Dynamic Design Method of High-Speed Duplex Rolling Bearing Electric Spindle Rotor System

A rolling bearing and system dynamic technology, which is applied in design optimization/simulation, computer-aided design, calculation, etc., can solve the inability to obtain the corresponding relationship between the dynamic characteristics of the rotor system of the electric spindle and the bearing configuration, reduce the accuracy of the dynamic design of the electric spindle, and cannot. Objectively reflect the dynamic behavior of the rotor of the high-speed motorized spindle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0123] The method for dynamic design of the rotor system of the high-speed double rolling bearing electric spindle of the present invention will be further described in detail below in conjunction with an embodiment (51000rpm high-speed grinding electric spindle).

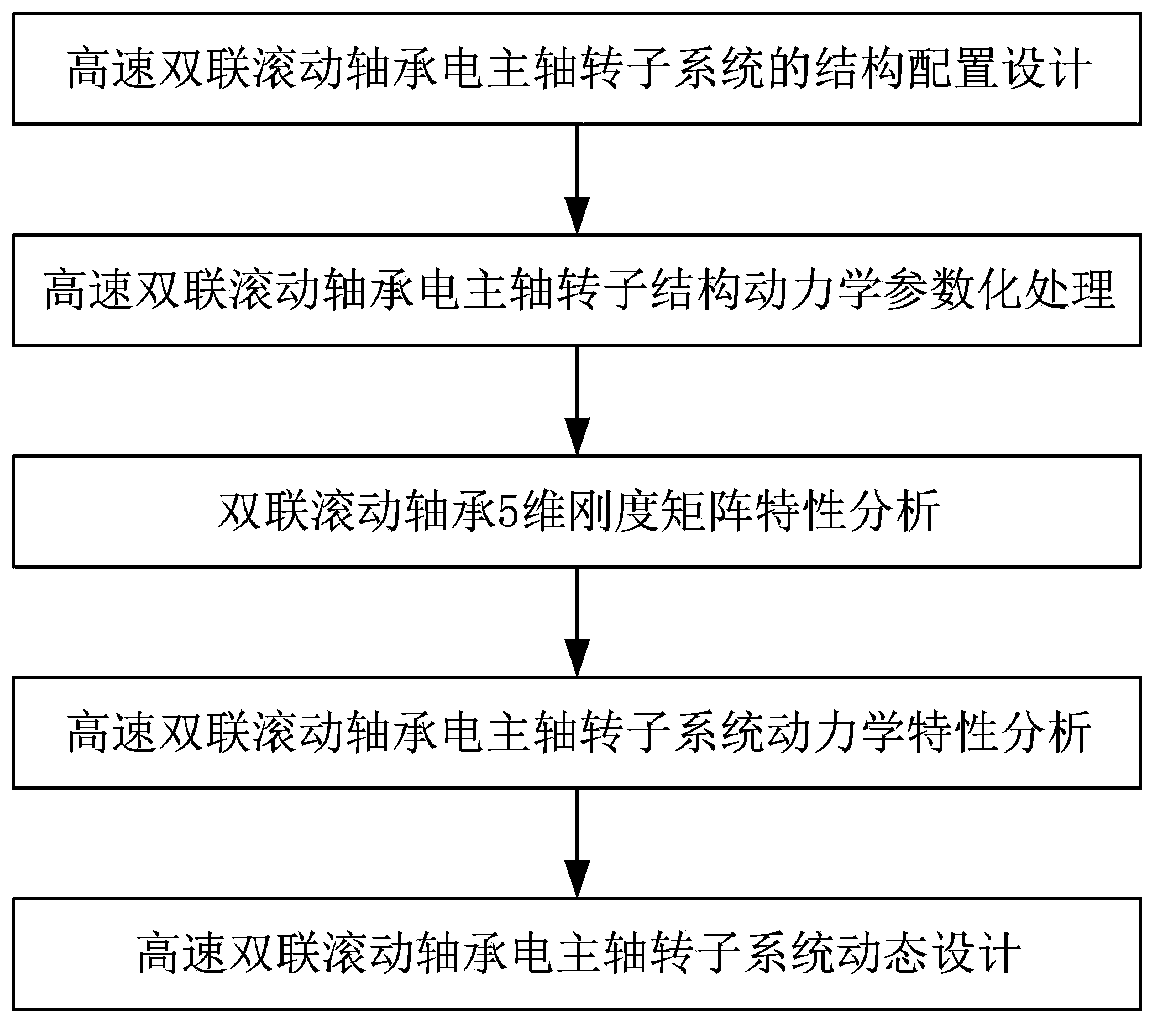

[0124] figure 1 The specific content of the dynamic design method of the high-speed double rolling bearing electric spindle rotor system of the present invention is given, including the following steps:

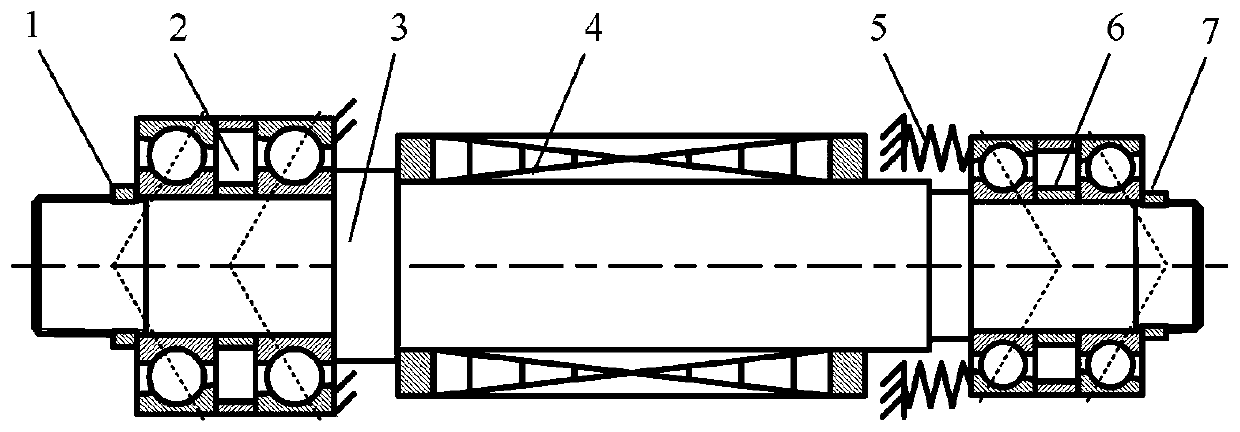

[0125] Step 1: According to the use requirements of the electric spindle: the working speed is 51000rpm, the static stiffness of the shaft end is greater than 10N / μm, complete the structural configuration design of the high-speed double rolling bearing electric spindle rotor system, such as figure 2 As shown: the main shaft rotor 3 is supported on two sets of double-connected rolling bearings, and the front bearing 2 and the rear bearing 6 are arranged in series. The motor rotor 4 is installed on the main shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com