Tunnel furnace

A technology of tunnel furnace and furnace body, which is applied in the field of tunnel furnace, which can solve the problems of narrow furnace body space, low cleaning efficiency, and fire in the furnace, and achieve the effects of improving food hygiene and safety, high food quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

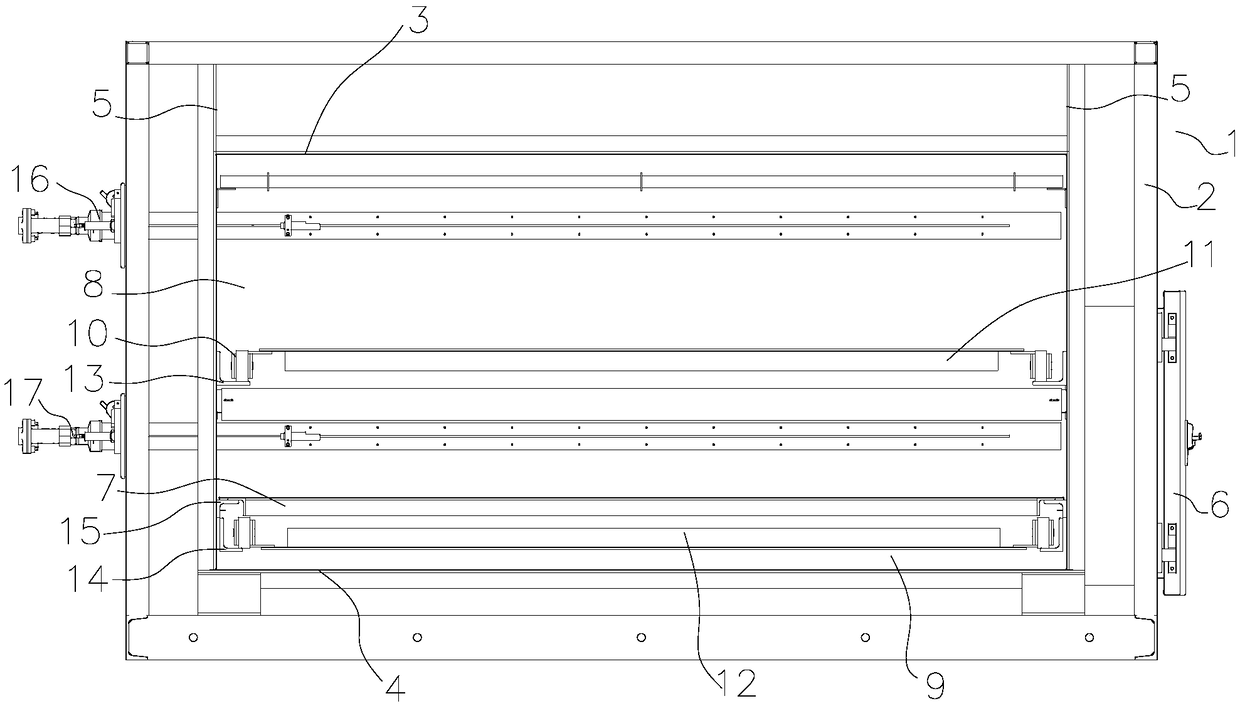

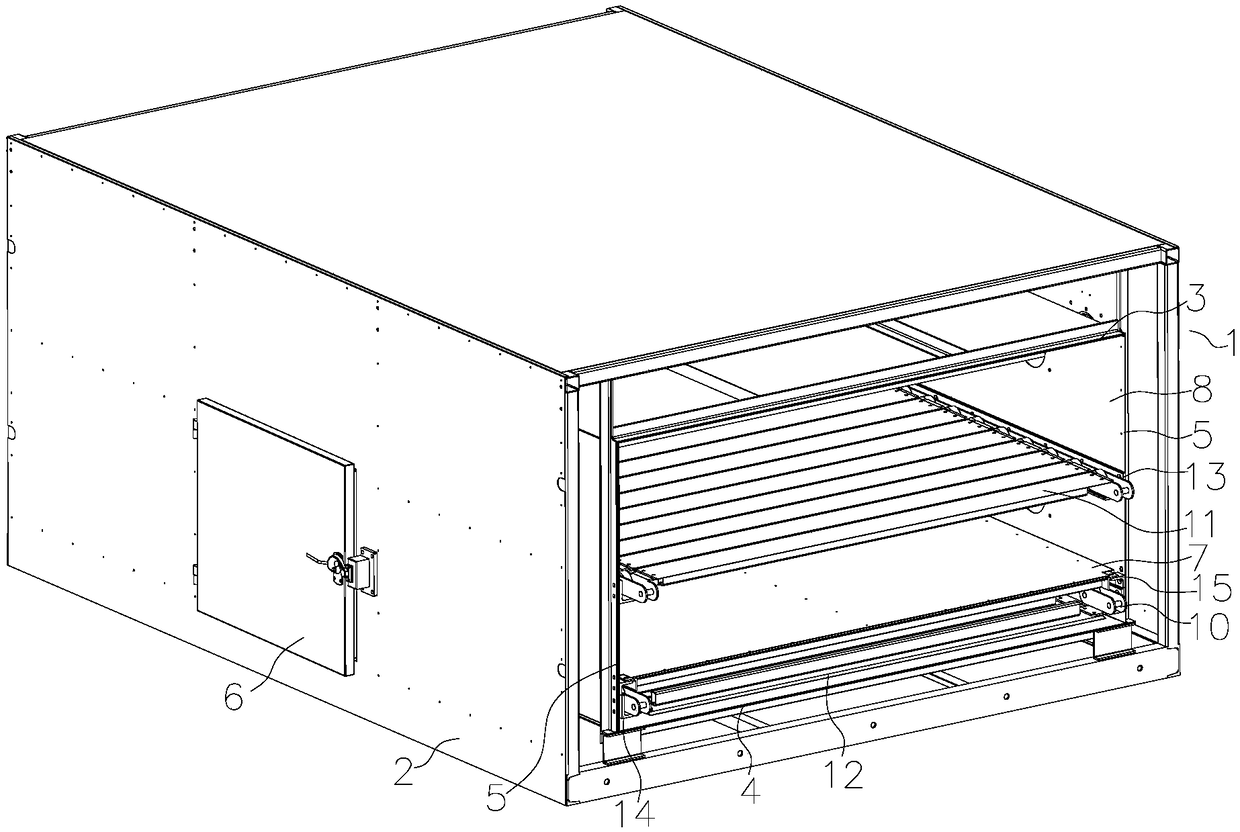

[0019] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0020] Such as figure 1 and figure 2 The shown tunnel furnace includes a furnace body 1, and also includes a conveying mechanism, a heating device and a cleaning assembly. Openings are provided at both ends of the furnace body 1, and the conveying mechanism is located in the furnace body 1, and the two ends of the conveying mechanism respectively pass through the The above-mentioned opening and the conveying mechanism are used to transport the food to be baked, the heating device is located in the furnace body 1 for baking the food to be baked, and the cleaning component is located on the furnace body 1 to facilitate cleaning operations.

[0021] On...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap