lawn mower blade

A lawn mower and cutter shaft technology, used in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of missed cutting and uneven cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

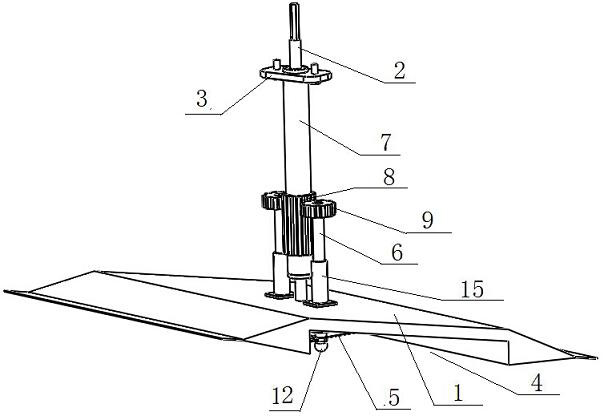

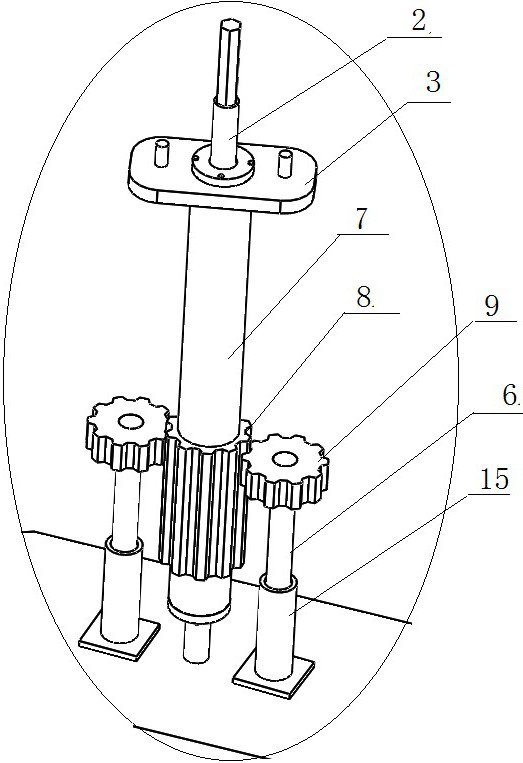

[0036] like figure 1 , 2 As shown in , 5, a cutting knife of a lawn mower comprises a knife body 1 positioned below the lawn mower and rotates horizontally around the knife axis A2, and the knife shaft A2 is fixed with the knife body 1 and is rotatably connected with the lawn mower ; The coaxial sleeve on the cutter shaft 2 is provided with a shaft sleeve 7, the top of the shaft sleeve 7 is fixed with the lawn mower through the connector 3, and the top of the cutter shaft A2 passes through the connector 3 upwards, and is fixed with The transmission device of the driving device of the lawn mower, the auxiliary knife 5 is connected to the horizontal rotation below the knife body 1, and the auxiliary knife 5 is located at the bottom of the knife body 1. The cutter shaft B6 of the cutter 5 passes through the cutter body 1 upwards and is connected to the shaft sleeve 7 in a transmission manner. The auxiliary cutter 5 is fixedly connected to the cutter shaft B6. The position sleev...

Embodiment 2

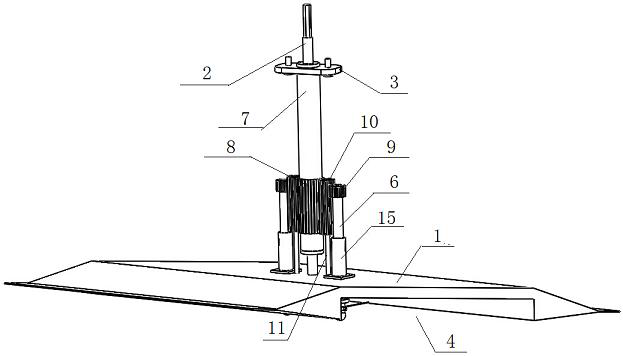

[0039] like image 3 , 4As shown in , 5, a cutting knife of a lawn mower comprises a knife body 1 positioned below the lawn mower and rotates horizontally around the knife axis A2, and the knife shaft A2 is fixed with the knife body 1 and is rotatably connected with the lawn mower ; The coaxial sleeve on the cutter shaft 2 is provided with a shaft sleeve 7, the top of the shaft sleeve 7 is fixed with the lawn mower through the connector 3, and the top of the cutter shaft A2 passes through the connector 3 upwards, and is fixed with The transmission device of the driving device of the lawn mower, the auxiliary knife 5 is connected to the horizontal rotation below the knife body 1, and the auxiliary knife 5 is located at the bottom of the knife body 1. The cutter shaft B6 of the cutter 5 passes through the cutter body 1 upwards and is connected to the shaft sleeve 7 in a transmission manner. The auxiliary cutter 5 is fixedly connected to the cutter shaft B6. The position sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com