Patents

Literature

37results about How to "Prevent oil accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

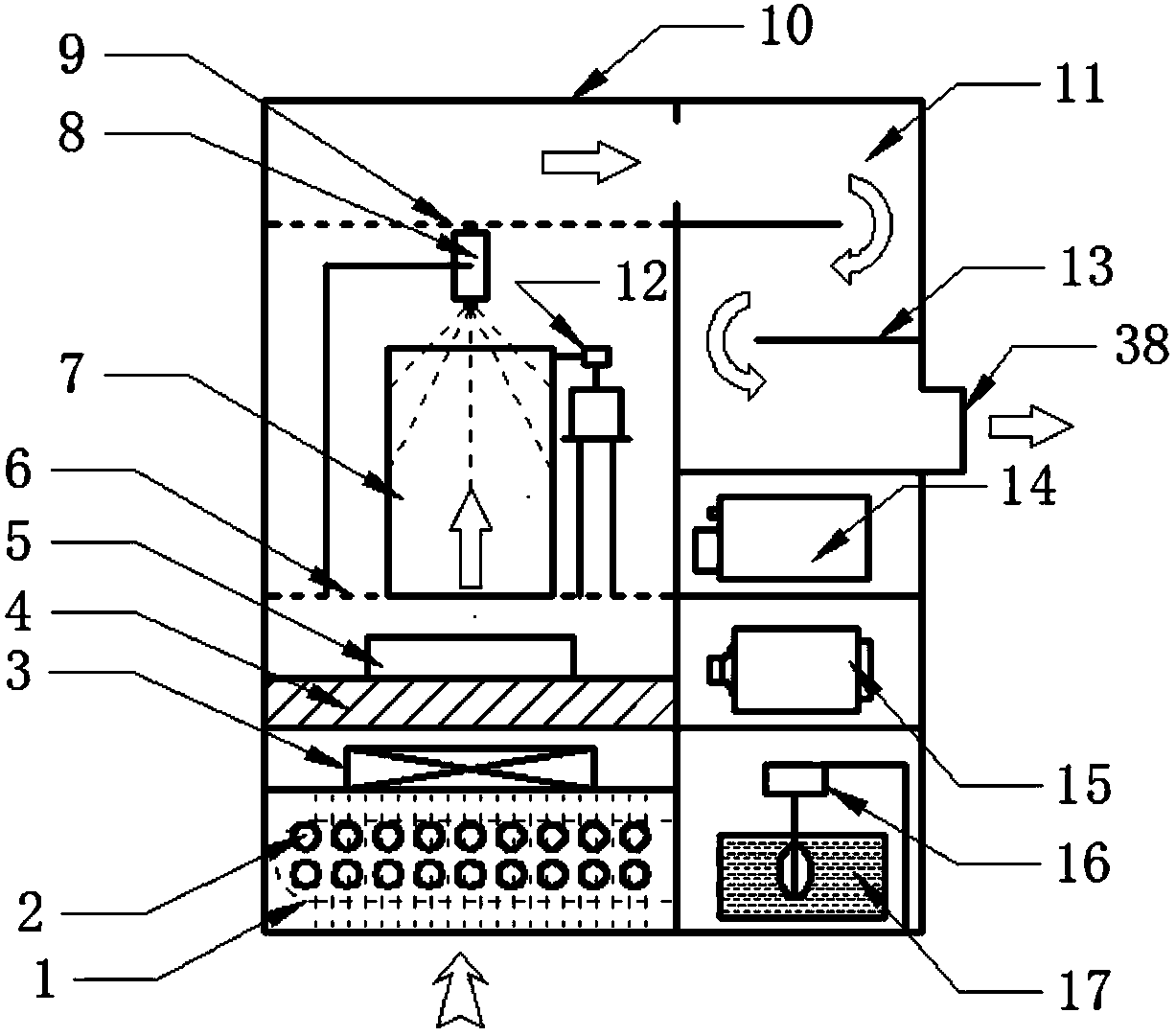

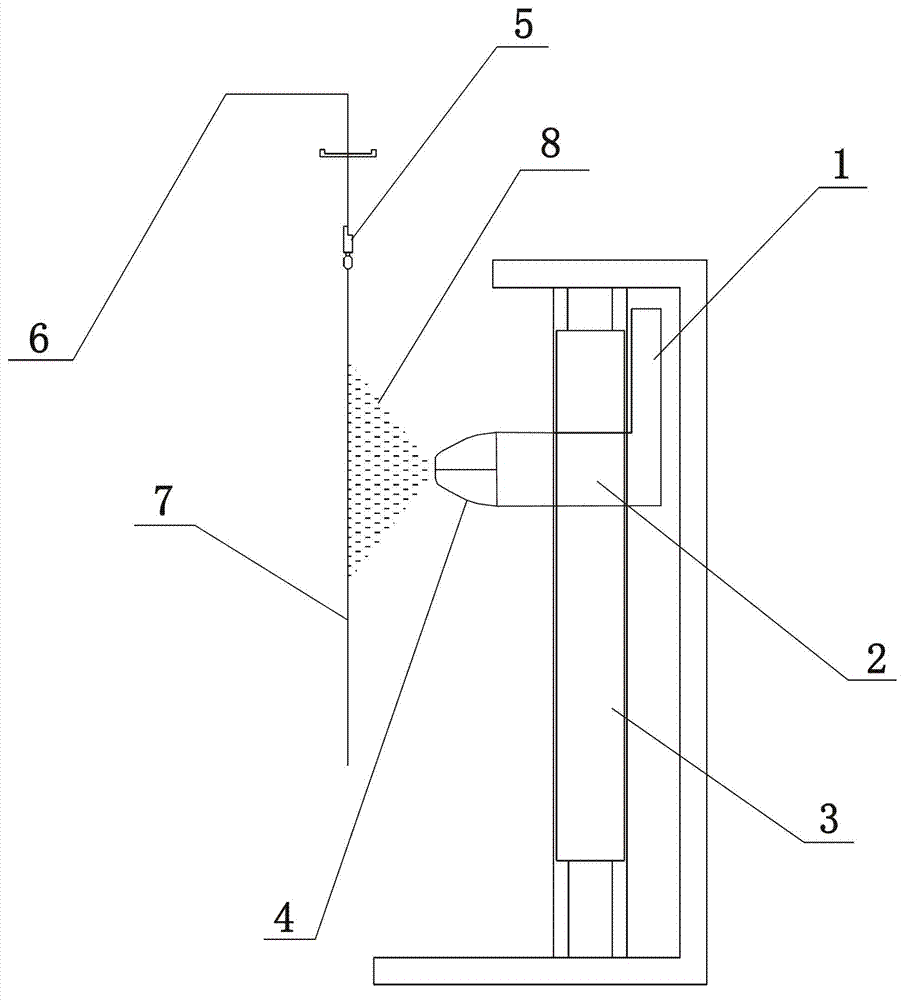

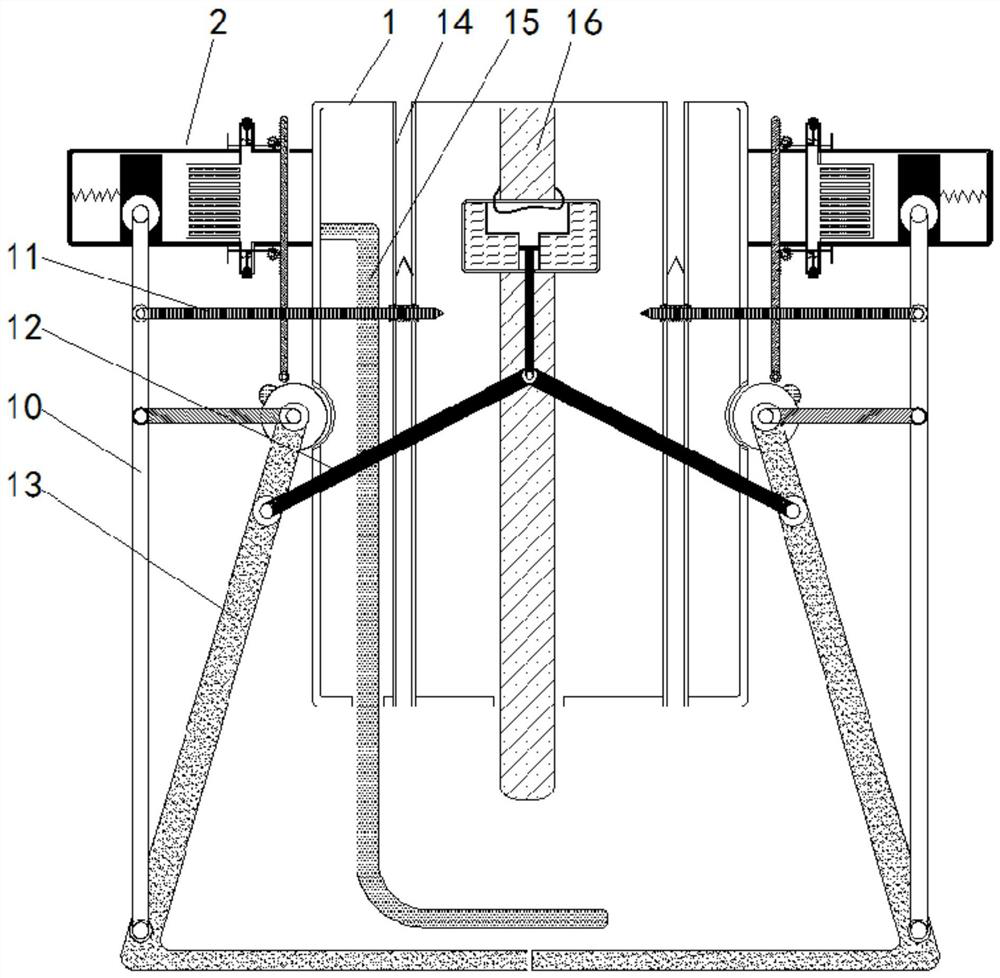

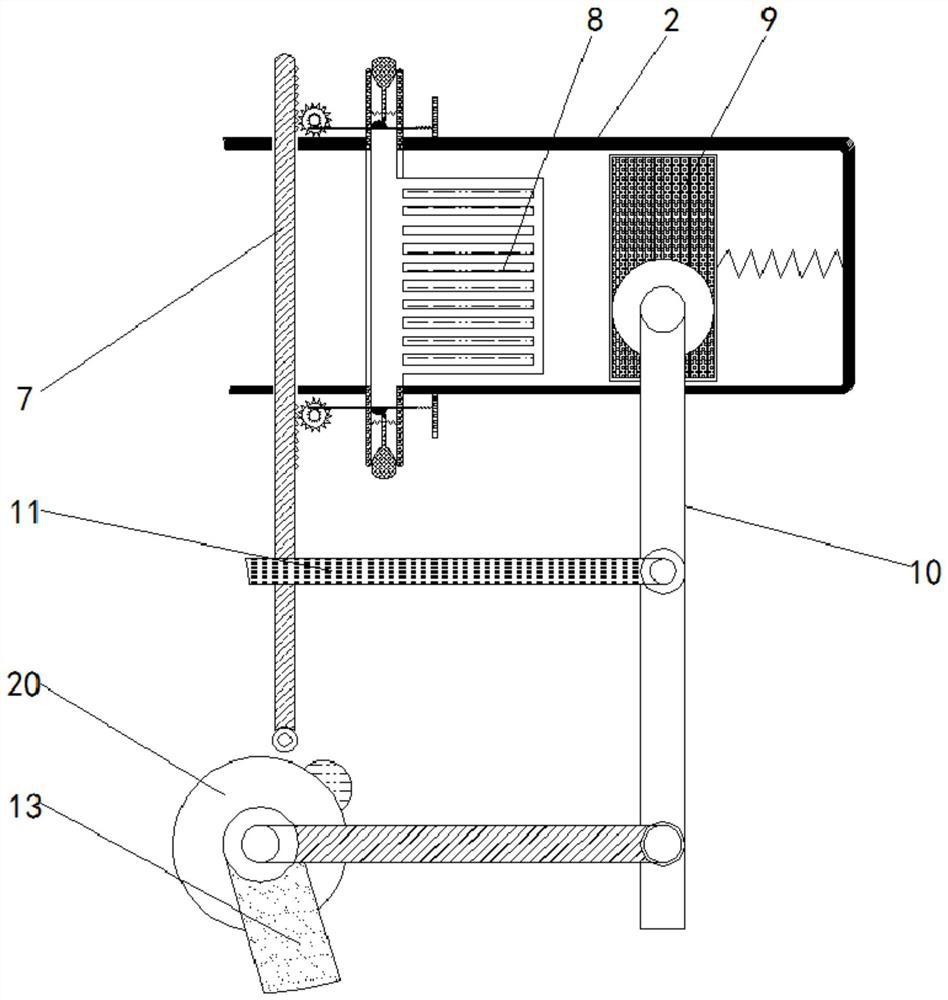

Oil smoke generating device

PendingCN108303358AImprove stabilityOvercome the splash phenomenonStructural/machines measurementParticle suspension analysisExperimental researchControl system

The invention discloses an oil smoke generating device. The device comprises an air temperature and humidity control system, an air purification system, an oil smoke generating system, an automatic cleaning system, a waste liquid recovery system and a cabinet with rectification and mixed flow functions. An oil-water mixing mode, a conveying mode and a heating mode of the oil smoke generating system fundamentally change an oil smoke generating mode. The oil smoke generated by the device has the characteristics of stable smoke generation and high accuracy, can represent real oil smoke and can simulate oil smoke produced in different cooking manners. The generated oil smoke can be used for oil smoke purification product detection and oil smoke detection instrument parameter calibration and asan oil smoke generating source for experimental researches.

Owner:TIANJIN UNIV

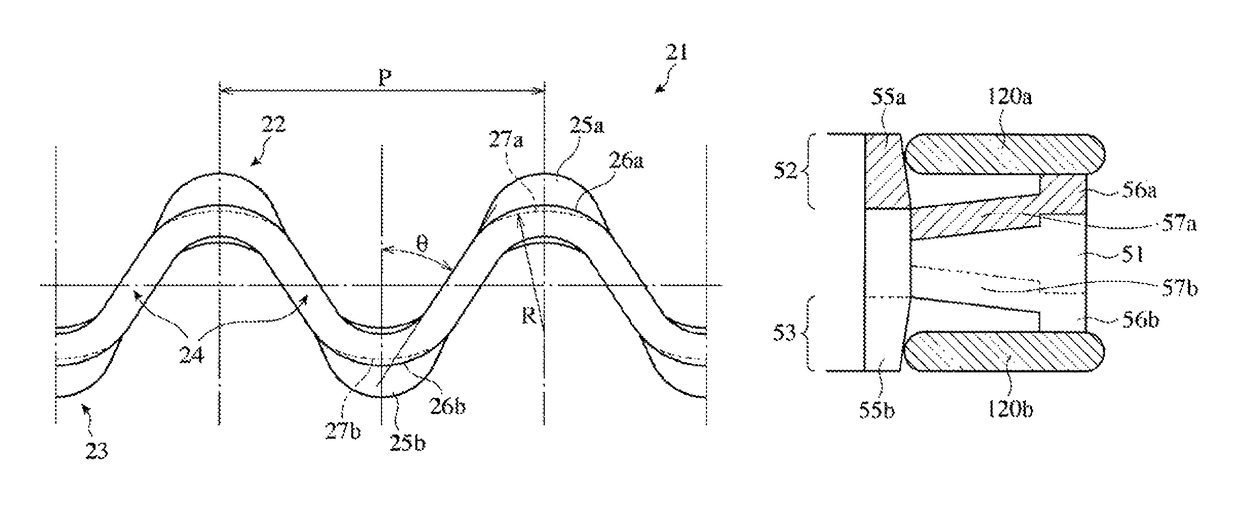

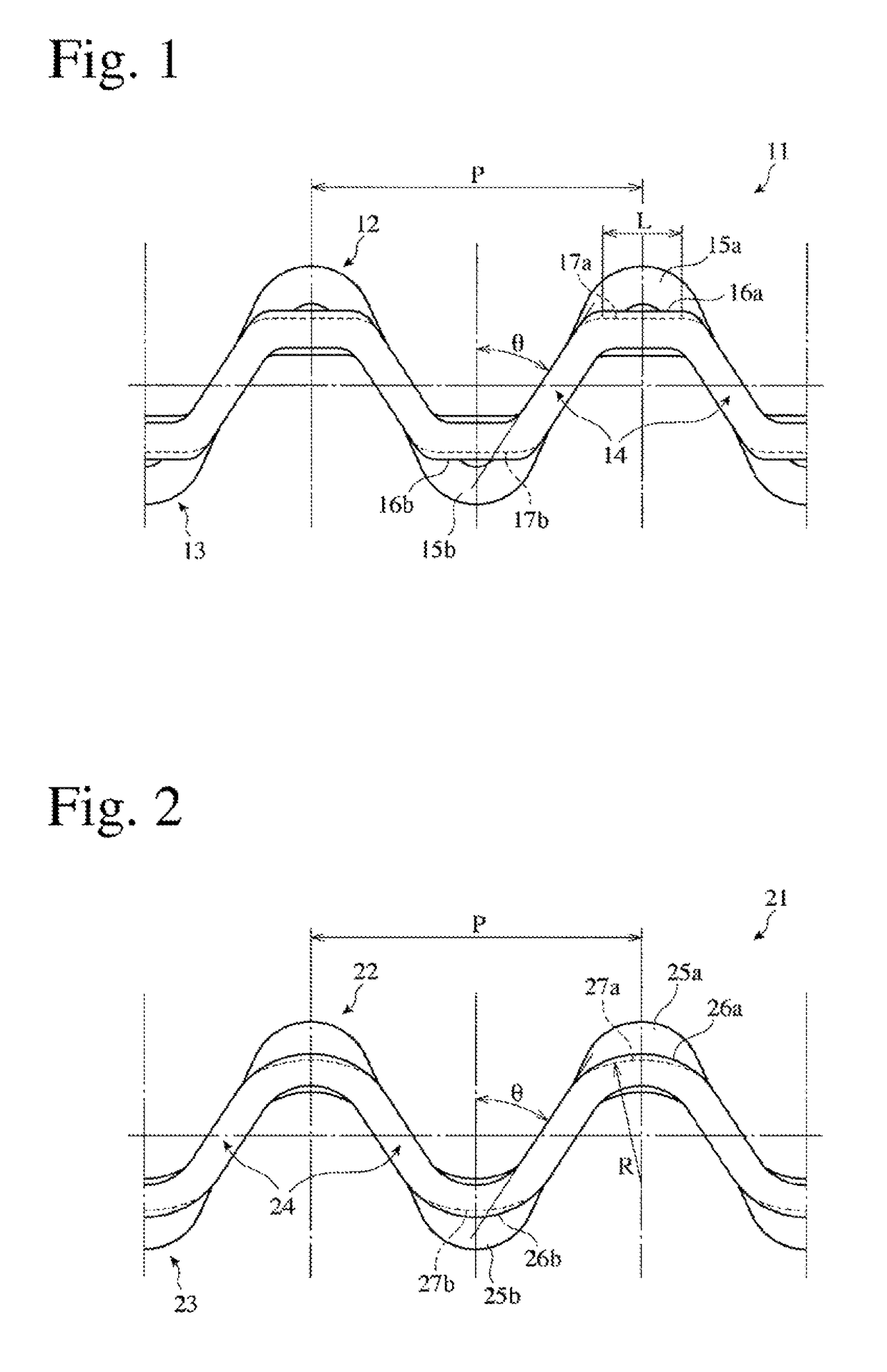

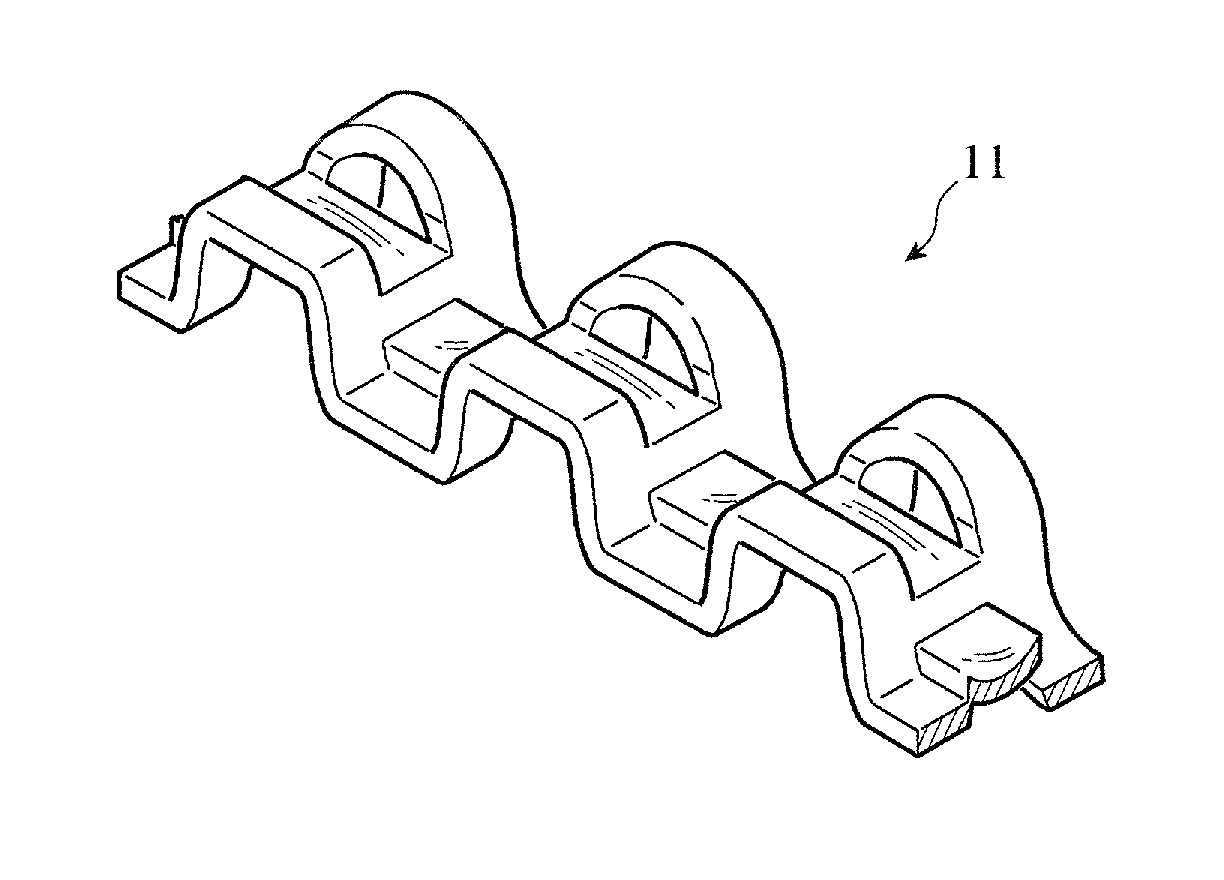

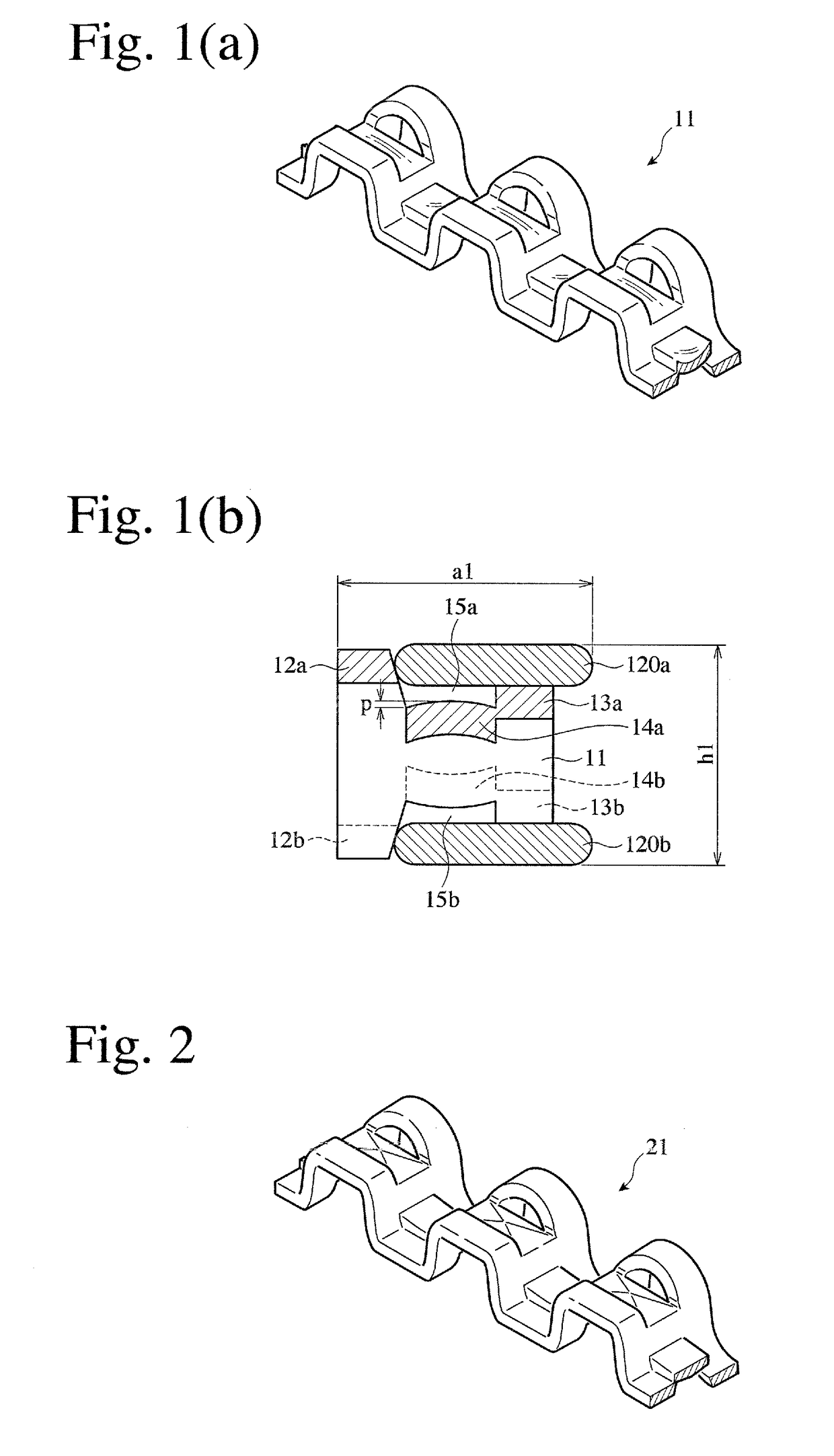

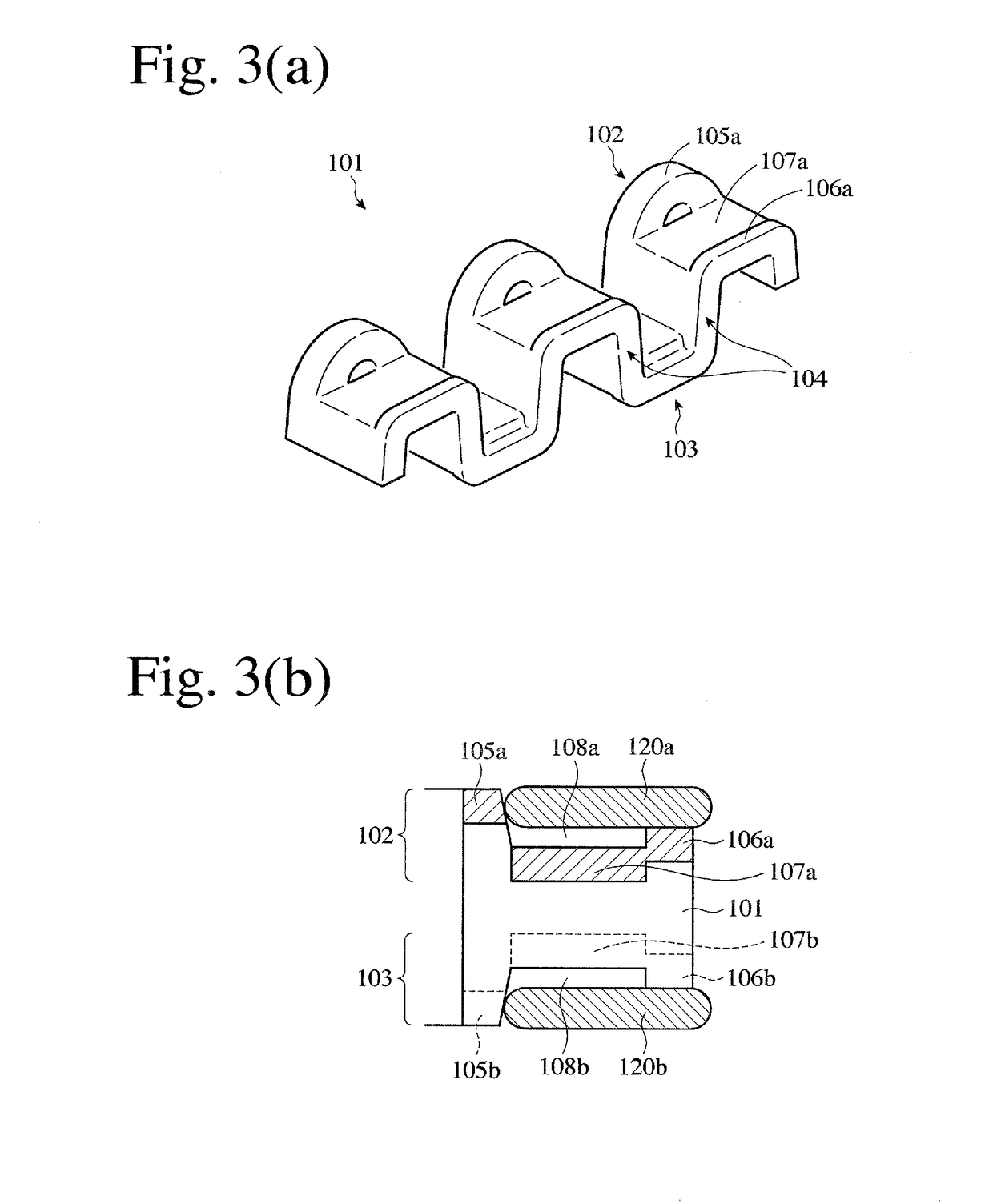

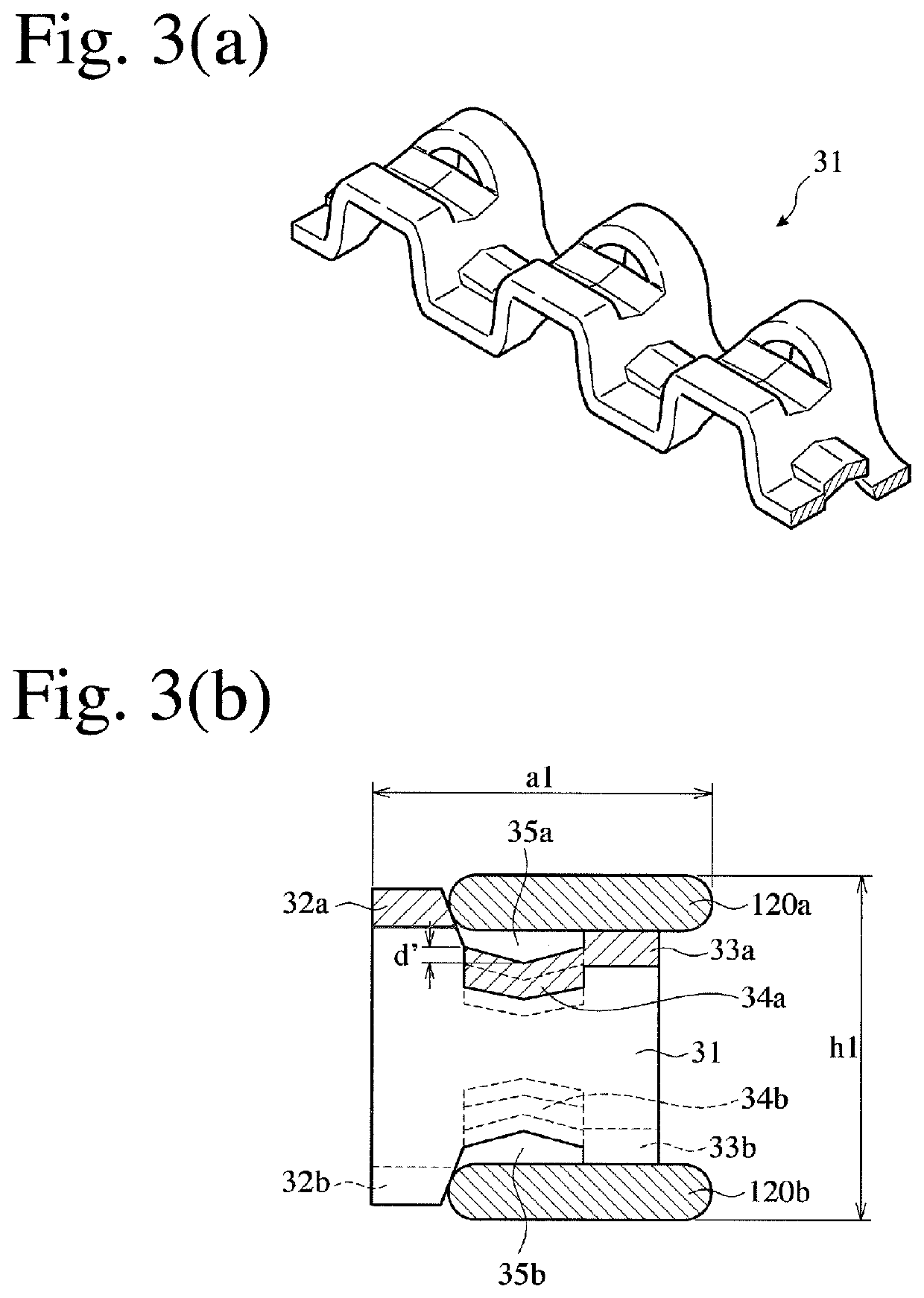

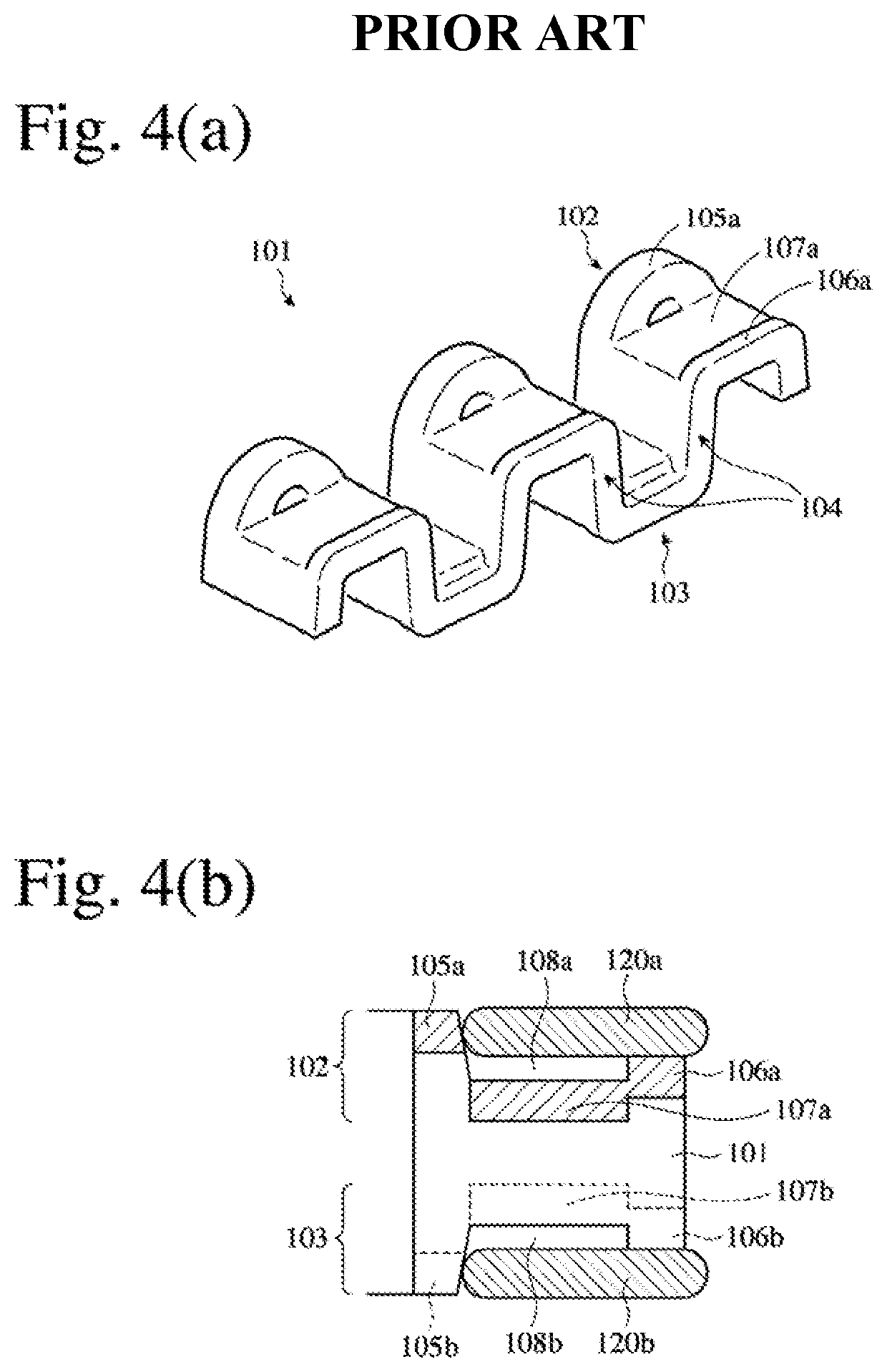

Combined oil control ring

InactiveUS20150145218A1Excellent oil-controlling functionPrevent oil accumulationPiston ringsBraking action transmissionControl functionEngineering

Owner:RIKEN CO LTD

Outdoor furniture anti-ultraviolet natural wood oil coating technology

InactiveCN106345671AImprove adhesionAvoid crackingPretreated surfacesIrregularity removal devicesBristleCotton cloth

The invention discloses an outdoor furniture anti-ultraviolet natural wood oil coating technology. The technology includes the following processes that a base material is selected to be processed into a white blank semi-finished product, and then the outer surface of the white blank semi-finished product is leveled and ground to obtain a ground semi-finished product; according to palette colors, commonly used color concentrates are selected for color repairing of the ground semi-finished product, and a color-repaired semi-finished product is obtained; the outer surface of the color-repaired semi-finished product is coated with anti-ultraviolet natural wood oil with a bristle brush to obtain a primary natural wood oil semi-finished product; the primary natural wood oil semi-finished product is still standing at normal temperature and aired for 15-25 min, then redundant anti-ultraviolet natural wood oil on the outer surface of the primary natural wood oil semi-finished product is wiped away by means of cotton cloth, and a primary trimmed semi-finished product is obtained. The anti-ultraviolet natural wood oil is used for coating, adhesion of a paint film can be enhanced, and the situations that furniture is placed outdoors and discolors and the paint film cracks and falls off are effectively avoided.

Owner:FUJIAN SENYUAN FURNITURE CO LTD

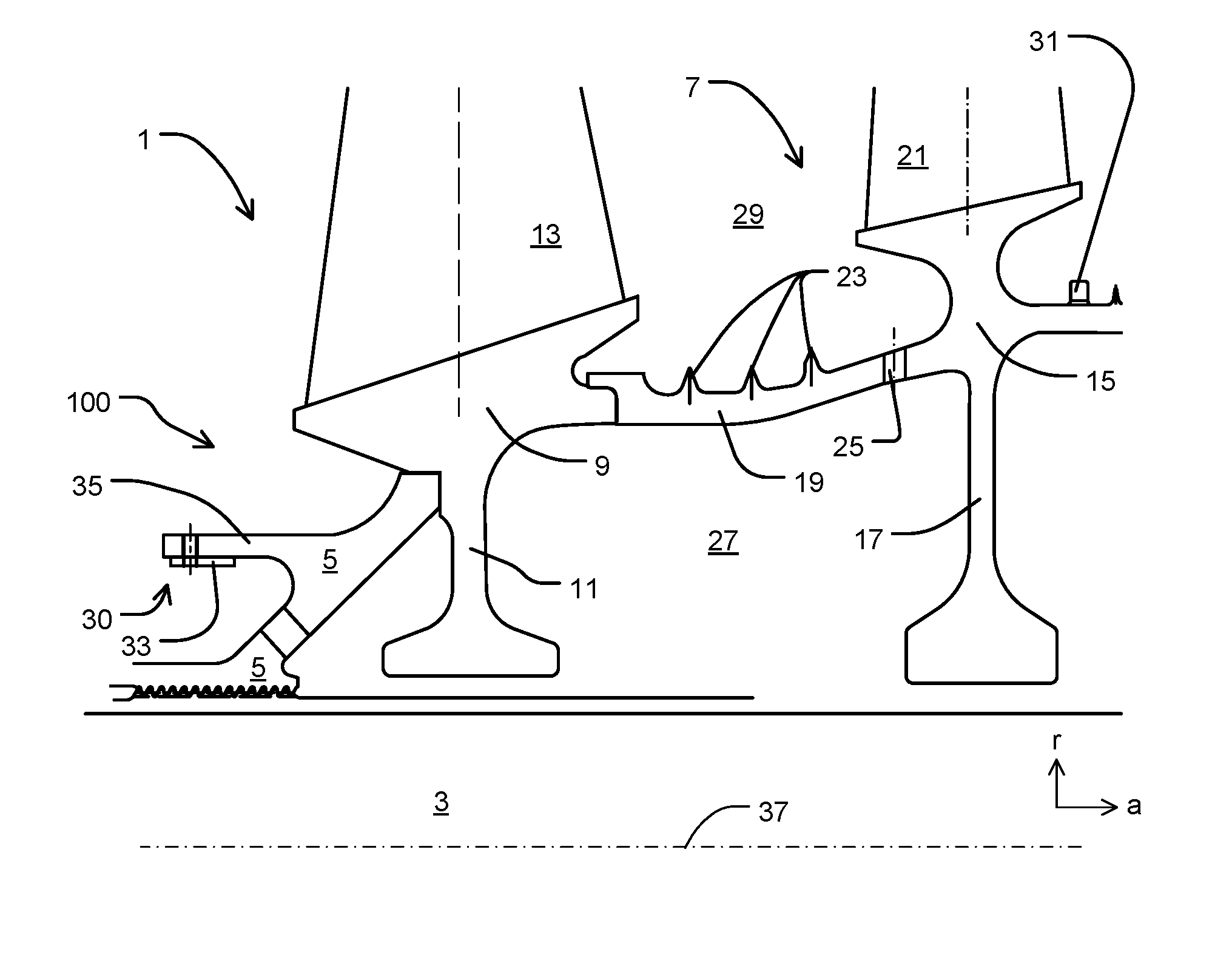

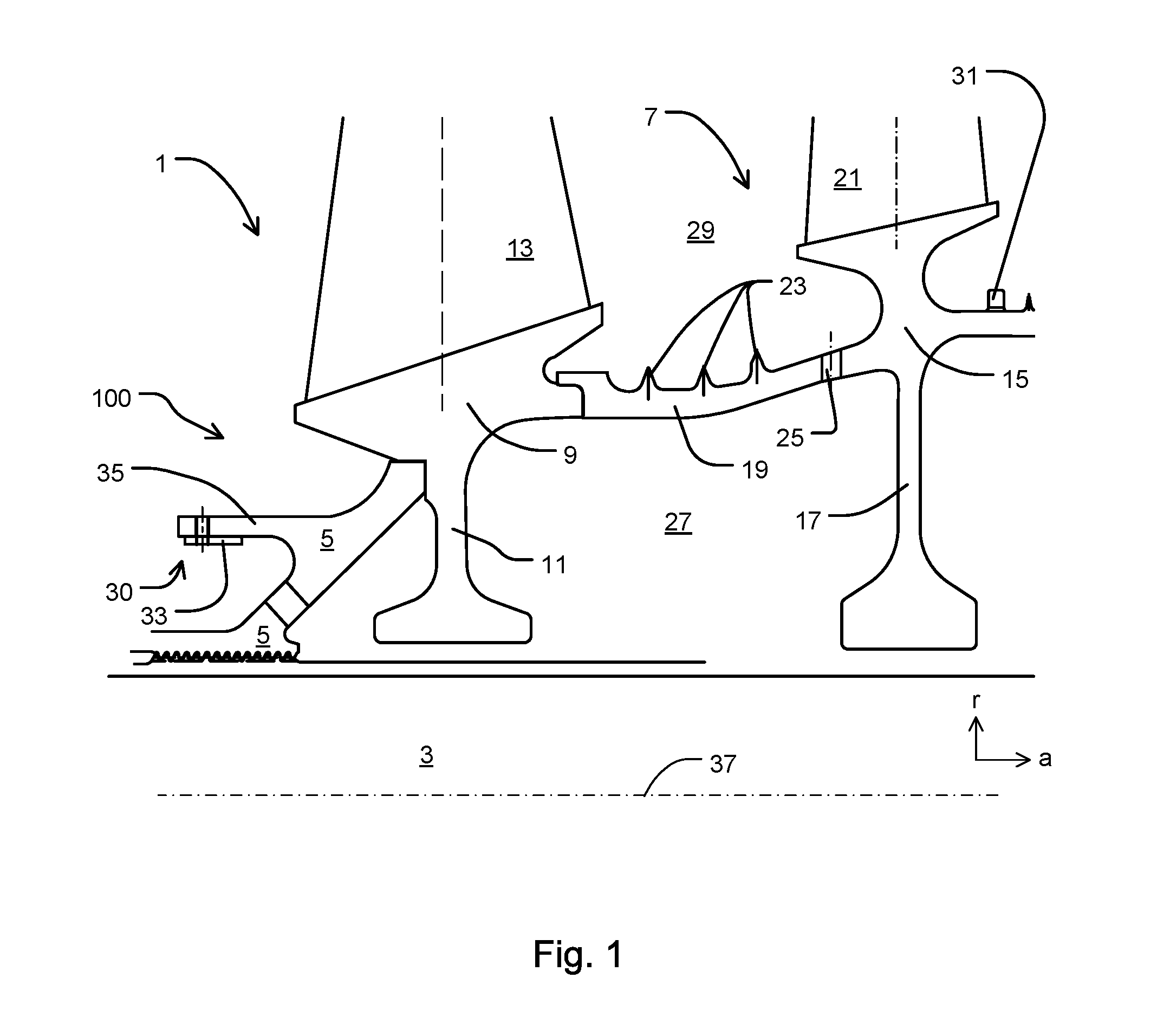

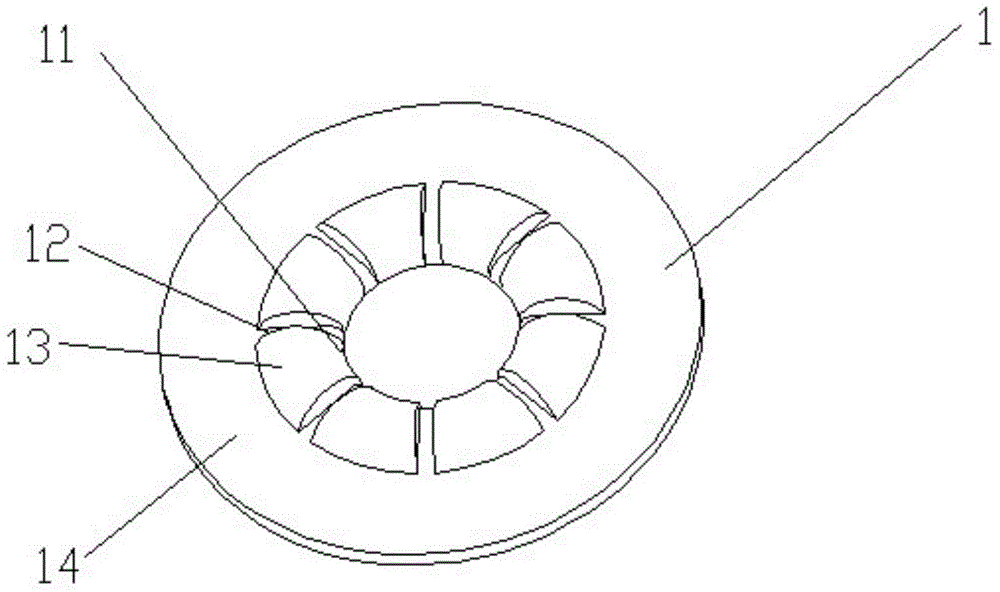

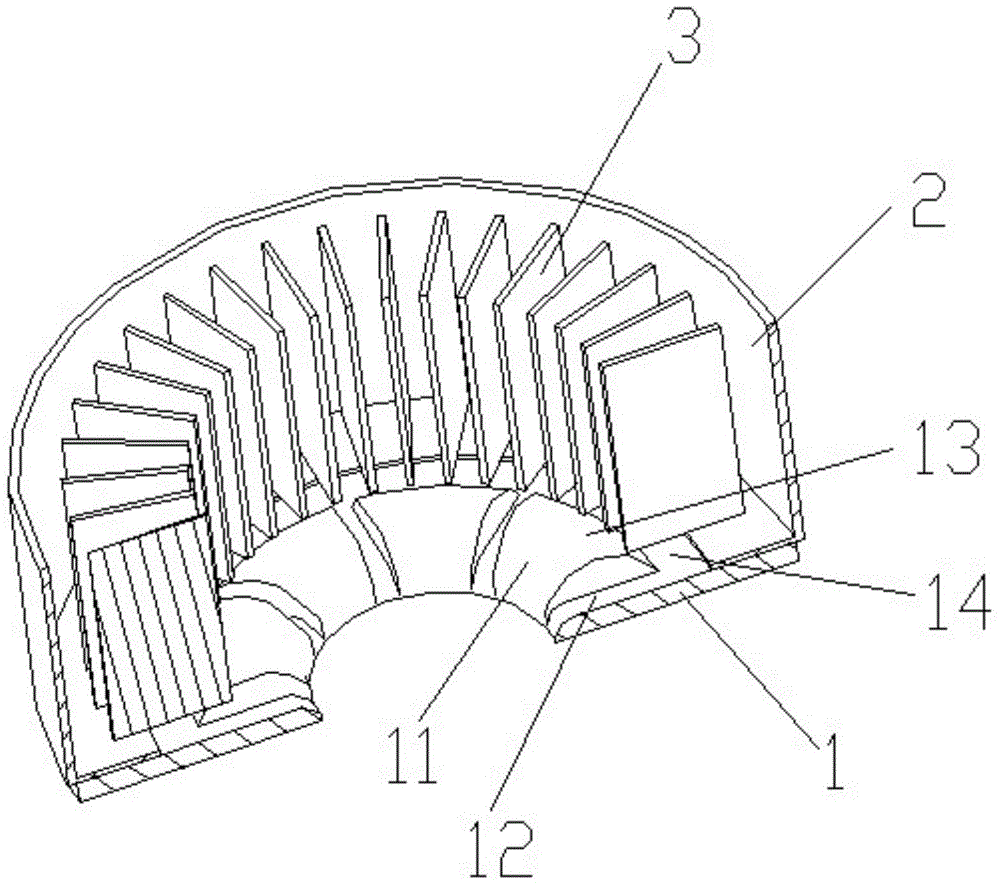

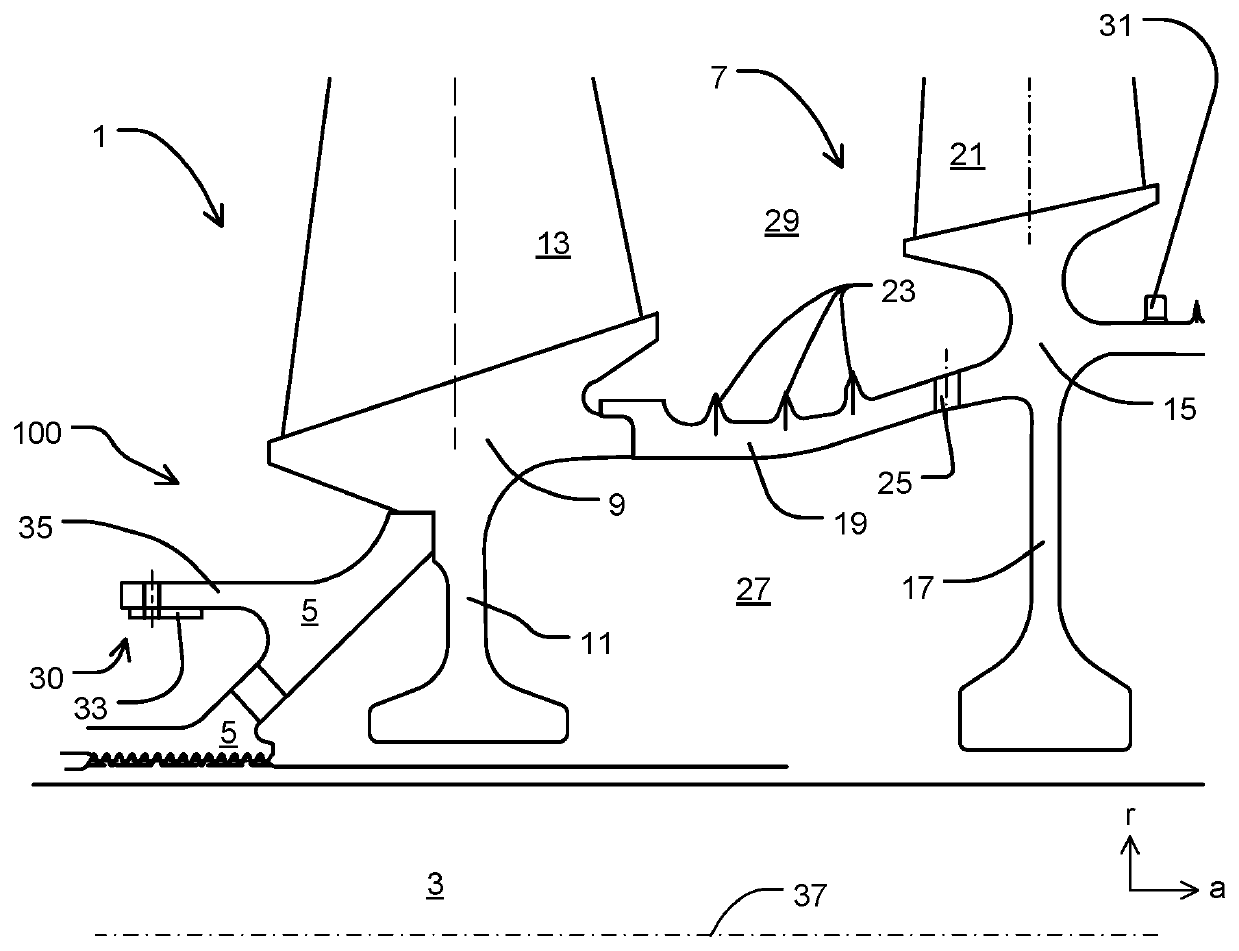

Rotor arrangement for a turbomachine and compressor

ActiveUS20160326877A1Possible fire dangerReduce fuel consumptionPump componentsBlade accessoriesEngineeringMechanical engineering

Owner:MTU AERO ENGINES GMBH

Cleaning cover cylinder provided with ultrasonic equipment for cleaning bottom sewage discharging channel

InactiveCN107159631AAvoid accumulation of oilSewage discharge smoothlyCleaning using liquidsMegasonic cleaningHigh pressure

The invention discloses a cleaning cover cylinder provided with ultrasonic equipment for cleaning a bottom sewage discharging channel. The cleaning cover cylinder comprises a cleaning cover cylinder body; openings at the two ends of the cleaning cover cylinder body are formed in a communicating mode; a sewage discharging groove body is arranged at the bottom end of the cleaning cover cylinder body; a sewage discharging water filtering grid plate is paved at the upper end of the sewage discharging groove body; movable tracks are paved in the center of the plate surface of the upper end of the sewage discharging water filtering grid plate; an ultrasonic cleaning machine is fixedly mounted at one end of the sewage discharging groove body; an ultrasonic oscillator is guided out at the output end of the ultrasonic cleaning machine and is guided into the sewage discharging groove body; high-pressure water spray gun bodies are mounted on the cylinder wall of the top end inside the cleaning cover cylinder body; and cleaning mist spray gun bodies are further mounted on the cylinder walls of the two sides inside the cleaning cover cylinder body. By means of the mode, the cleaning cover cylinder can be exclusively used for cleaning work of mechanical parts, and the ultrasonic cleaning machine is arranged in the sewage discharging groove body at the bottom of the cleaning cover cylinder body and can regularly clean the sewage discharging groove body.

Owner:WUXI BAIMA MACHINERY EQUIP CO LTD

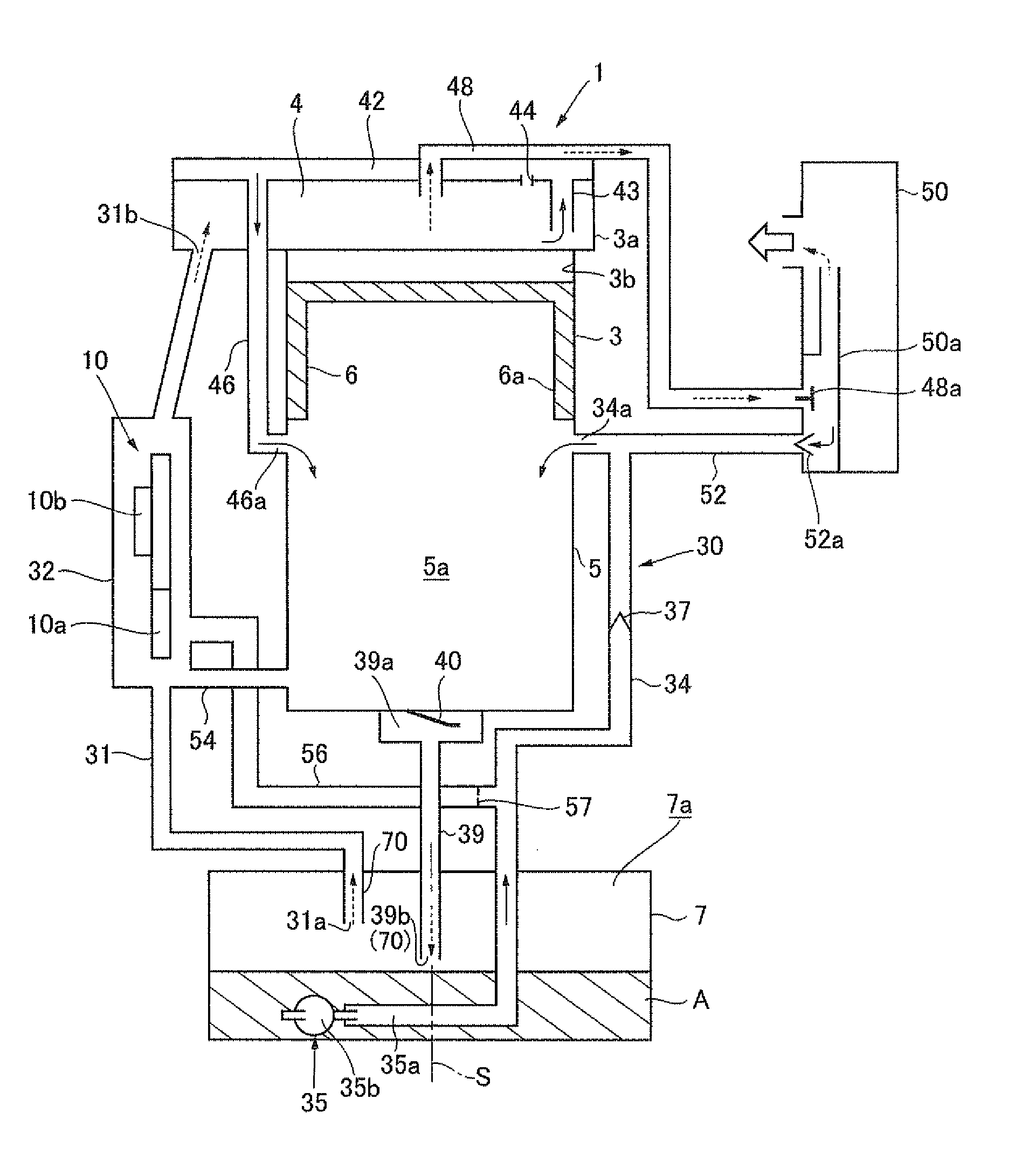

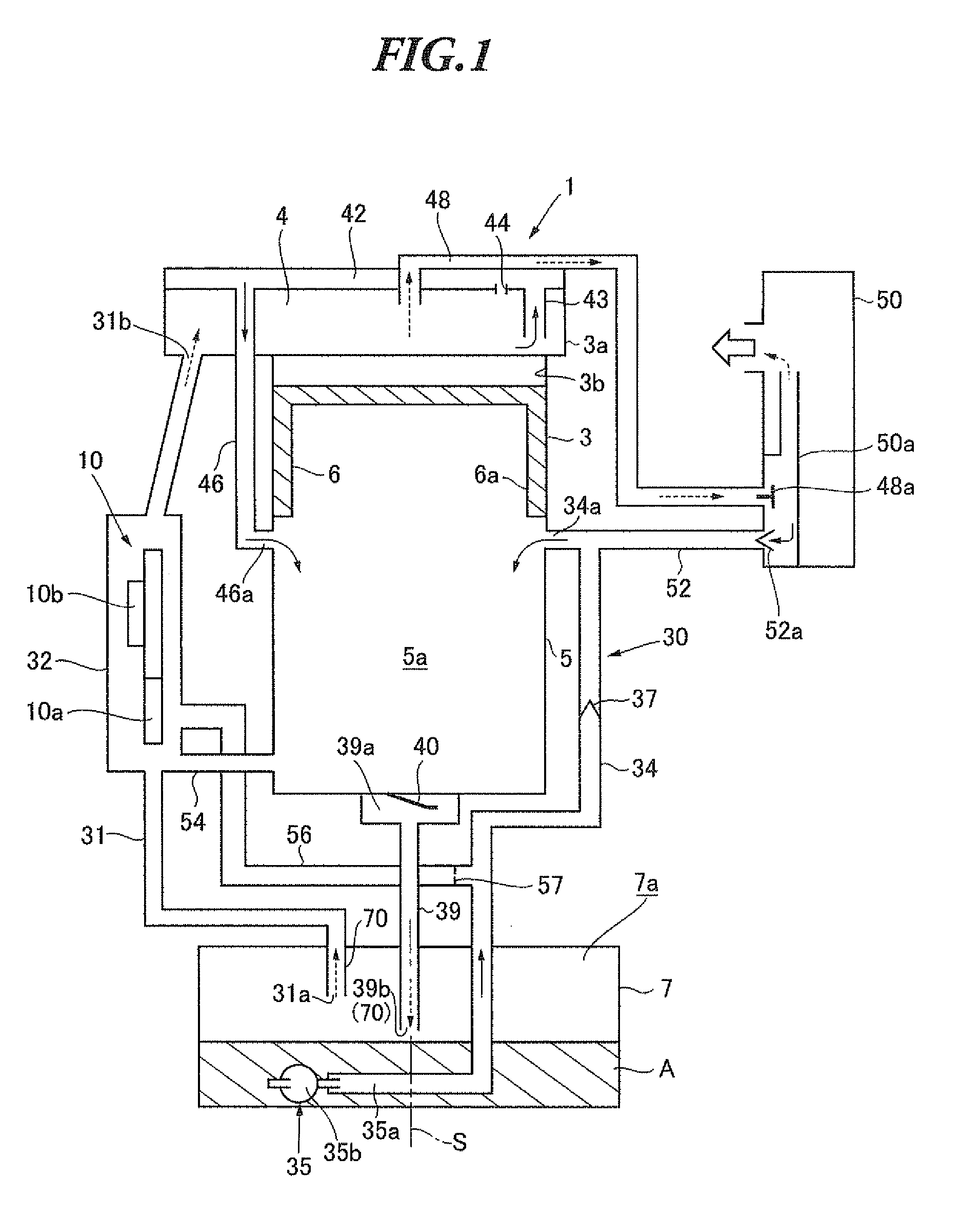

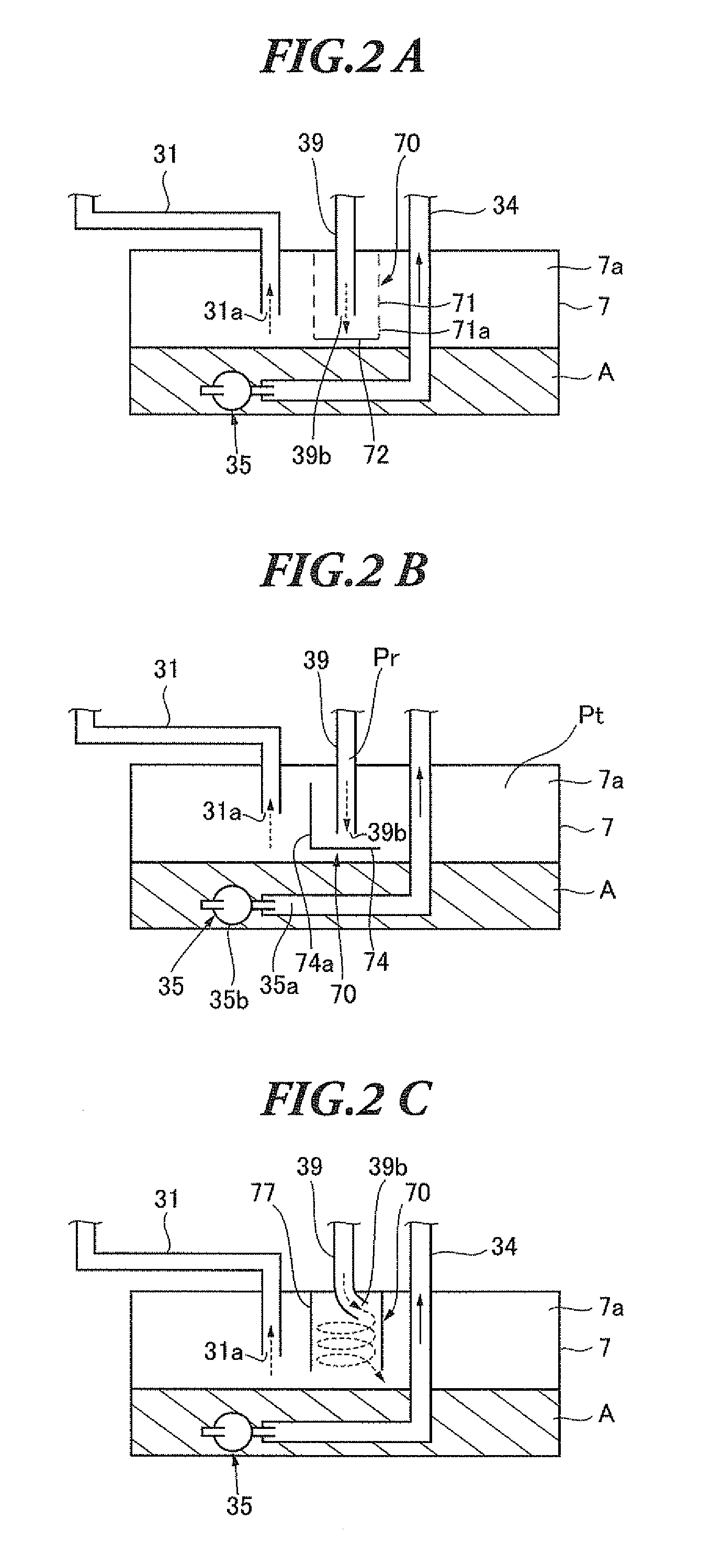

Lubrication system for four-stroke engine

ActiveUS8695563B2Increase blockingPrevent oil accumulationLubrication of auxillariesLubricant conduit arrangementsCrankFour-stroke engine

A lubrication system for a four cycle engine that lubricates the valve mechanism with the oil mist of the concentration, lowered by the liquefying means. The lubrication system has an oil feeding passage for connecting an oil reservoir with the crank chamber and sending the oil retained in liquid form in the oil reservoir to the crank chamber under a negative pressure of the crank chamber, a communication passage for connecting the crank chamber with the oil reservoir and sending oil mist generated in the crank chamber to the oil reservoir when under a positive pressure of the crank chamber, liquefying means in the oil reservoir for liquefying the oil mist sent from the communication passage to the oil reservoir to decrease the concentration of the oil mist, and a supply passage for supplying the oil mist from the oil reservoir to the valve operating chamber through the liquefying means.

Owner:MARUYAMA MFG CO INC

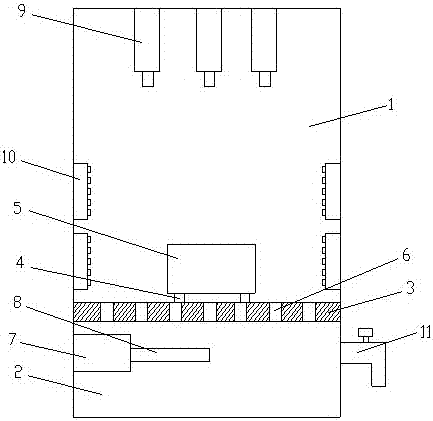

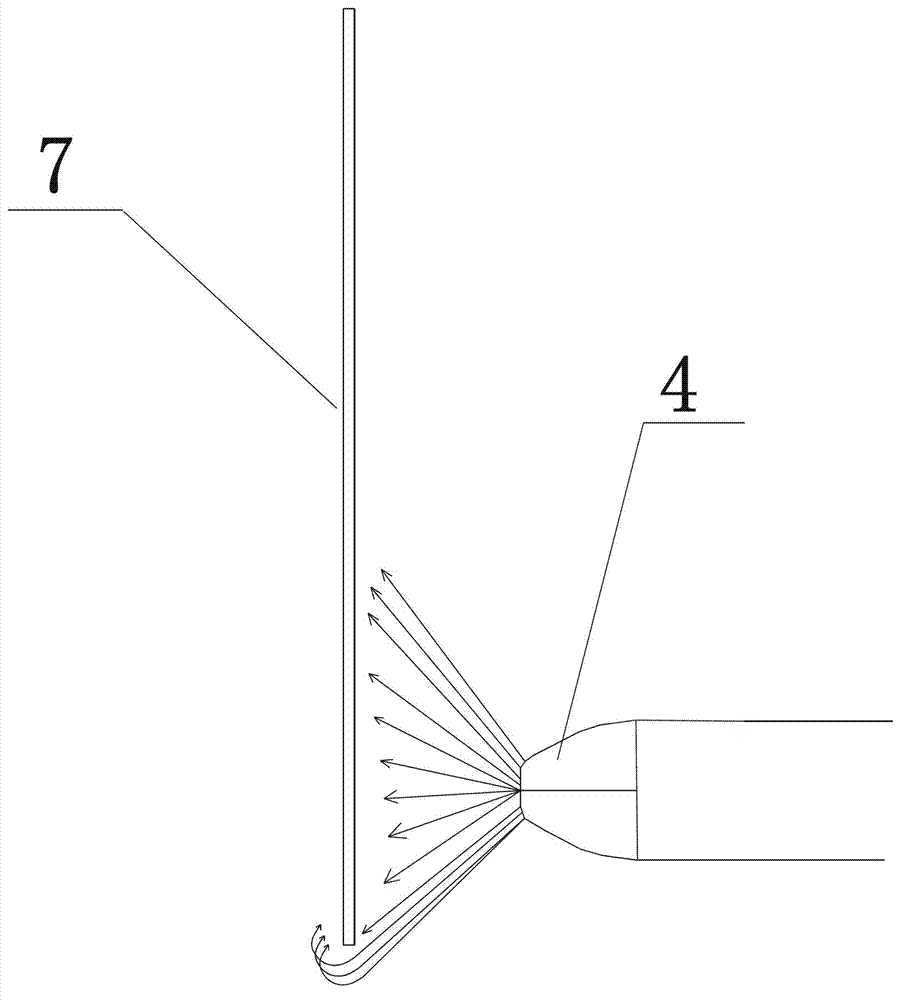

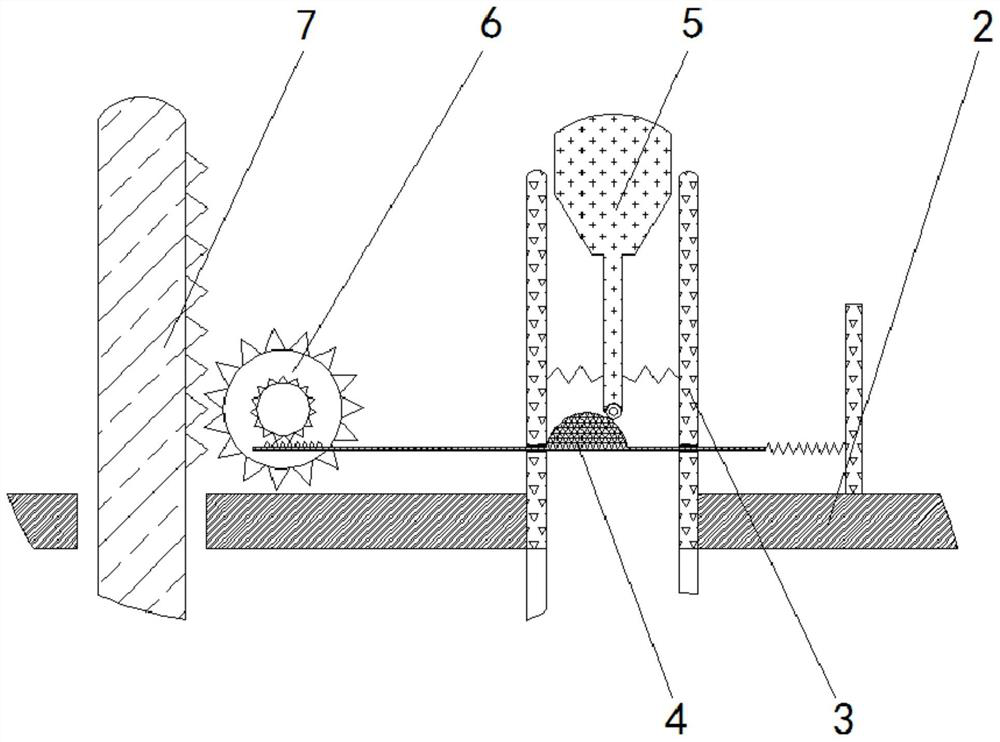

Anti-oil-gathering device for upper plate edge and lower plate edge during electrostatic spraying

InactiveCN102896059APrevent oil accumulationAvoid hittingElectrostatic spraying apparatusPrinting inkEngineering

The invention discloses an anti-oil-gathering device for an upper plate edge and a lower plate edge during electrostatic spraying. The device comprises a circuit substrate and a spray gun, wherein the circuit substrate is fixedly clamped in a clamp and is capable of moving forward and backward driven by the clamp, the spray gun is arranged in a sliding rail and is capable of moving upward and downward along the sliding rail, the spray gun is correspondingly arranged on the front side of the circuit substrate to be used for carrying out electrostatic spraying on the surface of the circuit substrate, an electrostatic screen is arranged on the rear side of the circuit substrate, a platform is arranged on the top of the electrostatic screen, and a grounding plate is arranged on the lower end of the circuit substrate. By the adoption of the device, since the electrostatic screen is arranged on the back of the circuit substrate, the platform is arranged on the top end of the electrostatic screen, and the grounding plate is arranged on the lower end of the circuit substrate, when the circuit substrate is sprayed, printing ink drifting from a plate edge was absorbed through the platform and the grounding plate, and thus the problem of oil gathering on the upper plate edge and the lower plate edge of the circuit substrate is effectively avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

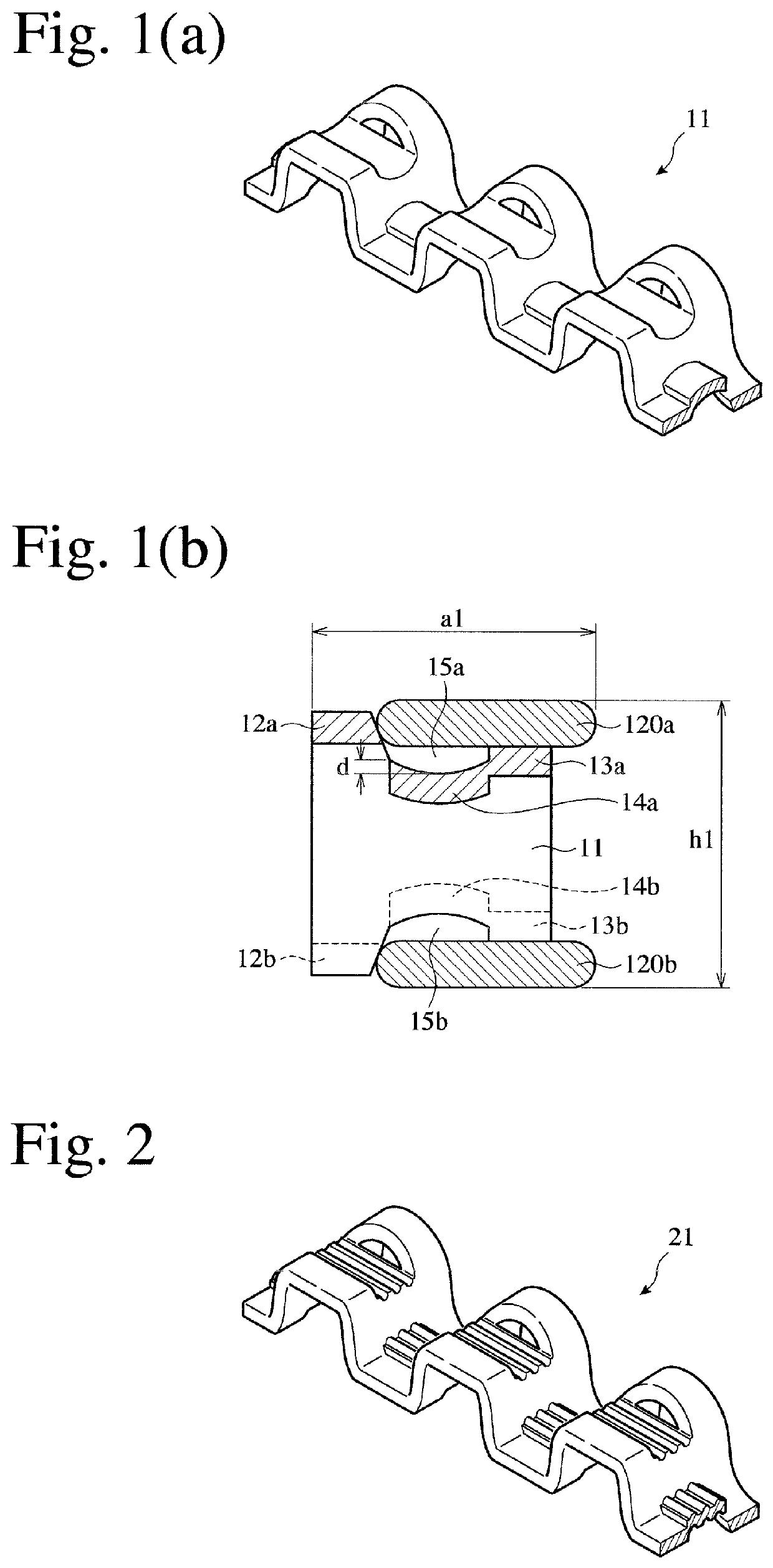

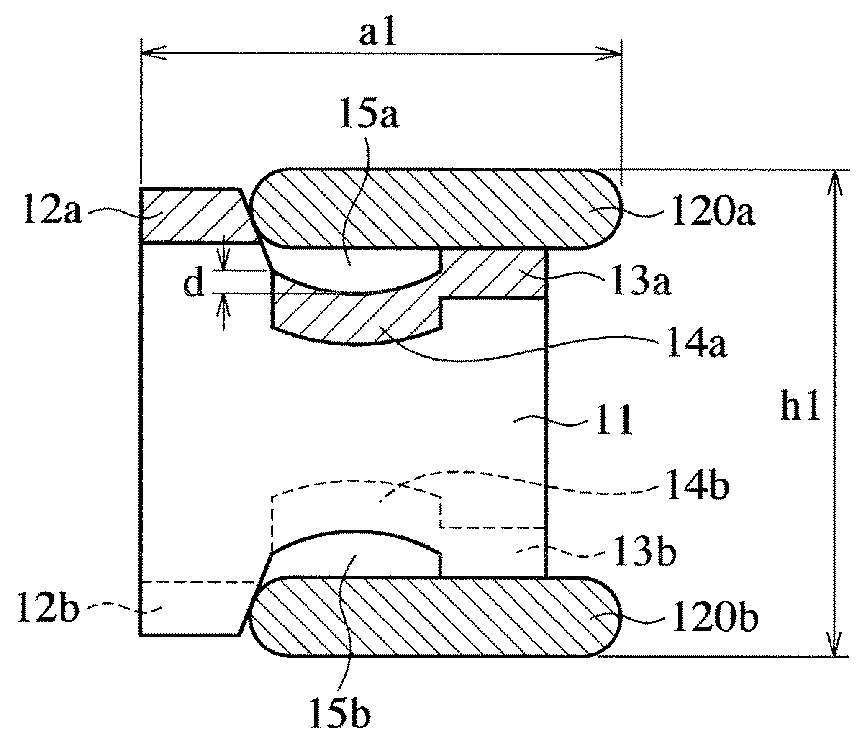

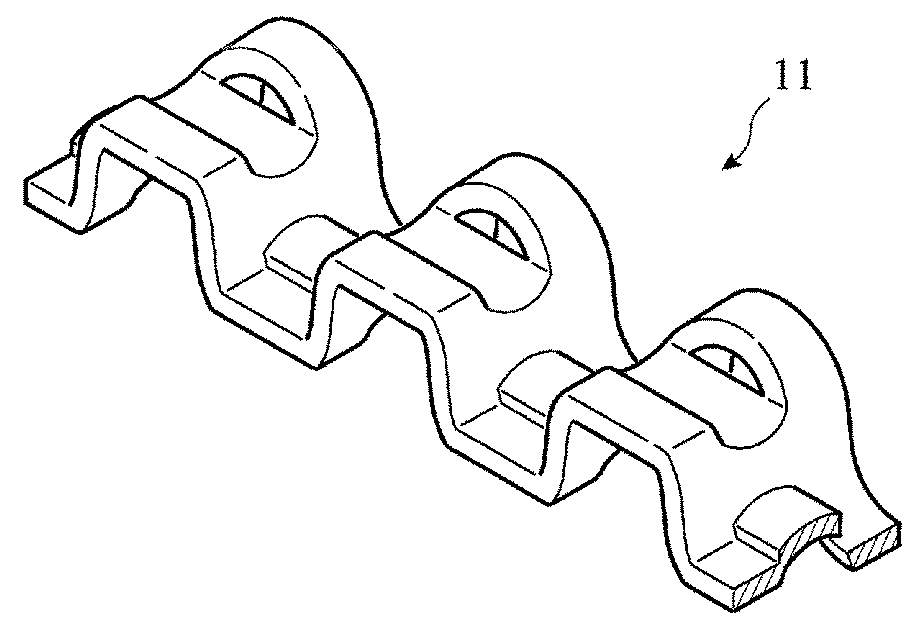

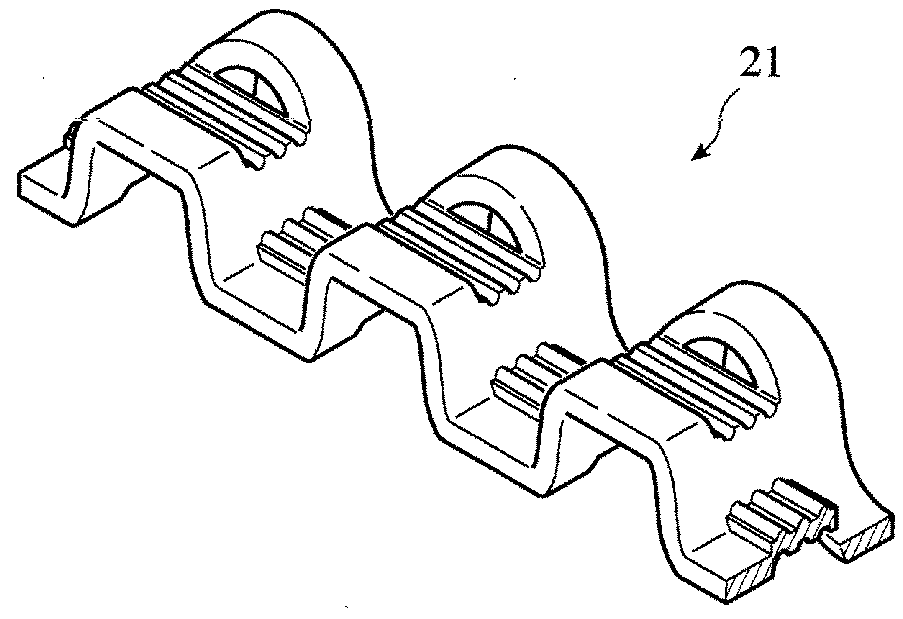

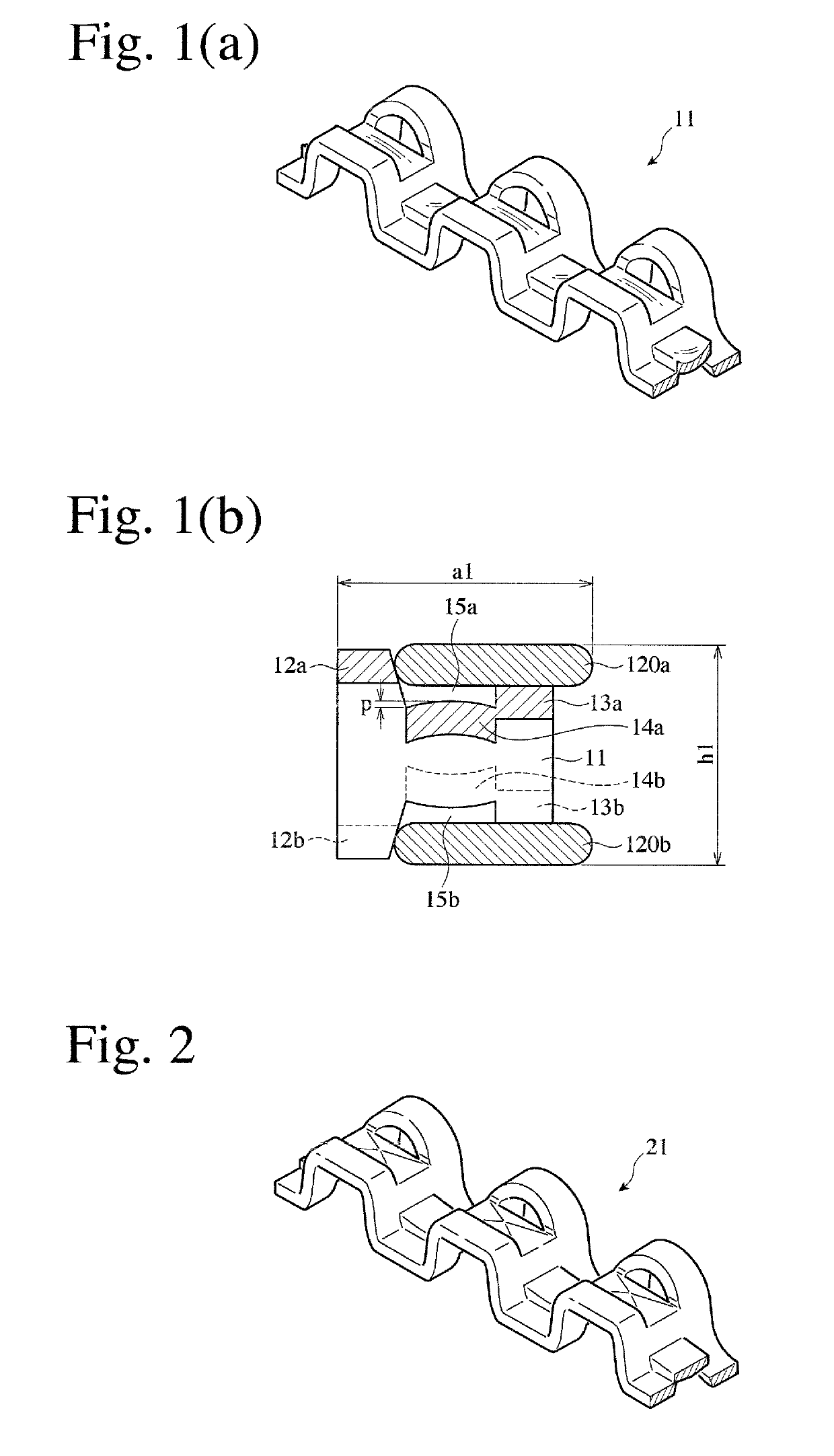

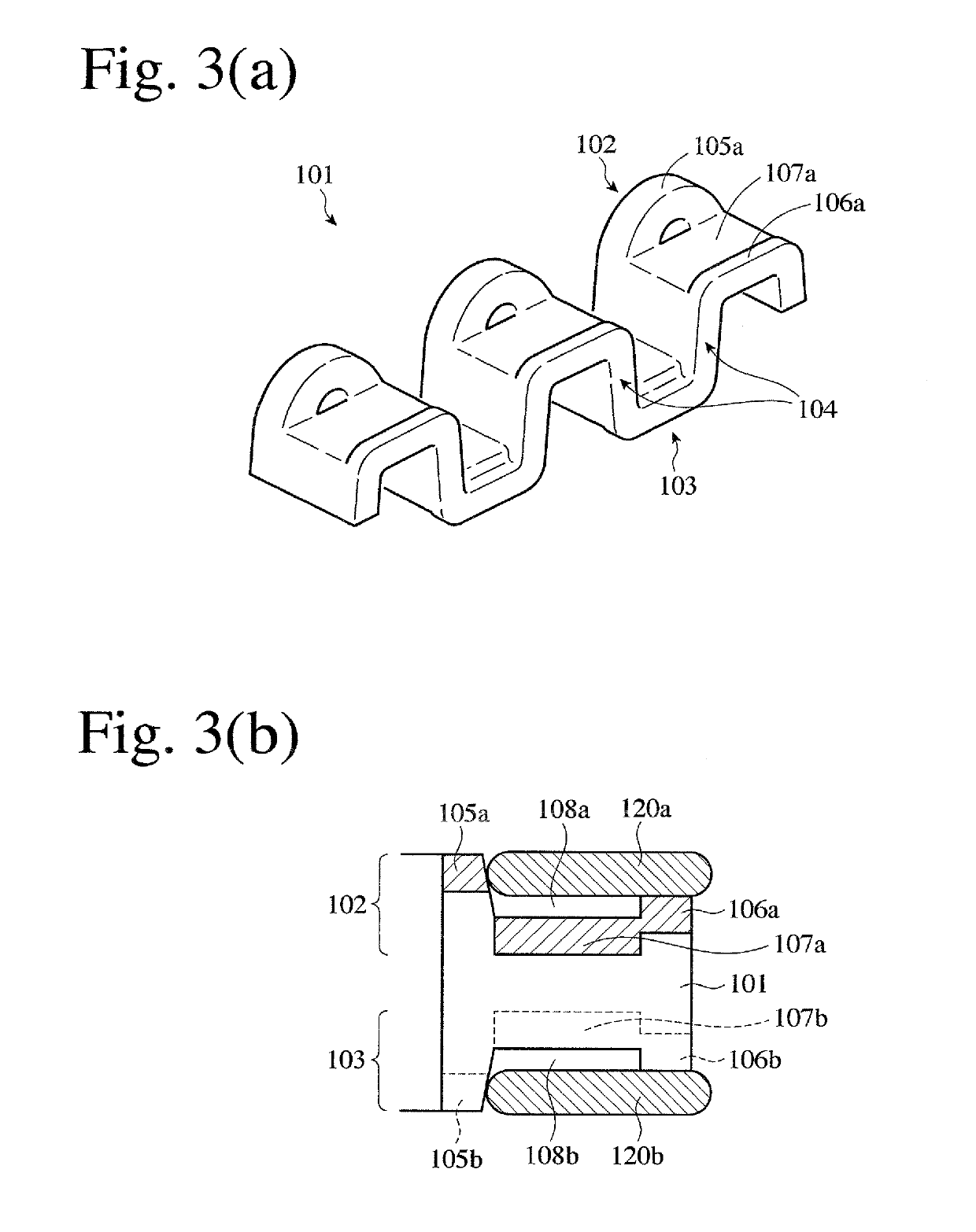

Combined oil control ring

InactiveUS9657838B2Excellent oil-controlling functionPrevent oil accumulationPiston ringsEngineeringAutomotive engine

Owner:RIKEN CO LTD

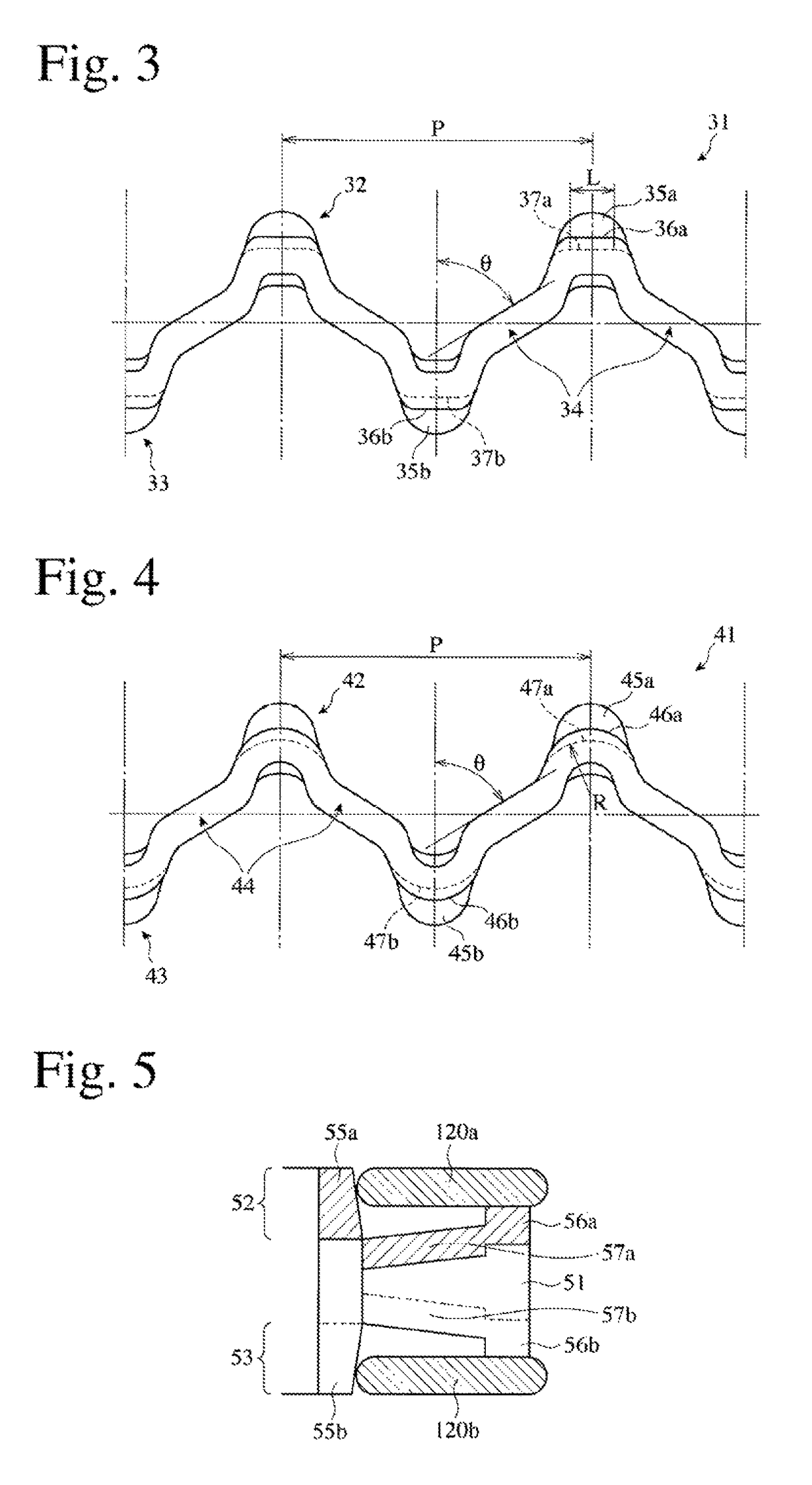

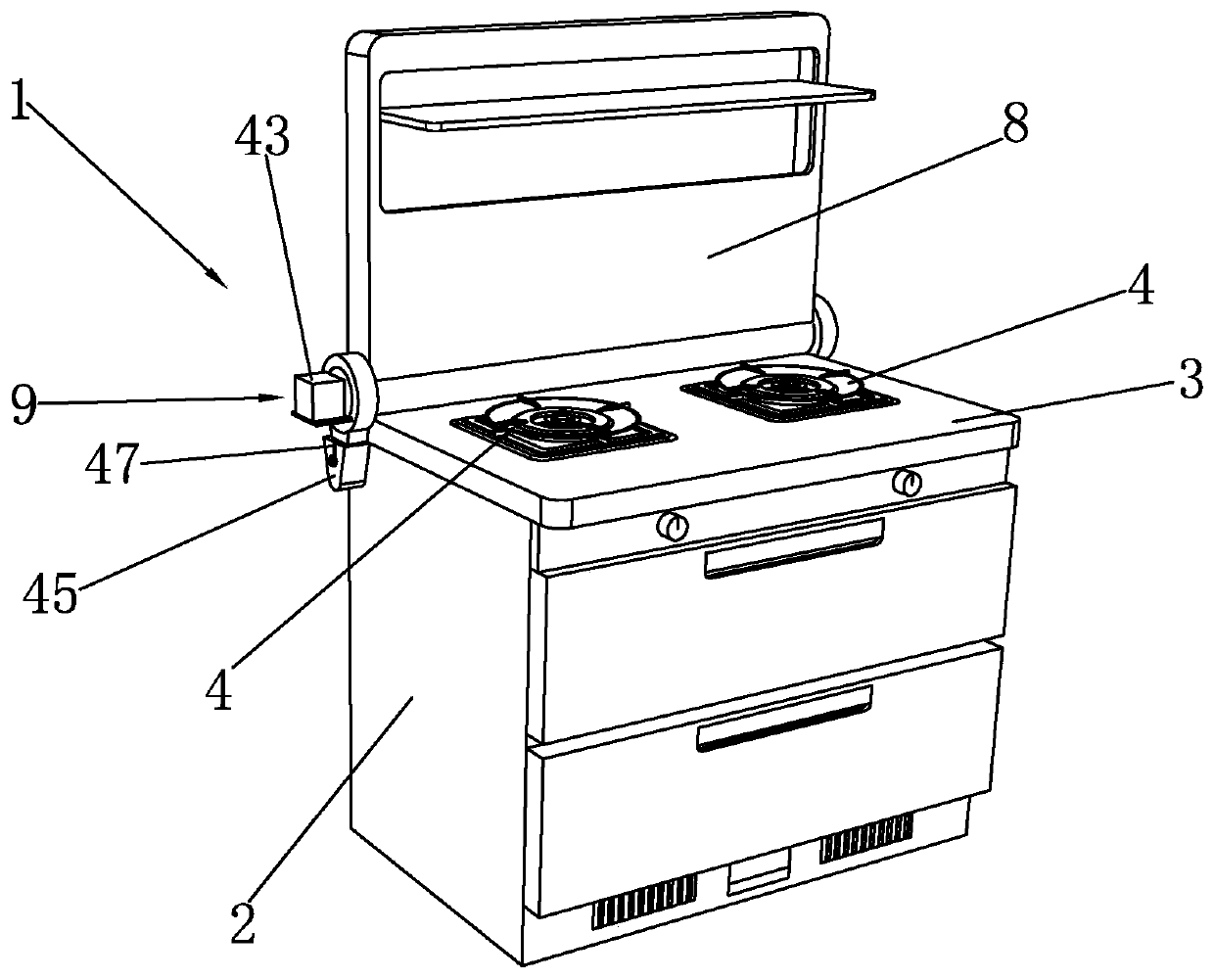

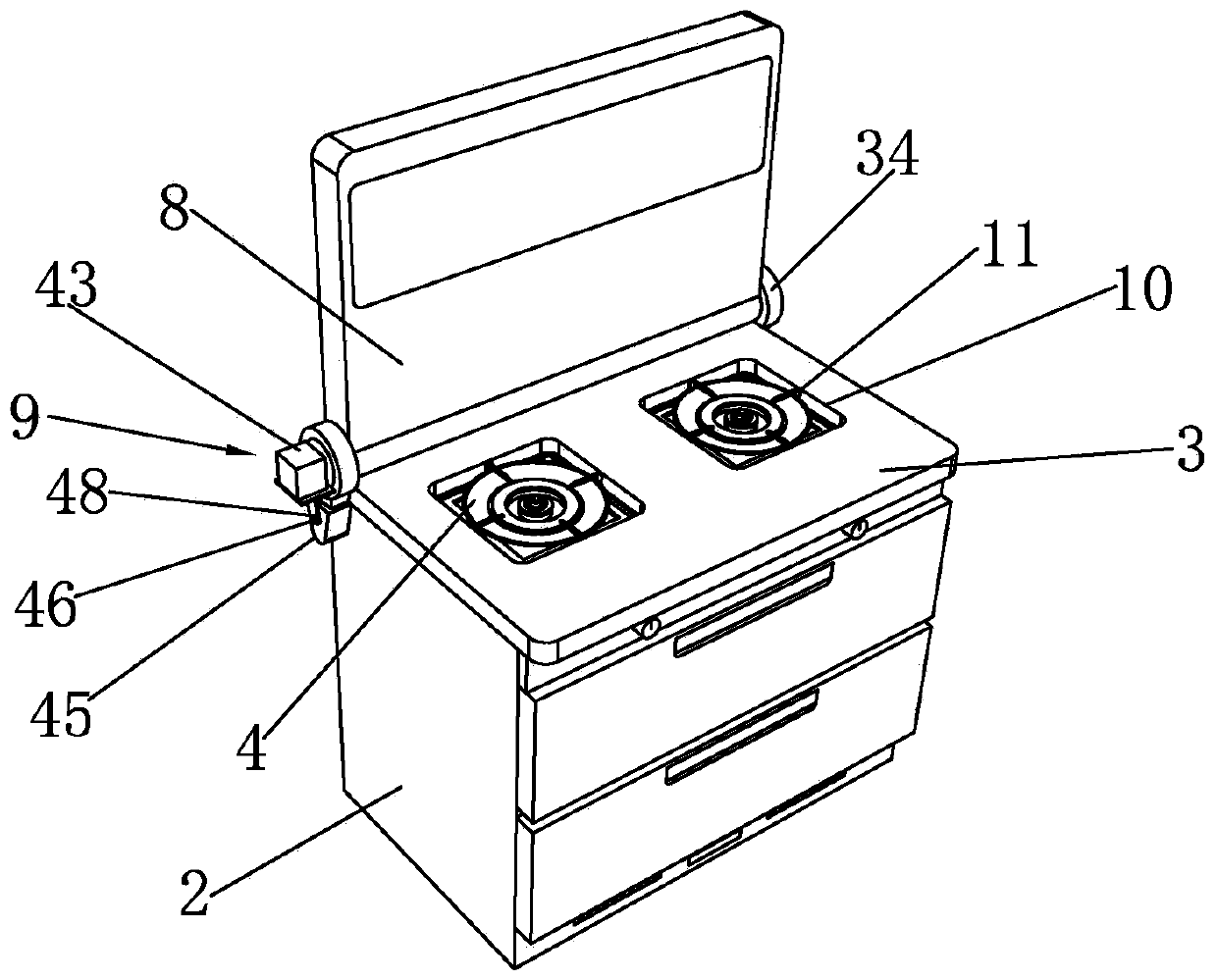

Concealed integrated stove for stoves and installation method thereof

PendingCN111503662AImprove space utilizationPromote absorptionDomestic stoves or rangesLighting and heating apparatusMechanical engineeringWaste management

The invention discloses a concealed integrated stove for stoves and an installation method thereof. The stove comprises a body, wherein the bottom of the body is provided with a cabinet, the top of the cabinet is provided with a stovetop, the top of the stovetop is provided with a stove, the top of the cabinet is provided with an installation cavity that is internally equipped with a lifting device, the lifting device controls the stove to lift on the stovetop, the back of the cabinet is equipped with a suction box, the back of the top of the stovetop is equipped with an air inlet box that usconnected to the suction box, a rotating assembly is provided between the air inlet box and the stovetop, the rotating assembly and the air inlet box are connected with the suction box, the rotating assembly controls the rotation of the air inlet box, and the air inlet box matches the stovetop. The method comprises the following steps of a, preparation before installation; b, installation of the lifting device; c, installation of the stovetop; and d, installation of the air inlet box and rotating assembly. The invention greatly increases the space utilization of the kitchen, facilitates the cleaning of the kitchen wall, avoids the accumulation of oil stains on the wall, and eliminates hidden safety hazards caused thereby.

Owner:浙江蓝炬星电器有限公司

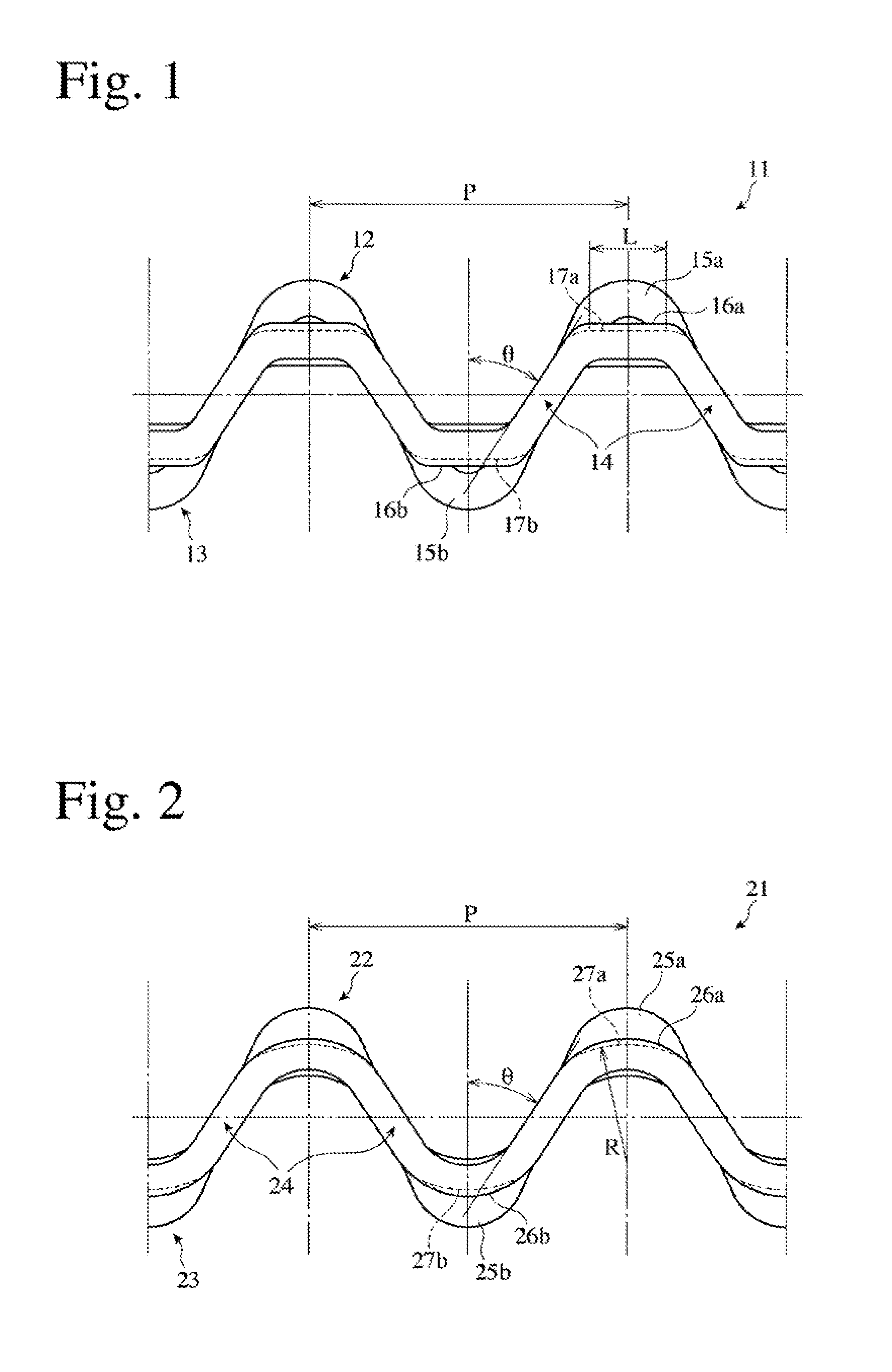

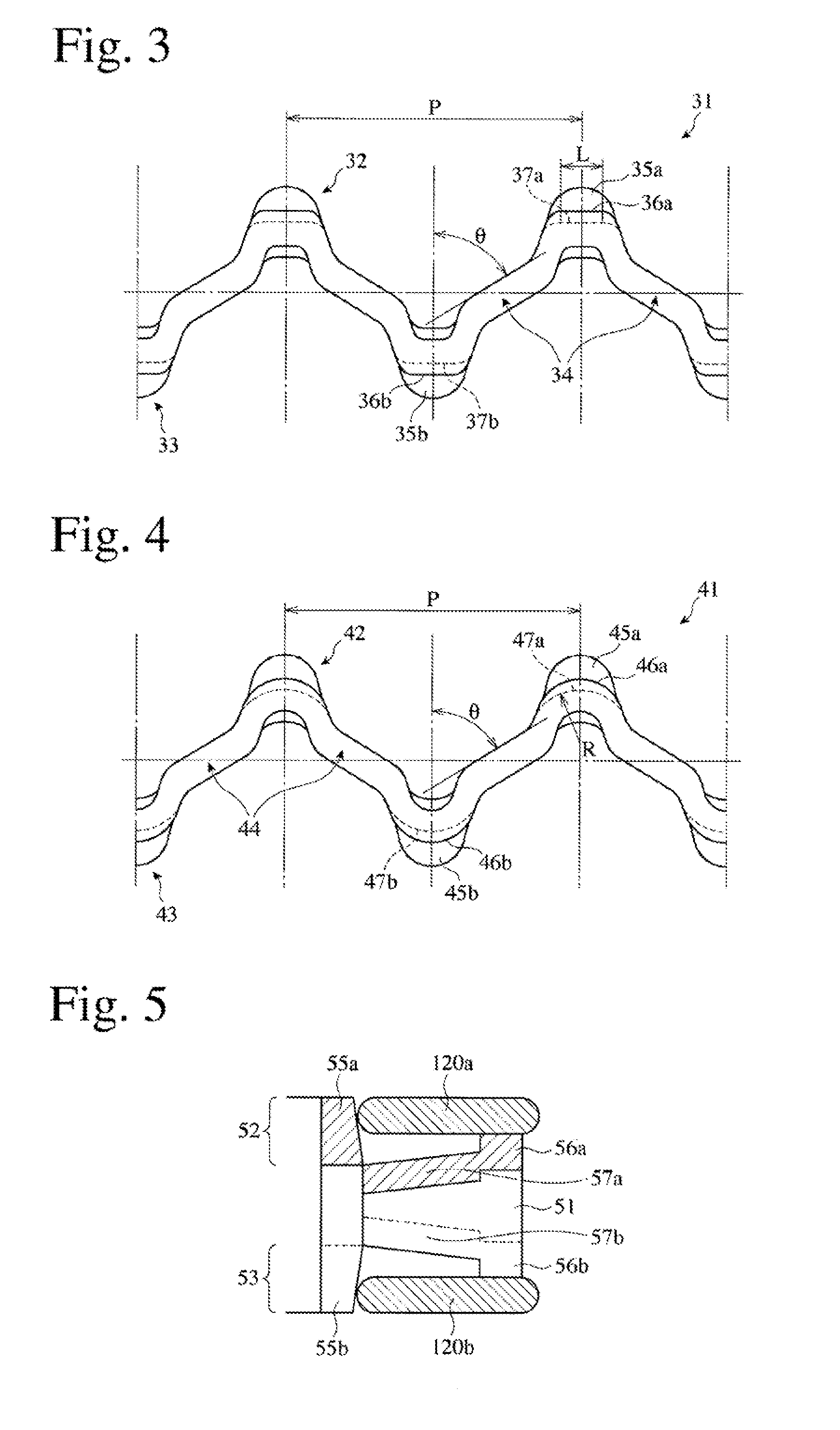

Combined oil control ring

ActiveUS20180112775A1Prevent accumulationSufficient durabilityPiston ringsMachines/enginesControl functionEngineering

To provide a combined oil control ring comprising a pair of upper and lower side rails and an axially corrugated spacer expander having upper and lower portions for automobile engines, which is capable of keeping an excellent oil-controlling function without sticking between a spacer expander and side rails even in a long period of engine operation, the upper and lower portions of the spacer expander have tabs pushing inner peripheral surfaces of the side rails, projections supporting the side rails, and intermediate portions between the tabs and the projections; and each intermediate portion opposing the side rail has a center-raised bottom having a center-raised shape when viewed along a substantially circumferential direction center-raised shape and a radial direction.

Owner:RIKEN CO LTD

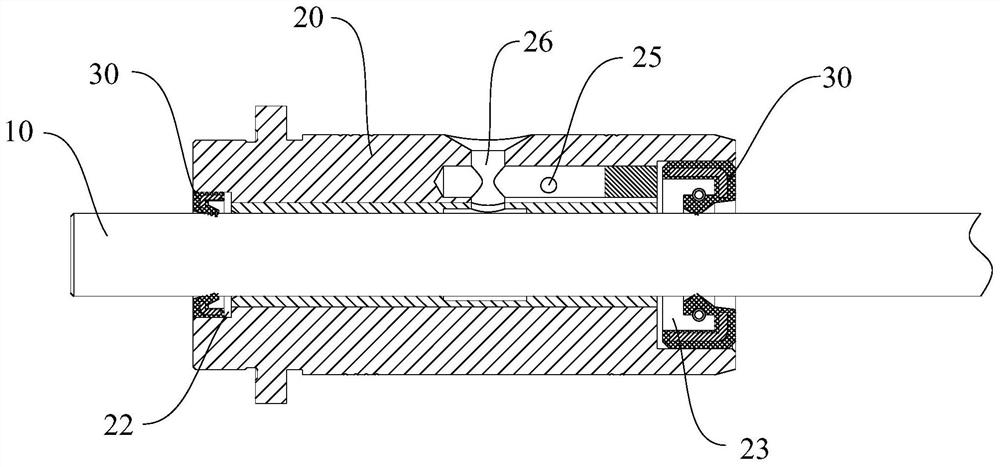

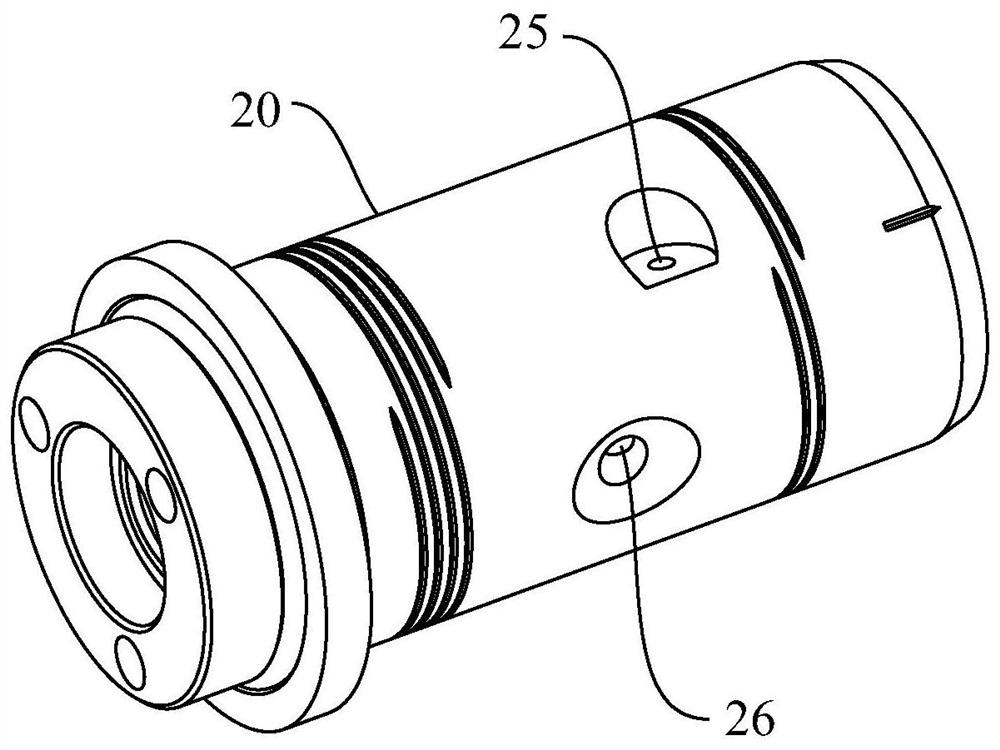

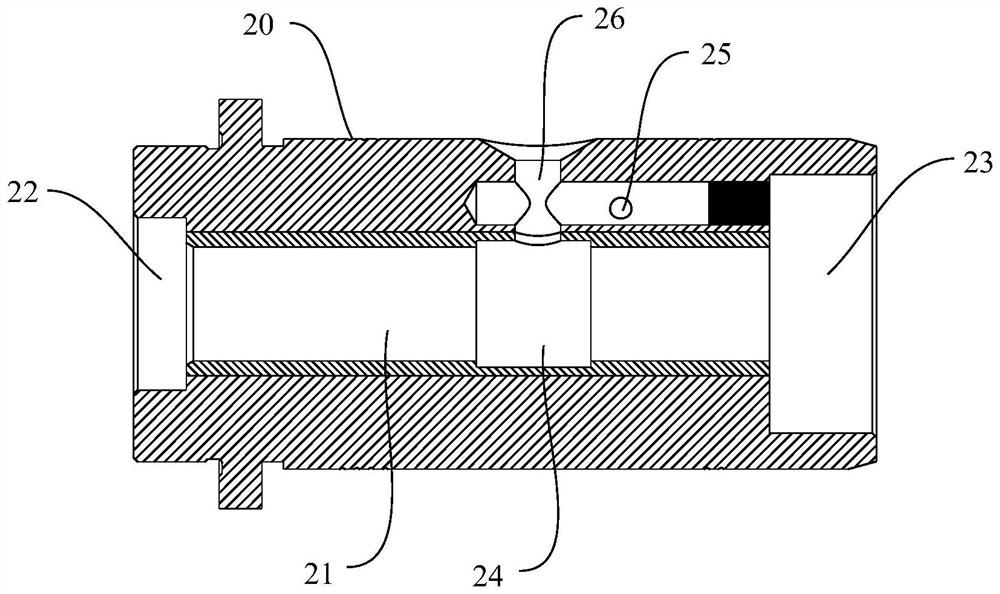

Air bellow and integrated cooker

PendingCN112648662APrevent oil accumulationLess oil accumulationDomestic stoves or rangesLighting and heating apparatusOil canThermodynamics

The invention provides an air bellow and an integrated cooker, and relates to the technical field of integrated cookers. An oil guide part is arranged at the bottom of the air bellow, the oil guide part is provided with an inclined inner wall, and the cross sectional area of the inner wall of the oil guide part is gradually reduced from top to bottom; and an air bellow oil leakage hole is formed in the lowest position of the oil guide part. After accumulated oil in the air bellow falls into the oil guide part, the accumulated oil can slide downwards along the inner wall of the oil guide part and finally can flow out of the air bellow oil leakage hole, and thus the oil is prevented from being accumulated in the air bellow. Therefore, after the air bellow provided by the embodiment of the invention is used for a long time, the oil accumulation amount is small, peculiar smell is not easily generated, and the influence on air suction and oil smoke discharge effects is low.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Combined oil control ring

ActiveUS10557551B2Inhibition retentionGood effectPiston ringsMachines/enginesEngineeringAutomotive engine

Owner:RIKEN CO LTD

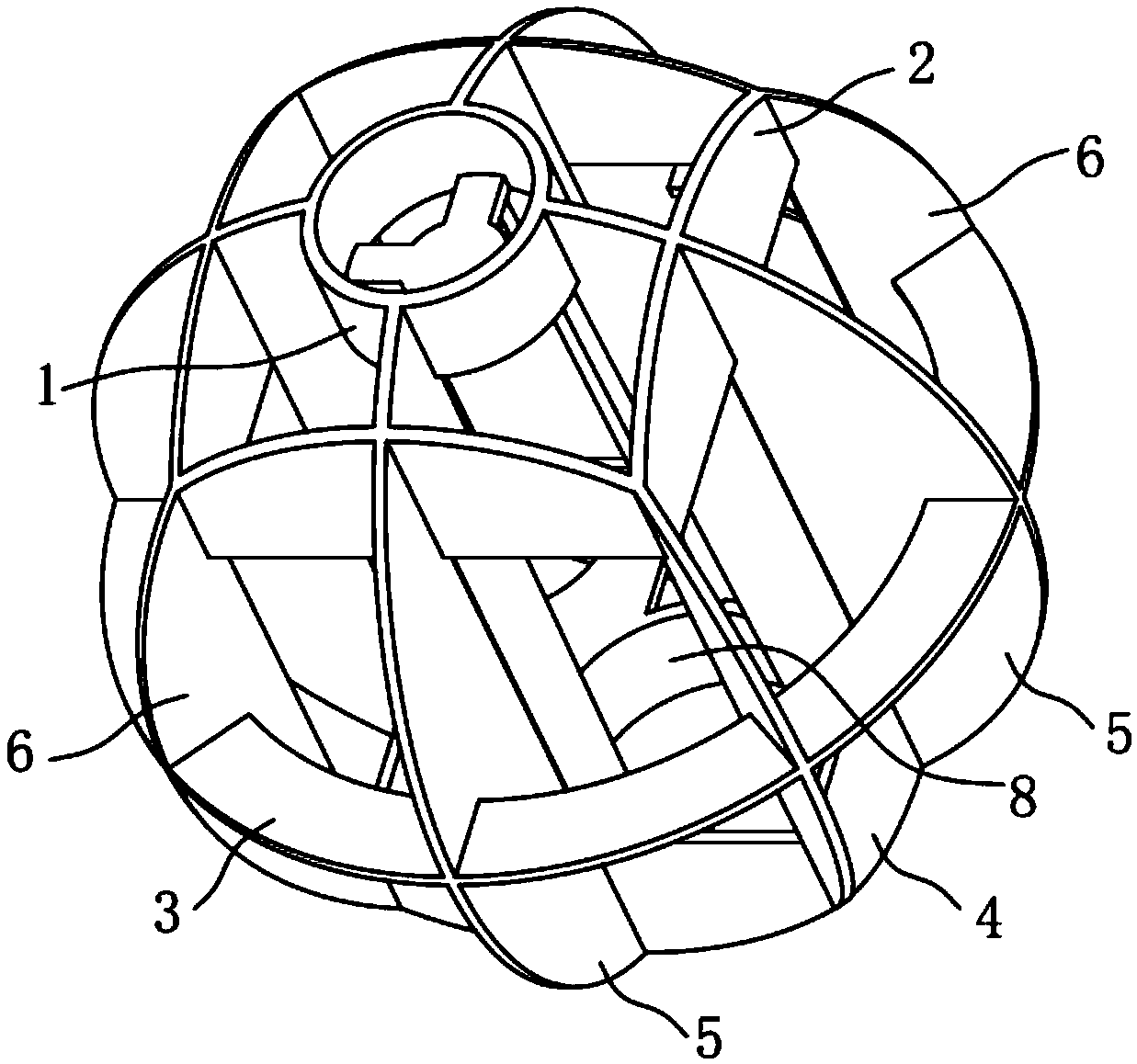

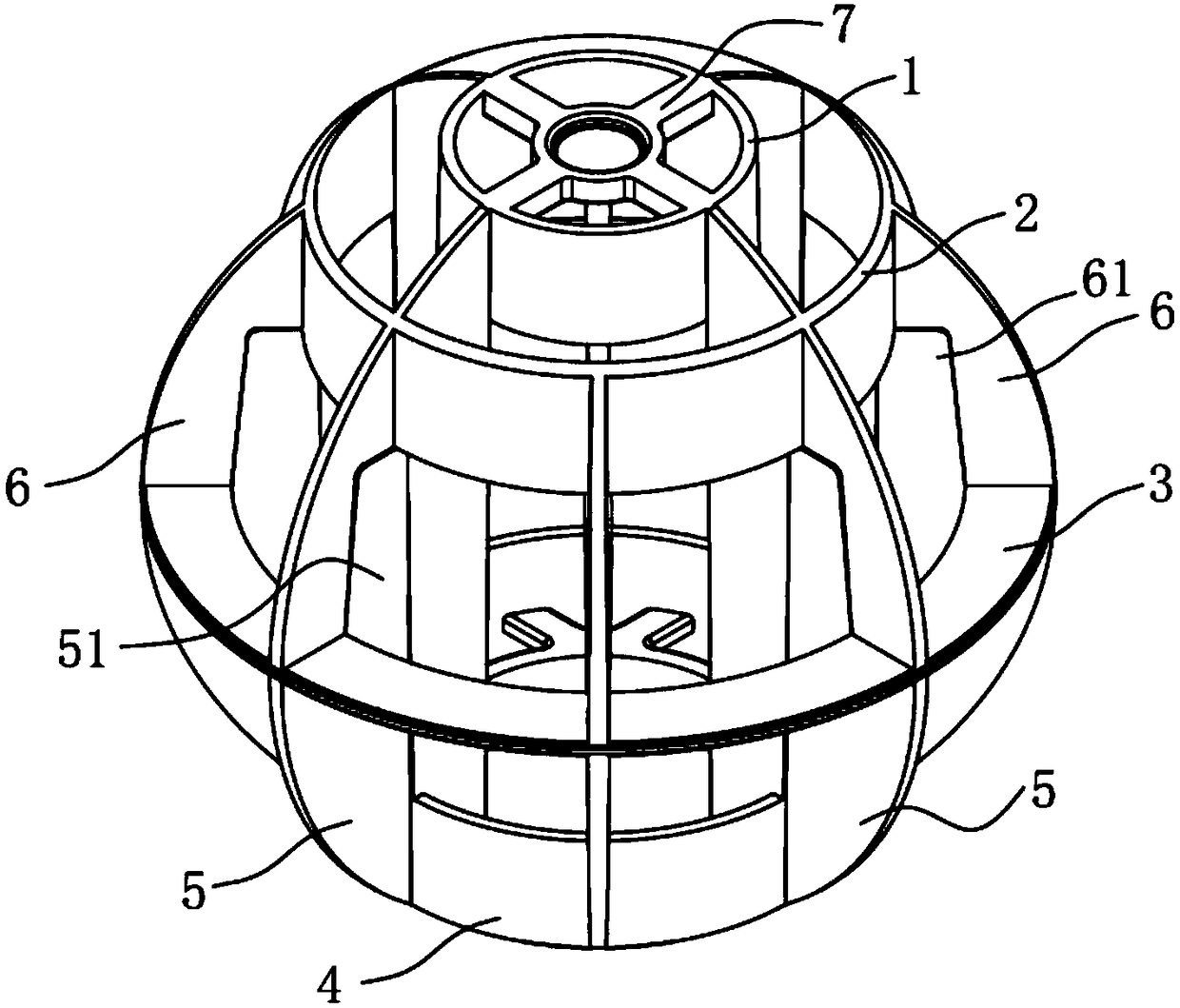

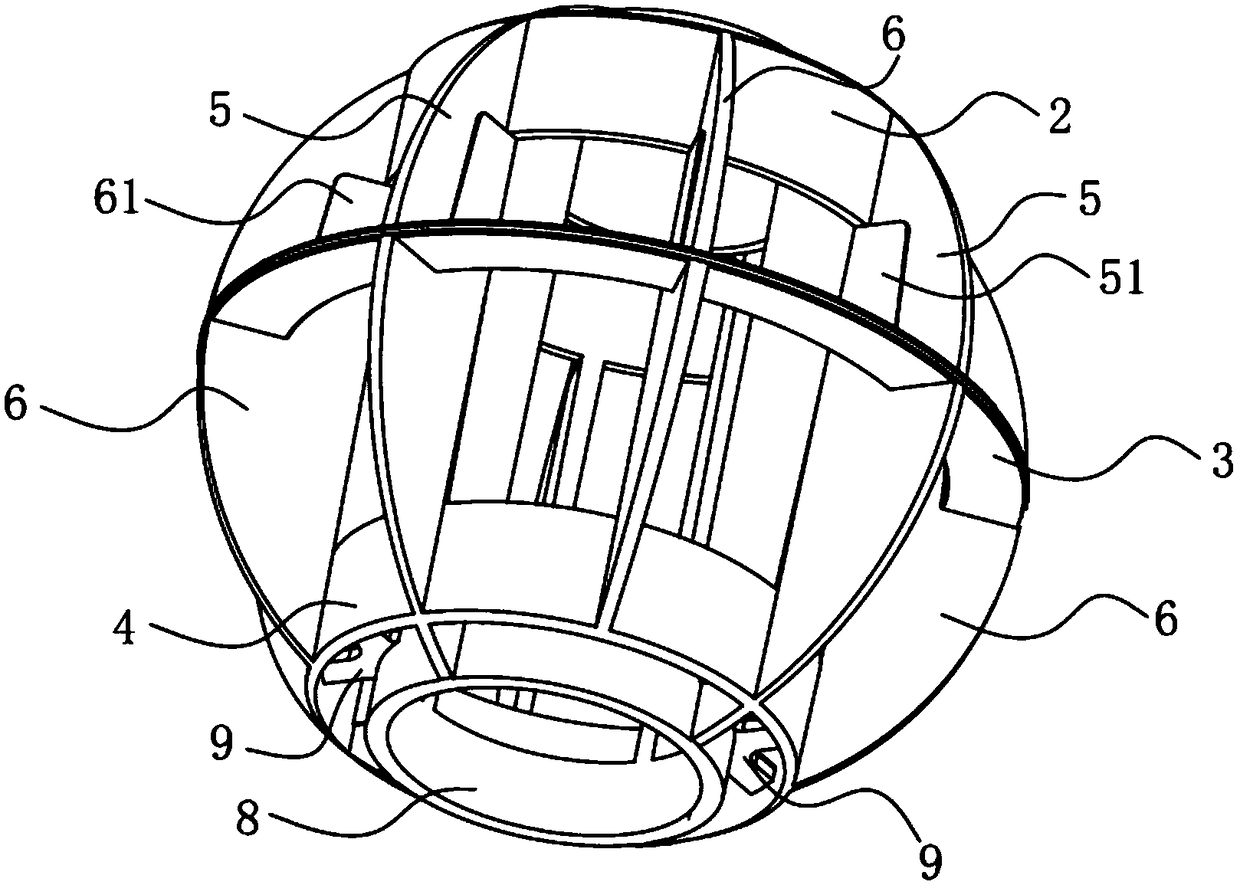

Non-metal explosion-proof ball

PendingCN108790801AReduce corner structureEase of mass productionContainer filling methodsUnderstructuresHigh volume manufacturingOil retention

The invention provides a non-metal explosion-proof ball to solve the problems that an existing non-metal explosion-proof ball is high in oil retention rate and difficult to produce in a large scale. The non-metal explosion-proof ball comprises an equatorial ring, a first reinforcing ring, a second reinforcing ring, a north pole ring, a south pole ring and a plurality of first longitude pieces; thenorth pole ring and the south pole ring are located on the two sides of the equatorial ring correspondingly, the first reinforcing ring is located between the north pole ring and the equatorial ring,and the second reinforcing ring is located between the south pole ring and the equatorial ring; the first reinforcing ring and the second reinforcing ring are both of a closed circular ring structure; and one ends of the first longitude pieces are connected to the north pole ring, the other ends of the first longitude pieces are connected to the south pole ring, and the middles of the first longitude pieces are sequentially connected with the first reinforcing ring, the equatorial ring and the second reinforcing ring. The non-metal explosion-proof ball provided by the invention is easy to produce in a large scale, the product injection molding yield can be improved, and meanwhile the oil retention rate can be reduced.

Owner:佳丰源(北京)科技发展有限公司

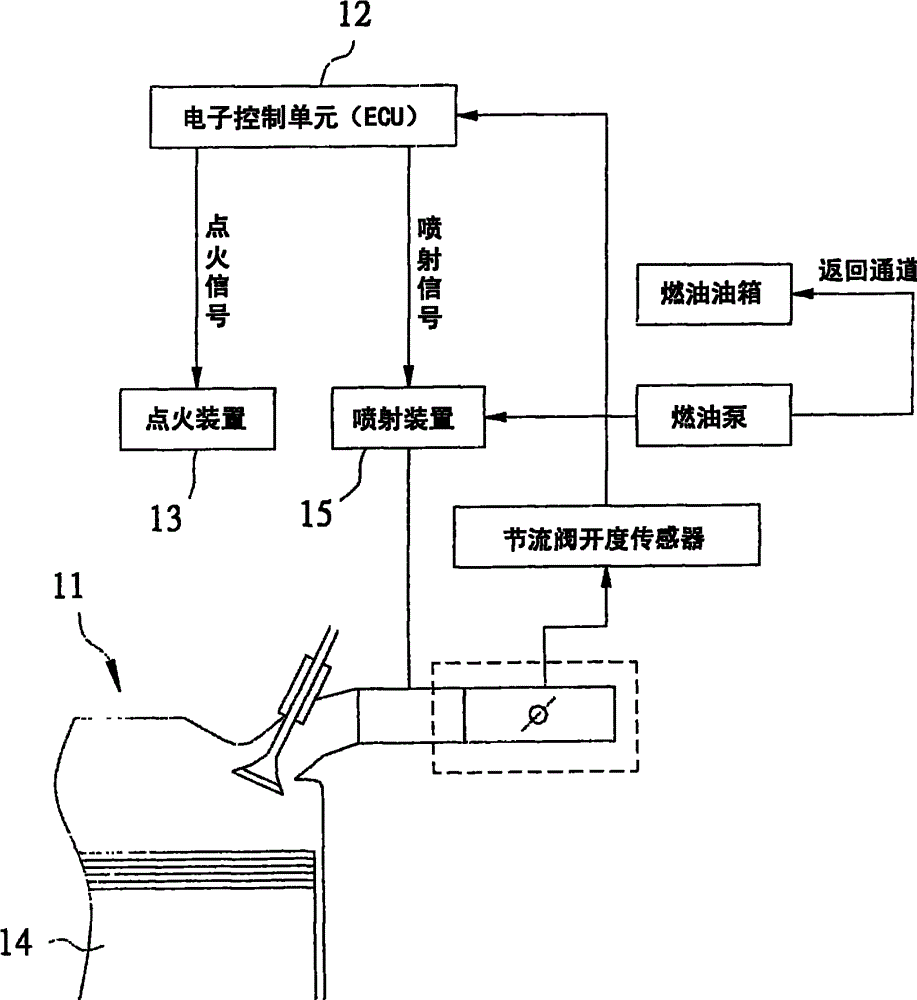

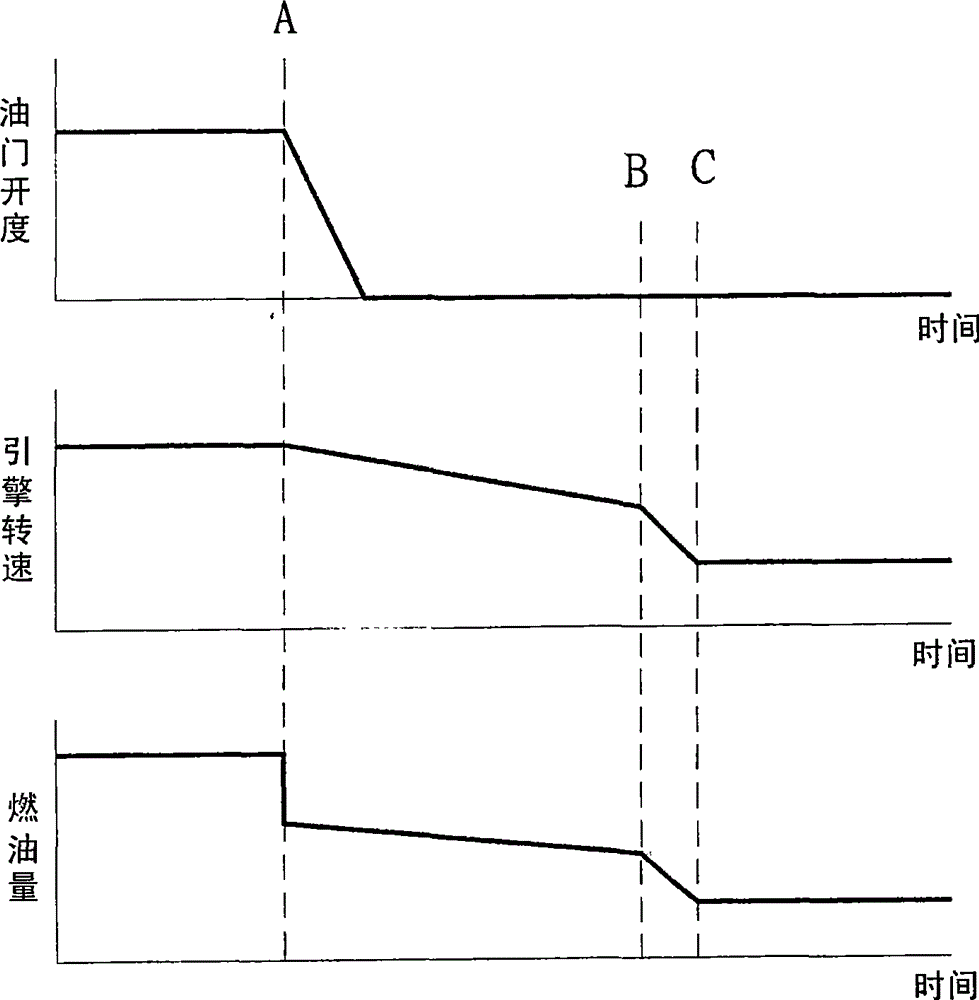

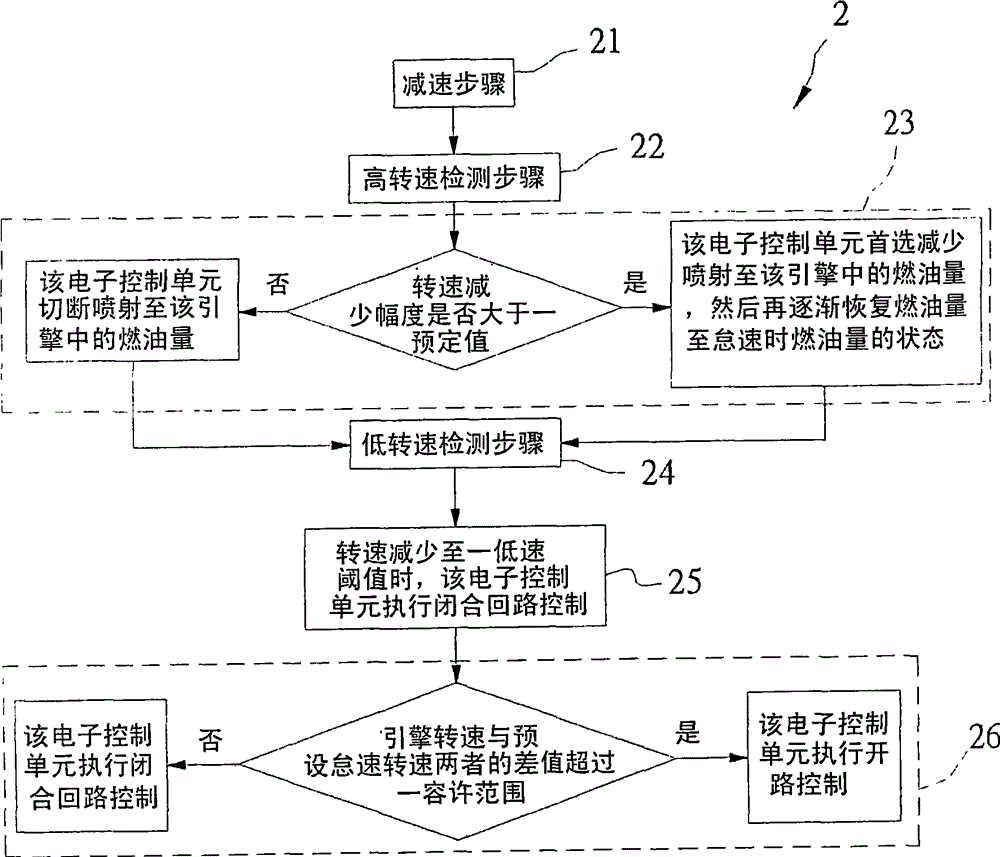

Reduced speed method of motorcycle injection type engines

InactiveCN101275493BReduce wasteAvoid stalled situationsElectrical controlMachines/enginesIdle speed controlJet engine

The invention relates to a speed reduction method for a jet engine of a motorcycle, comprising the steps of speed reducing, high rotating speed detecting, first controlling, low rotating speed detecting, second controlling and idle speed controlling. The reduction amplitude of the rotating speed of the engine is judged in the first controlling step, and then the fuel oil injection strategy for anelectronic control unit is determined, so that when the motorcycle slows down, no excessive fuel oil is injected into the engine, the fuel oil waste is effectively reduced, the exhaust pollution is lowered, and the oil sediment on an exhaust pipe is avoided; in addition, in the second controlling step and the idle speed controlling step, the amount of fuel oil injected to the engine is controlled, the case that engine flameout caused by lack of fuel oil in the process of speed reducing and speed idling is prevented, thus to effectively improve the ride marketability of the motorcycle.

Owner:KYMCO

Combined oil control ring

ActiveUS20180094726A1Preventing retention of oilGood effectPiston ringsMachines/enginesAutomotive engineControl function

To provide a combined oil control ring comprising a pair of upper and lower side rails and an axially corrugated spacer expander having upper and lower portions for automobile engines, which is capable of keeping an excellent oil-controlling function without sticking between a spacer expander and side rails even in a long period of engine operation, the upper and lower portions of the spacer expander have tabs pushing inner peripheral surfaces of the side rails, projections supporting the side rails, and intermediate portions between the tabs and the projections; each intermediate portion opposing the side rail has at least one groove extending in a substantially circumferential direction is recessed when viewed along a radial direction.

Owner:RIKEN CO LTD

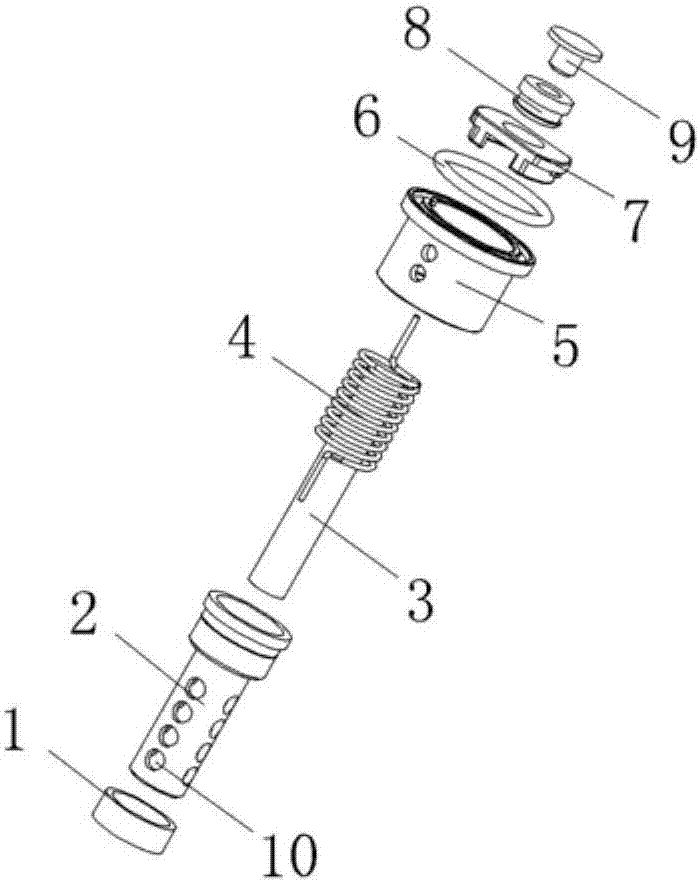

TUO atomization core

The invention discloses a TUO atomization core. The TUO atomization core comprises a heating wire casing and an oil guide pipe, oil guide cotton is connected with the inner cavity of the oil guide pipe in a sleeved mode, and the upper end of the outer surface of the oil guide pipe is in threaded connection with the heating wire casing; the top end of the oil guide pipe is in threaded connection with an atomization base, heating wires are connected with the inner cavity of the atomization base in a sleeved mode, the oil guide cotton is connected with the inner cavities of the heating wires in a sleeved mode, a cover plate is clamped at the top end of the atomization base, a reserved hole is formed in the top end of the cover plate, and an atomizing pin is connected with the inner cavity of the reserved hole in a sleeve mode. According to the TUO atomization core, the upper end of the outer surface of the oil guide pipe is in threaded connection with the heating wire casing, the top end of the oil guide pipe is in threaded connection with the atomization base, and through the function of the cover plate and the atomization pin, the demand of people for freely dissembling components of the atomized core can be met; the atomization core structure is simple and low in cost; when an atomization core is damaged and a customer needs to replace the atomization core, the expenditure of people is reduced.

Owner:DONGGUAN MAIANDUN ELECTRONICS TECH CO LTD

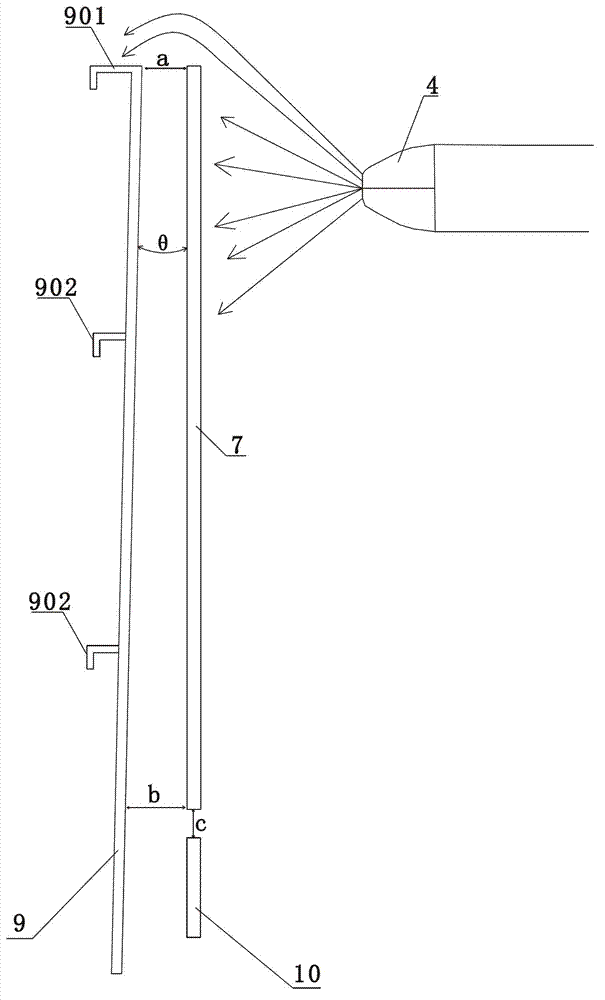

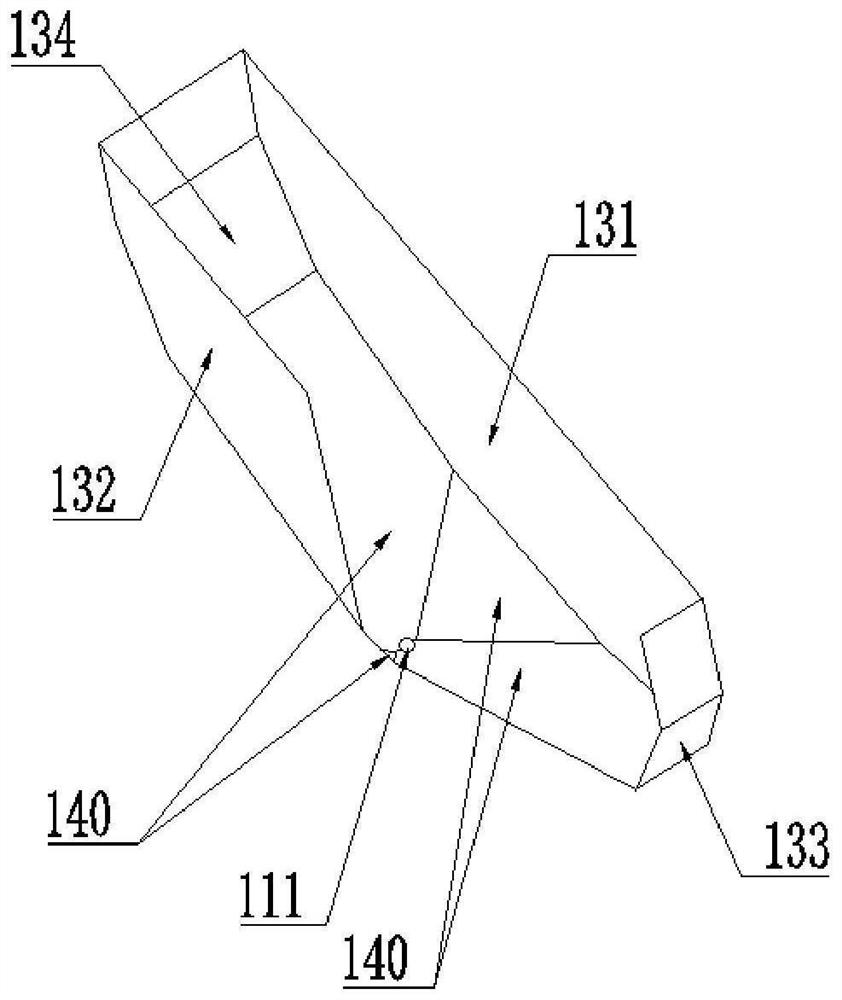

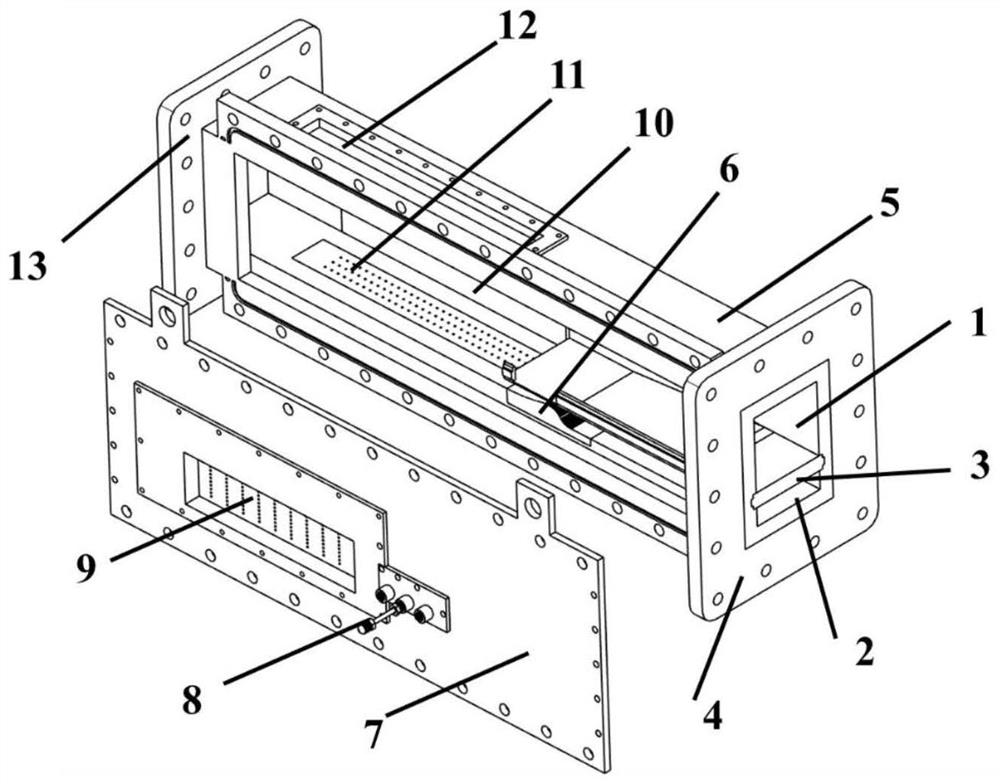

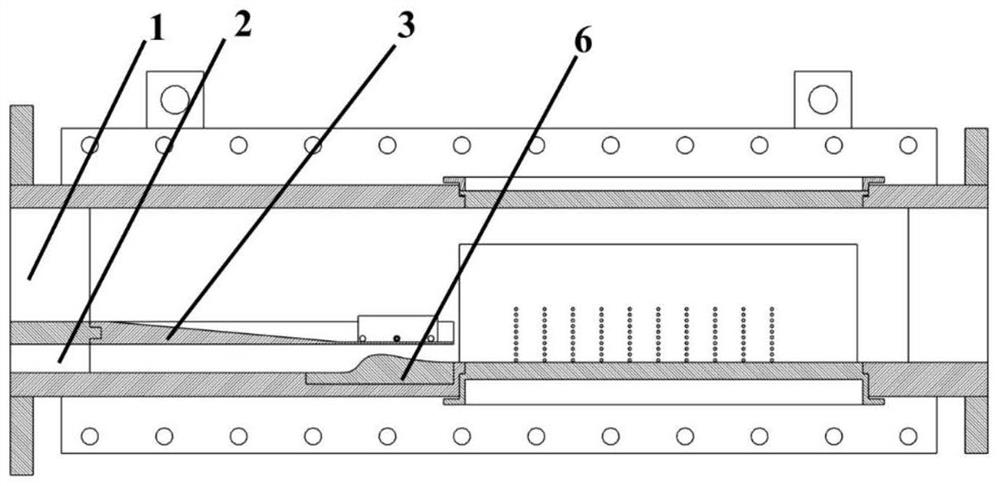

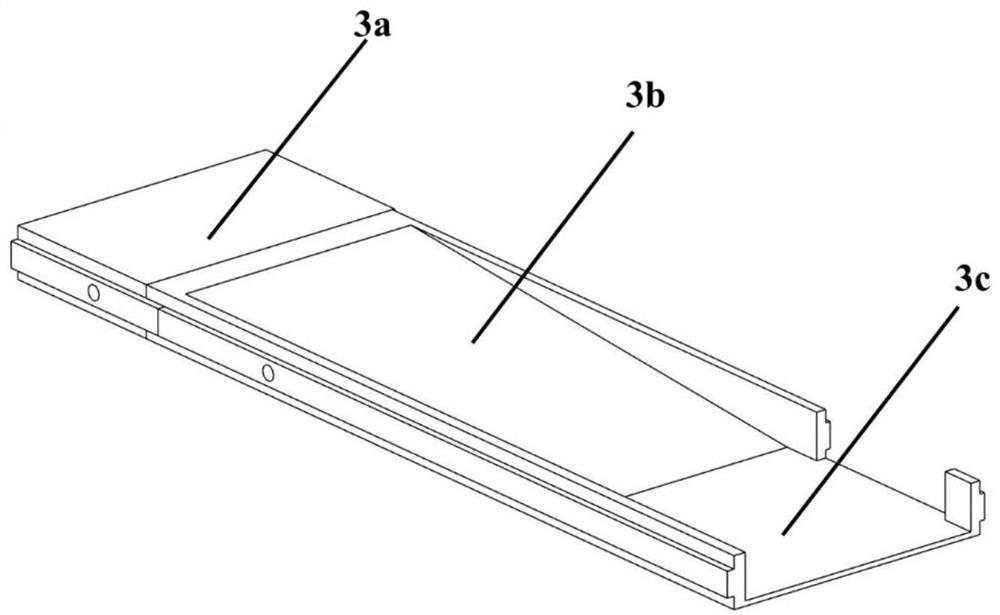

Fuel injection and atomization combustion test device suitable for large-gradient shear flow

InactiveCN112161812AChange spray angleControl Penetration DepthGas-turbine engine testingJet-propulsion engine testingAviationEngineering

The invention discloses a fuel injection and atomization combustion test device suitable for large-gradient shear flow, and relates to the technical field of aviation. The fuel injection and atomization combustion test device suitable for large-gradient shear flow comprises a mixing chamber main body 5, a subsonic flow channel 1, a supersonic flow channel 2, a support plate 3, a Laval nozzle 6, adirect injection type oil injection rod 8 and a cover plate 7, and a side wall surface optical measurement window 10 and an upper wall surface optical measurement window 12 which are used for shootingan oil mist field after fuel oil atomization, and a side wall surface temperature and pressure measurement point 9 and a lower wall surface temperature and pressure measurement point 11 which are used for measuring the temperature and pressure of the inner wall of the observation cavity, are arranged in an observation cavity. According to the designed mixing chamber, oil accumulation and coking can be effectively prevented, the atomization effect of liquid fuel is improved, and the problems that ignition is difficult, flames are unstable, and fuel is difficult to completely burn are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A shaft part lubrication structure, a shaft part lubrication system, and a sewing machine

ActiveCN113026234BFully lubricatedPrevent oil accumulationLubrication/cooling devicesWind energy generationOil intakeLubrication

Owner:JACK SEWING MASCH CO LTD

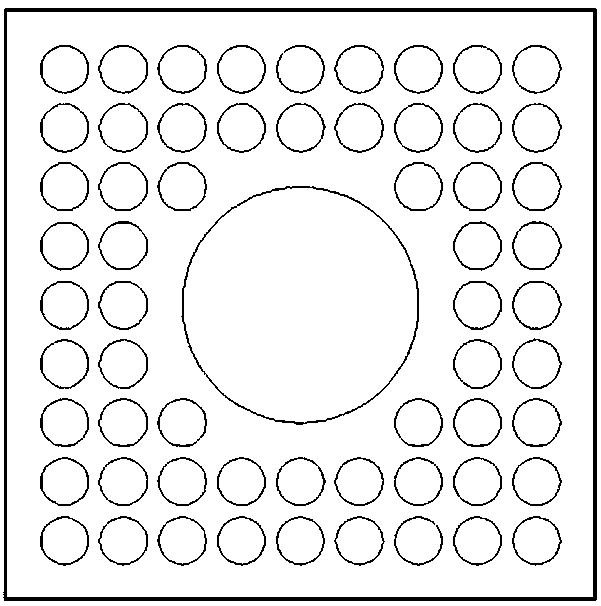

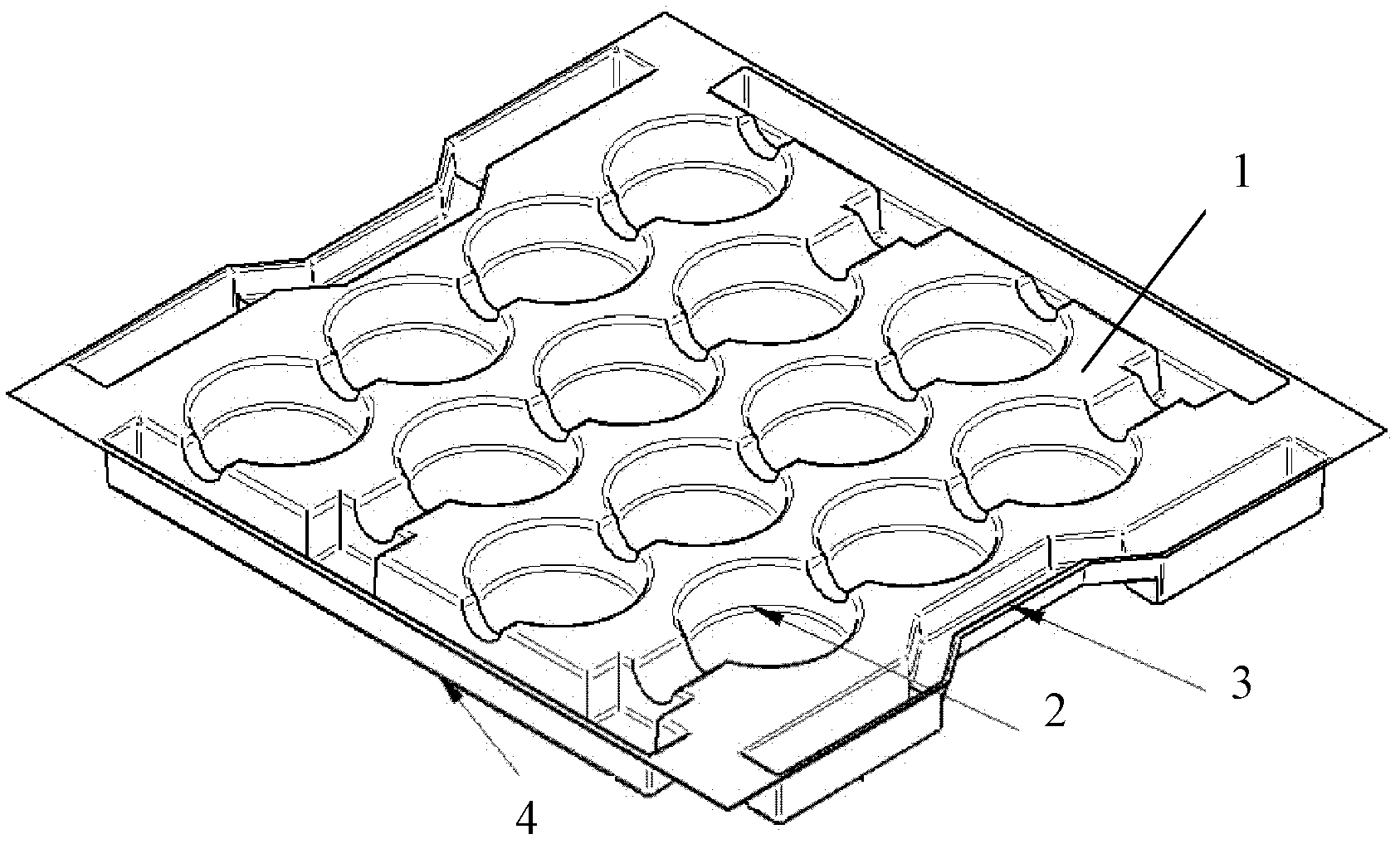

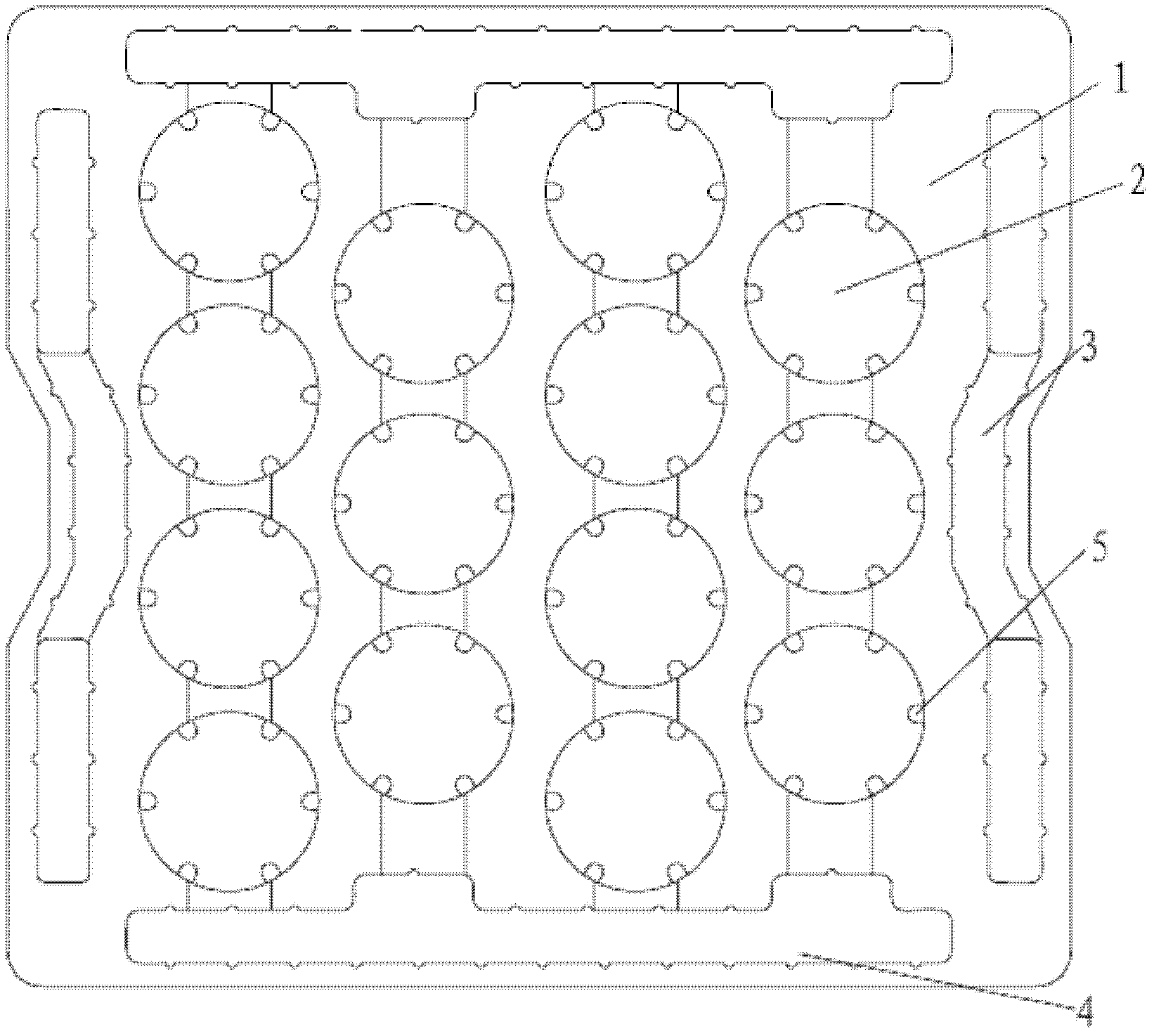

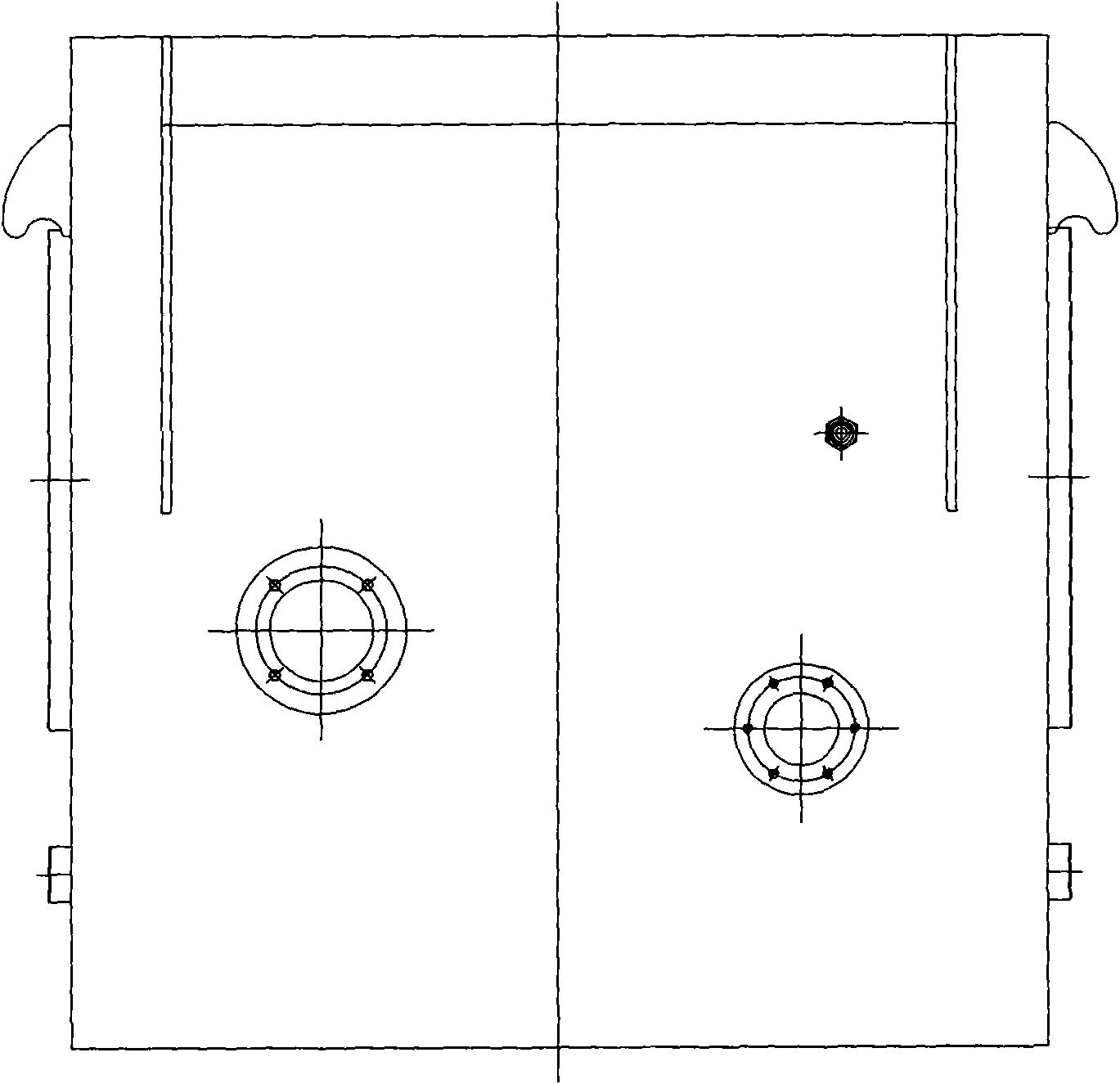

Blister tray for inner packing of bearing

InactiveCN102431722BPrevent oil accumulationImprove protectionRigid containersContainers with multiple articlesBlistersMechanical engineering

The invention discloses a blister tray for inner packing of a bearing. The blister tray is in a square shape; a plurality of small circular trays for putting bearings are distributed on a main boy position of the blister tray; bosses are integrally formed on the bottom parts of the circular trays; a pair of opposite sides of the blister tray is respectively provided with a concaved handle; and the other two sides of the blister tray, which are not provided with the handles, are respectively provided with a reinforcing rib.

Owner:江苏前程工业包装有限公司

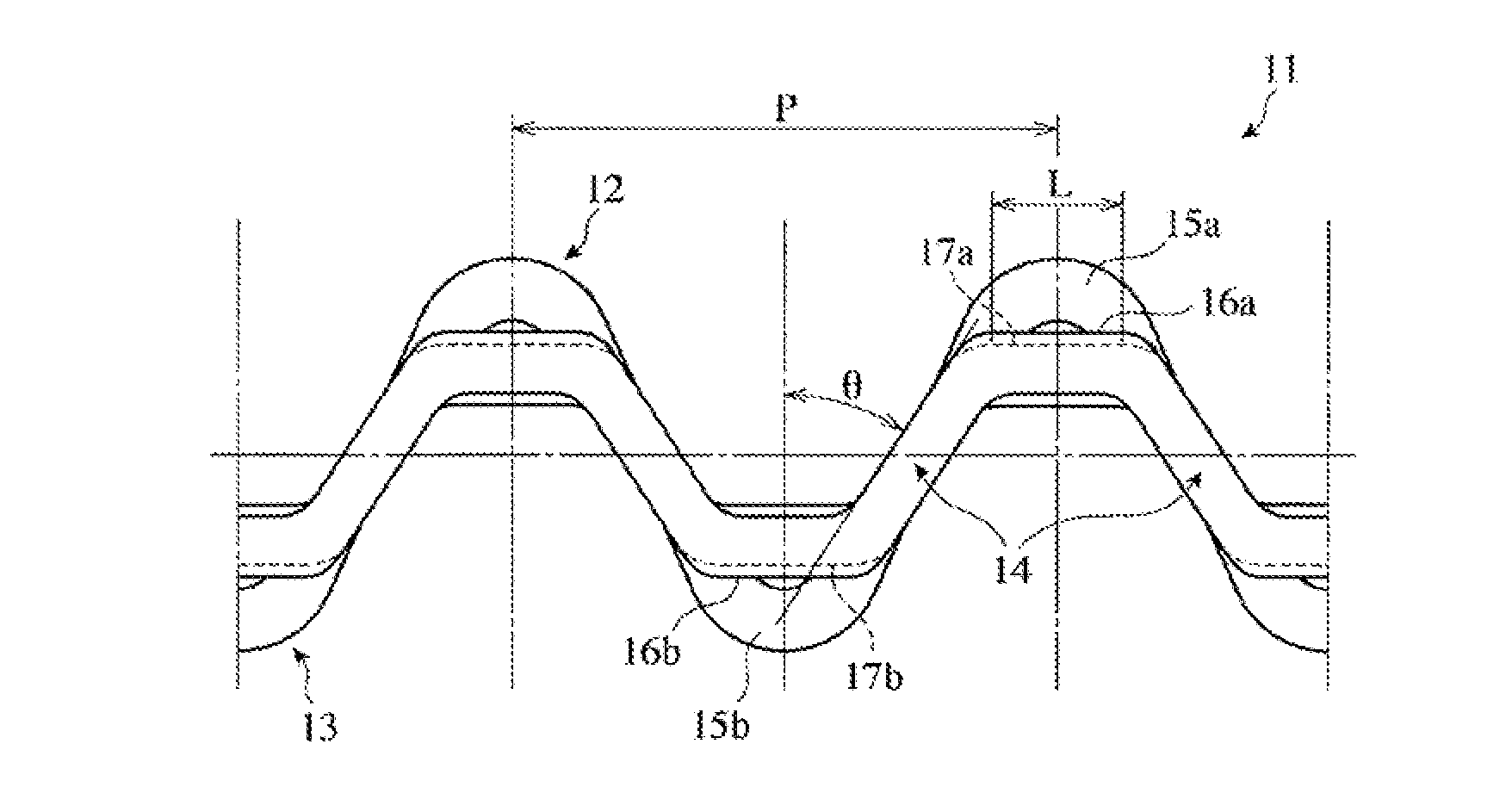

Combined oil control ring

ActiveUS10247306B2Solve the lack of durabilityInhibition retentionPiston ringsMachines/enginesEngineeringAutomotive engine

To provide a combined oil control ring comprising a pair of upper and lower side rails and an axially corrugated spacer expander having upper and lower portions for automobile engines, which is capable of keeping an excellent oil-controlling function without sticking between a spacer expander and side rails even in a long period of engine operation, the upper and lower portions of the spacer expander have tabs pushing inner peripheral surfaces of the side rails, projections supporting the side rails, and intermediate portions between the tabs and the projections; and each intermediate portion opposing the side rail has a center-raised bottom having a center-raised shape when viewed along a substantially circumferential direction center-raised shape and a radial direction.

Owner:RIKEN CO LTD

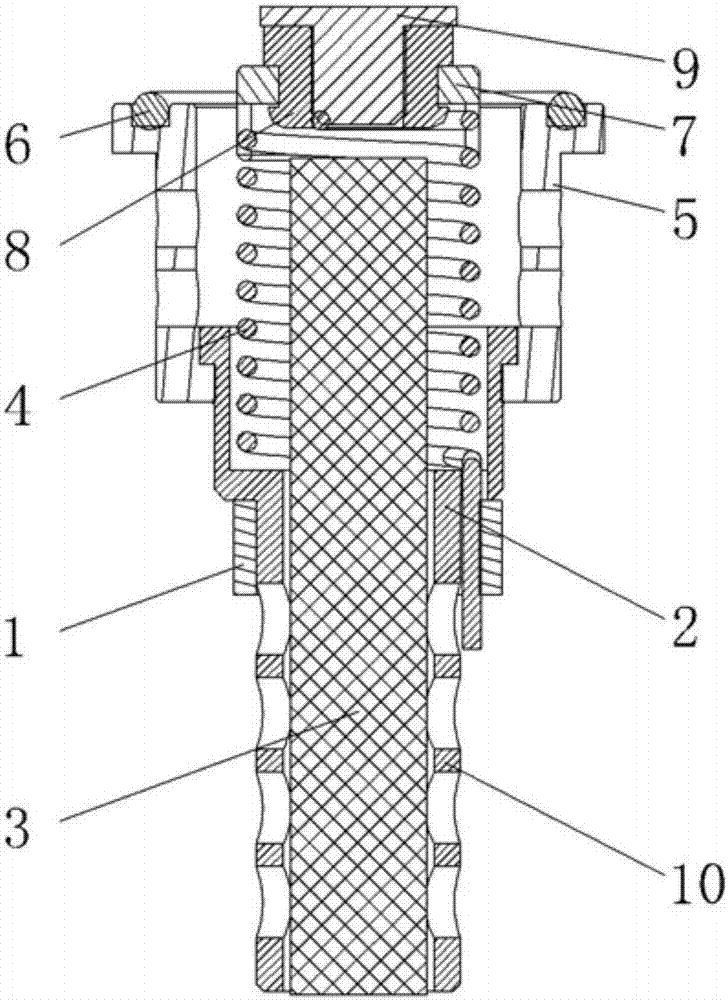

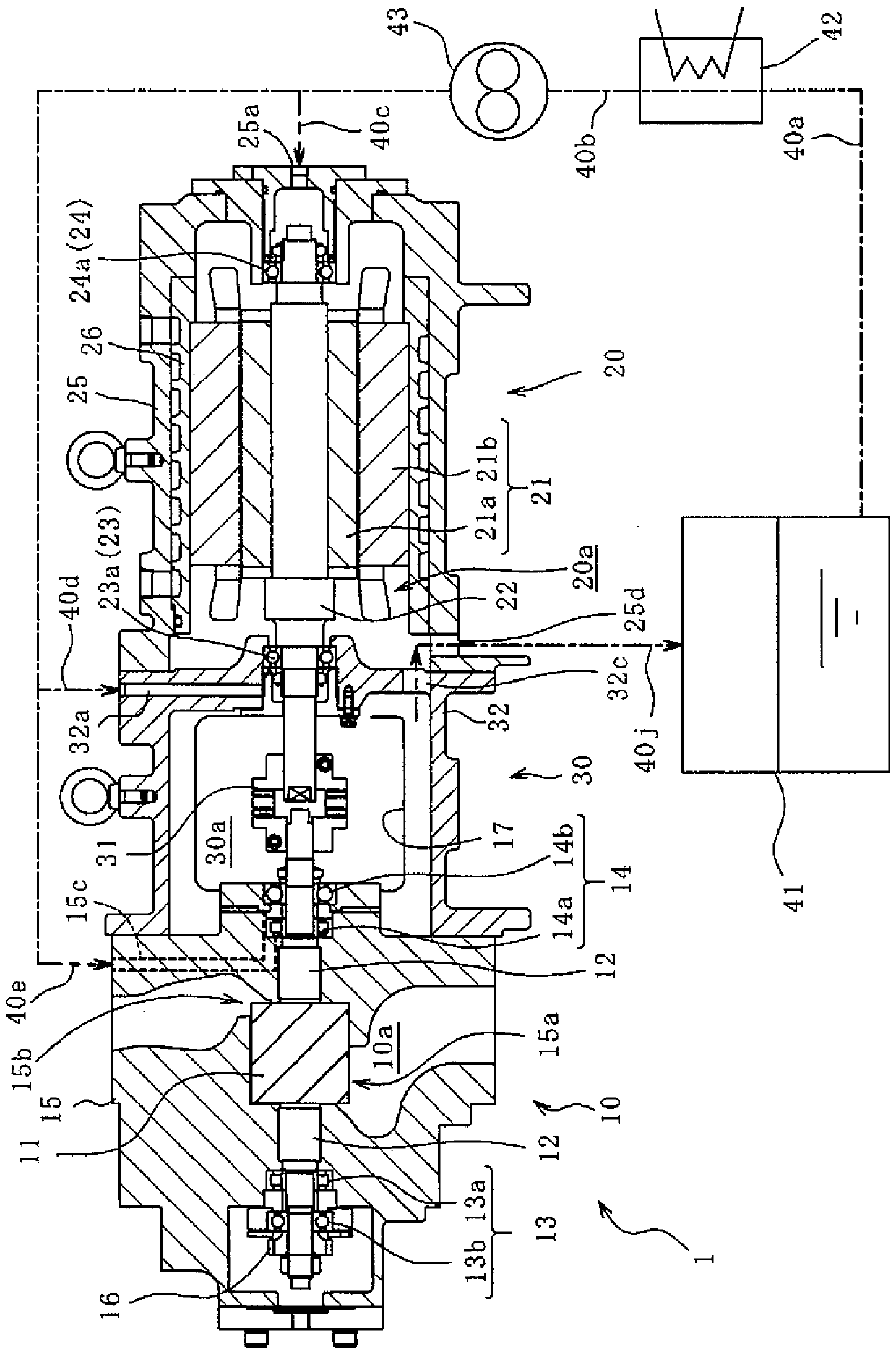

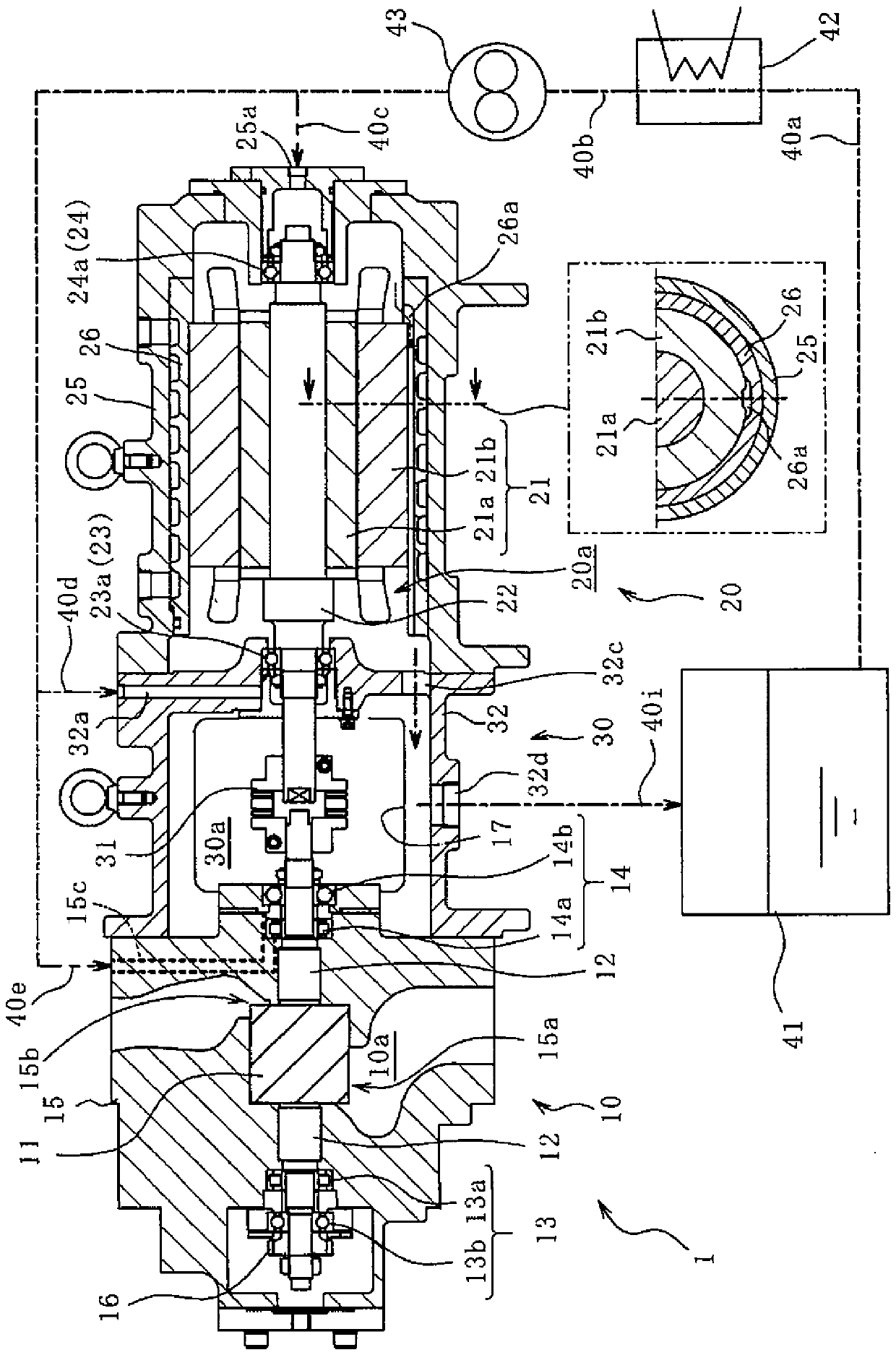

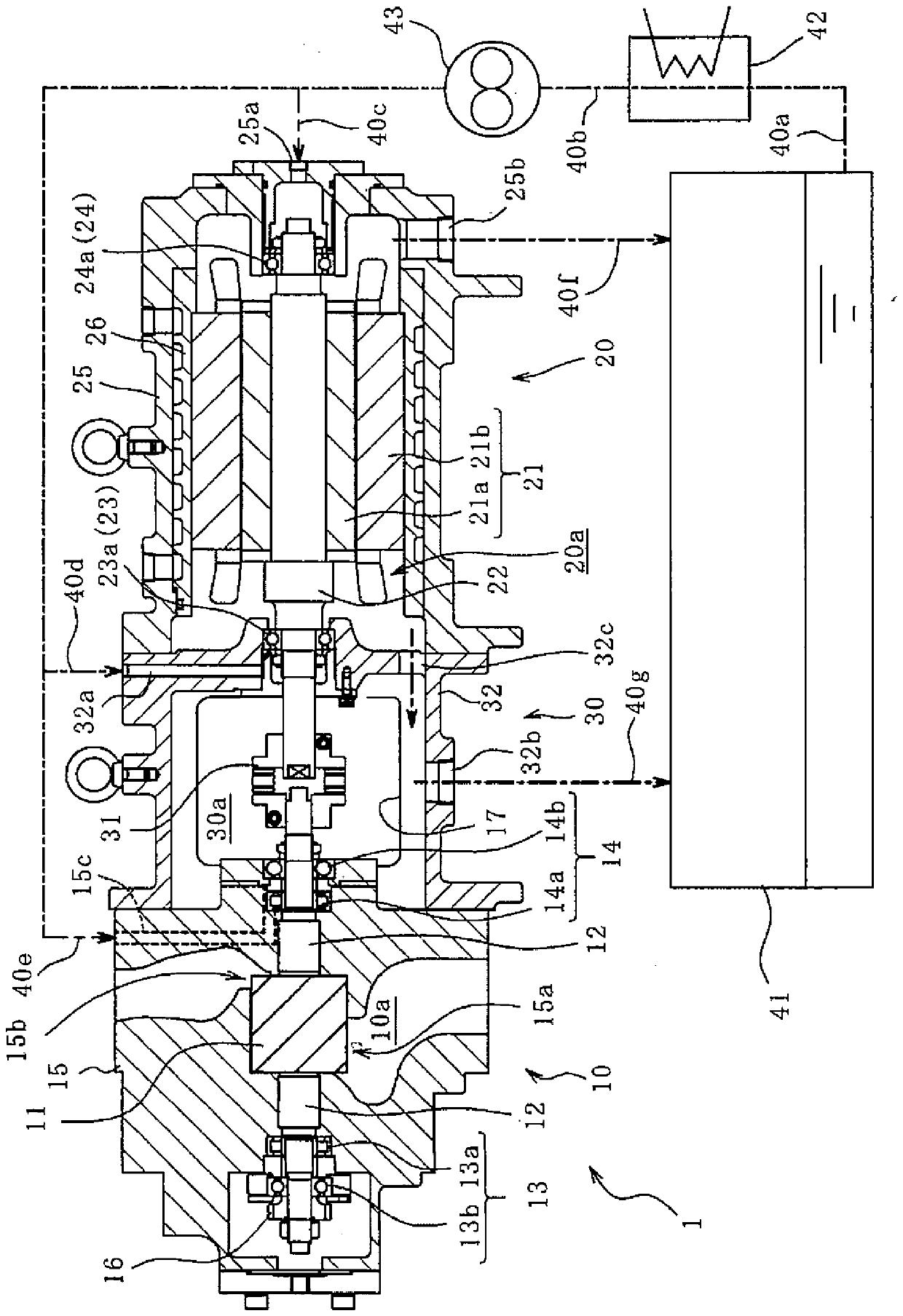

Oil-free screw compressor

ActiveCN109844320APrevent oil accumulationAvoid stockpilingRotary piston pumpsRotary piston liquid enginesFuel tankOil free

An oil-free screw compressor (1) is provided with: a screw rotor (11); a motor (21); a rotor casing (15) that defines a rotor chamber (10a); a motor casing (25) that defines a motor chamber (20a); a connection chamber (30a) provided between the rotor chamber (10a) and the motor chamber (20a); a communication part (32c) that connects the motor chamber (20a) and the connection chamber (30a); a second oil discharge port (32b) that discharges oil from the connection chamber (30a); and an oil line that forcibly circulates a lubricant oil by causing an oil pump (43) to flow the lubricant oil so as to supply the lubricant oil from an oil tank (41) to a second bearing (14), a third bearing (23), and a fourth bearing (24), and to return the lubricant oil to the oil tank (41) via a first oil discharge port (25b) and the second oil discharge port (32b).

Owner:神钢压缩机株式会社

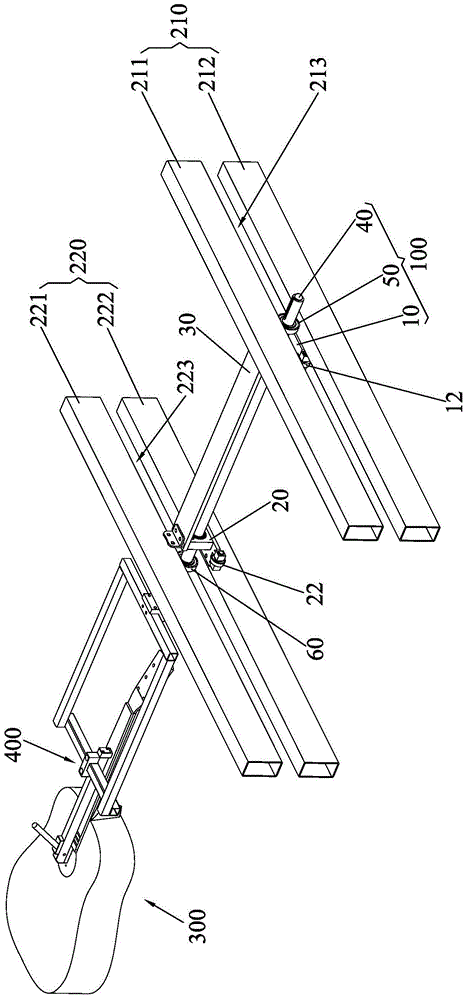

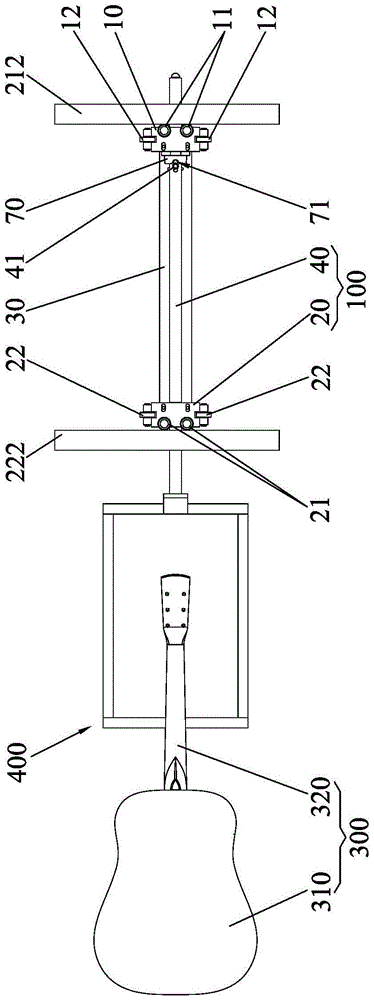

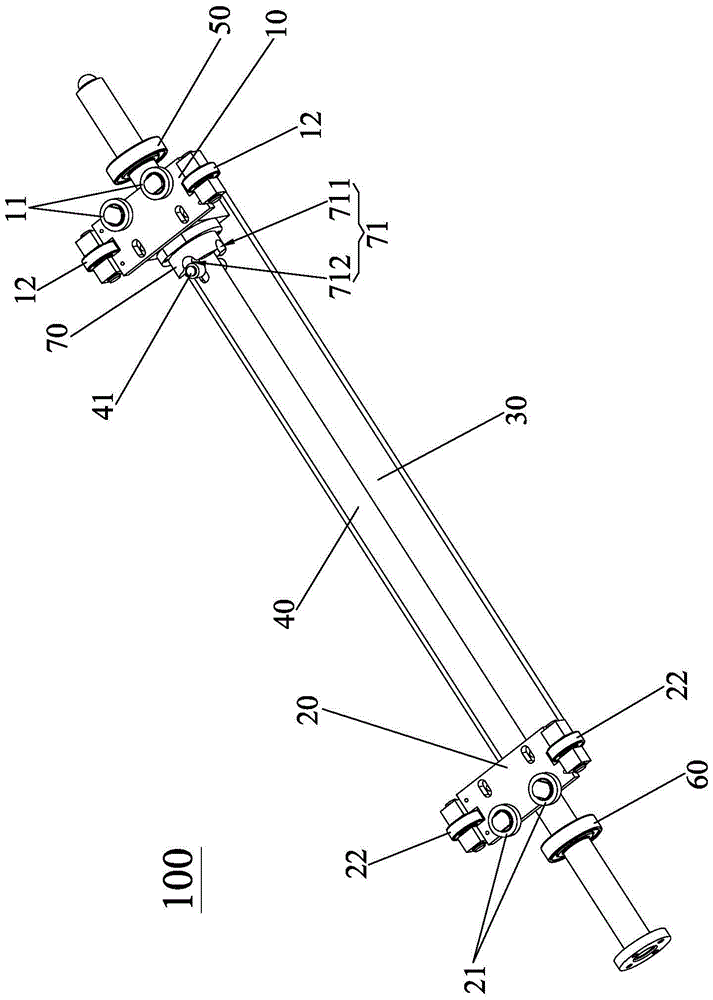

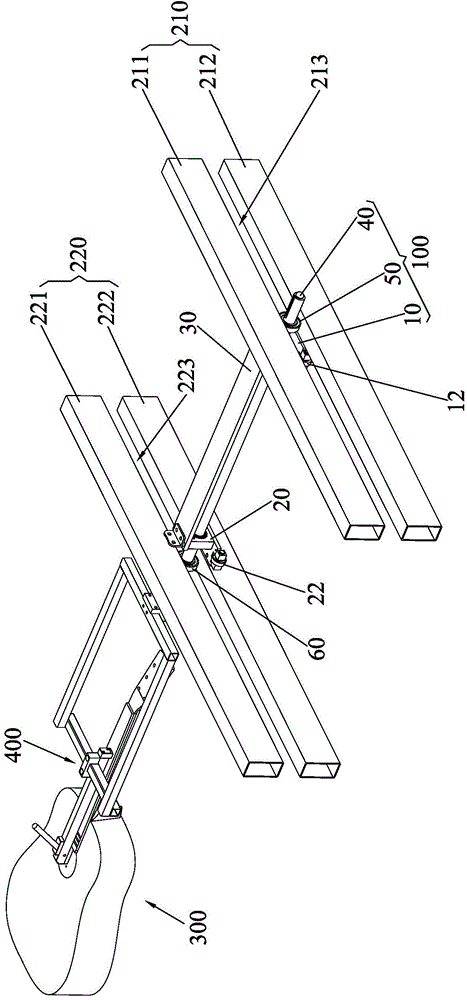

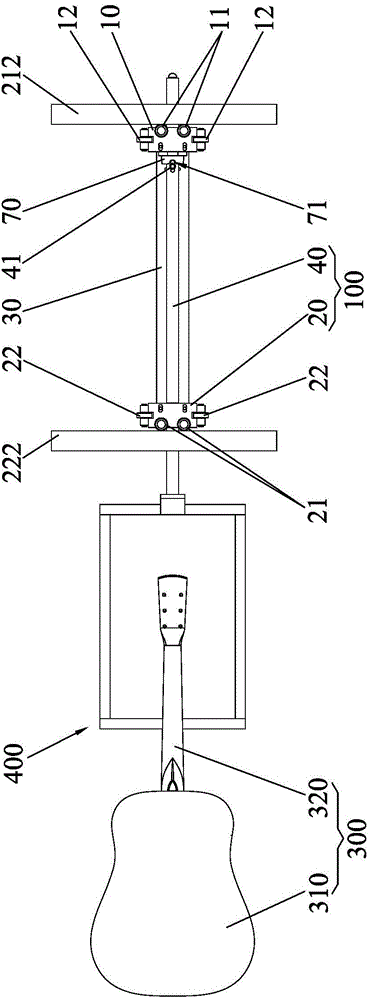

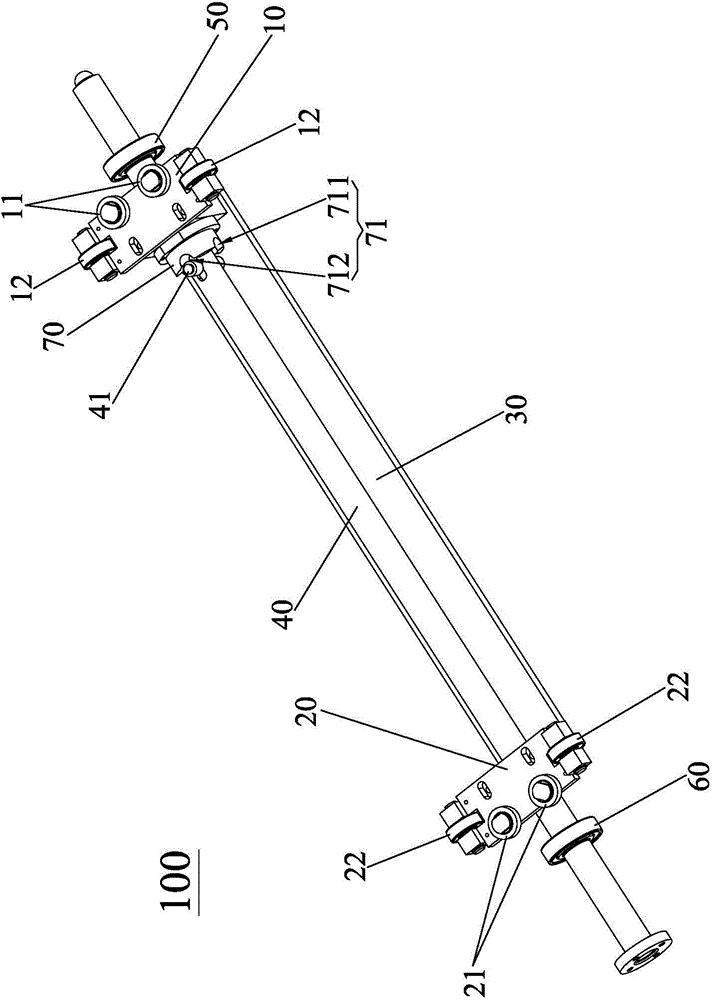

Running mechanism for guitar painting

ActiveCN104549919BPrevent tamperingReliable Horizontal Pan SwipeLiquid surface applicatorsCoatingsEngineeringGuitar

The invention discloses a running mechanism for guitar coating. The running mechanism comprises a first slide seat, a second slide seat, a connecting bracket, a rotary shaft, a first rolling wheel and a second rolling wheel, wherein the first slide seat is provided with a first horizontal wheel movably propped against an upper guide rail and / or a lower guide rail of first guide rails and a first vertical wheel contacted with an outside drive chain; the second slide seat is provided with a second horizontal wheel movably propped against an upper guide rail and / or a lower guide rail of second guide rails and a second vertical wheel contacted with the drive chain; a connecting bracket is fixed with the first slide seat and the second slide seat respectively; the rotary shaft penetrates through a first guide channel, the first slide seat, the second slide seat and a second guide channel and is pivoted with the first slide seat and the second slide seat respectively; a clamp is mounted at one end of the rotary shaft; the rotary shaft is sleeved with the first rolling wheel and the first rolling wheel is positioned in the first guide channel; the rotary shaft is sleeved with the second rolling wheel and the second rolling wheel is positioned in the second guide channel, so that a guitar frame body on the clamp always keeps horizontal translation on the guide rails.

Owner:广东创智智能装备有限公司

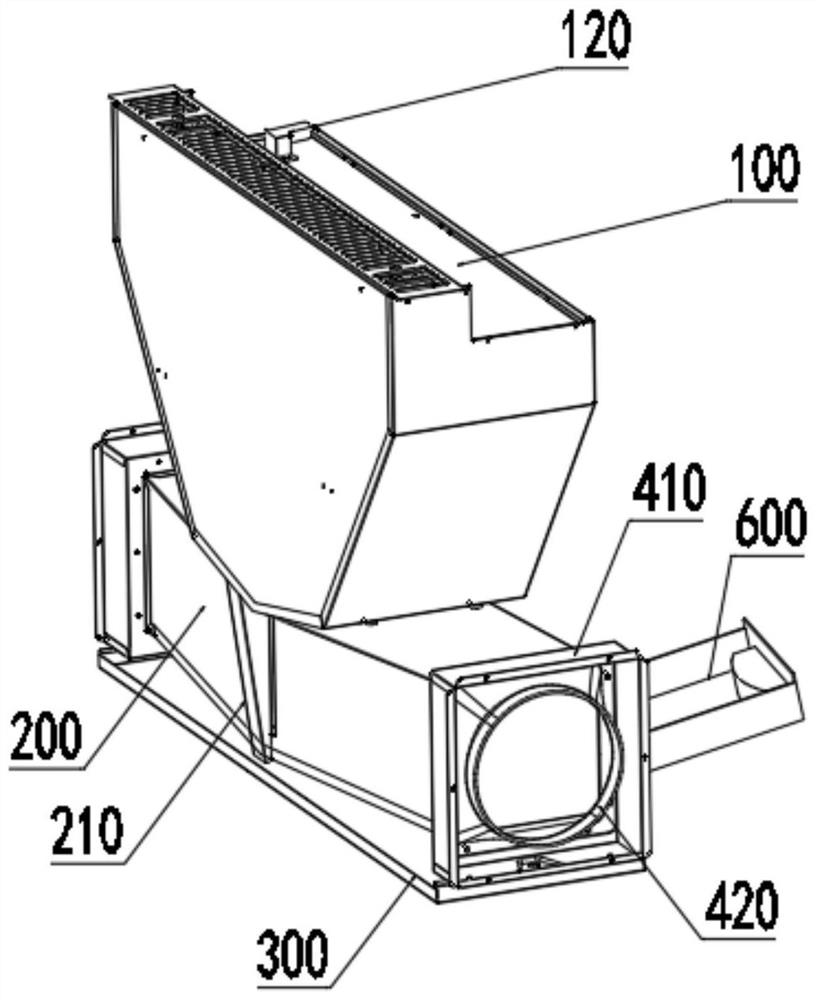

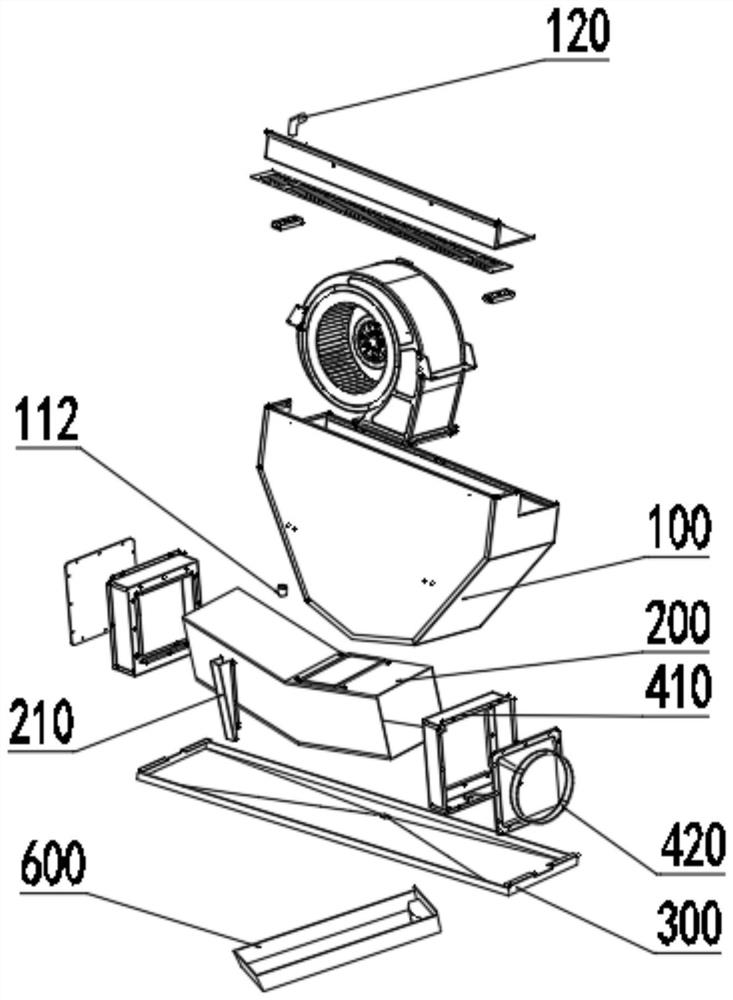

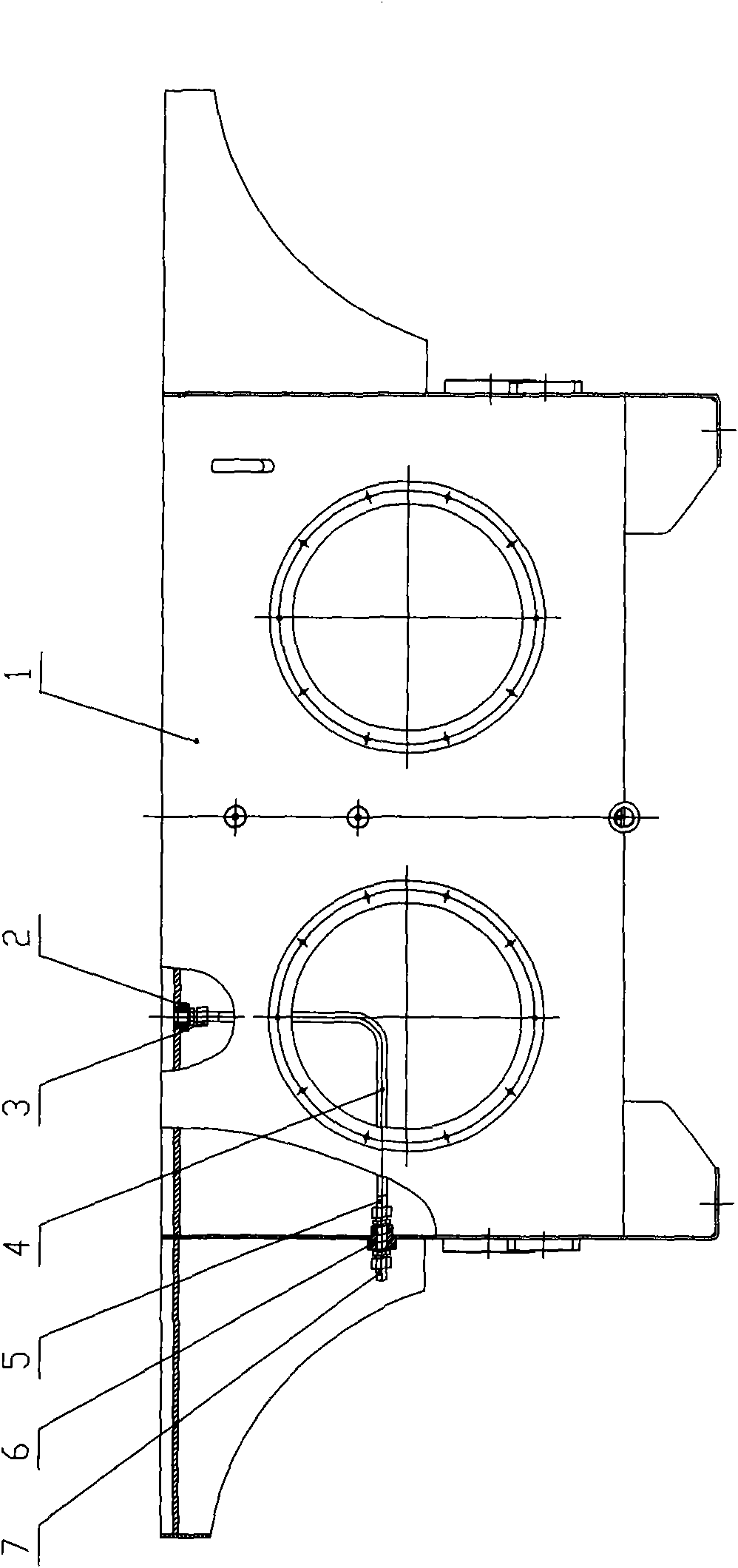

Oil-accumulation-free air guiding structure of range hood

ActiveCN104633735ALarge air volumeReduce noiseDomestic stoves or rangesLighting and heating apparatusImpellerInlet channel

The invention discloses an oil-accumulation-free air guiding structure of a range hood. The oil-accumulation-free air guiding structure comprises a wind bellow, multiple blades and an air guiding ring, wherein the blades are arranged in the wind bellow, the air guiding ring is installed in an air inlet channel; an inclined air guiding plane is formed in the inner side wall of the air guiding ring and the inclined direction of the air guiding plane points to the inner sides of the blades; and an oil discharging port is formed in the air guiding ring, so that the accumulated oil at the bottom of the wind bellow can be discharged.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

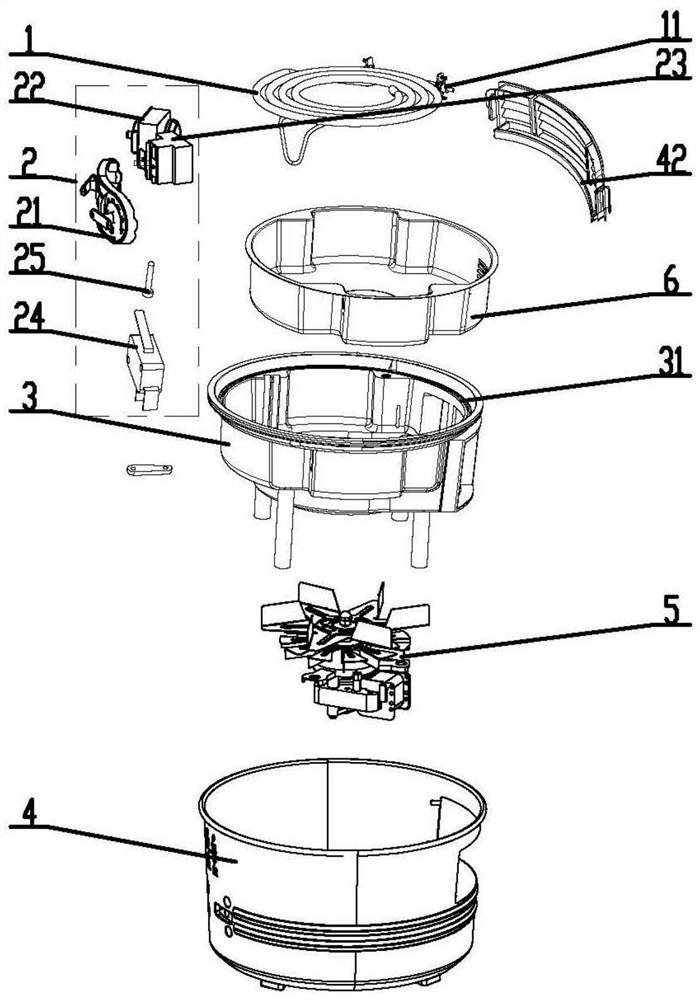

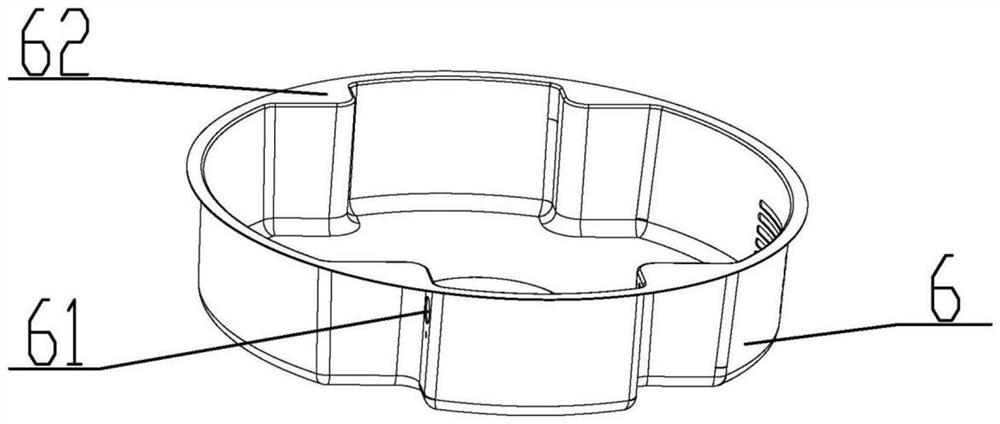

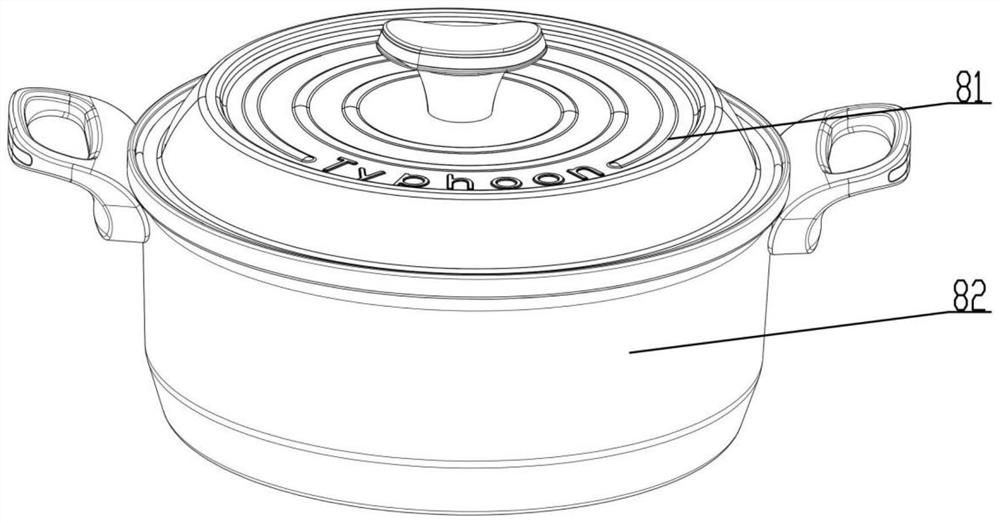

Multifunctional kitchenware

InactiveCN112315352AGood cooking effectEasy to installBoiling over preventionCooking-vessel lids/coversEngineeringFrying-pans

A multifunctional kitchenware comprises a base assembly, a stockpot cover, a stockpot body, a steamer, a steamer cover, a frying pan body and an air fryer assembly; the air fryer assembly comprises afood frame, an oil receiving tray and a sealing cover, the base assembly comprises a heating assembly, a fan assembly, a control assembly, a lower frame body and a base assembly, and the steamer coverand the steamer are matched to form an electric steamer. The base assembly, the stockpot cover and the stockpot body are arranged in a matched mode to form an electric stockpot, the base assembly andthe frying pan body are arranged in a matched mode to form an electric frying pan, and the base assembly, the sealing cover, the oil receiving tray and the food frame are arranged in a matched mode to form an air fryer. The electric steamer, the air fryer, the electric soup pot and the electric frying pan can be composed of different parts, the defect that most pots are single in function is overcome, and different cooking requirements of people are met; meanwhile, protrusions are arranged at the bottom of the food frame, a channel is provided for air circulation, and the cooking effect is better.

Owner:ZHEJIANG LETAI KITCHENWARE CO LTD

Rotor arrangement for a turbomachine and compressor

ActiveUS10519774B2Avoid accumulationReduce and eliminate oil accumulationPump componentsBlade accessoriesEngineeringMechanical engineering

Owner:MTU AERO ENGINES GMBH

Running mechanism for guitar coating

ActiveCN104549919APrevent tamperingReliable Horizontal Pan SwipeLiquid surface applicatorsCoatingsEngineeringGuitar

The invention discloses a running mechanism for guitar coating. The running mechanism comprises a first slide seat, a second slide seat, a connecting bracket, a rotary shaft, a first rolling wheel and a second rolling wheel, wherein the first slide seat is provided with a first horizontal wheel movably propped against an upper guide rail and / or a lower guide rail of first guide rails and a first vertical wheel contacted with an outside drive chain; the second slide seat is provided with a second horizontal wheel movably propped against an upper guide rail and / or a lower guide rail of second guide rails and a second vertical wheel contacted with the drive chain; a connecting bracket is fixed with the first slide seat and the second slide seat respectively; the rotary shaft penetrates through a first guide channel, the first slide seat, the second slide seat and a second guide channel and is pivoted with the first slide seat and the second slide seat respectively; a clamp is mounted at one end of the rotary shaft; the rotary shaft is sleeved with the first rolling wheel and the first rolling wheel is positioned in the first guide channel; the rotary shaft is sleeved with the second rolling wheel and the second rolling wheel is positioned in the second guide channel, so that a guitar frame body on the clamp always keeps horizontal translation on the guide rails.

Owner:广东创智智能装备有限公司

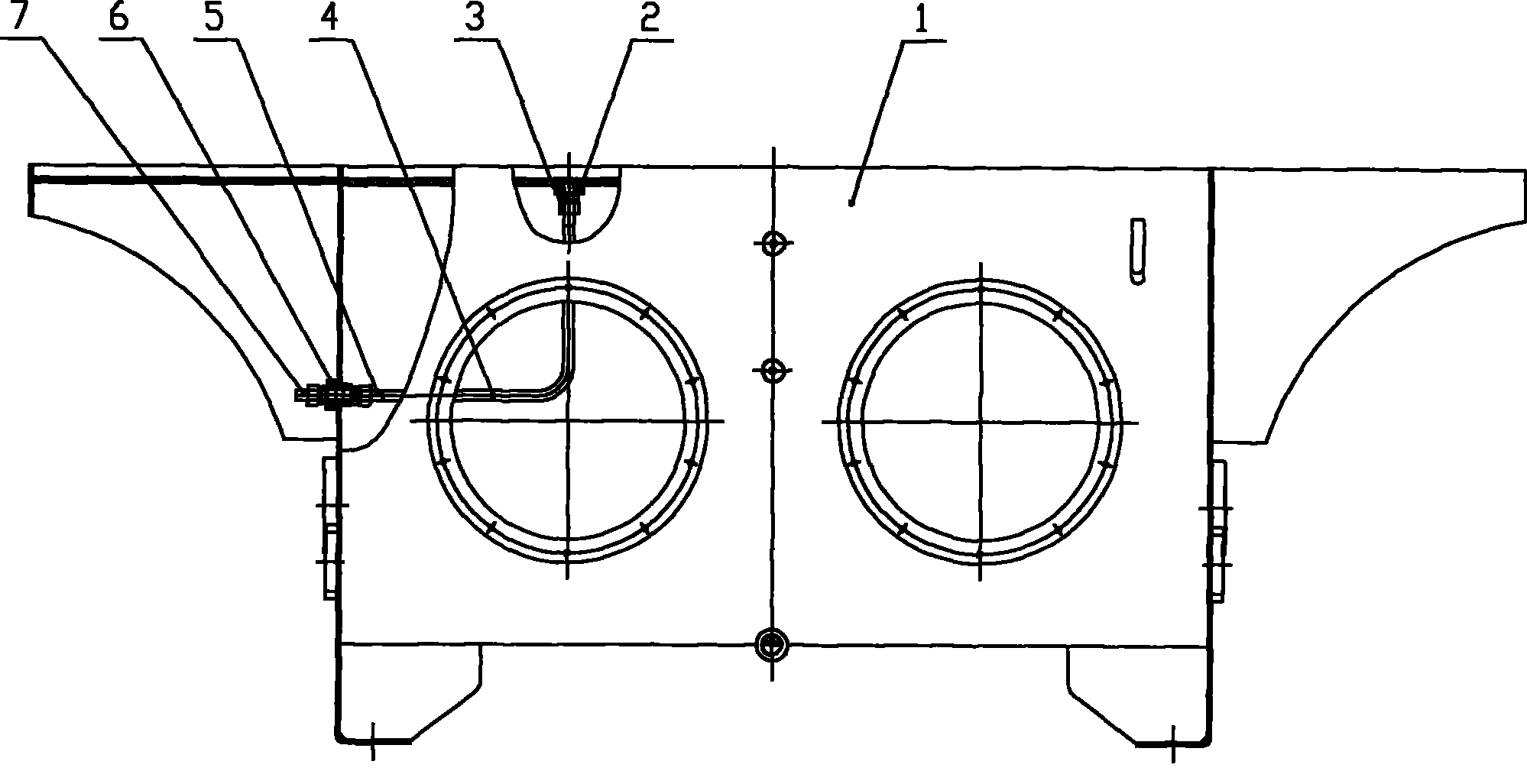

Oil collector for hydraulic oil tank of roll bending hydraulic station

InactiveCN101782086ASimple structurePrevent oil accumulationMetal rolling stand detailsPump assembliesSteel tubeSystem maintenance

The invention relates to an oil collector for a hydraulic oil tank of a six-roller cold mill hydraulic system. The oil collector comprises a hydraulic oil tank, an internal thread joint, a first through joint, a steel tube, a second through joint, a joint body and a third through joint. The internal thread joint is welded on the top of the hydraulic oil tank. The joint body is welded on the side face of the hydraulic oil tank so as to facilitate arranging a hydraulic tube joint. The steel tube is bent into 90 degrees, and the first through joint and the second through joint are welded on two sides of the steel tube respectively. The first through joint and the second through joint are welded on the top and on the side face of the hydraulic oil tank respectively. The third through joint is also arranged outside the joint body on an external plate of the hydraulic oil tank, so that the hydraulic oil on the top of the oil tank is led to an oil drum. The oil collector for the hydraulic oil tank has the advantages of avoiding oil accumulation on the top of the oil tank, easily leading the hydraulic oil into the oil drum and lightening the workload for system maintenance, along with simple, compact and reasonable structure.

Owner:WUXI WUYE METAL ROLLING

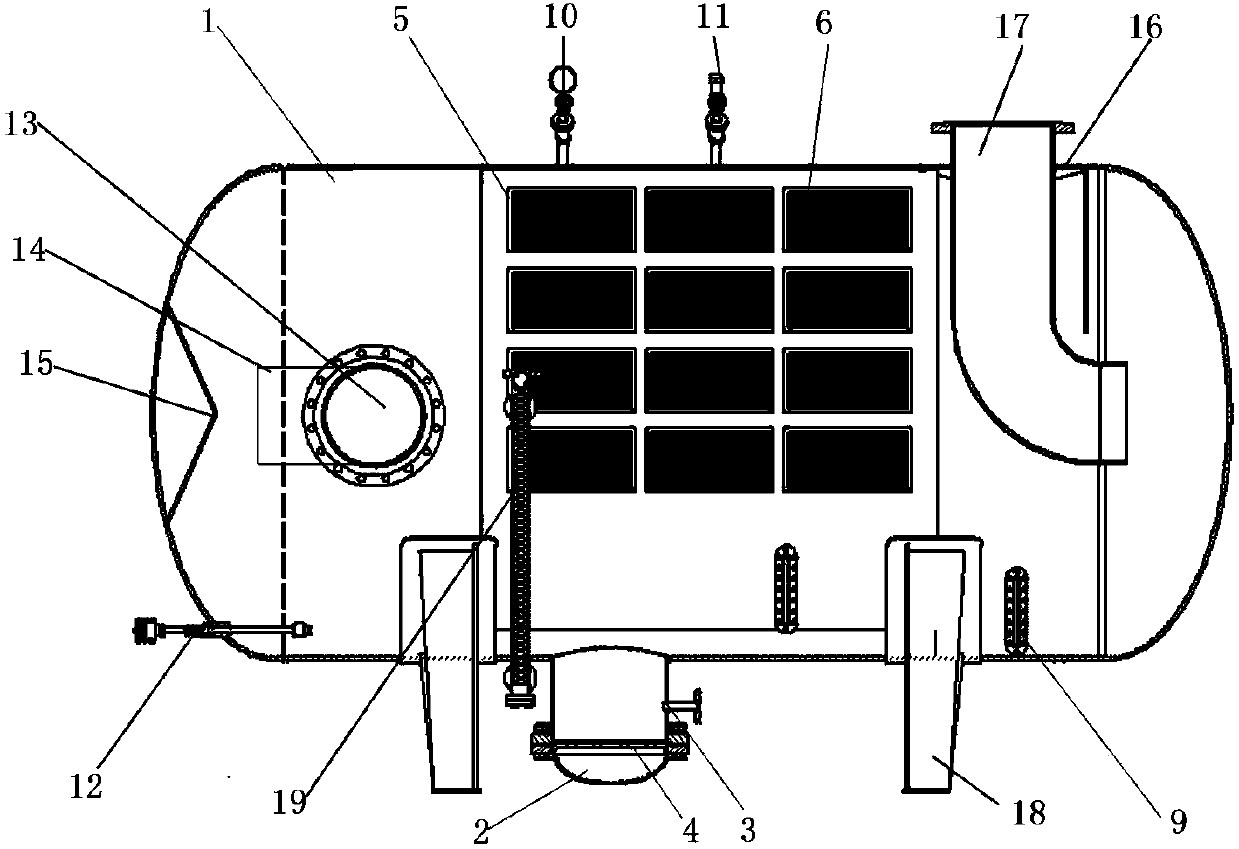

Oil-gas separation device of screw expander

PendingCN107676135AEasy to separateAvoid remixingDispersed particle separationMachines/enginesOil separationExhaust pipe

The invention discloses an oil-gas separation device of a screw expander, and relates to the screw expander. The oil-gas separation device of the screw expander comprises a tank; an oil storage bag isfixed at the bottom of the tank; a blade separator is fixed in the tank; the oil storage bag is provided with an oil outlet, and a seal is arranged at the bottom; the blade separator comprises bladesand an oil guide tank fixed on a frame; the frame and the tank are welded in a Z form; an oil return hole is formed in the tank on the lowermost side of the frame below an oil level; an oil viewing mirror is arranged on the outer wall of the tank, a pressure gauge and a safety valve are arranged at the top, and a thermal resistor is mounted on the lower side; an oil-gas inlet is formed in the side wall of the middle part of the tank; a liquid inlet pipe communicates into the tank from the oil-gas inlet, and the tail end is corresponding to the center of the seal of the tank; a flow separatoris arranged in the center position of the seal; an exhaust port is formed in the top of the tank; an exhaust pipe communicates into the tank from the exhaust port; and the tail end is positioned on aseal on the other side of the tank. The oil-gas separation device of the screw expander is compact in structure, easy to install, stable in performance and excellent in oil separation effect, and canbe widely applied to an oil-gas separation system of the screw expander for ORC afterheat power generation.

Owner:SHANXI YITONG ENVIRONMENTAL ENERGY TECH GROUP

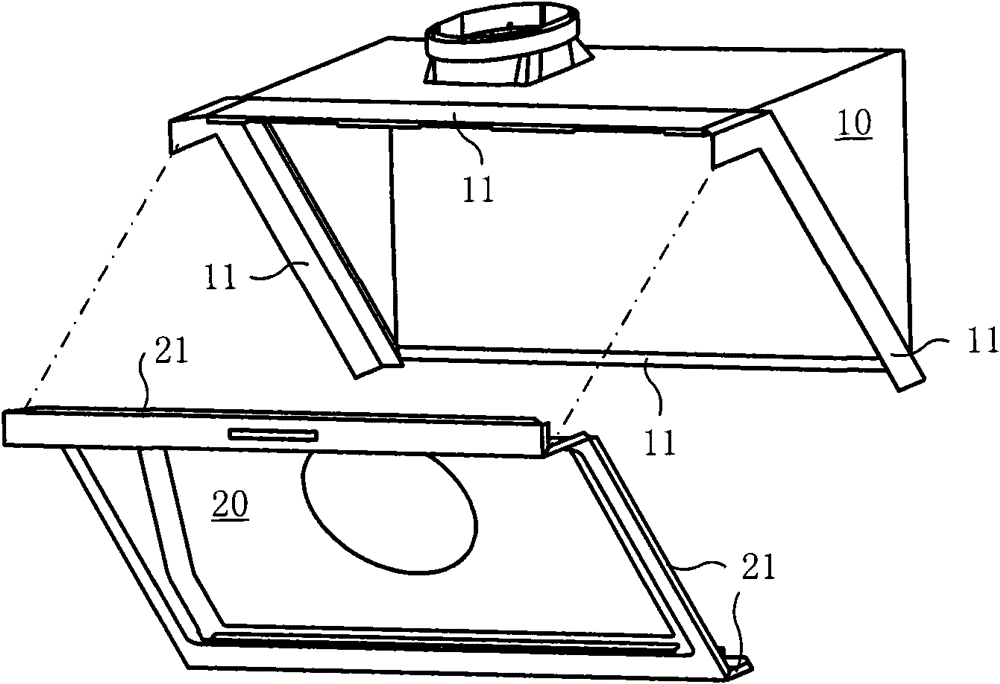

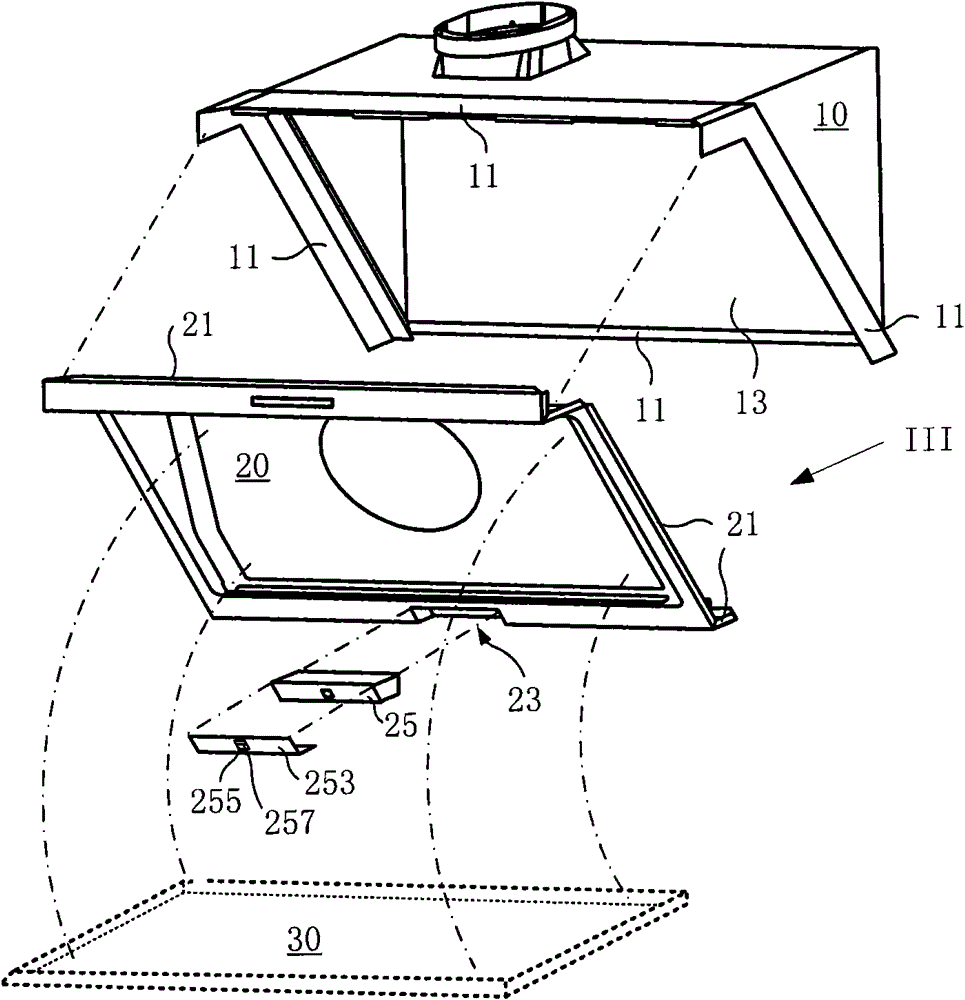

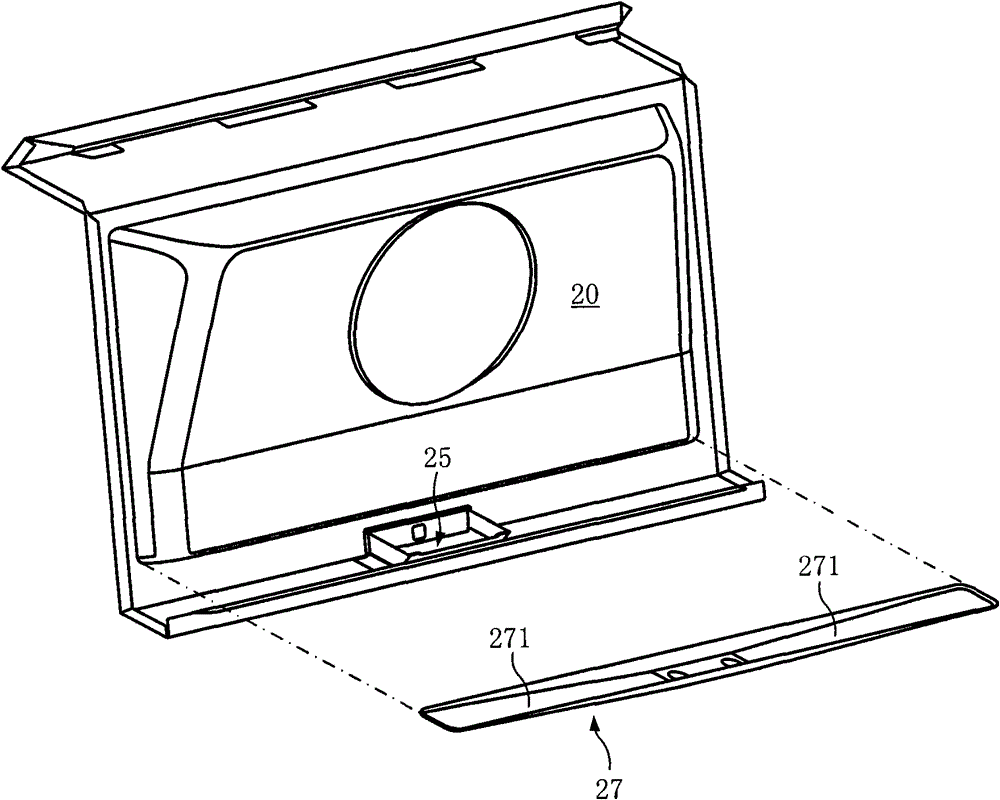

Method for manufacturing range hood and range hood

ActiveCN102444924BPrevent oil accumulationAvoid ignition safety issuesDomestic stoves or rangesLighting and heating apparatusMechanical engineeringIndustrial engineering

The invention provides a manufacturing method of a rang hood. The manufacturing method comprises the following steps: obtaining a smoke collecting hood (20) through molding integration; and connecting shell frames (11) of the rang hood with a smoke collecting hood frame (21) in a welding manner without a gap between the smoke collecting hood frame (21) and the shell frames (11). The invention also provides the rang hood manufactured by using the manufacturing method of the same. By using the rang hood and the manufacturing method thereof, the molding integration of the smoke collecting hood effectively avoids the problem that a joint slot in the structure of the existing smoke collecting hood causes accumulation of greasy dirt in service; and meanwhile, a welded method is used for installing the smoke collecting hood on shells and polishing traces left by welding, thereby effectively avoiding the problem that greasy dirt is accumulated in the gap connecting the smoke collecting hood with the shells.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

A spark plug capable of preventing carbon deposition on the surface of electrode machine

ActiveCN111146692BInhibit carbon depositionPrevent sticking carbon depositsSparking plugsCamCarbon deposition

The invention discloses a spark plug capable of preventing carbon deposition on the surface of an electrode machine. It includes a shell, and heat insulation cylinders are fixedly connected to both sides of the shell. The opposite side is provided with a liquid blocking block, the bottom of the rotating cam is rotatably connected with a blocking plate, the top of the housing is interspersed with an outlet pipe, and the side of the suction wheel is meshed with a receiving gear rod, so The inner left wall of the casing is fixedly connected with a side electrode, the inner top wall of the casing is fixedly connected with a central electrode, the side of the central electrode is fixedly connected with a heating wire, and the bottom of the heating wire is provided with a water tank, so The bottom of the water tank is slidably connected with a pressure rod, and the bottom of the pressure rod is connected with a bifurcated rod, which can prevent the spark plug of the surface of the electrode machine from being carbonized. The effect of preventing the electrode from being attached to carbon deposits.

Owner:徐州奥纳富霖电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com