a Film sensor ITO pattern according to an embodiment of the present invention includes: an ITO channel pattern 3 etched on an ITO conductive film, an ITO Dummy block pattern 4, a conductive silver paste pattern 1 and an ITO Dummy block pattern 6 added. Wherein, the ITO conductive thin film is deposited on the Film substrate, including a substrate layer and an ITO layer disposed on the substrate layer. The window area 5 of the ITO layer is provided with an ITO channel area and an ITO pattern area. The ITO channel pattern 3 is etched in the ITO channel area. The ITO Dummy block pattern 4 is etched in the ITO pattern area, and the ITO Dummy block pattern 4 is located between the ITO channel patterns 3 . The conductive silver paste pattern 1 is located in the frame area surrounding the window area 5 and is connected to the ITO channel pattern 3 . The ITO Dummy block pattern 6 is added and etched on the ITO layer, and is located at th...

Embodiment 2

[0034] Embodiment 2, a kind of making method of Film sensor ITO figure, comprises the following steps:

[0035] Step 1, forming an ITO layer on the Film substrate;

[0036] Step 2, etching the ITO channel pattern 3 and the ITO Dummy block pattern 4 in the window area 5 on the ITO layer, and the ITODummy block pattern 4 is located between the ITO channel patterns 3;

[0037] Step 3, printing conductive silver paste on the ITO layer around the frame area of the window area 5, and etching the conductive silver paste pattern 1, and the conductive silver paste pattern 1 is connected to the ITO channel pattern 3;

[0038] Step 4: Etch an additional ITO Dummy block pattern 6 at the overlap between the conductive silver paste pattern 1 on the ITO layer and the ITO channel region.

[0039] Among them, the ITO channel pattern 3, the ITO Dummy block pattern 4 and the added ITO Dummy block pattern 6 are all etched into periodically arranged patterns. ITO Channel Graphics 3, ITO Dummy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com