Patents

Literature

57results about How to "Change spray angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

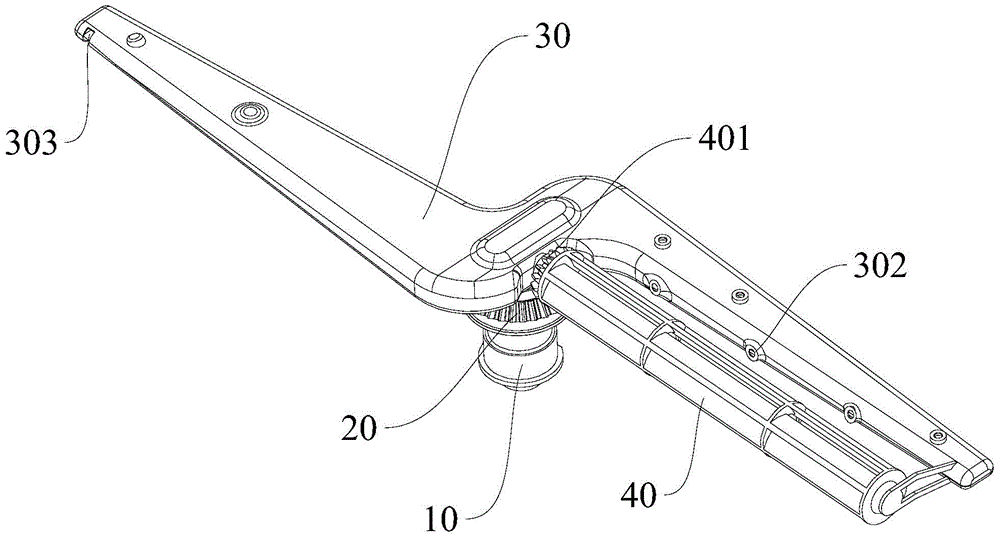

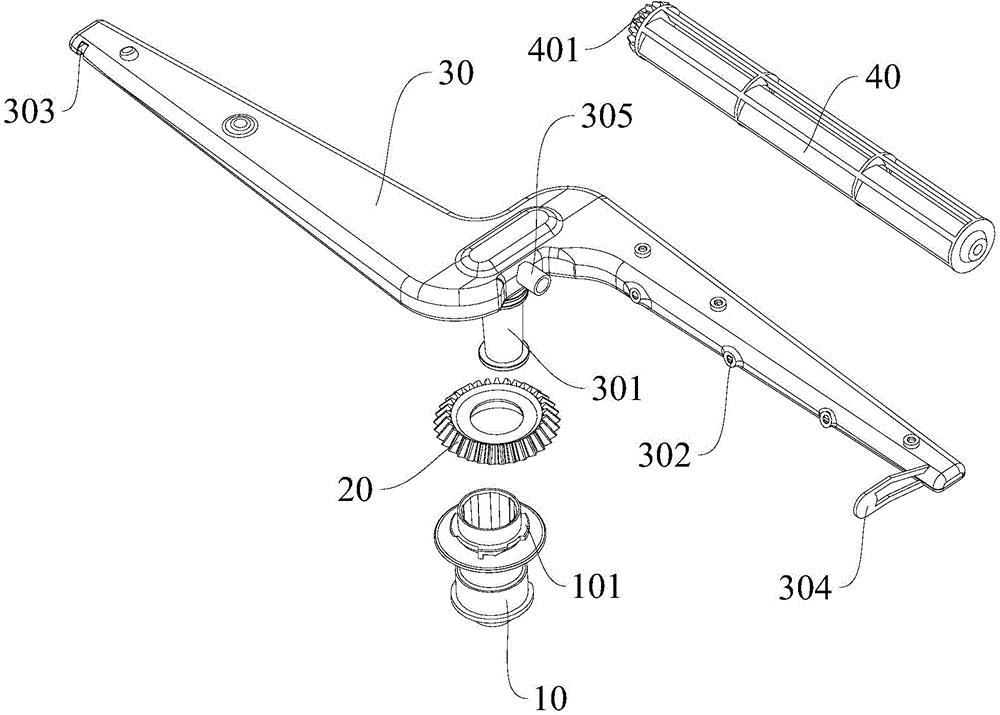

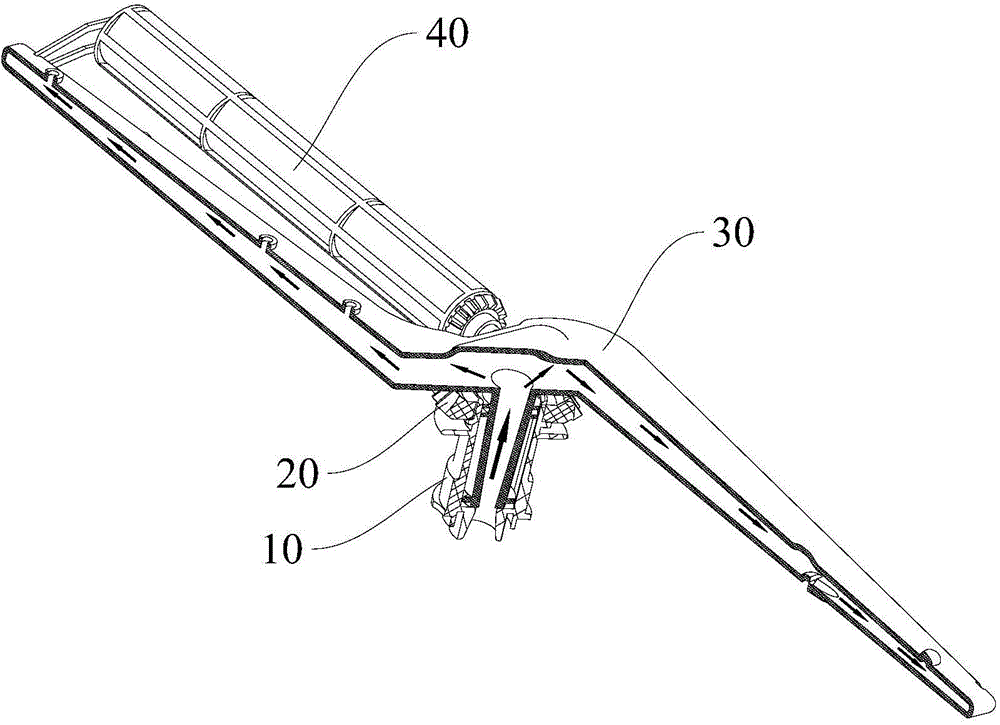

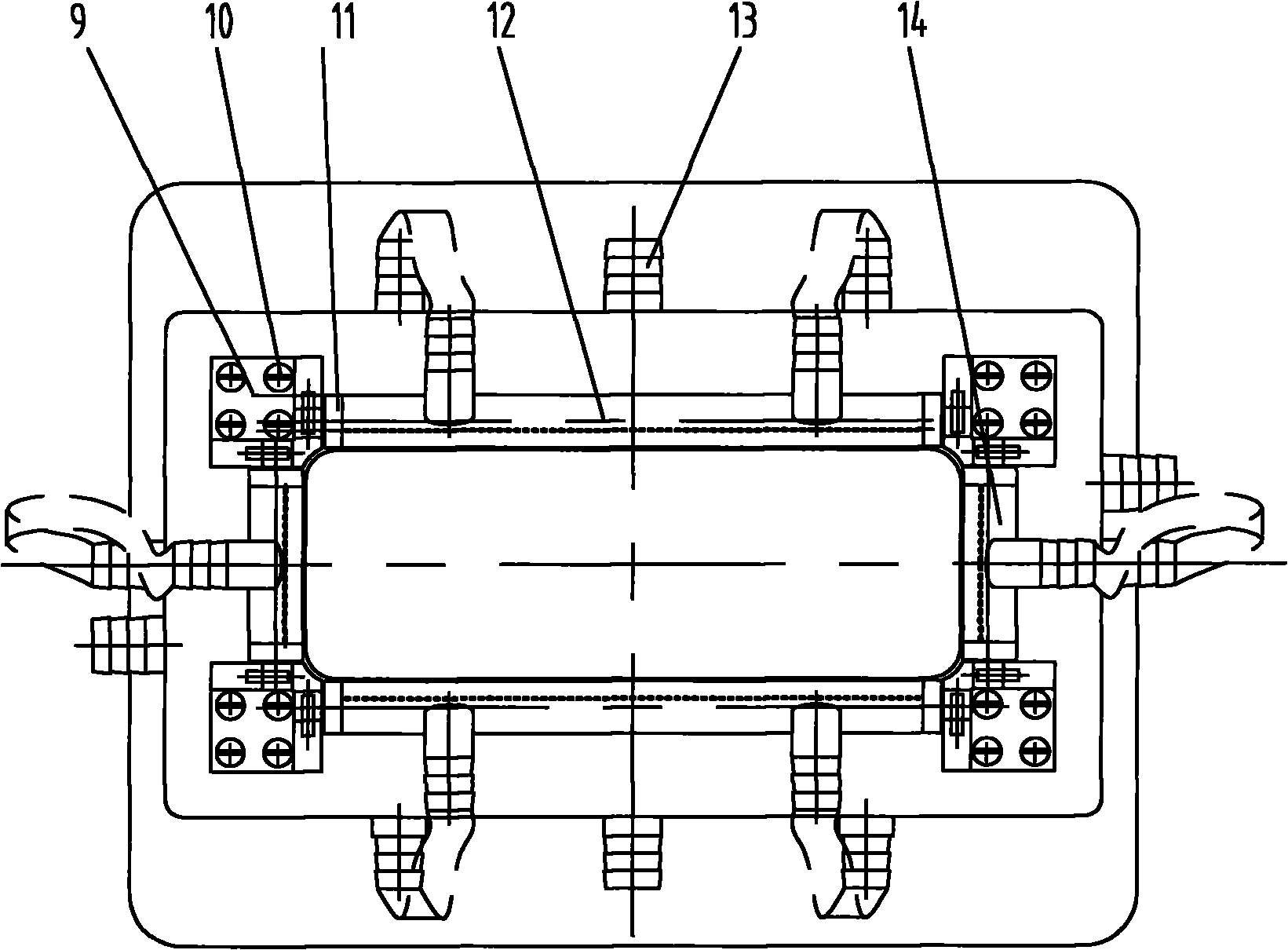

Spraying arm component for dish washer and dish washer

ActiveCN104644097ALarge spray surfaceChange spray angleTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention provides a spraying arm component for a dish washer and the dish washer with the spraying arm component for the dish washer. The spraying arm component for the dish washer comprises a spraying arm base, a first bevel gear, a spraying arm and a water baffle component, wherein the first bevel gear is fixedly connected to the upper end of the spraying arm base in a sleeving way; the spraying arm is provided with a center water-inlet pipe; the center water-inlet pipe penetrates through the first bevel gear so as to be downwards connected into the spraying arm base in an inserting way; a plurality of spraying holes are formed in the spraying arm; a first end of the water baffle component can be rotationally arranged at one end of the spraying arm; a second bevel gear meshed with the first bevel gear is arranged at a second end of the water baffle component; the water baffle component faces at least one of the spraying holes. According to the spraying arm component for the dish washer provided by the embodiment of the invention, the angle of injecting water flow from the spraying holes can be changed, and the injection area is increased.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG

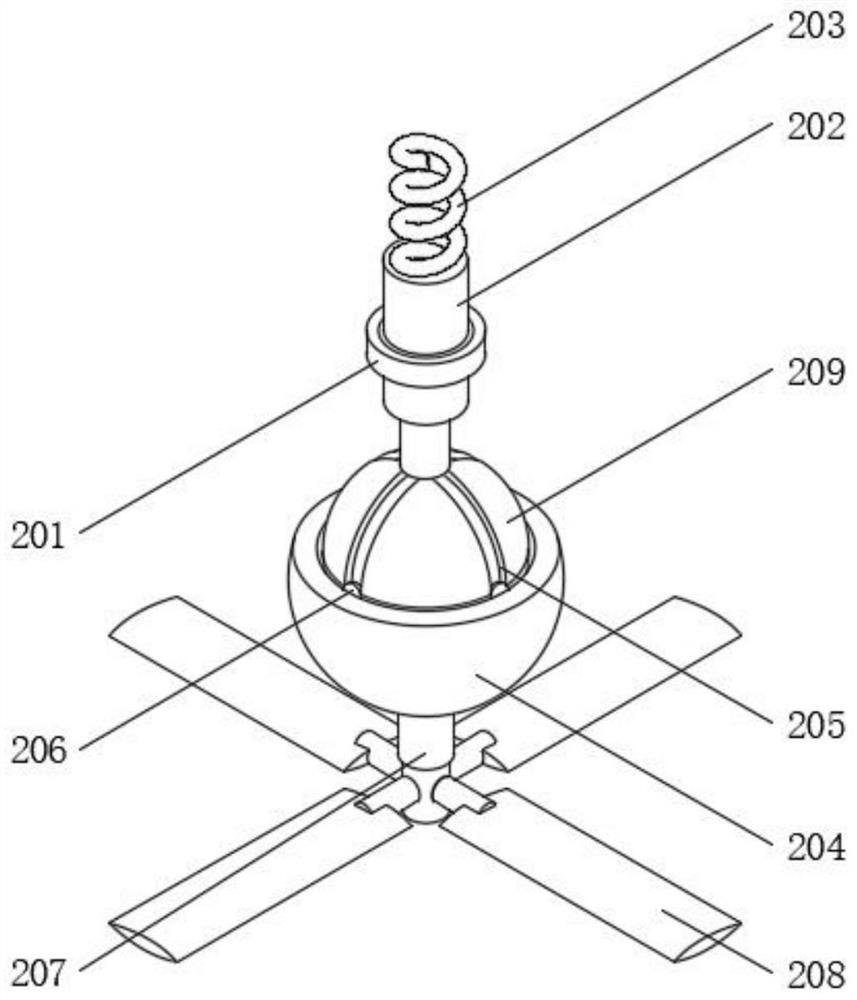

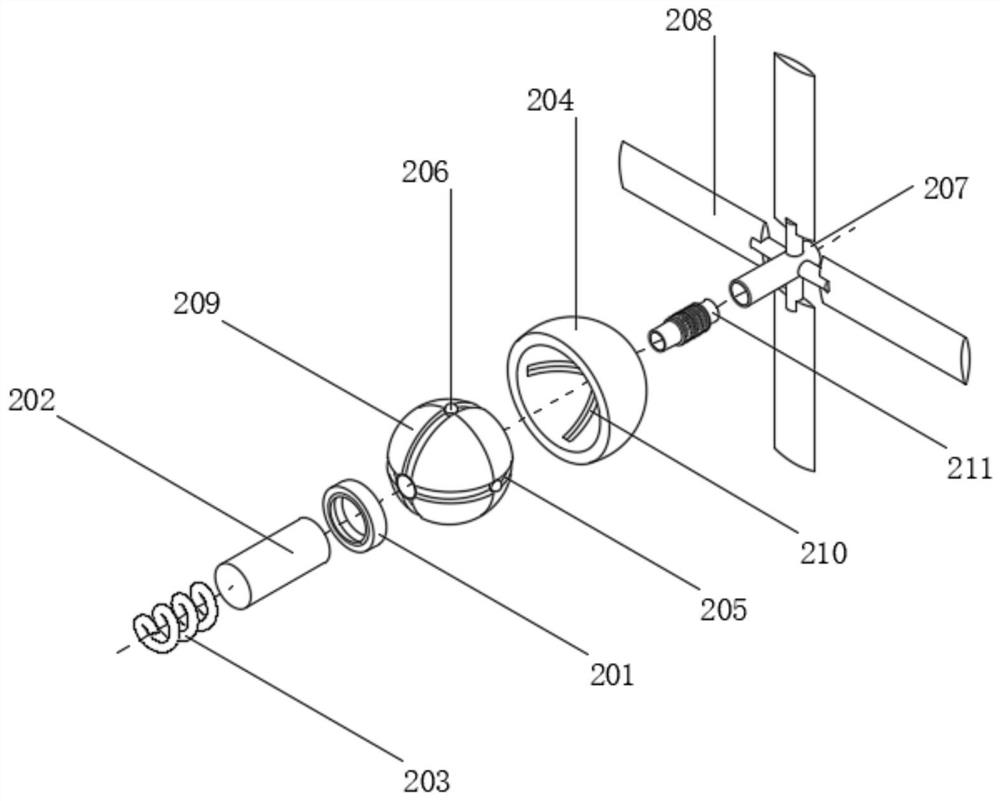

Low-frequency ultrasonic secondary atomizing nozzle with adjustable spray angle

InactiveCN102294313ALarge adjustment rangeChange spray angleSpray nozzlesLiquid spraying apparatusSprayerEngineering

The invention discloses a low-frequency ultrasonic secondary atomizing sprayer with an adjustable spray angle of an ultrasonic atomizer. A nozzle is provided with a liquid inlet hole, the liquid inlet hole is communicated with one end of a liquid outlet hole, the tail end of the nozzle is a trapezoid nozzle groove, a trapezoid secondary atomizing active cell is arranged at the trapezoid nozzle groove, and the other end of the liquid outlet hole is communicated with the trapezoid nozzle groove; an adjusting screw penetrates the trapezoid secondary atomizing active cell and is connected with the secondary atomizing active cell and the nozzle by virtue of screw threads; the adjusting screw is provided with a balance spring, one end of the balance spring is supported on the tail end face of the trapezoid secondary atomizing active cell, and the other end of the balance spring is supported on the tip of the adjusting screw; and a distance between the trapezoid nozzle groove and the trapezoid secondary atomizing active cell is 0-1mm. The adjustable trapezoid secondary atomizing active cell is adopted, thus the regulating range of fog drop size is increased, the nozzle can regulate the fog drop size at any position by virtue of the balance spring, and a mounting angle is flexible.

Owner:JIANGSU UNIV

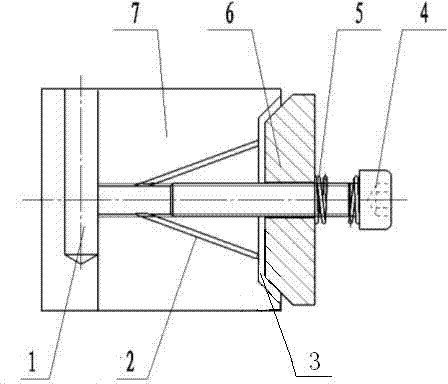

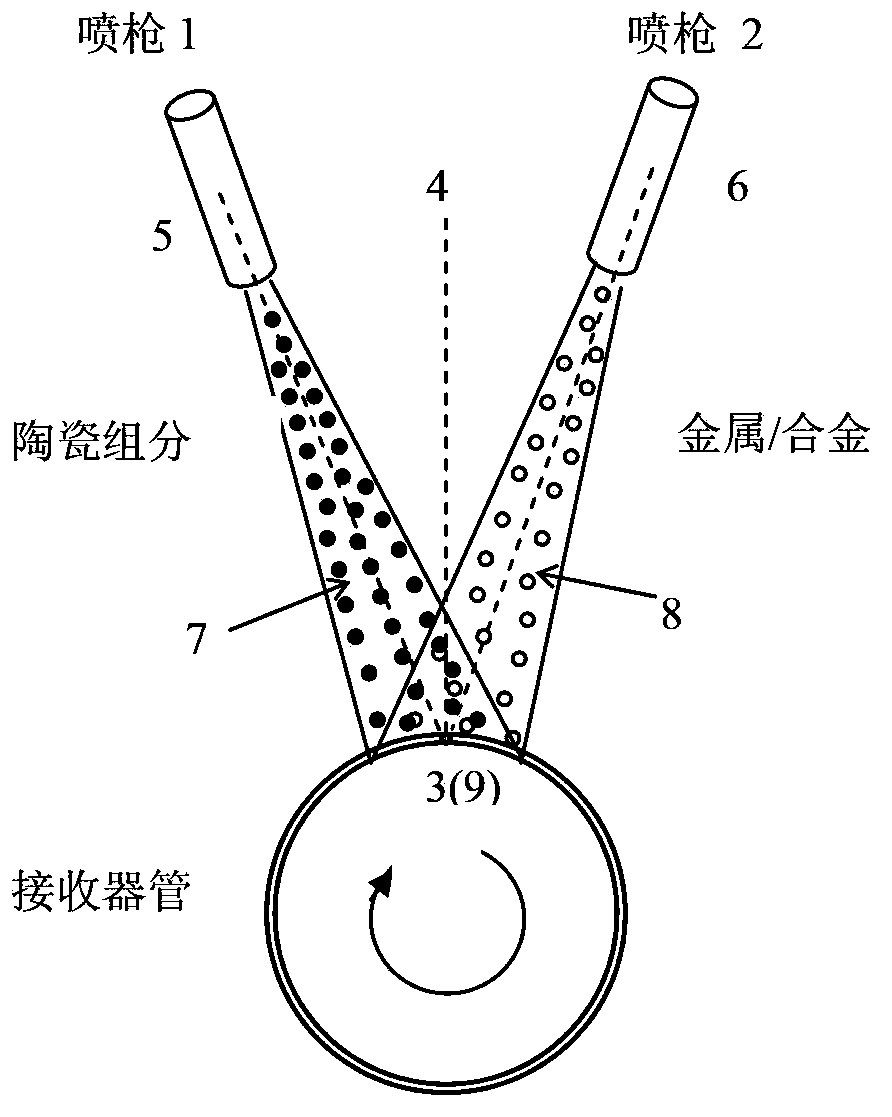

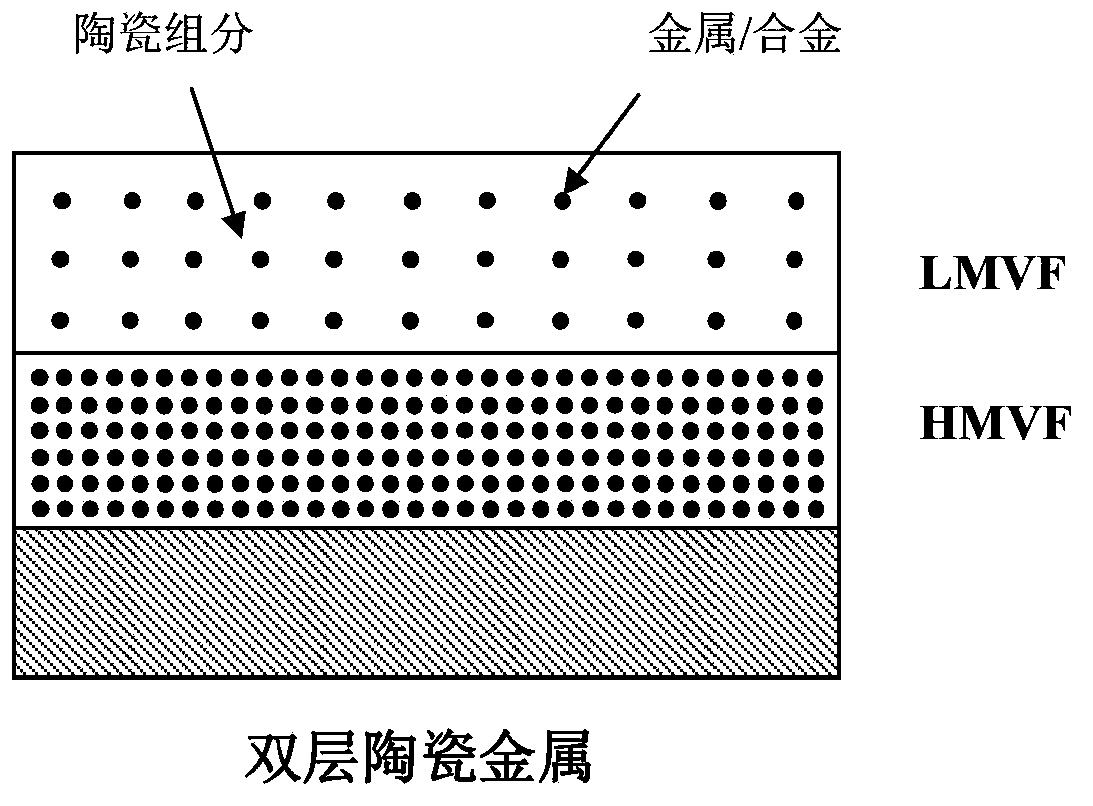

High speed oxygen fuel spraying system and metal ceramic coating prepared by the same

InactiveCN103628018AChange the content at any timeChange spray angleMolten spray coatingJet flowMetal alloy

The invention on the one hand provides a high speed oxygen fuel spraying system, which includes a first high speed oxygen fuel spray gun for spraying ceramics and a second high speed oxygen fuel spray gun for spraying metal or metal alloy. The jet flows sprayed simultaneously from the first high speed oxygen fuel spray gun and the second high speed oxygen fuel spray gun are overlapped and covered on the surface of a workpiece to be coated, so as to form the coating. The metal or metal alloy in the coating varies along the thickness direction, and the closer to the surface of the workpiece, the content of metal or metal alloy is higher. On the other hand, the invention also provides a method for preparing ceramic metal coating according to the above system.

Owner:SIEMENS AG

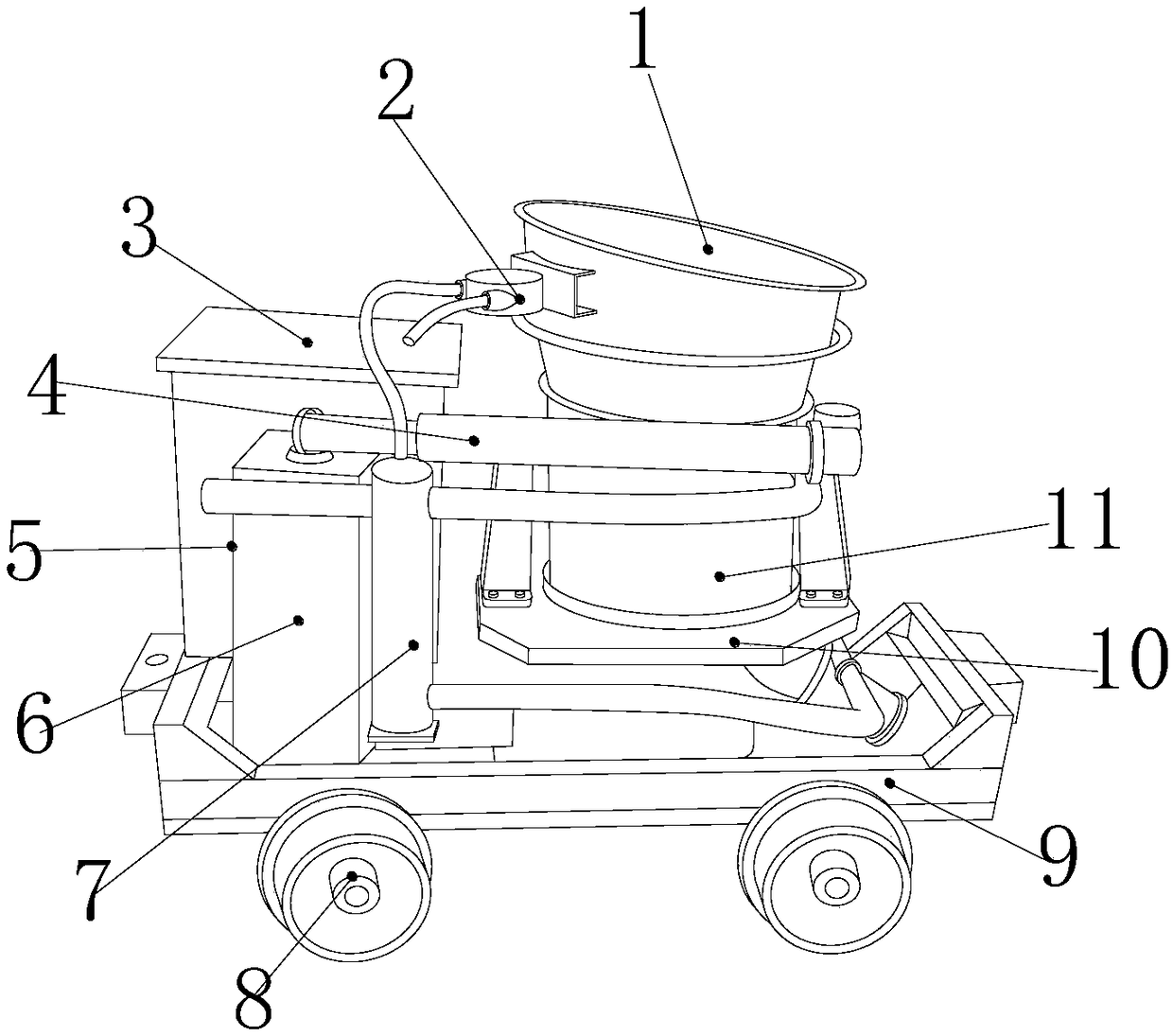

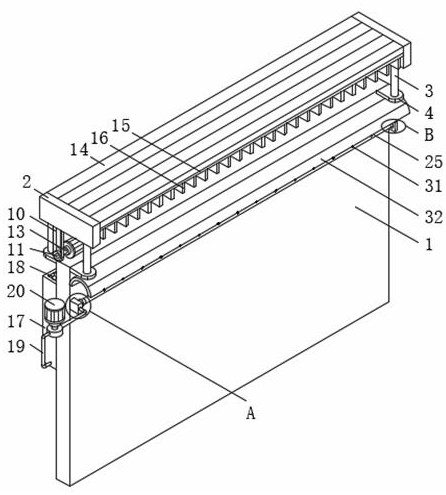

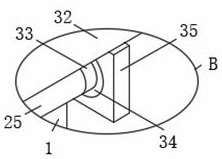

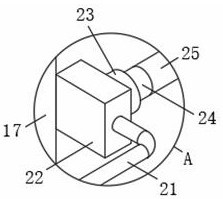

Water and fertilizer integrated irrigation device

ActiveCN108811666AAvoid cloggingSave rainwater resourcesGeneral water supply conservationPressurised distribution of liquid fertiliserAgricultural irrigationEngineering

The invention relates to the field of agricultural irrigation, and in particular, relates to a water and fertilizer integrated irrigation device comprising a supporting plate, a rainwater collection mechanism, a water and fertilizer mixing mechanism and irrigation mechanisms. The water and fertilizer mixing mechanism is arranged at the right end of the rainwater collection mechanism; the irrigation mechanisms are located on both sides of the water and fertilizer mixing mechanism and include a first irrigation assembly and a second irrigation assembly which are arranged symmetrically, the firstirrigation assembly and the second irrigation assembly have the same structure and each comprise a liquid transport component, a support plate, a swing component and an angle change component, and the support plate is of a cuboid structure and is horizontally arranged. The water and fertilizer integrated irrigation device has the beneficial effects that rainwater can be collected by the rainwatercollecting mechanism, filter holes of a filter screen can be prevented from being blocked by falling impurities through a closed assembly, and moreover, more planting areas can be irrigated by the irrigation mechanisms from multiple angles.

Owner:山东华胜物联网科技有限公司

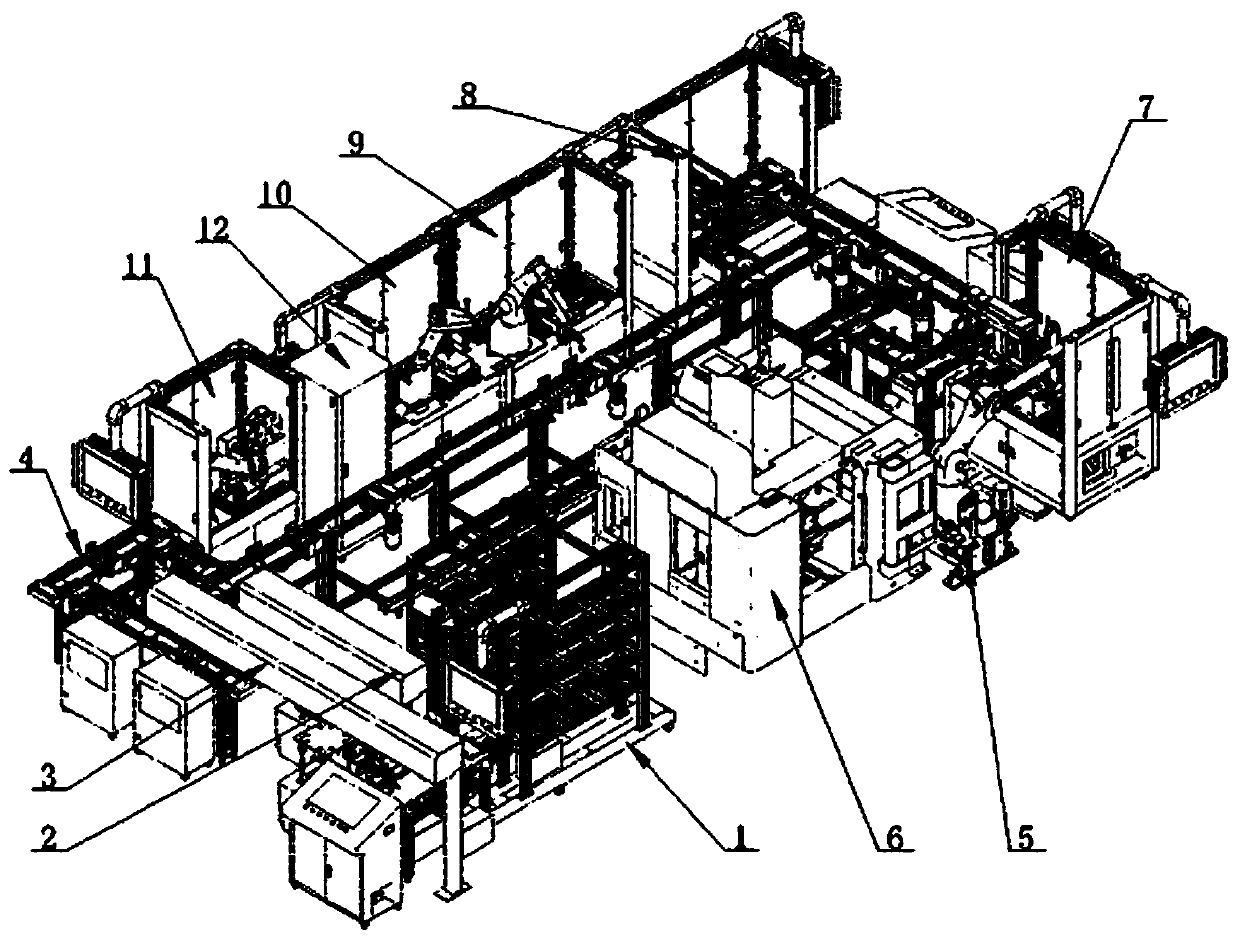

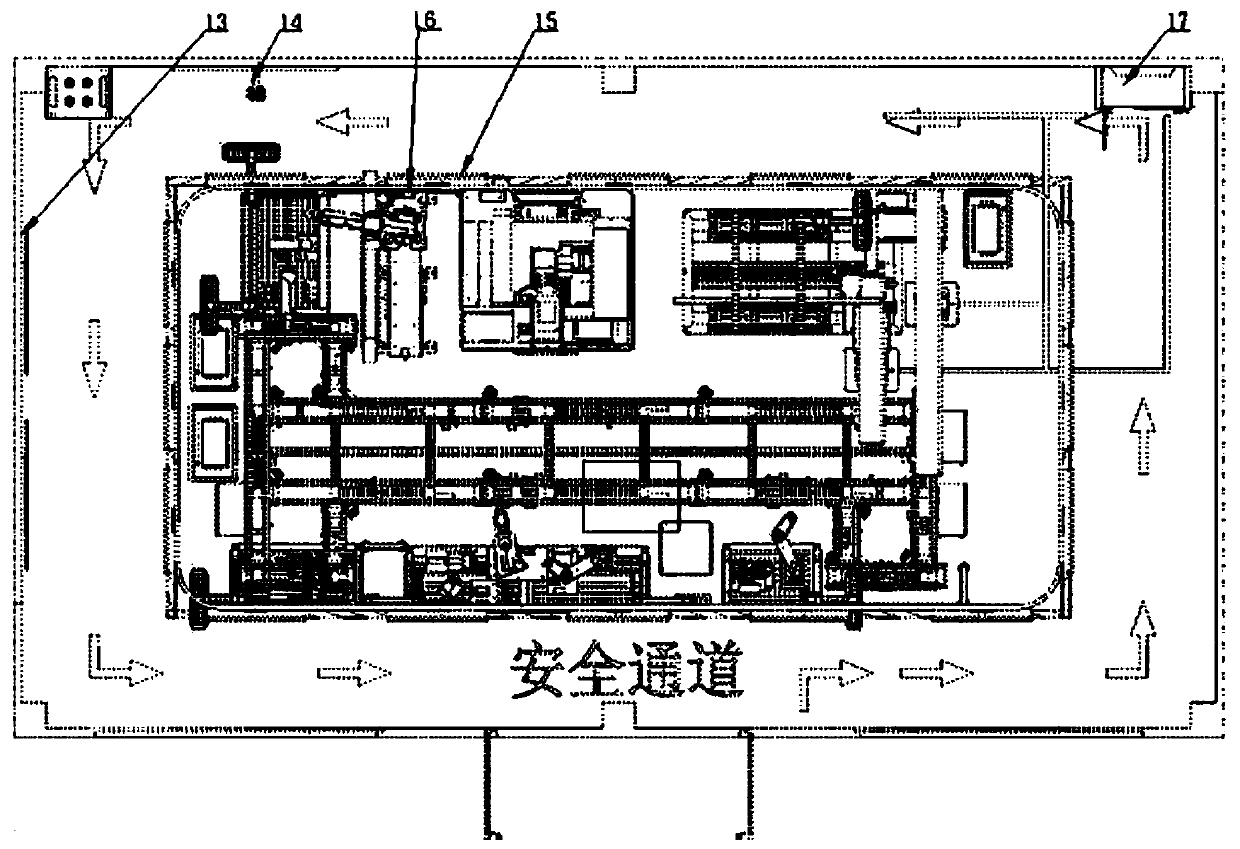

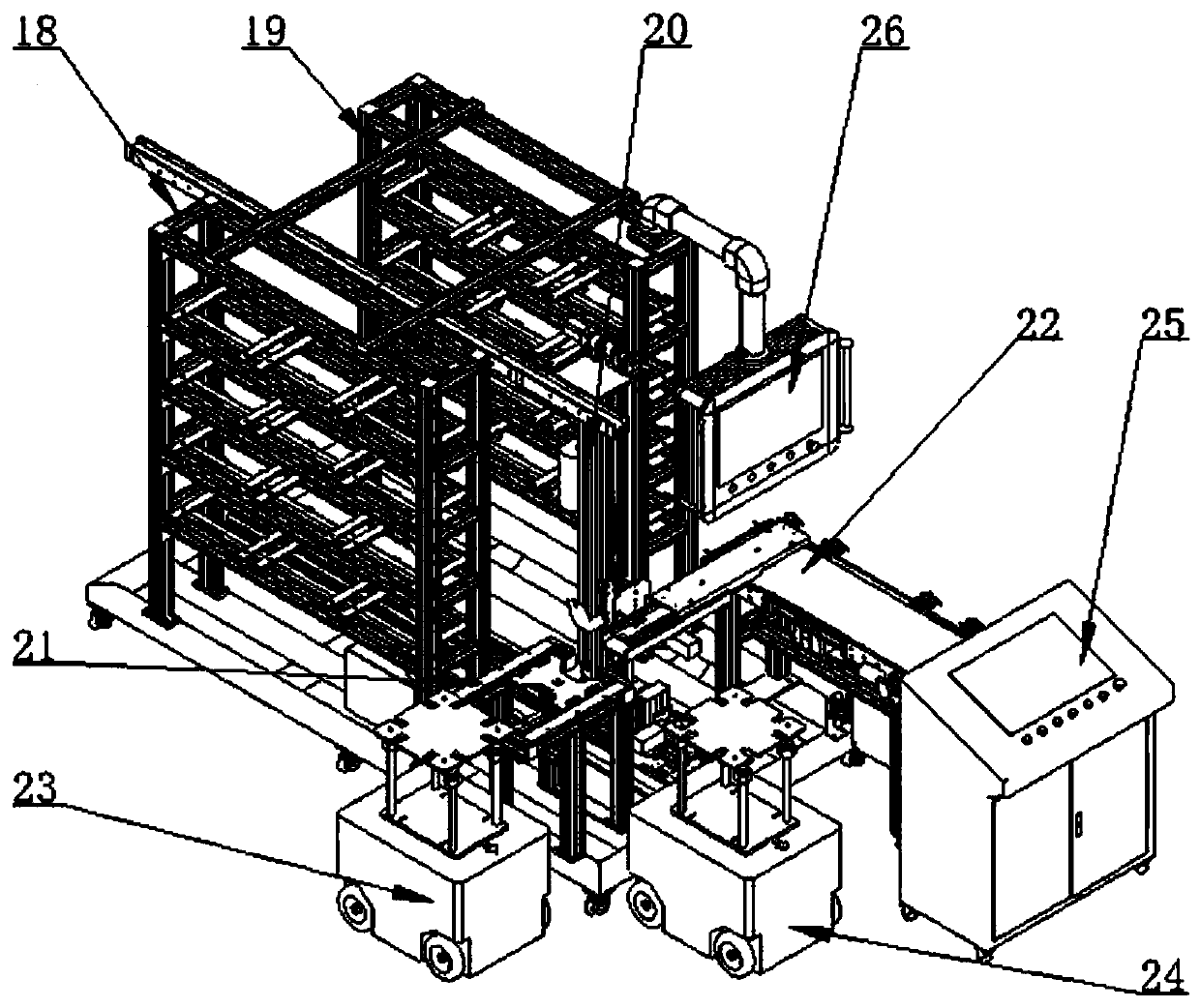

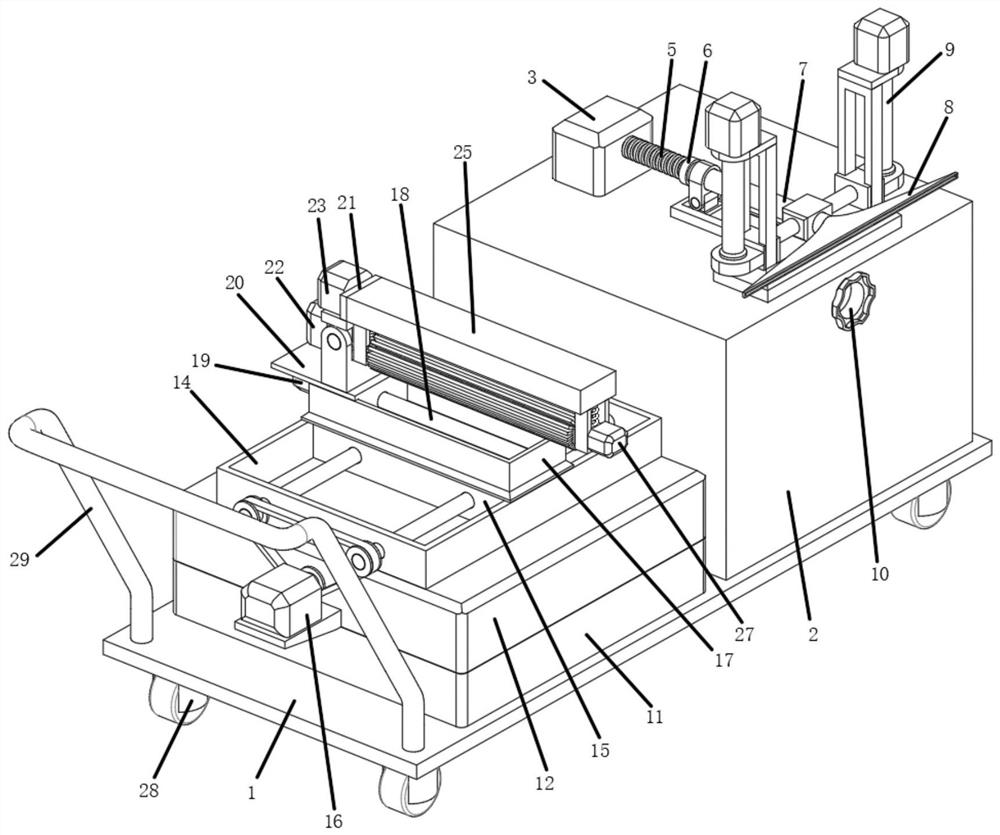

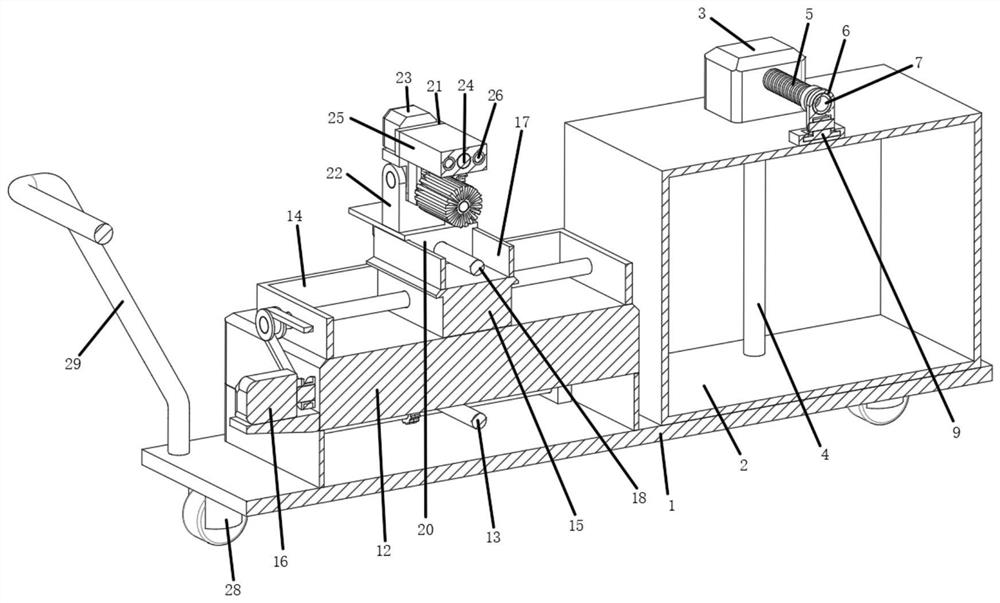

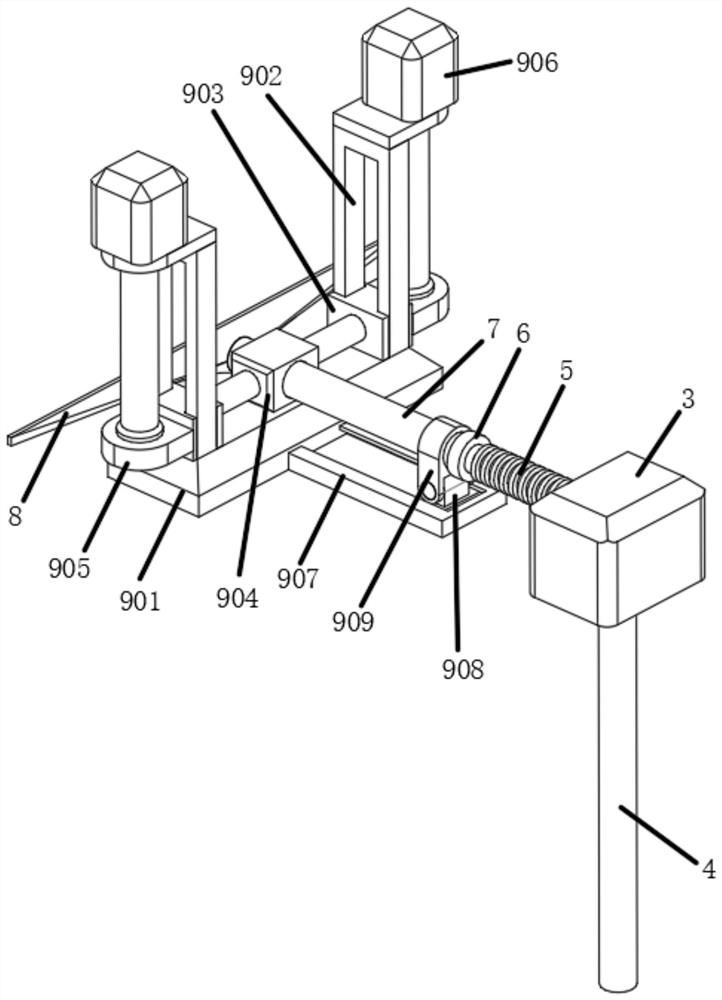

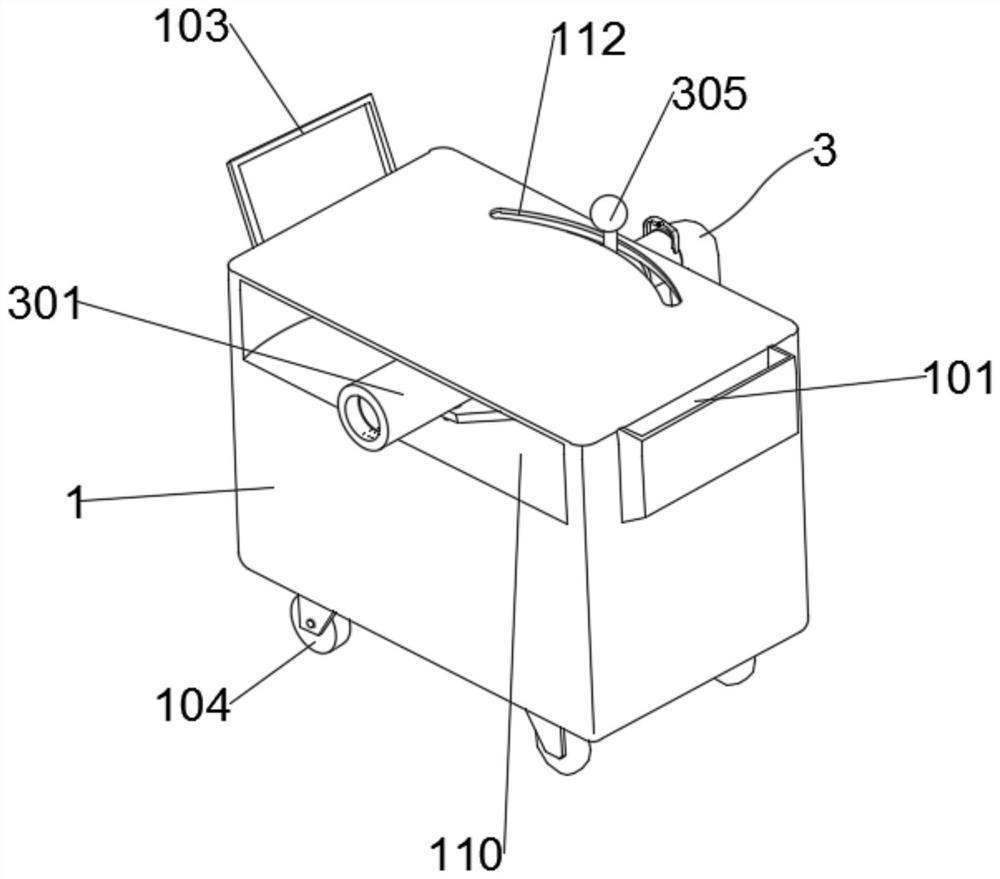

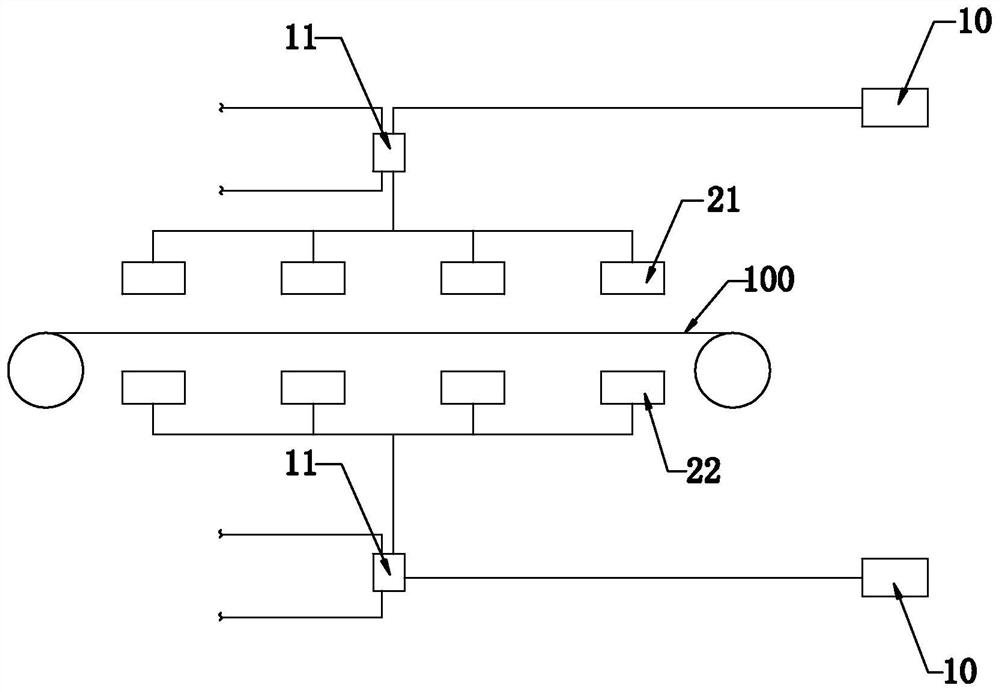

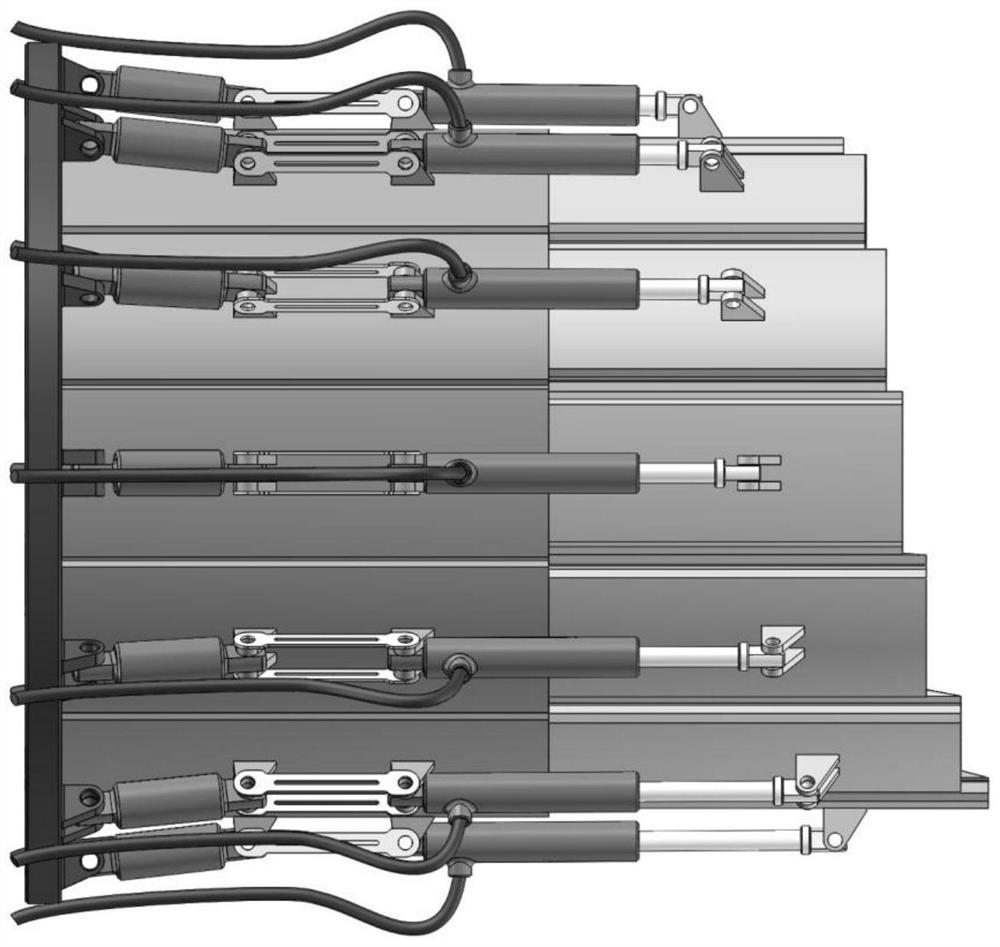

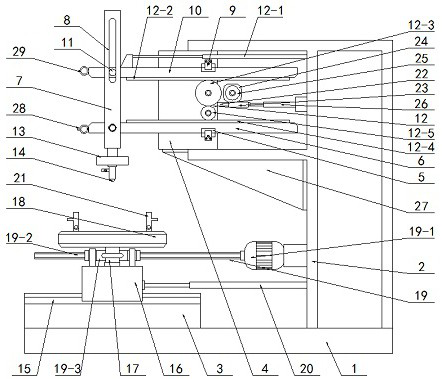

Intelligent manufacturing technology and application production training system

ActiveCN110449577AReduce processing timeIncrease productivityAdditive manufacturing apparatusCeramic shaping apparatusProduction lineManufacturing technology

The invention relates to an intelligent manufacturing technology and application production training system. The invention aims to provide intelligent flexible production line type production and a training technical scheme of photo frame products and solve the problems that a traditional production is dispersing in process, high in labor force, low in production efficiency and insufficient in quality guarantee. According to the system, equipment has an intuitive functions of product output and detection, industrial field application is truly represented, and external interfaces are arranged for facilitating expansion and upgrade of the equipment; construction combination is reasonable, and control is precise, so that application of intelligent manufacturing technology is fully embodied; and meanwhile, a raw material tray and a finished product tray are jointly used for conveying photo frame assemblies, to-be-dissembled photo frame assemblies are placed on the two different trays according to differences of machining processes, and corresponding machining treatment can be respectively carried out before final assembly, in this way, machining time in the production line is saved, and production efficiency is improved.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE +1

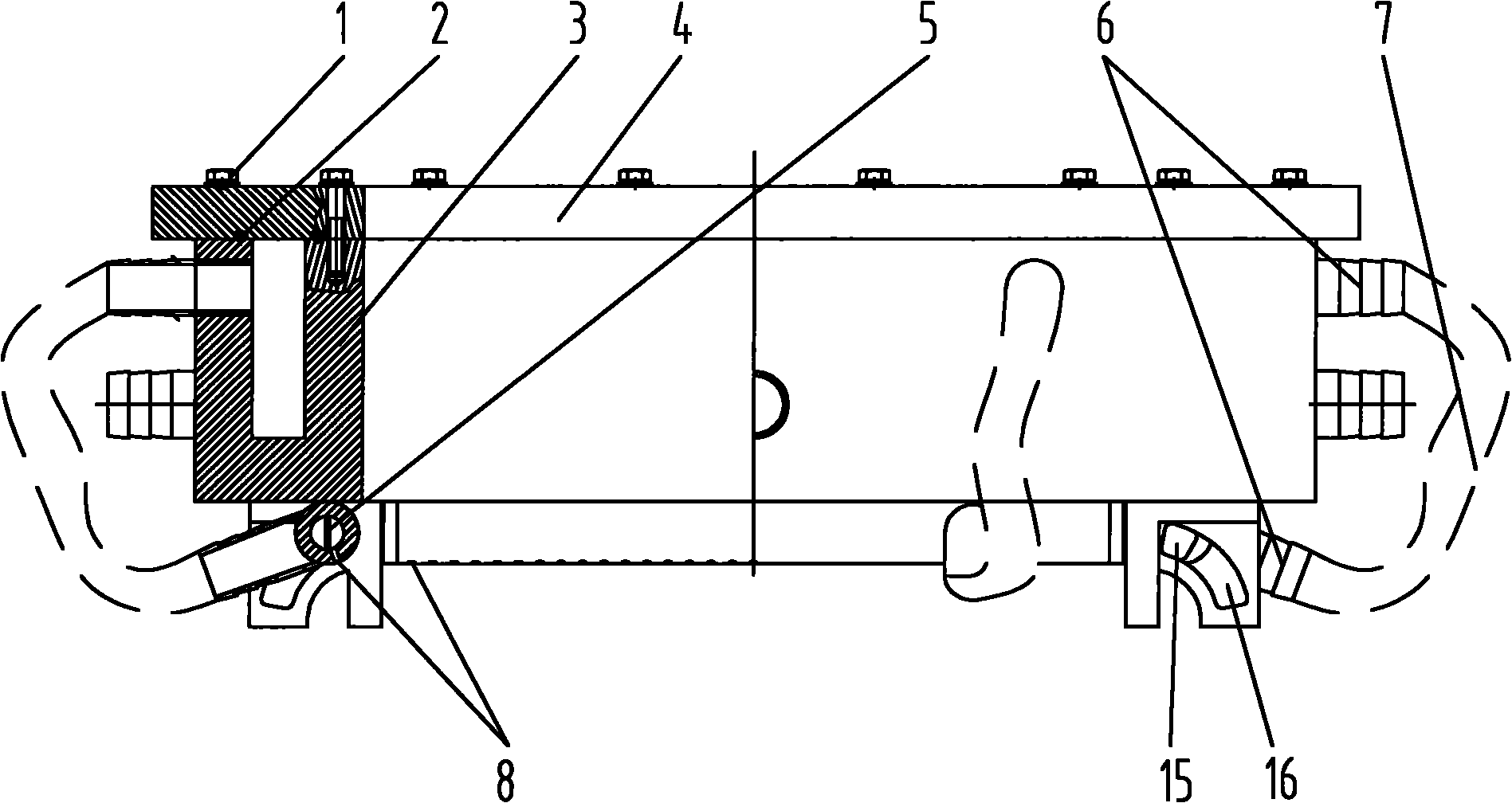

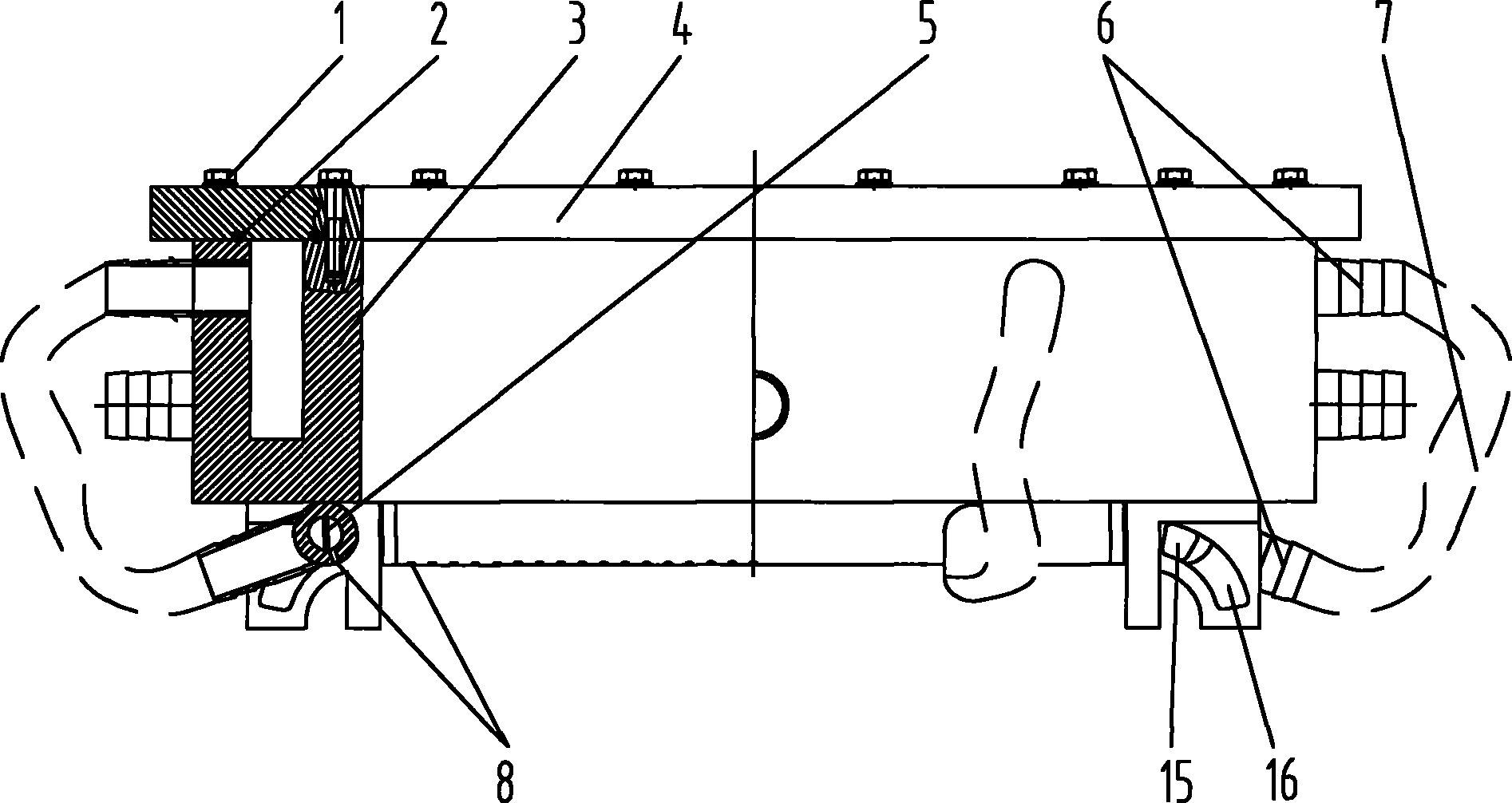

Cooling water angle adjustable crystallizer for aluminium alloy casting

The invention relates to a cooling water angle adjustable crystallizer for aluminium alloy casting. An upper cover is connected on the body, the body is provided with a cooling water cavity, the front and back rolling faces of the cooling water cavity are respectively provided with a rolling face cooling pipeline, the rolling face cooling pipeline is communicated with the rolling face cooling water cavity, the left and right narrow faces of the cooling water cavity are respectively provided with a narrow face cooling pipeline, the narrow face cooling pipeline is communicated with the narrow face cooling water cavity, the four corners of the bottom of the body are respectively provided with a fixed block, the two ends of the front and back rolling face cooling pipeline and the two ends of the left and right narrow face cooling pipeline are respectively movably connected with the corresponding fixed block by a slide block, and the front and back rolling face cooling pipeline and the left and right narrow face cooling pipeline are uniformly distributed with cooling water holes. A cooling pipeline is additionally arranged below the body of the crystallizer, the cooling pipeline is designed with cooling water hole, the cooling water hole is separated from the water cavity of the crystallizer body; the fixed block and slide block structure causes the cooling pipeline to rotate around ingot casting water seeing point, thus achieving the aim of changing cooling water spraying angle.

Owner:SHANDONG HUAYU ALUMINUM & POWER

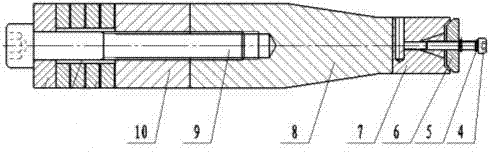

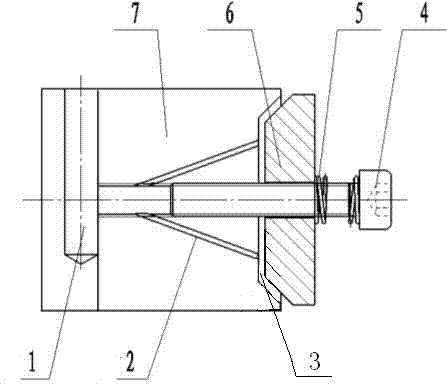

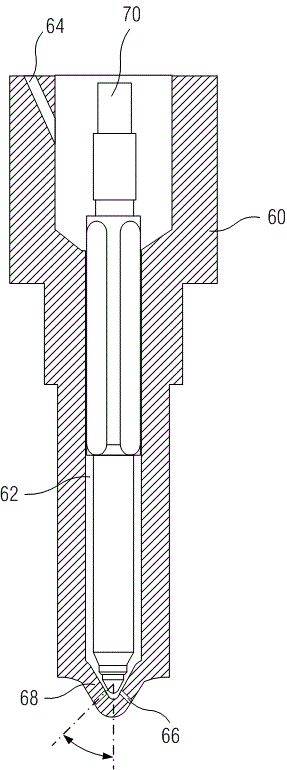

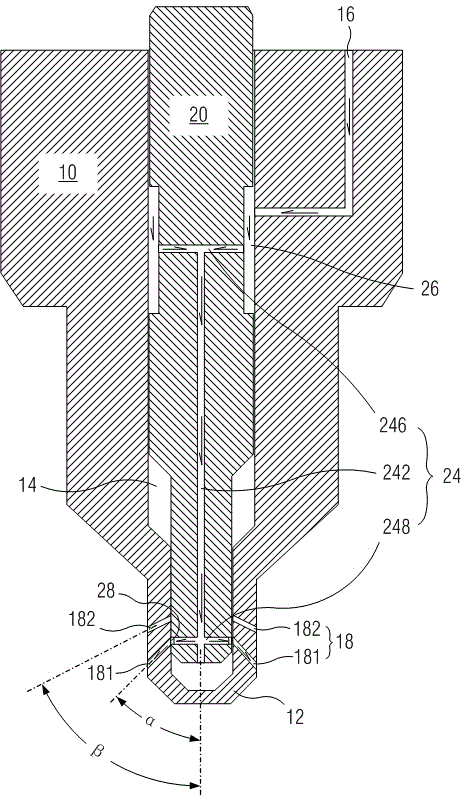

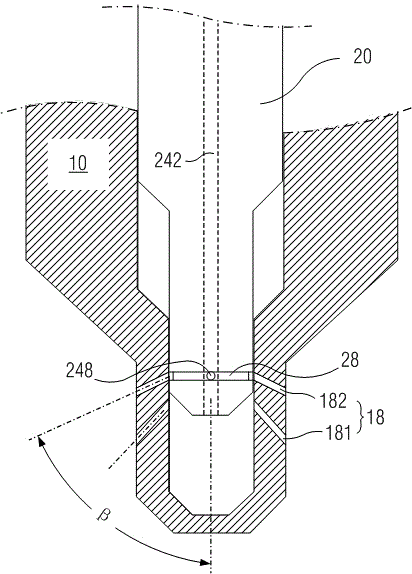

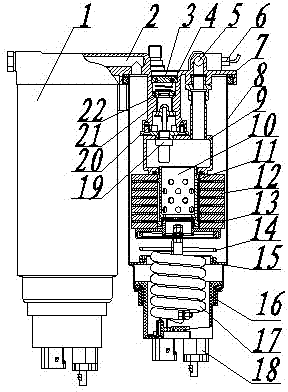

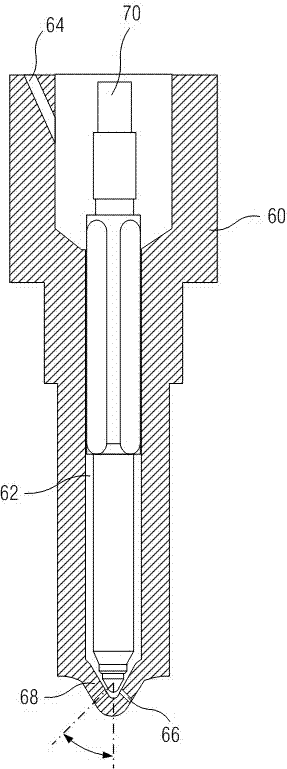

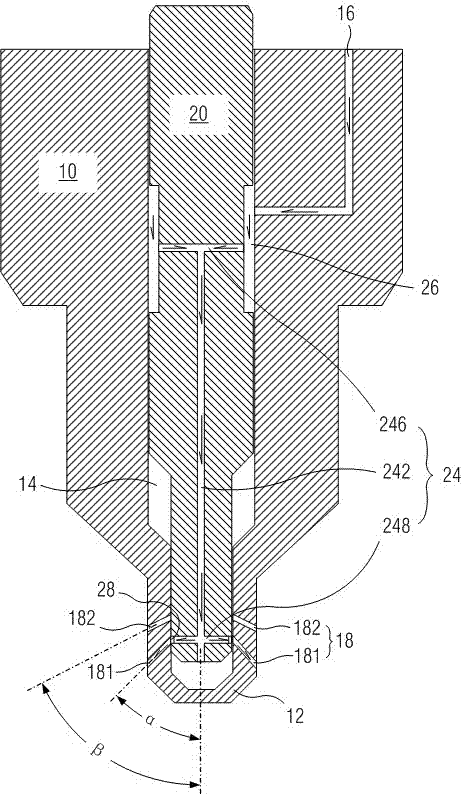

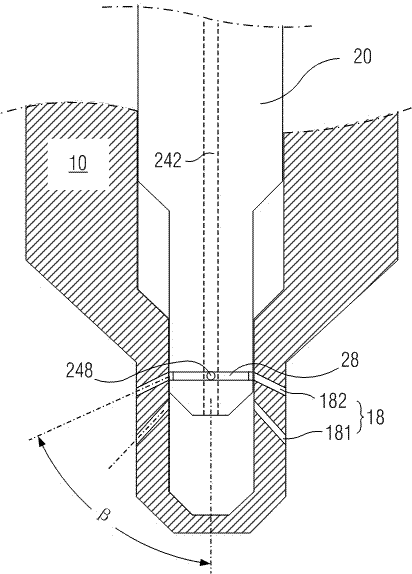

Needle valve component for fuel injection device

ActiveCN103982350ASimple structureEasy to processFuel injection apparatusMachines/enginesInlet channelReciprocating motion

The invention discloses a needle valve component for a fuel injection device. The needle valve component comprises a valve body (10) and a needle valve (20). The valve body is provided with a valve body end (12), a valve hole (14), an oil inlet channel (16) and an oil injection hole (18). The oil injection hole comprises a first group of oil injection holes (181) and a second group of oil injection holes (182), wherein the first jet angles of the first group of oil injection holes are smaller than the second jet angles of the second group of oil injection holes, and the communicating positions of the first group of oil injection holes and the valve hole are closer to the valve body end than the communicating positions of the second group of oil injection holes and the valve hole. The needle valve can reciprocate in the valve hole and comprises an oil inlet ring groove (26), an oil outlet ring groove (28) and an oil supply channel (24) for communicating the oil inlet ring groove and a first oil outlet ring groove. The first oil outlet ring groove is respectively communicated with the first group of oil injection holes and the second group of oil injection holes, the fuel oil is sprayed at different jet angles so as to adapt to oil-gas mixing under different loads, the oil consumption and discharge under the different conditions are both considered, and the needle valve component has the advantages of simple structure and convenience for processing.

Owner:JIANGSU UNIV +1

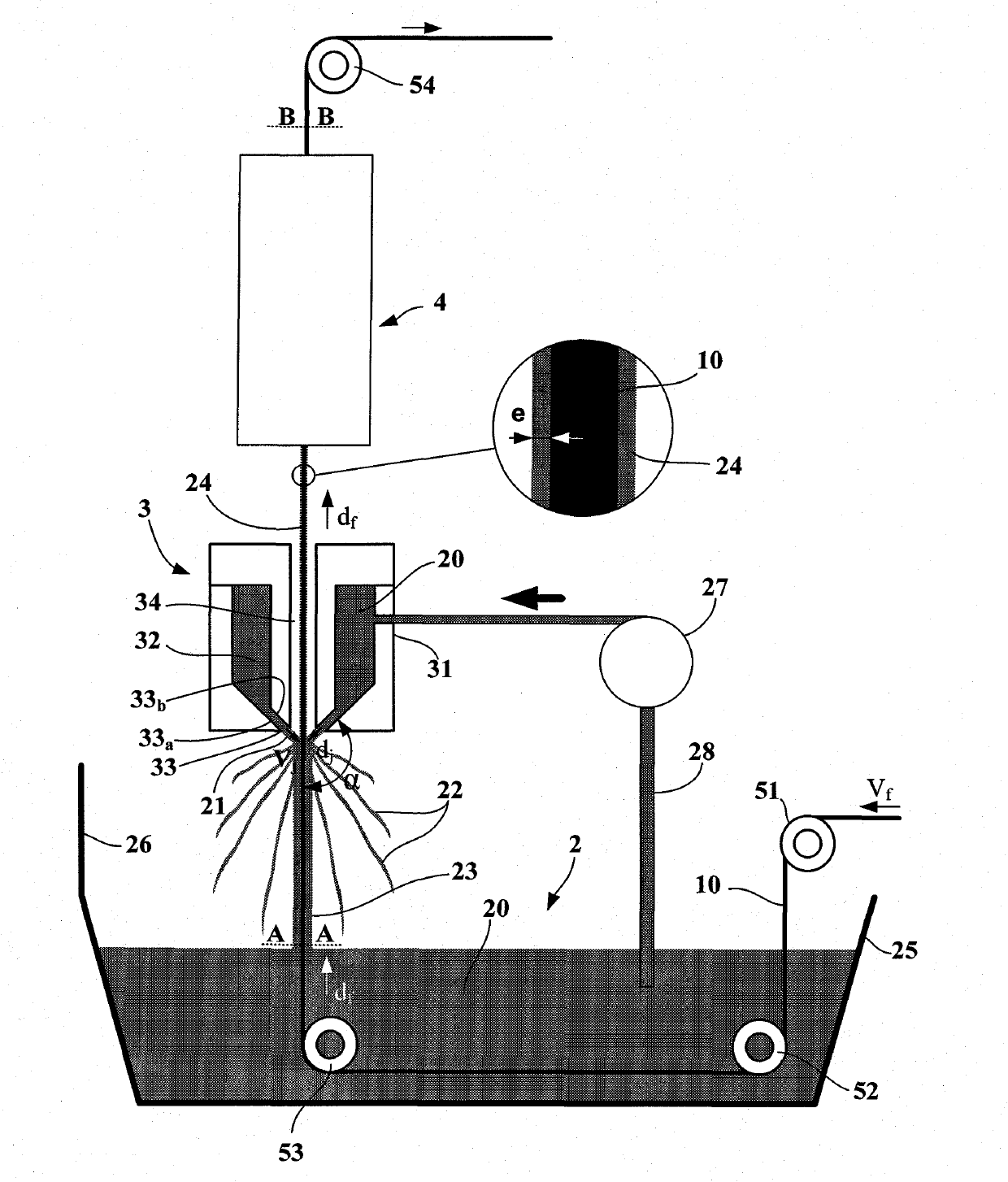

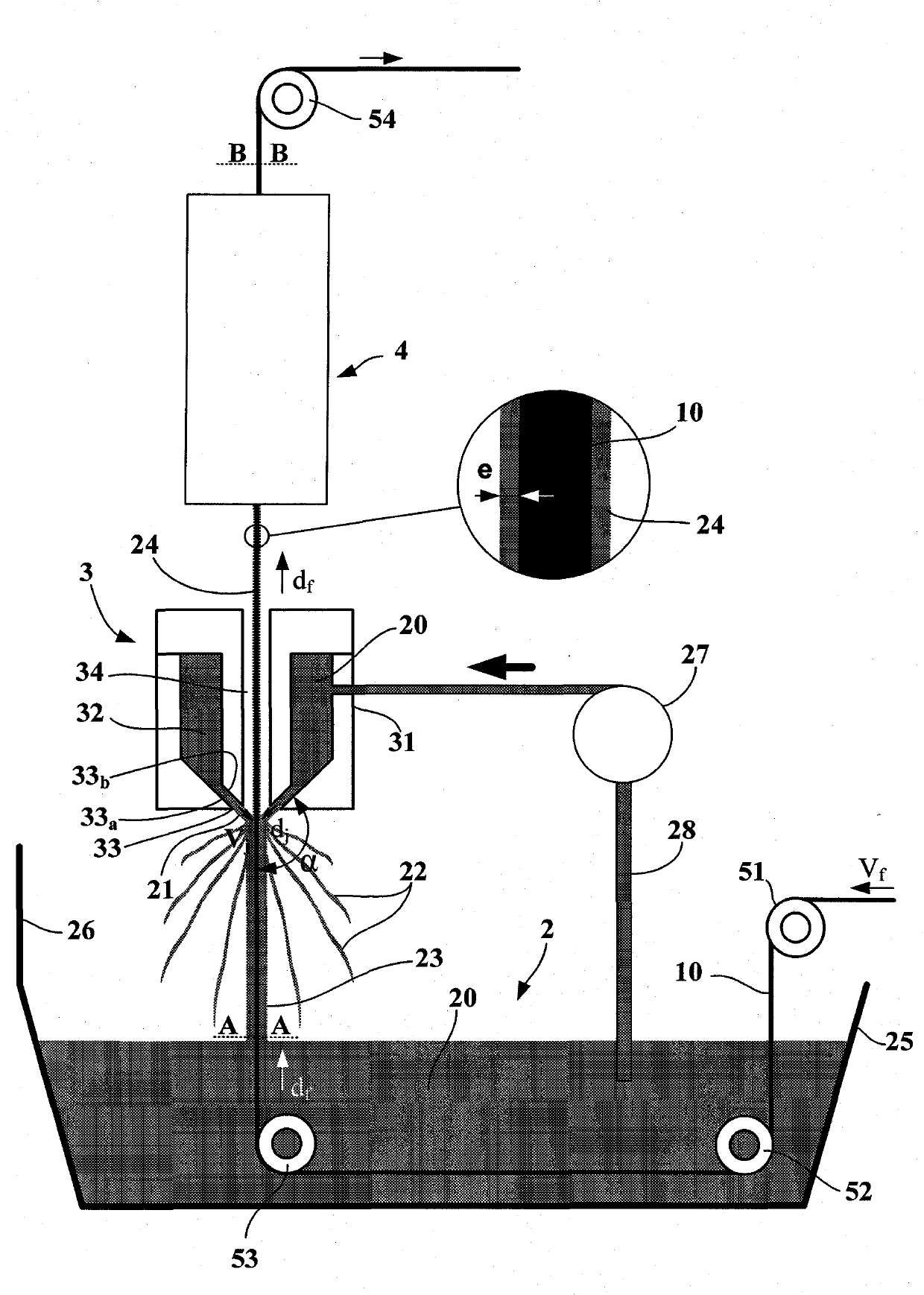

High-speed wire coating device and method

ActiveCN102016152AEasy to adjustChange spray angleTextile treatment machine partsPretreated surfacesBiomedical engineering

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

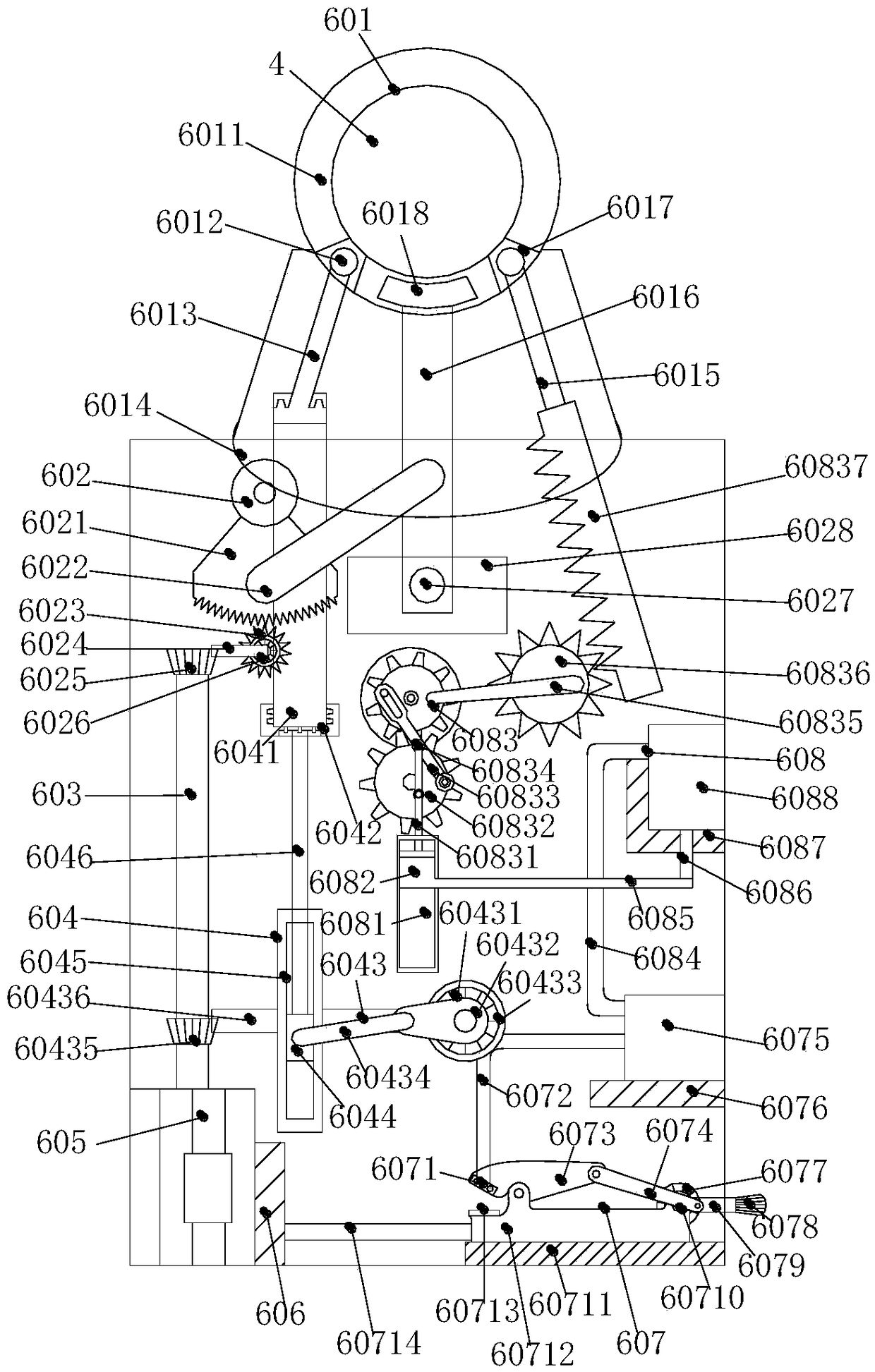

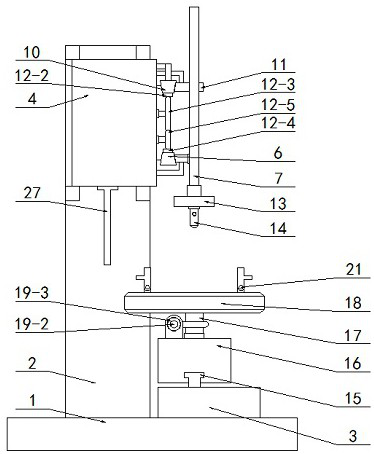

Fixed denture preparation device based on mechanical process

InactiveCN112872488AChange the angle of rotationEfficient recyclingMaintainance and safety accessoriesFixed prosthodonticHydraulic ram

The invention discloses a fixed denture preparation device based on a mechanical process, and relates to the technical field of mechanical processes. The fixed denture preparation device based on the mechanical process comprises a bottom rack and a guide rail, a trough plate chamber is arranged in the bottom rack, the end part of the trough plate chamber is connected with a connecting pipe, the end part of the connecting pipe is connected with a filter tank chamber, a connecting frame is arranged in the filter tank chamber, a connecting filter screen is arranged in the connecting frame, a connecting pin penetrates through the end part of the connecting frame, one side of the connecting frame is connected with an adjusting hydraulic oil cylinder, a water pump is installed on one side of the filter tank chamber, and one side of the water pump is connected with a liquid supply pipe. The fixed denture preparation device based on the mechanical process is provided with a denture storage mechanism, a miniature hydraulic oil cylinder can effectively push a pressing plate to rotate along the outside of a lock pin, the rotating angle of the pressing plate can be effectively changed, the pressing plate can be adjusted to a proper angle until the pressing plate tightly presses a processed denture, and therefore the processed denture can be effectively limited.

Owner:SHANGHAI REPARO DENTAL LAB

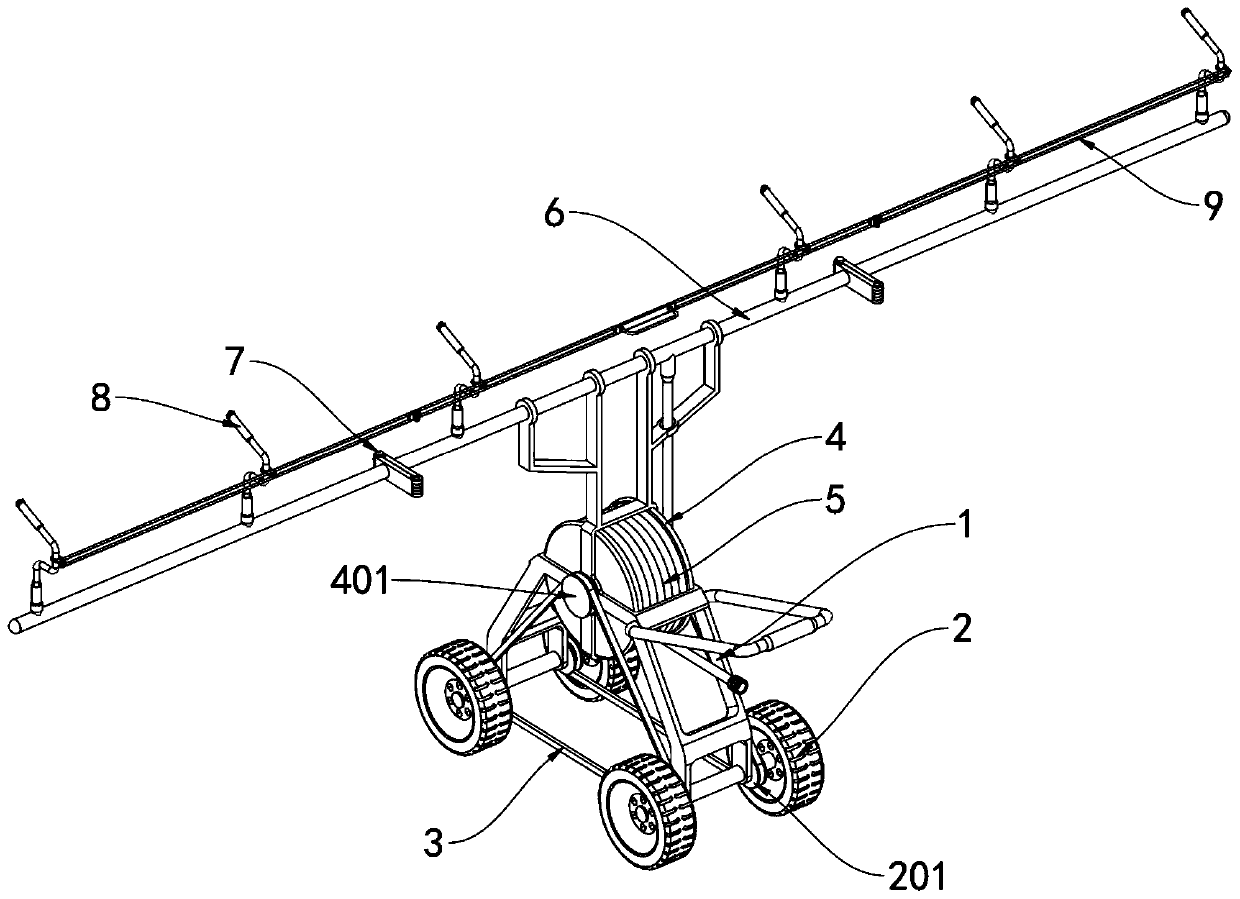

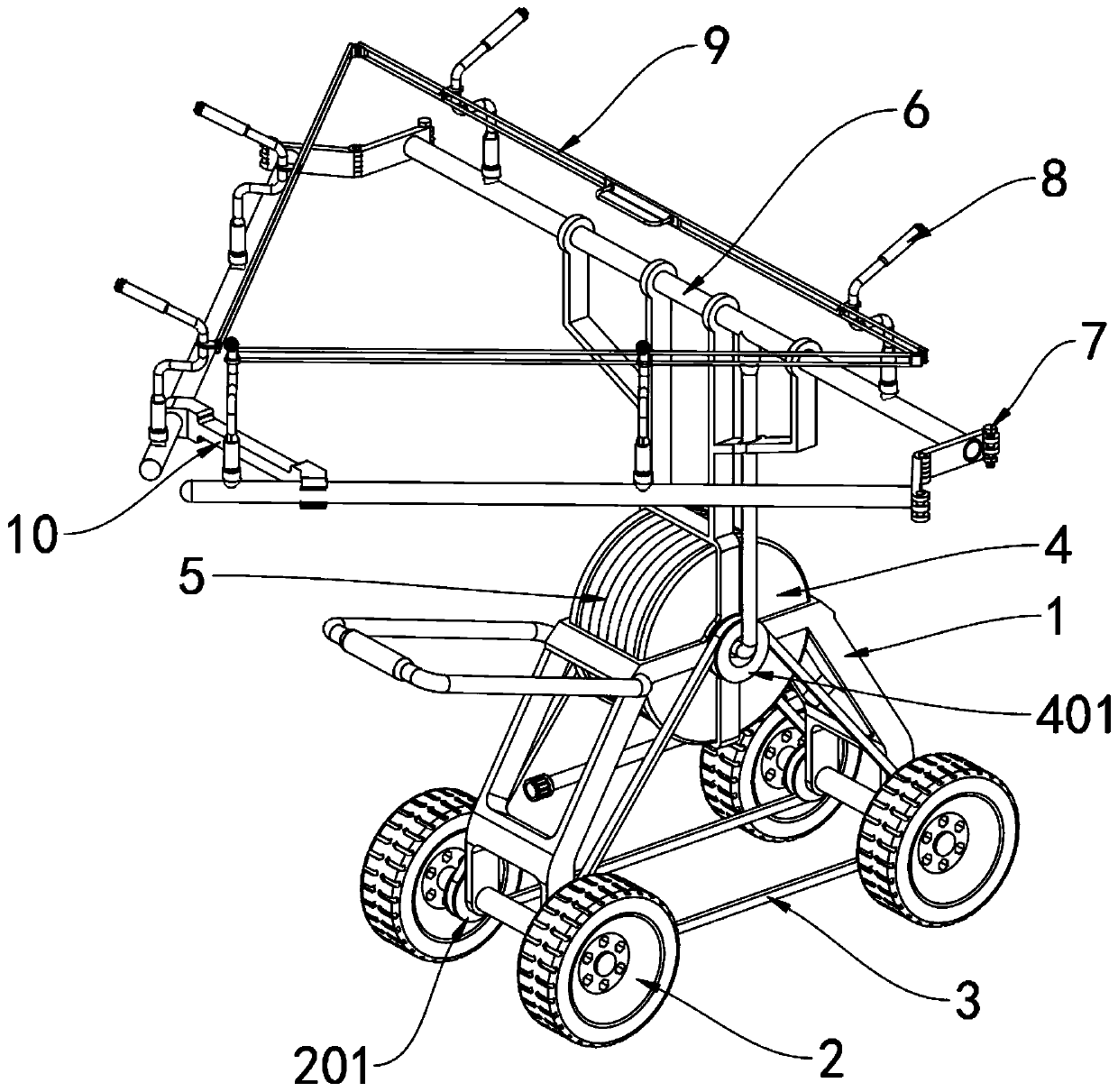

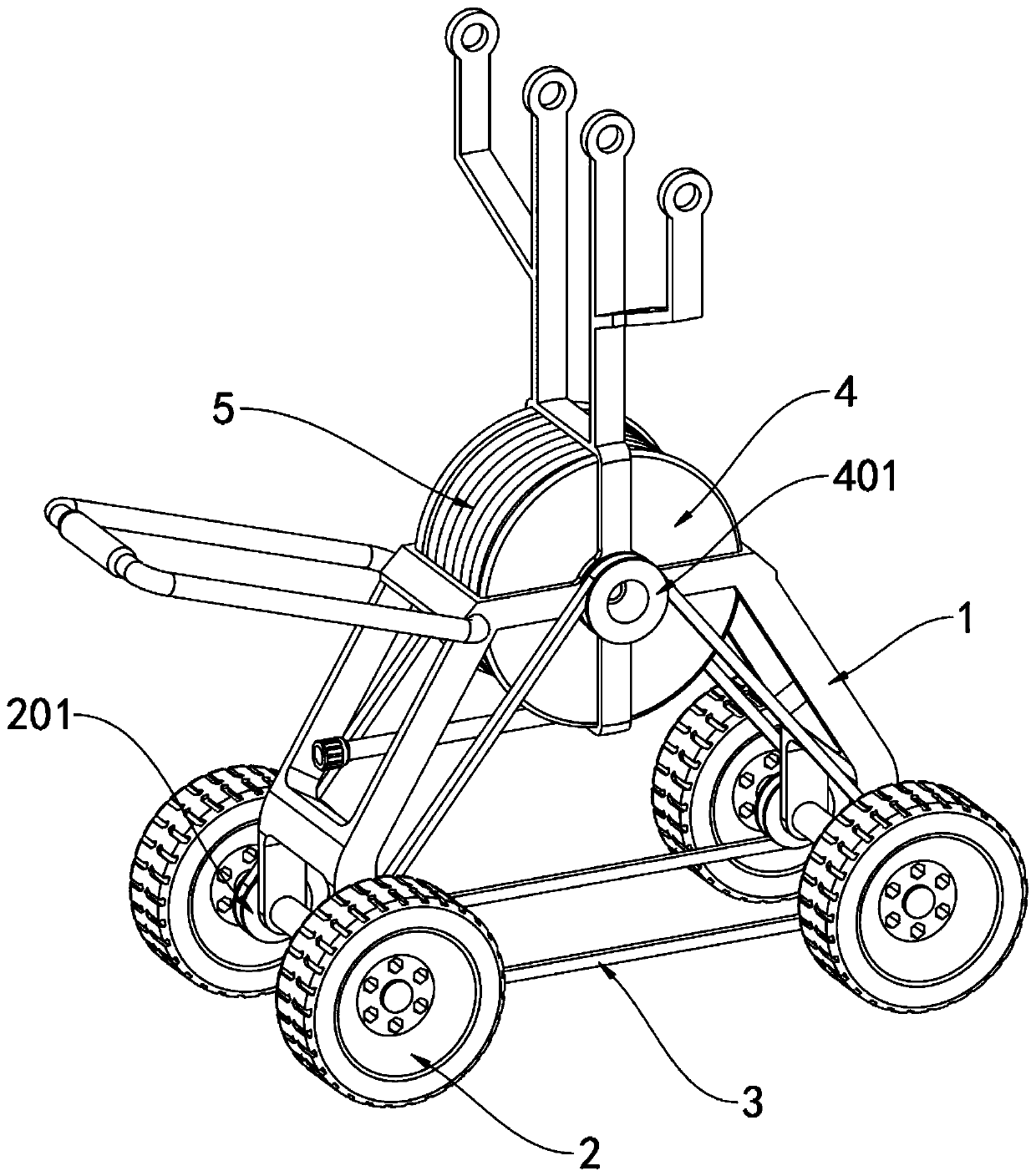

Tea planting based multi-angle irrigation device

ActiveCN110612896AEasy to rollReduce labor intensityWatering devicesCultivating equipmentsTransmission beltWater flow

The invention provides a tea planting based multi-angle irrigation device, which comprises a pipeline winding roller and a metal sprinkling pipe. Two groups of wheels are mounted at the bottom of a frame and in transmission connection with the pipeline winding roller through two transmission belts at outer left and right ends of the frame. The pipeline winding roller is positioned in the frame, awater outlet end of a water supply hose is positioned in the pipeline winding roller, and a water inlet end of the water supply hose is communicated with an external water supply pipeline. The metal sprinkling pipe is horizontally mounted at the top of the frame, and the water outlet end of the water supply hose is in rotational connection with a water inlet end at the bottom of the metal sprinkling pipe. By side-to-side pulling, an adjustment traction rod drives six nozzles mounted at the top of the metal sprinkling pipe to rotate synchronously to further rotationally adjust jet angles of thesix nozzles to change water jet angles, so that the device can be better applied to tea spray irrigation.

Owner:云南中吉号茶业有限公司

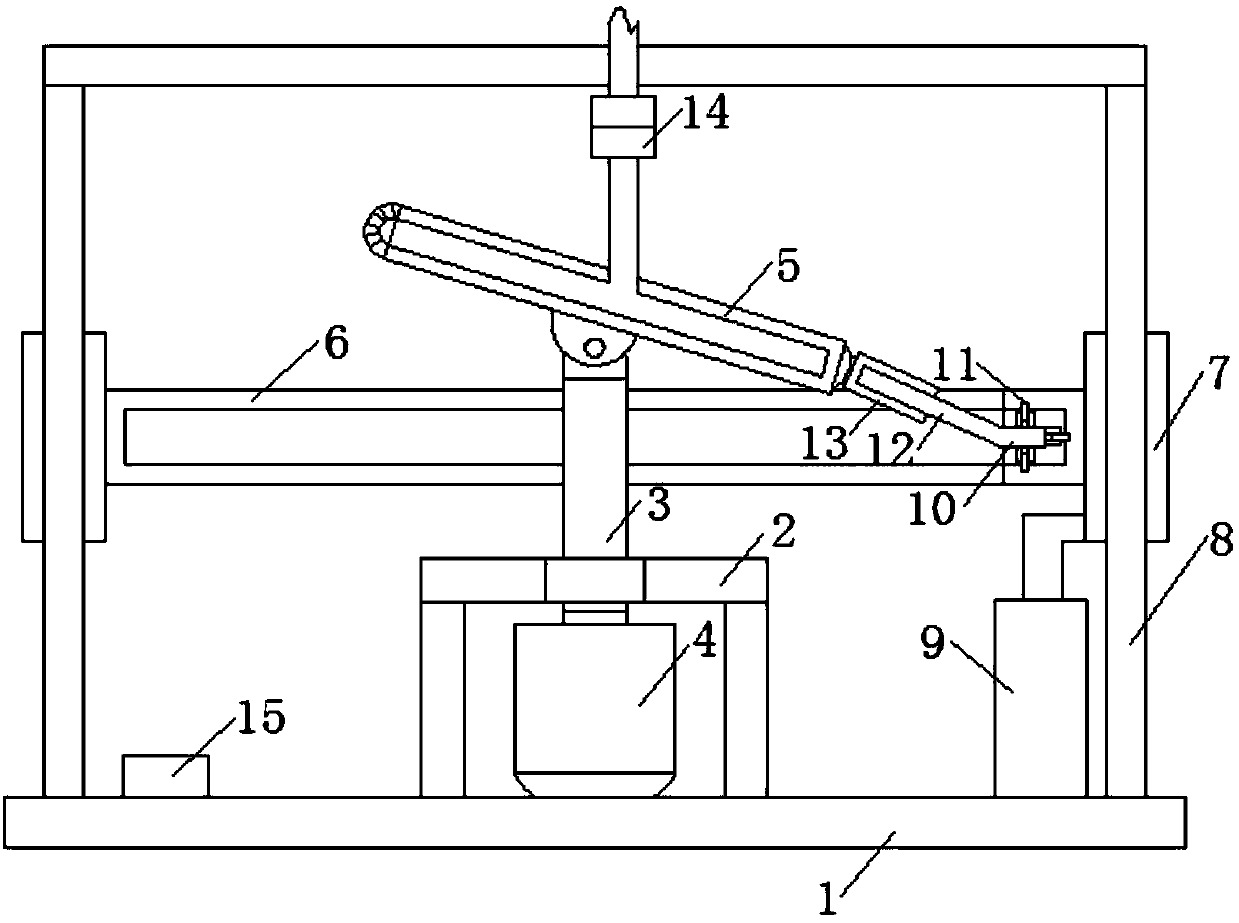

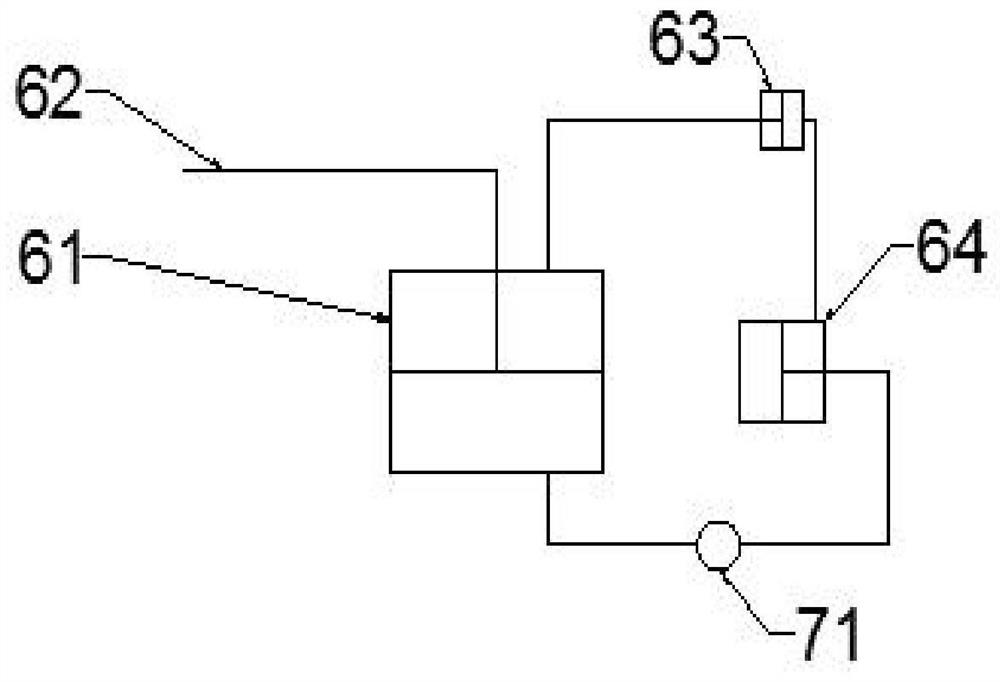

Water-saving controller for automatic irrigation

InactiveCN107750919AChange spray angleChange spray rangeWatering devicesCultivating equipmentsWater savingSolenoid valve

The invention discloses a water-saving control device for automatic irrigation, comprising a bottom plate, the upper ends of two guide rods are connected by a cross bar, and a liquid inlet pipe is fixed on the cross bar, and the liquid inlet pipe is provided with For the electromagnetic valve, a controller is provided on the base plate, and a humidity sensor is provided around the land where the base plate is located. The humidity sensor is electrically connected to the controller, and the controller is electrically connected to the motor, the electromagnetic valve and the electric push rod respectively. The water-saving control device for automatic irrigation, when the humidity sensor in the soil detects that the humidity is low, it will send a signal to the controller, so that the controller controls the motor to rotate, the solenoid valve is opened, and the water is sprayed, so that the spray gun will Spraying water in circles, the slider moves along the guide ring, while the electric push rod works at intervals, moving the guide cylinder up and down, so that the connecting rod drives the spray cylinder to rotate, changes the spray angle, and changes the spray range. When it comes to spraying water evenly, it saves more water.

Owner:张锡林

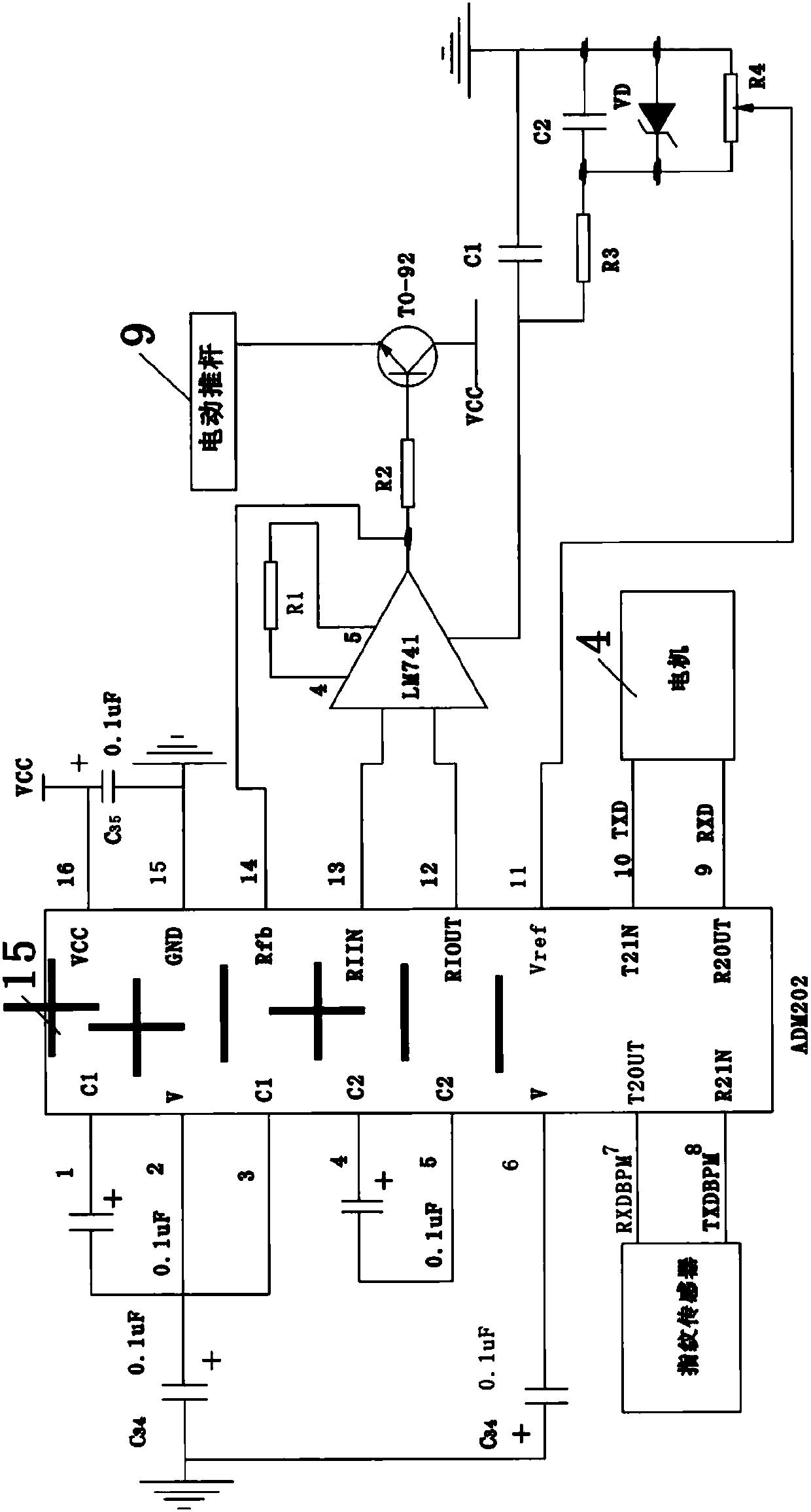

High-frequency triggered direct-current welding power source

InactiveCN113681120AEasy to recycleImprove seismic performanceWelding accessoriesWelding power supplyEngineering

Herein The invention discloses a high-frequency triggered direct-current welding power source, and belongs to the technical field of welding equipment. The high-frequency triggered direct-current welding power source comprises an outer protection sound insulation component, wherein a heat dissipation component is arranged in the outer protection sound insulation component, and the heat dissipation component is used for generating air vortexes. According to the high-frequency triggered direct-current welding power source, through mutual cooperation of the designed structures such as the outer protection sound insulation component, the energy conversion component, the heat dissipation component and an air flow filtering component, air sprayed out of a spiral pipe can enter a direct-current arc welding power source case in a spiral shape, the radiation range of low-temperature air is enlarged, and in addition, heat in cracks of electronic components in the direct-current arc welding power source case can be quickly dissipated by means of attraction force generated by the spiral air flow. Therefore, the heat dissipation effect is further improved, energy recovery is conducted in the whole stroke of vibration, waste energy utilization is facilitated, and the shock resistance of the direct-current arc welding power source is further improved.

Owner:深圳比斯特自动化设备有限公司

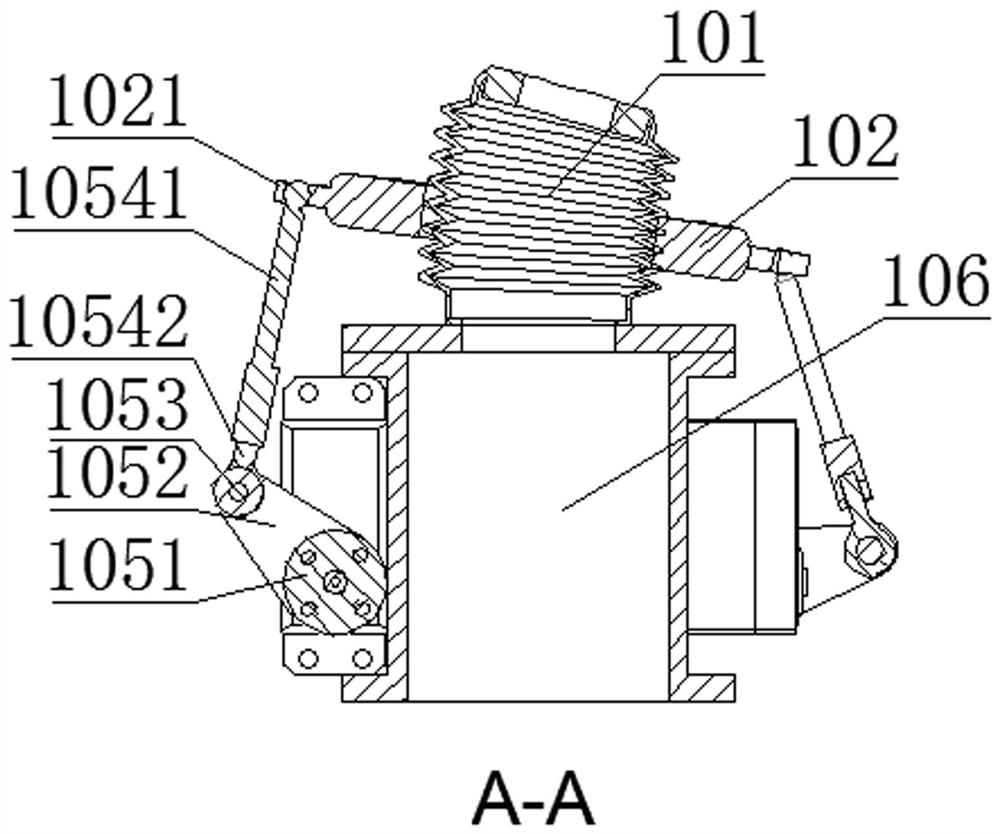

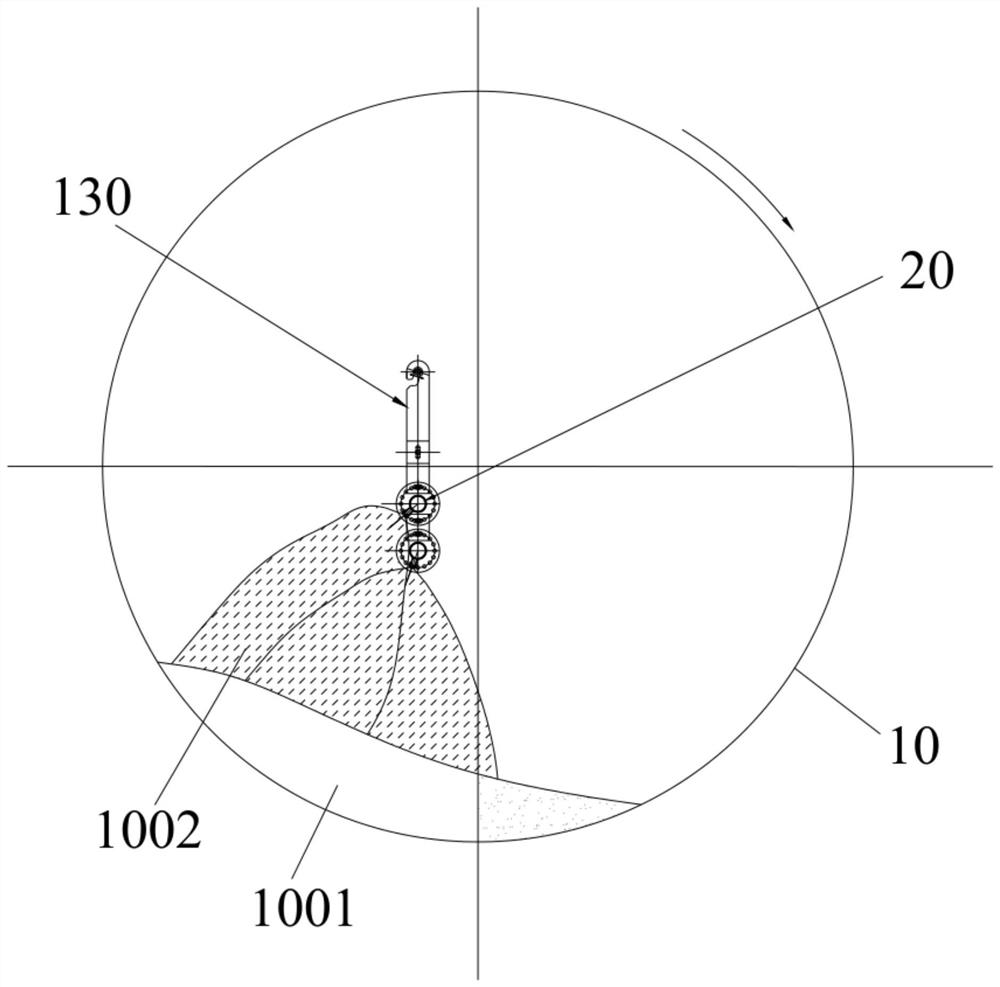

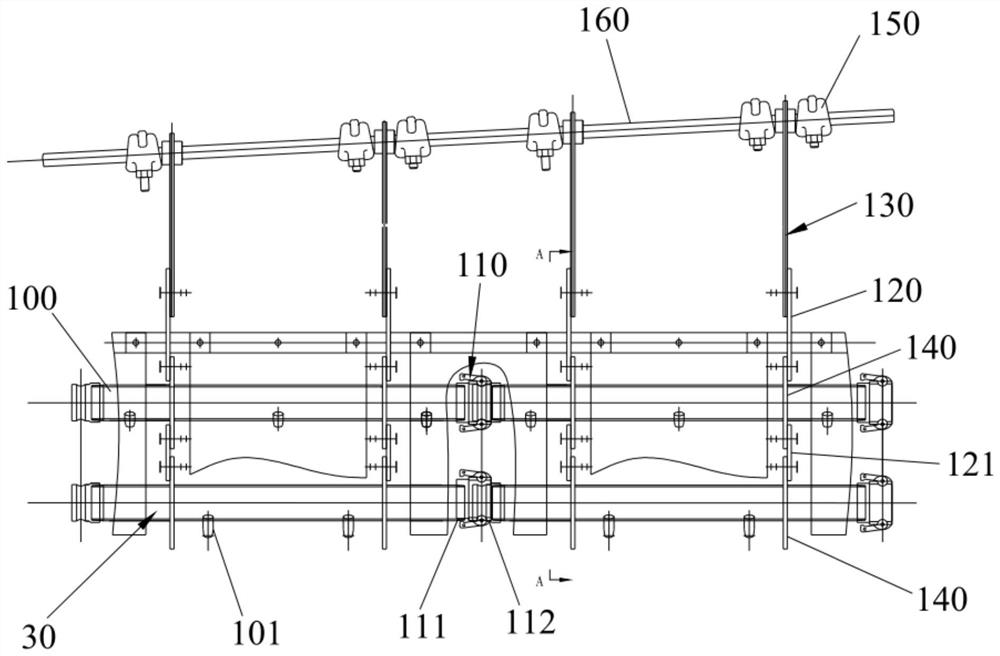

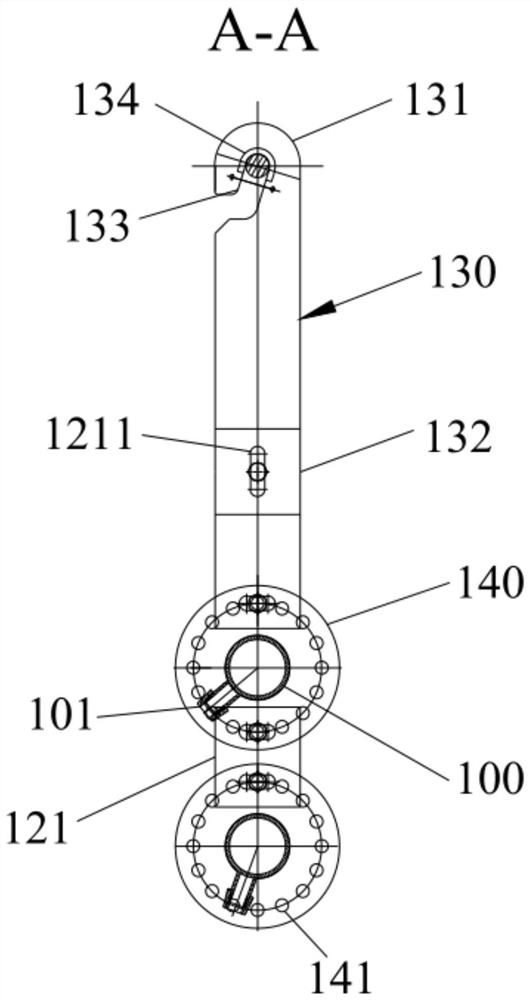

Underground tunnel construction equipment

InactiveCN108756938AChange spray angleAchieve fitUnderground chambersTunnel liningFixed frameUnderground tunnel

The invention discloses underground tunnel construction equipment. The underground tunnel construction equipment structurally comprises a hopper, a pneumatic oscillator, a meter box, a slurry sprayinghead, a shell, a slurry spraying head fixing device, a wind path, rail wheels, a fixing frame, a fixing face plate and a rotor body; the meter box and the shell are located on the same horizontal line and both mounted on the fixing frame; the fixing face plate is arranged on the fixing frame; the rotor body is fixedly arranged on the fixing face plate and mechanically connected with the hopper; and the slurry spraying head fixing device is mounted in the shell. Through the joint effect of a fixing mechanism, a central rotating mechanism, a first rotating mechanism, a manual starting device, an air cylinder driving device, a first rotating mechanism driving device and a second rotating mechanism, the spraying direction of the slurry spraying head can be changed according to the actual demands, manual slurry spraying is not needed, manpower input is reduced, and safety accidents in the slurry spraying process are avoided.

Owner:庄玉琼

Dust cleaning device for high-altitude electronic information board based on highway

InactiveCN112359742APlay a role in dust removalHeat dissipationPhotovoltaic supportsGeneral water supply conservationWater storageDrive wheel

The invention discloses a dust cleaning device for a high-altitude electronic information board based on a highway, and the device comprises an information board main body and an intelligent control system disposed at one side of the information board main body, and a water collection assembly is disposed above the information board main body. A water storage assembly is arranged on the rear sideof the information board body, and a spraying dust removal assembly is arranged at the position, corresponding to the water storage assembly, of the front side of the information board body. Accordingto the device, through mutual cooperation of the designed mechanisms such as the first driven wheel, the second driven wheel, the first connecting belt, the second connecting belt, the driving wheel,the motor, the condensation plate, the cooling fins, the intelligent control system, the drainage pipe, the water pump, the connecting pipe and the turbine, rainwater can be recycled on the basis that solar power supply is achieved; and water in the air can be recycled, so that a water source can be automatically provided for the cleaning work of the information board main body, a pipeline does not need to be laid, and the effects of dust removal and heat dissipation are achieved on the information board main body.

Owner:南京易百丰软件科技有限公司

Solar cold and hot water jetting device

InactiveCN109365159AChange heightChange spray angleSolar heating energySolar heat collector detailsWater storageWater storage tank

The invention relates to the technical field of civil engineering accessory devices, in particular to a solar cold and hot water jetting device capable of regulating water temperature. Meanwhile, theheight of a spray nozzle can be regulated, and the angle of the spray nozzle can be changed. The solar cold and hot water jetting device comprises a water storage tank, a water spray pump and the spray nozzle. A water storage cavity is formed in the water storage tank. A water spray opening is formed in the top of the water storage tank in a communicating manner. The water spray pump is connectedwith the right side of the top of the water storage tank. A water inlet pipe is arranged at the water inlet end at the bottom of the water spray pump in a communicating manner. The bottom end of the water inlet pipe penetrates the water spray opening and extends to the bottom of the water storage cavity. A water spray pipe is arranged at the water outlet end on the top of the water spray pump in acommunicating manner. The water inlet end of the spray nozzle communicates with the water spray pipe. The solar cold and hot water jetting device further comprises two threaded pipes, two threaded rods, a regulation plate, a rotation motor, a rotation rod, a base, a cold water box, a circulation pump, a cold water pump, a solar panel and two fixed rods. The bottom ends of the two threaded pipes are connected with the right side of the top of the water storage tank in a rotating manner. The bottom ends of the two threaded rods are installed in the two threaded pipes in a screwed manner correspondingly.

Owner:邓胜仙

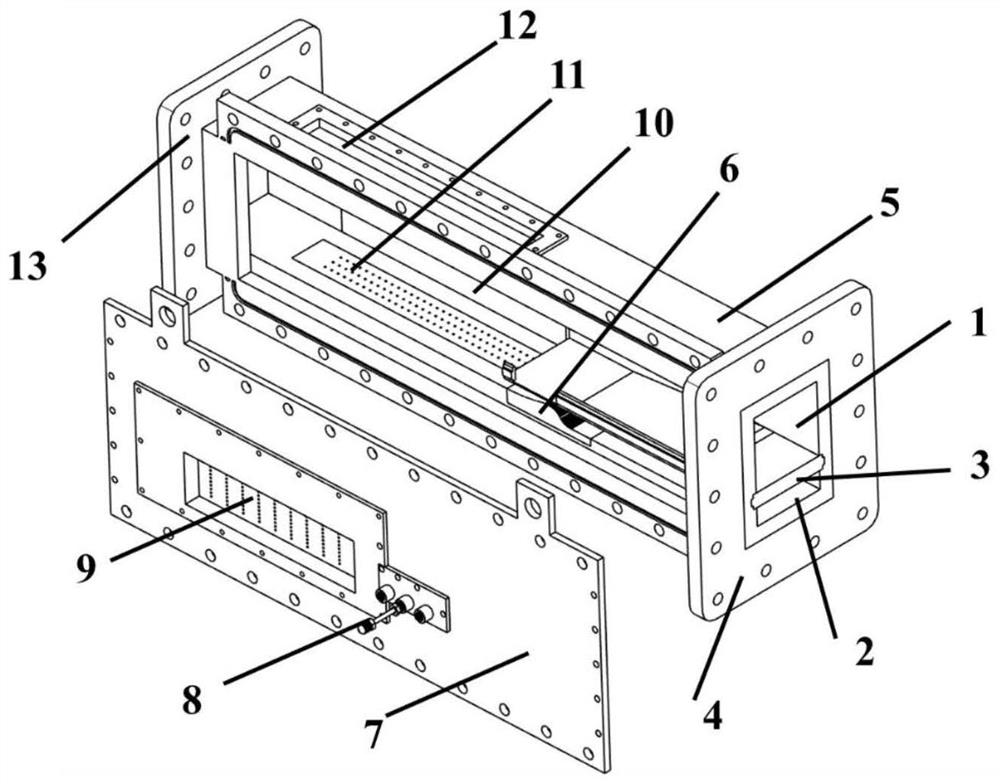

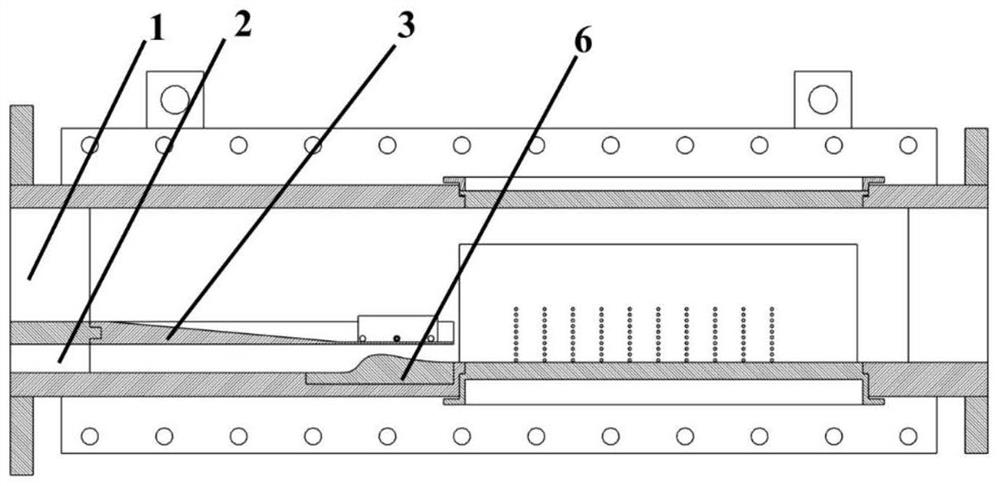

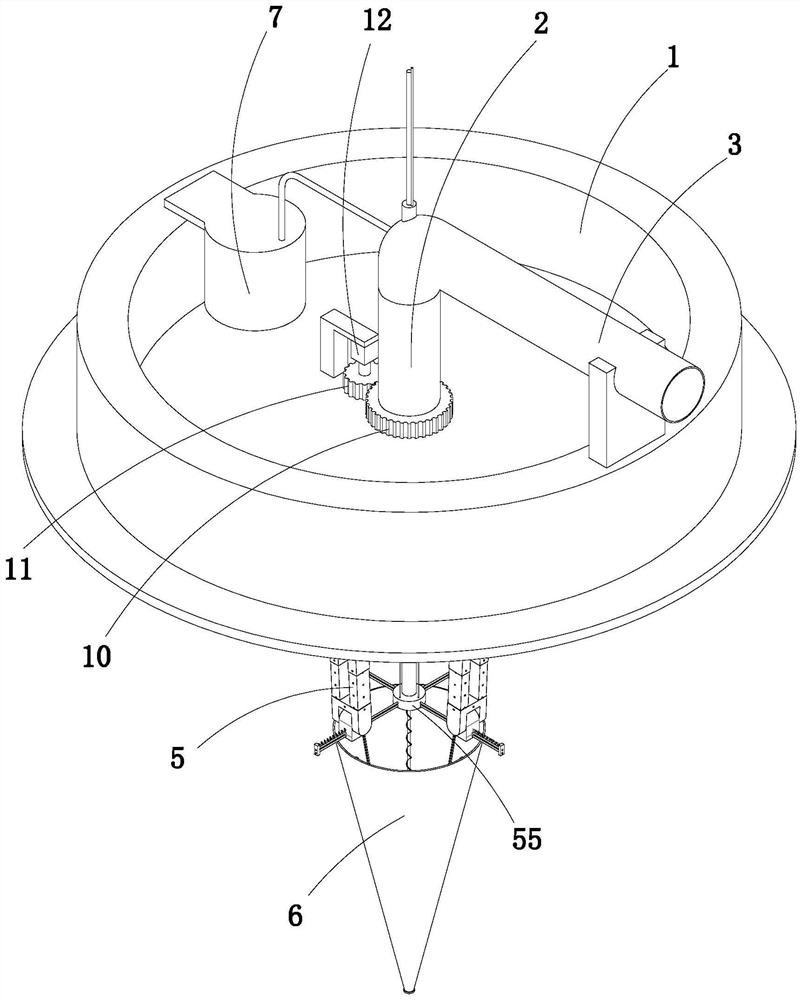

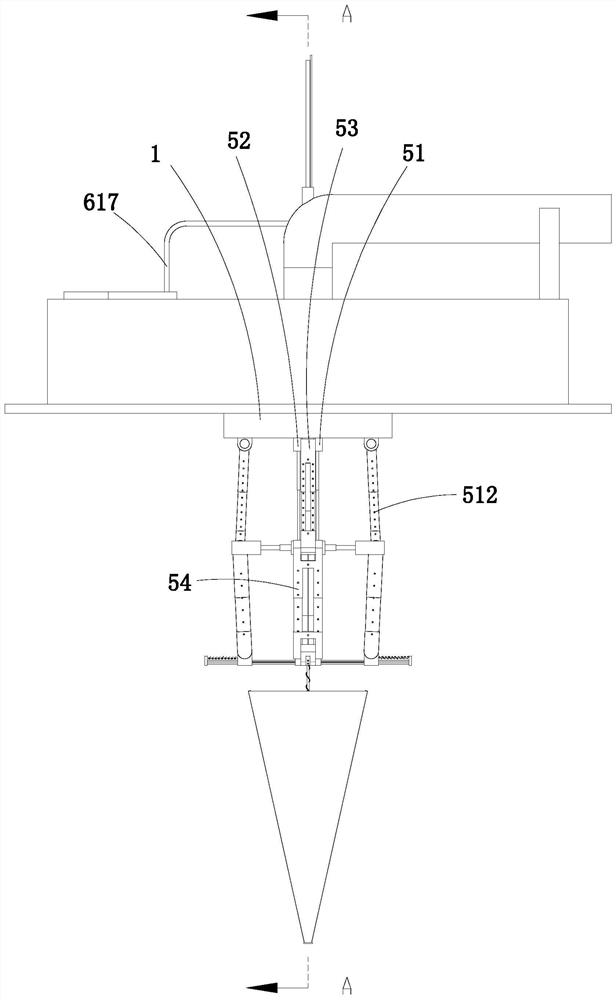

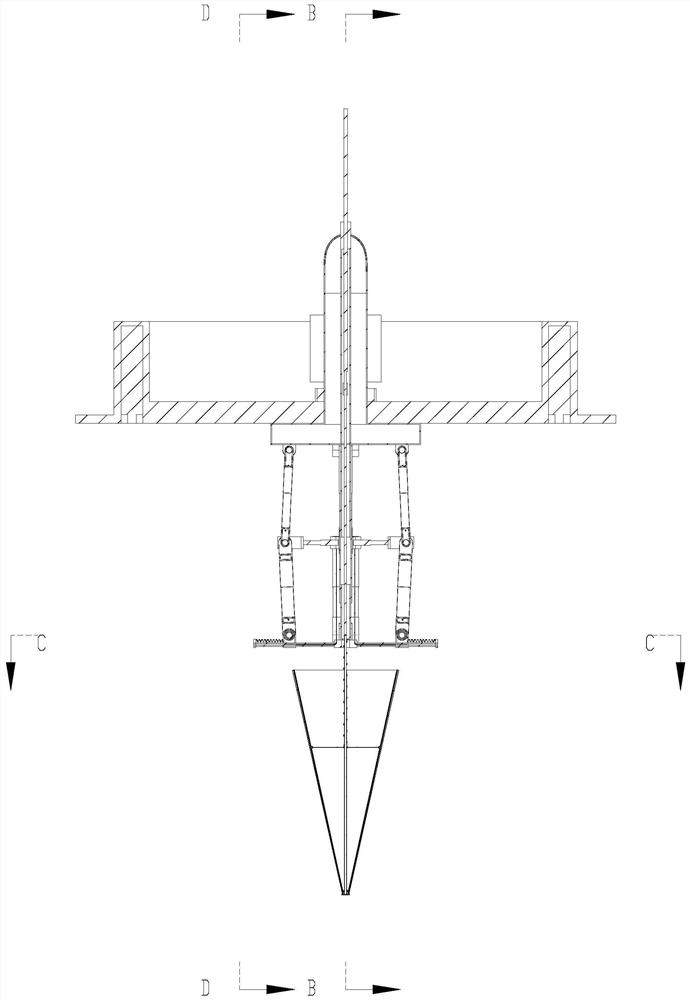

Fuel injection and atomization combustion test device suitable for large-gradient shear flow

InactiveCN112161812AChange spray angleControl Penetration DepthGas-turbine engine testingJet-propulsion engine testingAviationEngineering

The invention discloses a fuel injection and atomization combustion test device suitable for large-gradient shear flow, and relates to the technical field of aviation. The fuel injection and atomization combustion test device suitable for large-gradient shear flow comprises a mixing chamber main body 5, a subsonic flow channel 1, a supersonic flow channel 2, a support plate 3, a Laval nozzle 6, adirect injection type oil injection rod 8 and a cover plate 7, and a side wall surface optical measurement window 10 and an upper wall surface optical measurement window 12 which are used for shootingan oil mist field after fuel oil atomization, and a side wall surface temperature and pressure measurement point 9 and a lower wall surface temperature and pressure measurement point 11 which are used for measuring the temperature and pressure of the inner wall of the observation cavity, are arranged in an observation cavity. According to the designed mixing chamber, oil accumulation and coking can be effectively prevented, the atomization effect of liquid fuel is improved, and the problems that ignition is difficult, flames are unstable, and fuel is difficult to completely burn are solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

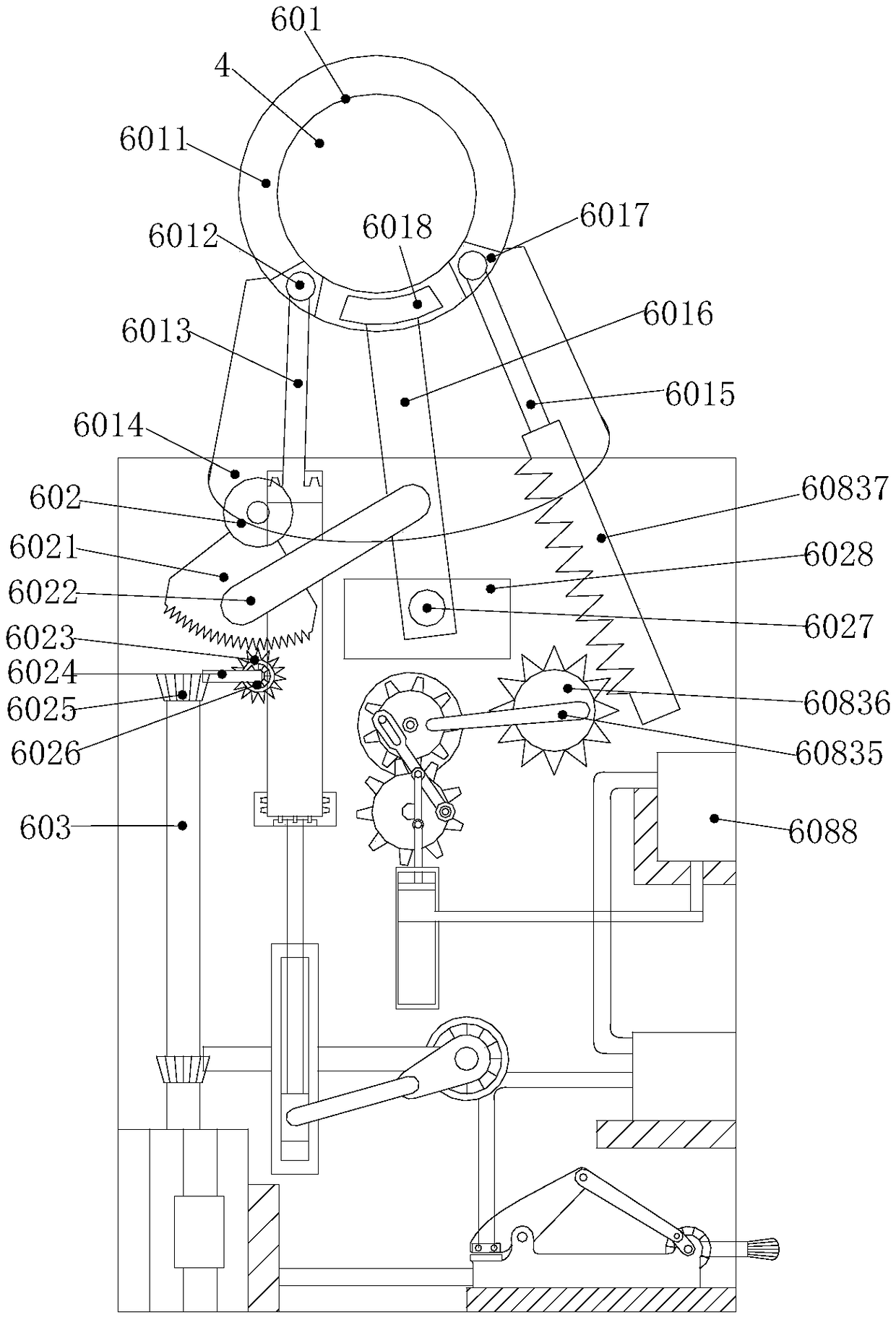

Intelligent fire-fighting management system based on big data Internet of Things

ActiveCN114191762APrevent foggingReduce labor intensityLighting and heating apparatusFire rescueGear wheelElectric machinery

The invention discloses an intelligent fire-fighting management system based on a big data Internet of Things. Comprising a base, a rotating disc rotationally arranged on the base, a water inlet pipe, an electromagnetic valve arranged in the water inlet pipe, a water spraying device arranged on the rotating disc, a water collecting device arranged in the water spraying device, a housing fixedly arranged on the base, and a smoke sensor fixedly arranged in the housing, wherein one end of the water inlet pipe is rotationally arranged on the rotating disc, and the water inlet pipe is fixedly arranged on the base; the electronic cigarette is located under the smoke sensor and fixedly arranged on the base, the rotating disc is fixedly sleeved with the first gear, the second gear is rotationally arranged on the base and meshed with the first gear, and the motor is fixedly arranged on the base and used for driving the second gear to rotate.

Owner:浙江省邮电工程建设有限公司

Oil purifier for motor vehicle

InactiveCN102140983BIncrease cold use flexibilityChange spray angleInternal combustion piston enginesThermal treatment of fuelFiltrationEngineering

Owner:日照安瑞机电科技有限公司

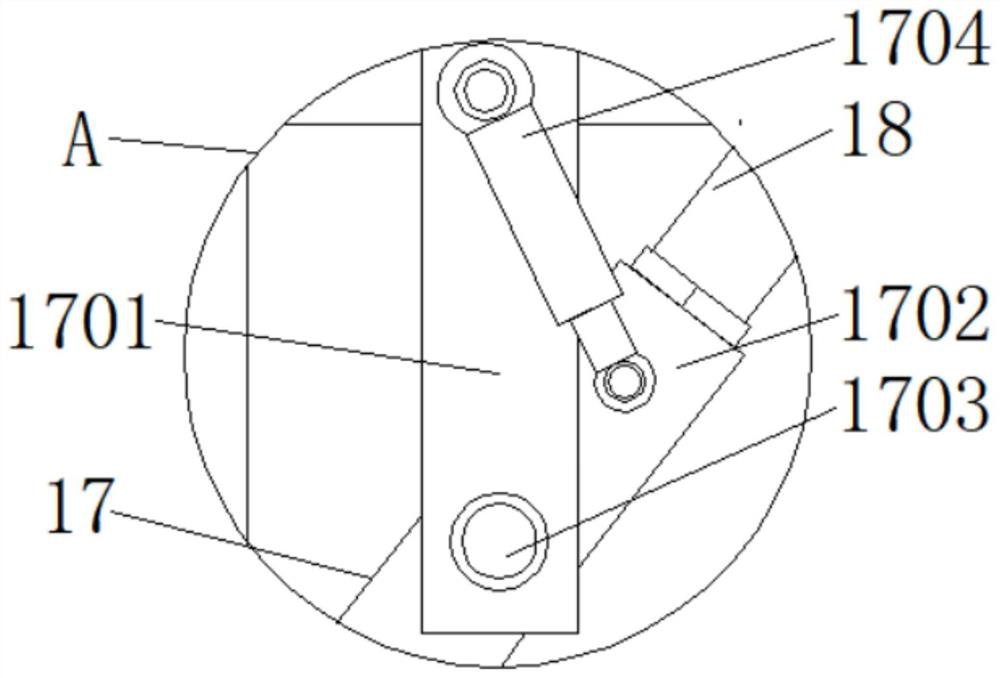

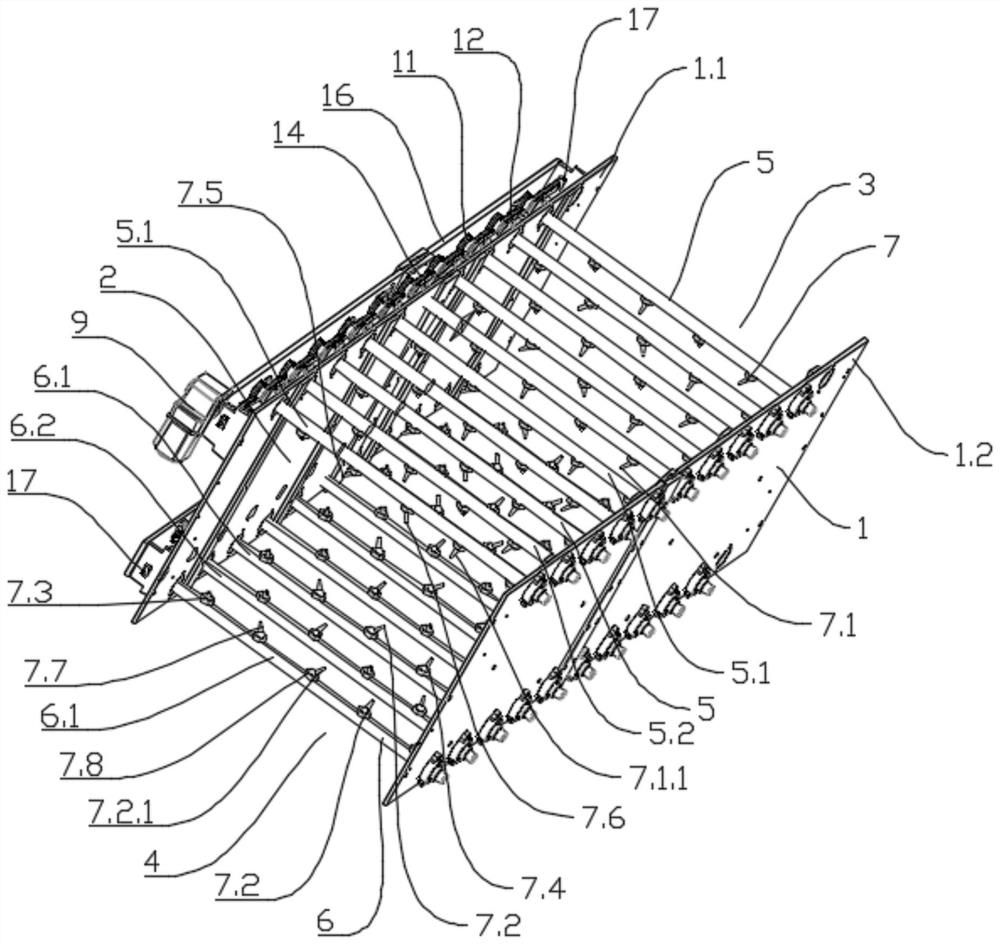

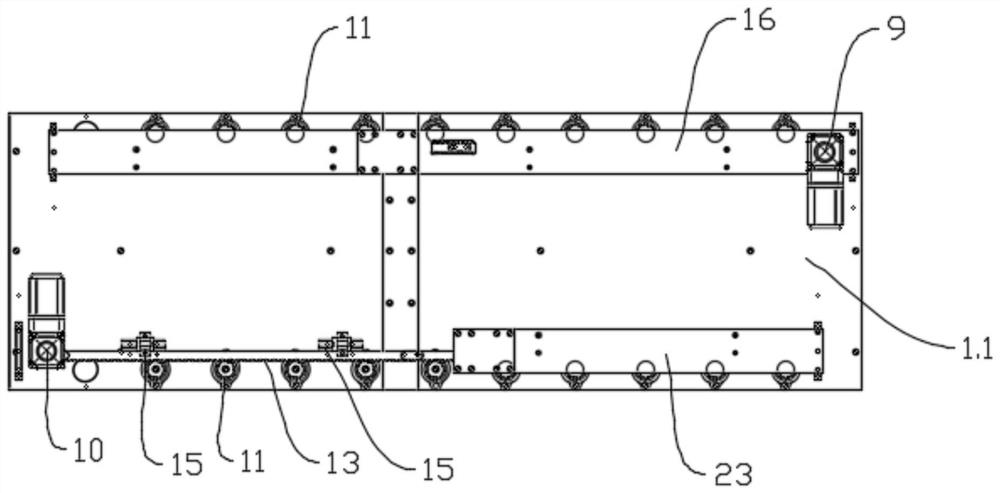

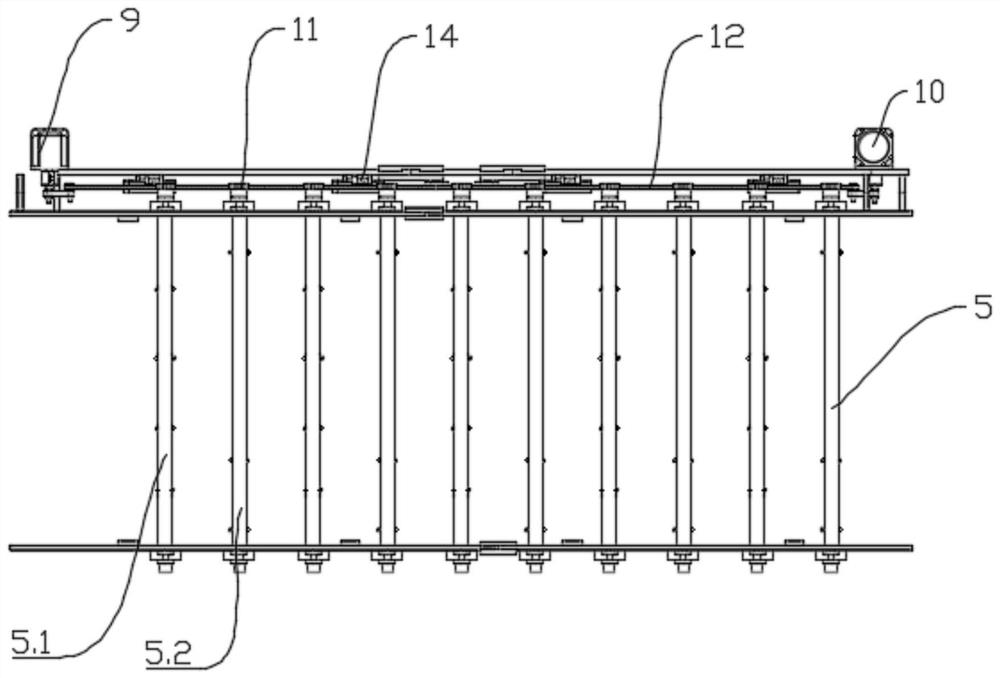

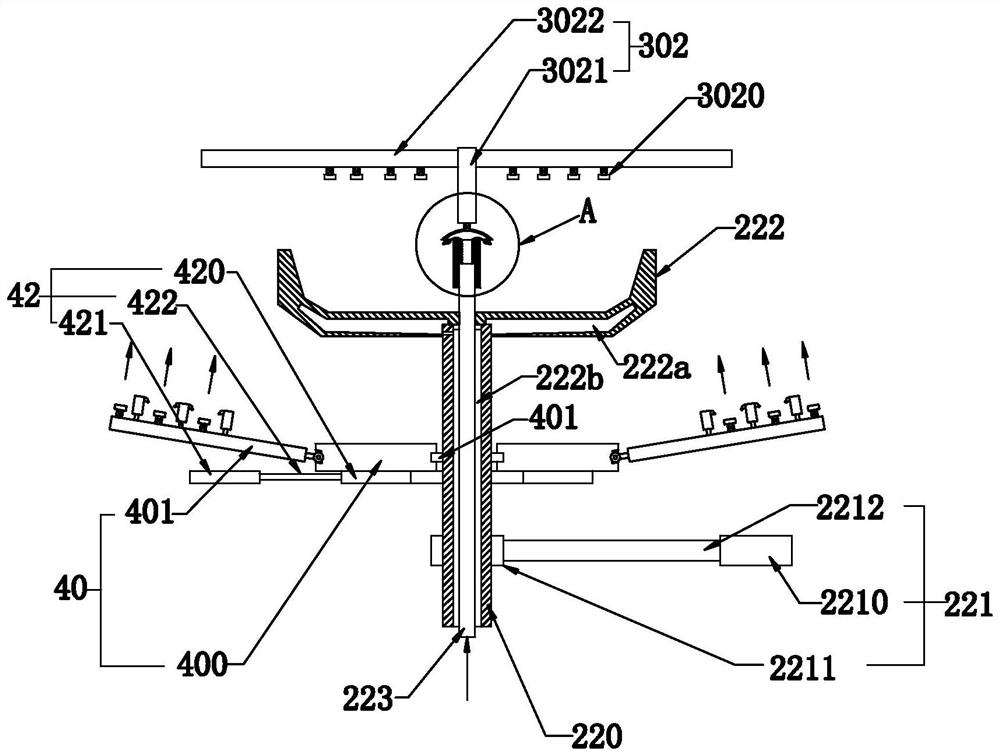

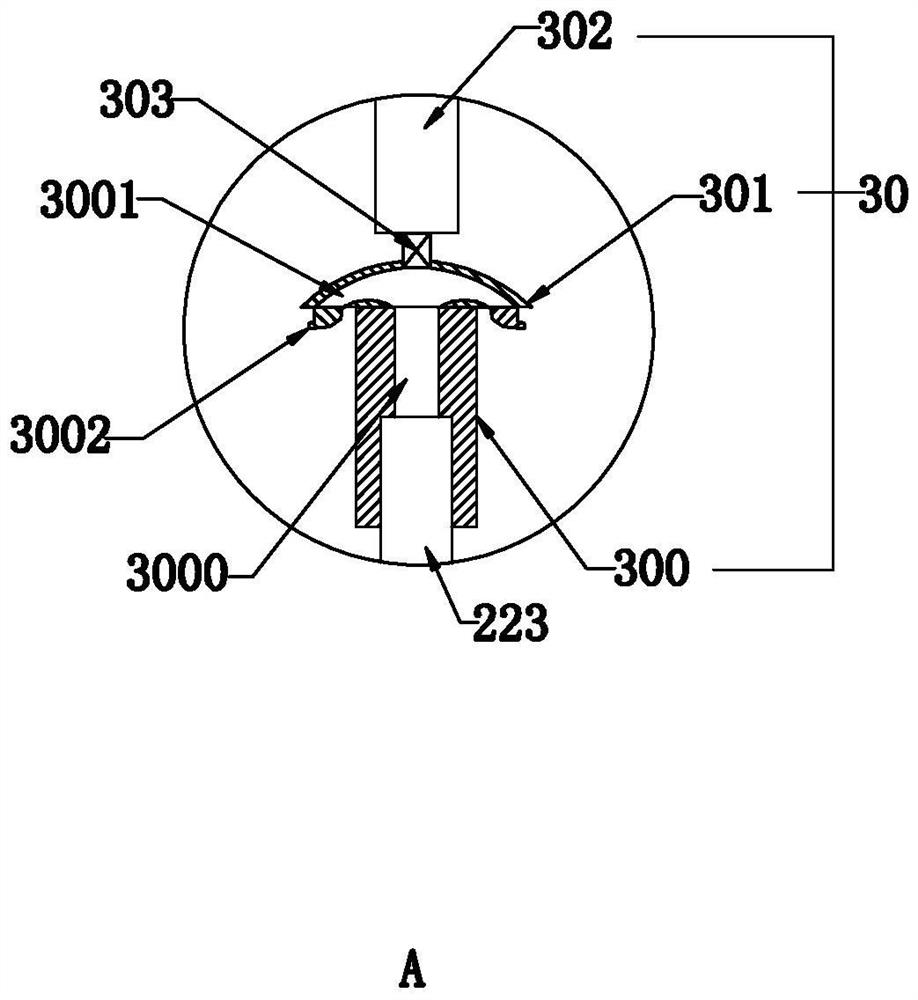

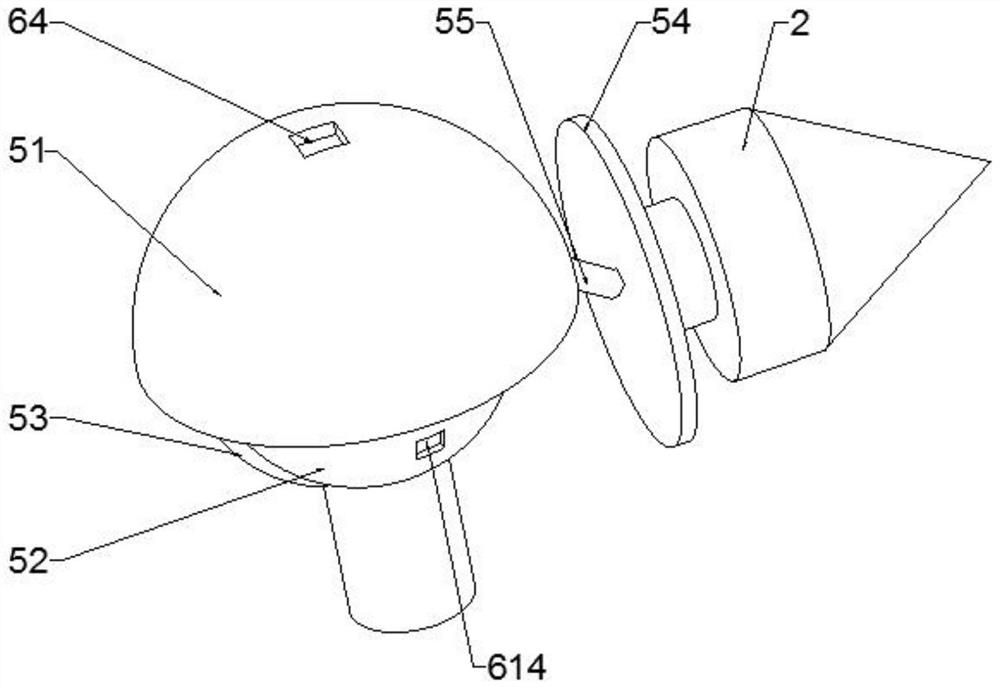

A nozzle steering mechanism and a plastic tank cleaning device using the nozzle steering mechanism

ActiveCN109701980BChange spray angleEffective flushingHollow article cleaningControl engineeringWater resources

The invention belongs to the technical field of cleaning equipment, and discloses a nozzle steering mechanism and glue vat cleaning equipment using the nozzle steering mechanism, including a mounting frame, which is provided with an upper installation position, a lower installation position below the upper installation position and a The cleaning area between the upper installation position and the lower installation position, the cleaning area is provided with an inlet end and an outlet end, the upper installation position is provided with a number of rotating shafts 1, the lower installation position is provided with a number of rotating shafts 2, a number of rotating shafts 1 and The two rotating shafts are arranged side by side sequentially from the inlet end to the outlet end, the first rotating shaft and the second rotating shaft are rotationally connected with the mounting frame, and the first rotating shaft and the second rotating shaft are provided with nozzles; the present invention can be used from different angles Realize the high-pressure water flushing of the glue tank, which has the advantages of good flushing effect, high cleaning efficiency, high utilization of water resources and saving water resources.

Owner:成都慧晶机械设备有限公司

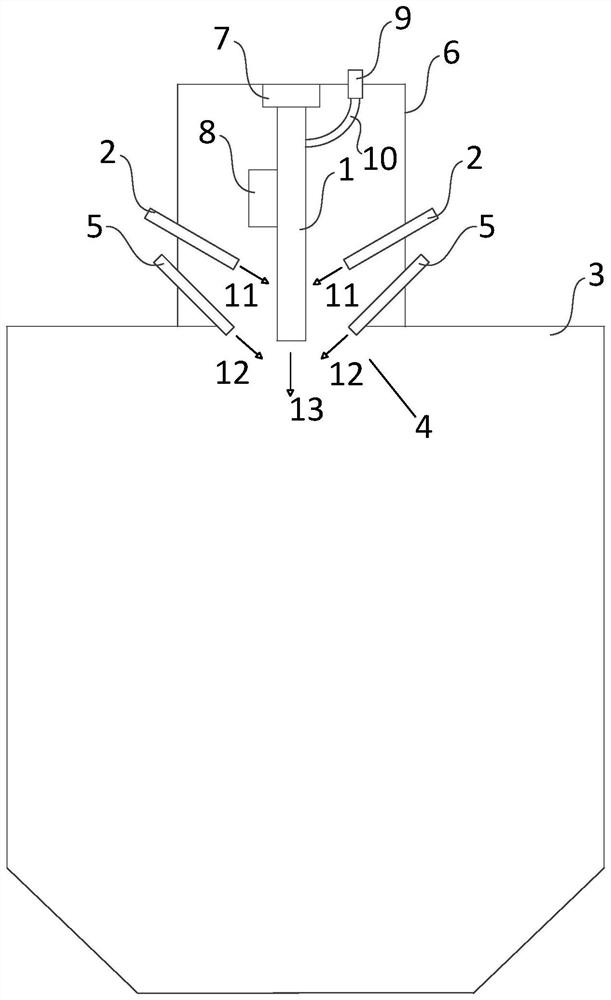

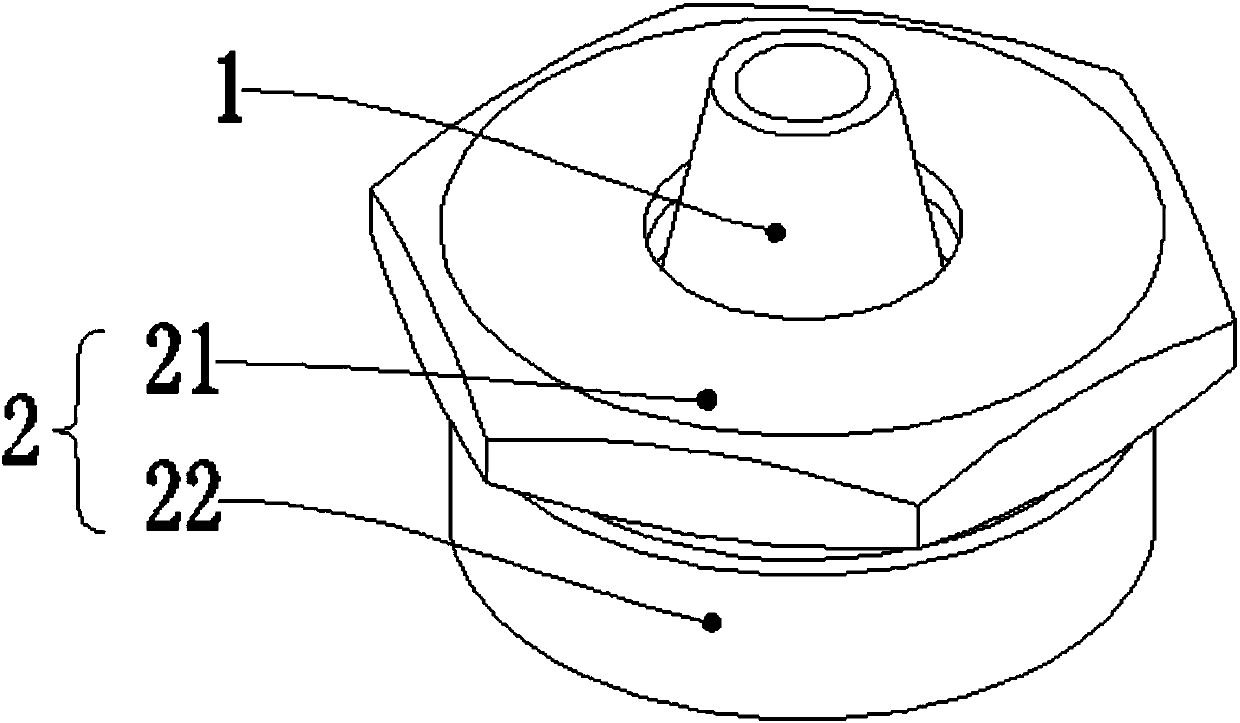

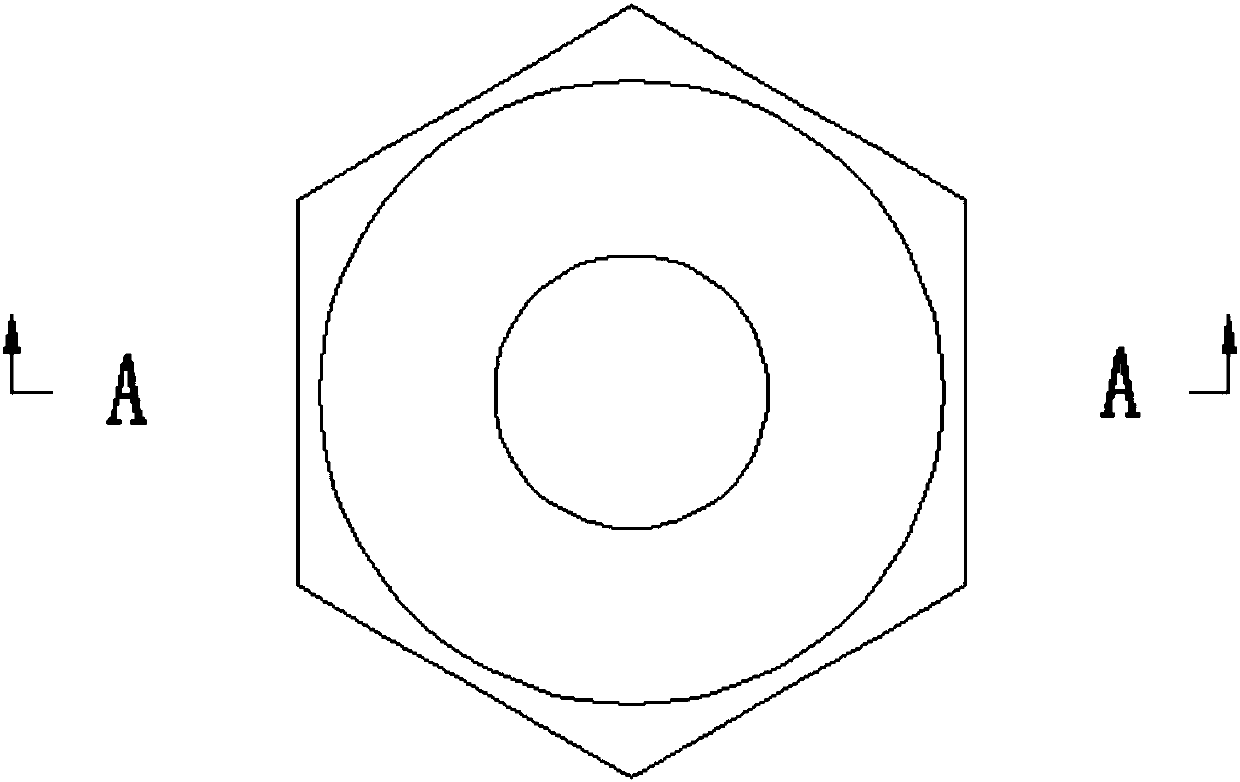

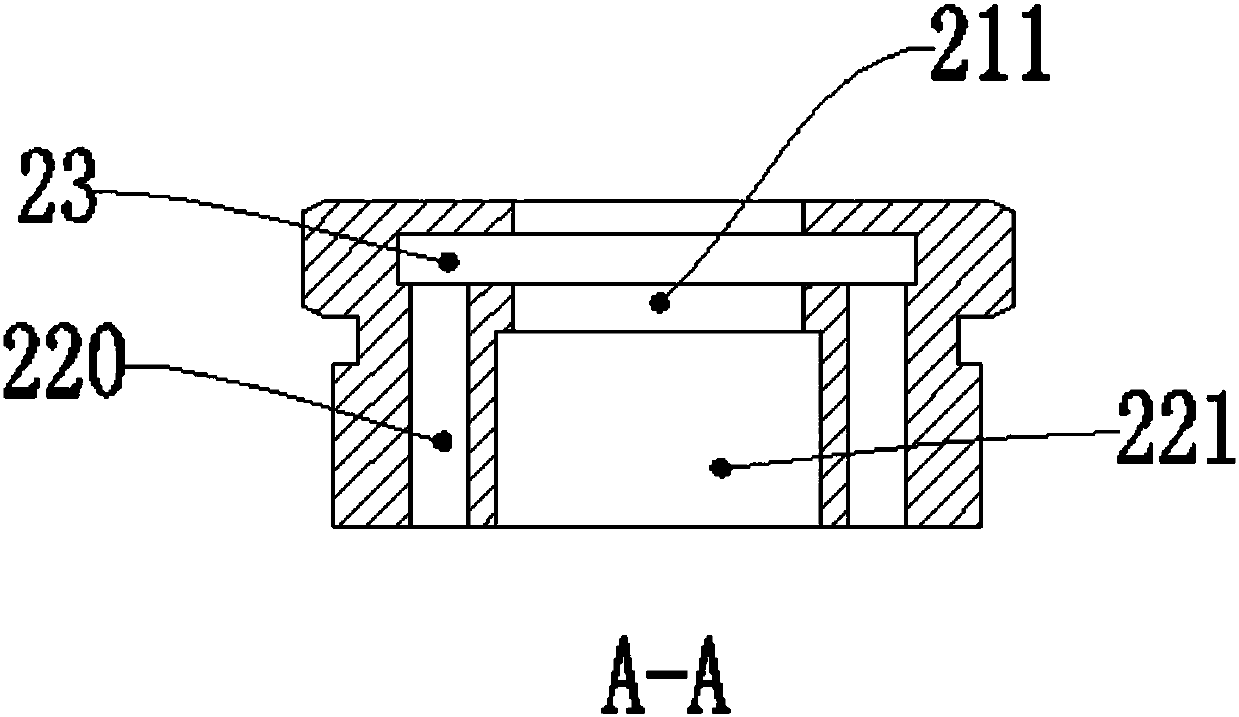

Combustion/gasifier and nozzle modules for combustion/gasifier

ActiveCN108342224BExpand the spraying rangeChange injection trajectory in real timeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustionChemical reaction

The present invention provides a combustion / gasification furnace and a nozzle module for combustion gasification, a static nozzle of the prior art is converted into a movable nozzle having a movable joint, and an auxiliary nozzle sprays a gas, so that the movable nozzle can move and motion without a mechanical drive device, a spraying angle can be changed in real time, and a spraying range is increased; at the same time, a nozzle with an adjustable spraying angle sprays a gas, so that a spraying trajectory of a spraying airflow sprayed by the movable nozzle can be changed, the spraying range of the movable nozzle can be expanded to improve the heat transfer, mixing and chemical reaction effects of a fuel in the combustion / gasification furnace; the gas sprayed by the auxiliary nozzle and the gas sprayed by the nozzle with the adjustable spraying angle are combustion-supporting gases, the spraying range of the movable nozzle can be expanded, the combustion of the fuel in the combustion / gasification furnace can be further promoted, and the efficiency of combustion and gasification can be increased.

Owner:范全荣

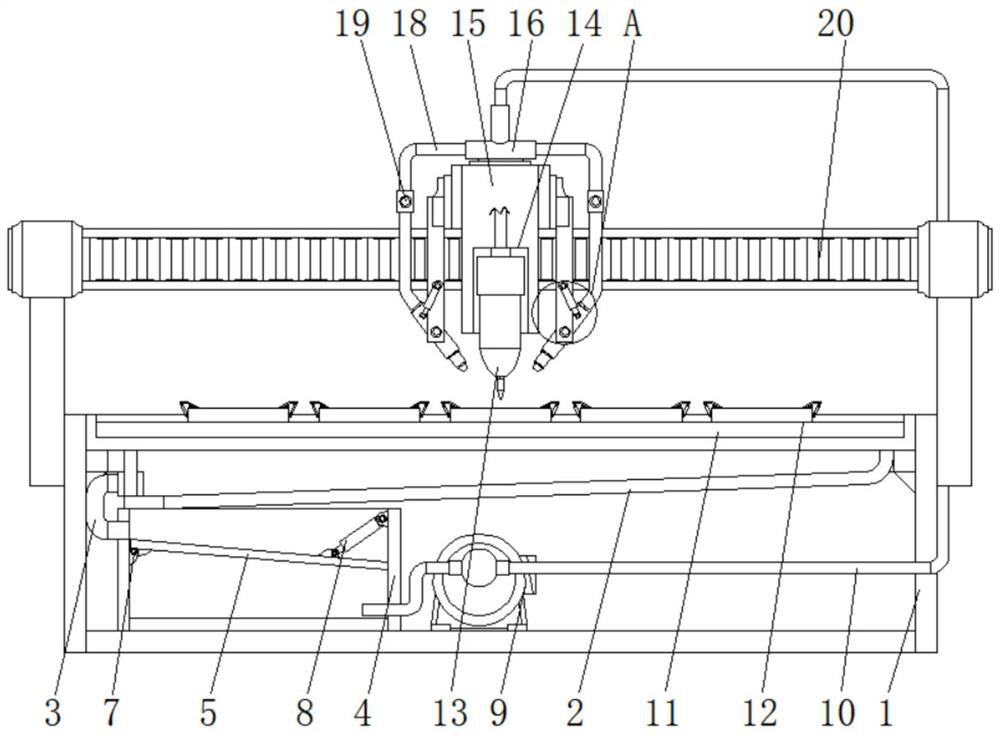

Water spray nozzle for linear cutting machine

The invention relates to a water spray nozzle for a linear cutting machine. The water spray nozzle for the linear cutting machine is characterized by comprising a water spray pillar and a base. The base comprises an upper base body and a lower base body. The upper base body is connected with the outer side of the lower base body. A water introducing groove is arranged between the upper base body and the inner side of the lower base body. The lower base body is provided with a plurality of water introducing holes. An upper through hole is formed in the center of the upper base body. A lower through hole is formed in the center of the lower base body. The water spray pillar is fixed in the lower through hole and comprises a cone portion and a pillar portion, and the pillar portion is installed and fixed in an installing hole. The center of the water spray pillar is provided with a wire penetrating hole penetrating through the water spray pillar. The range of the angle A between the lateral wall of the cone portion and the vertical direction is 1.9-2.5 degrees. The diameter of the upper through hole is 9 mm. The diameter of the lower through hole is 10 mm. The horizontal distance between the lateral wall of the water spray pillar and the upper through hole is 1.8-1.9 mm. The cooling effect and machining flatness of the water spray nozzle are improved.

Owner:FOSHAN DATIE NUMERICAL CONTROL MACHINERY

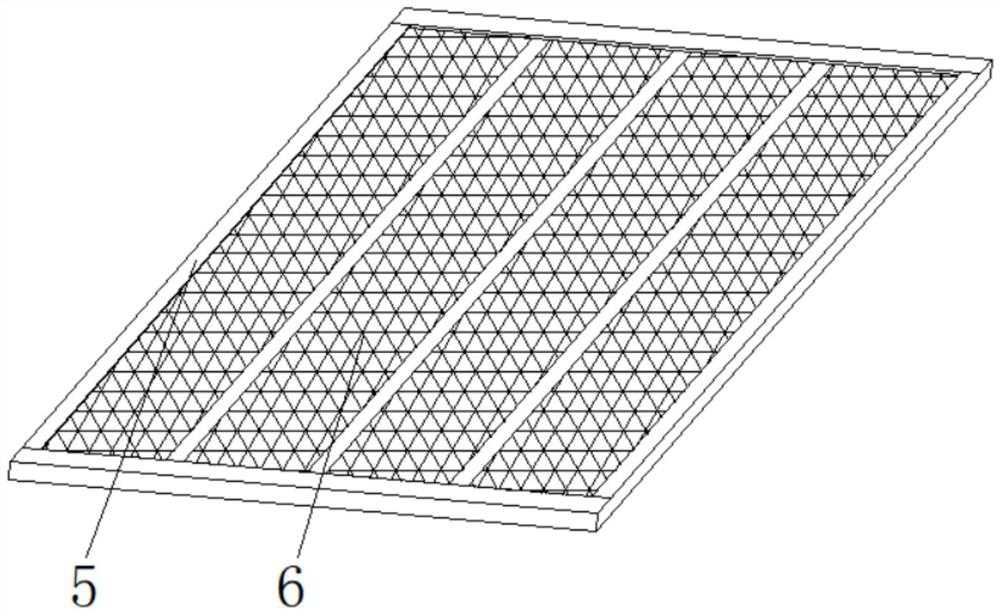

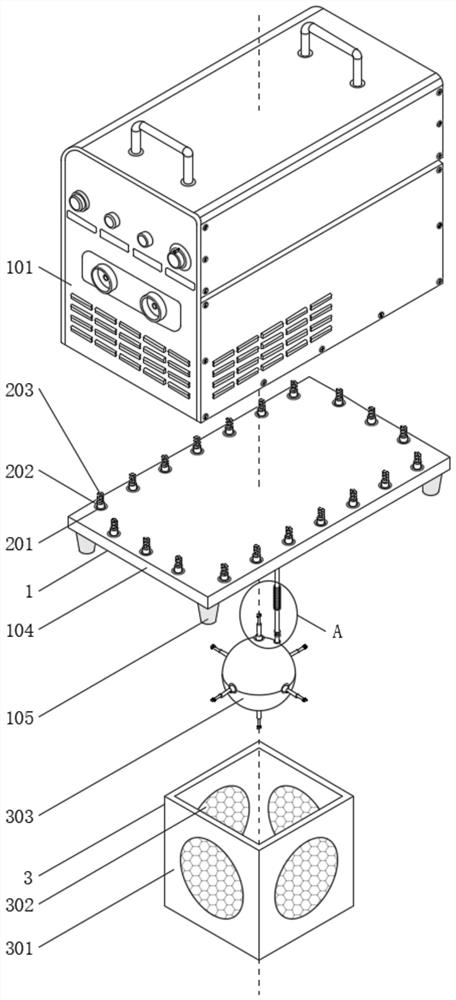

A new energy solar panel washing device

ActiveCN112491353BChange spray angleFully softenedPhotovoltaicsCleaning using toolsWater storage tankElectric machinery

The invention relates to the technical field of solar panels, in particular to a new energy solar panel washing device, comprising a workbench, a water storage tank is fixedly arranged on the workbench, a water pump is fixedly arranged in the water storage tank, and a water spray is fixedly arranged on the water pipe cover, the workbench is fixed with a mounting frame, the mounting frame is provided with a circuit control seat, the circuit control seat is fixed with a horizontal mounting frame, the horizontal mounting frame is slidably connected with a horizontal moving seat, the horizontal The movable seat is fixed with a longitudinal installation frame, the longitudinal threaded screw is threadedly connected with a longitudinal movable seat, the longitudinal movable seat is provided with a mounting plate, the first motor is fixed with a threaded column, and the threaded column is threadedly connected With mounting seat. On the basis of the common flushing device, the invention is provided with angle adjustment, water spraying, transmission, lifting and brushing devices, which improves the conversion efficiency of the solar panel, reduces the labor intensity of the staff and makes the cleaning effect more thorough.

Owner:苏州碳索能源科技有限公司

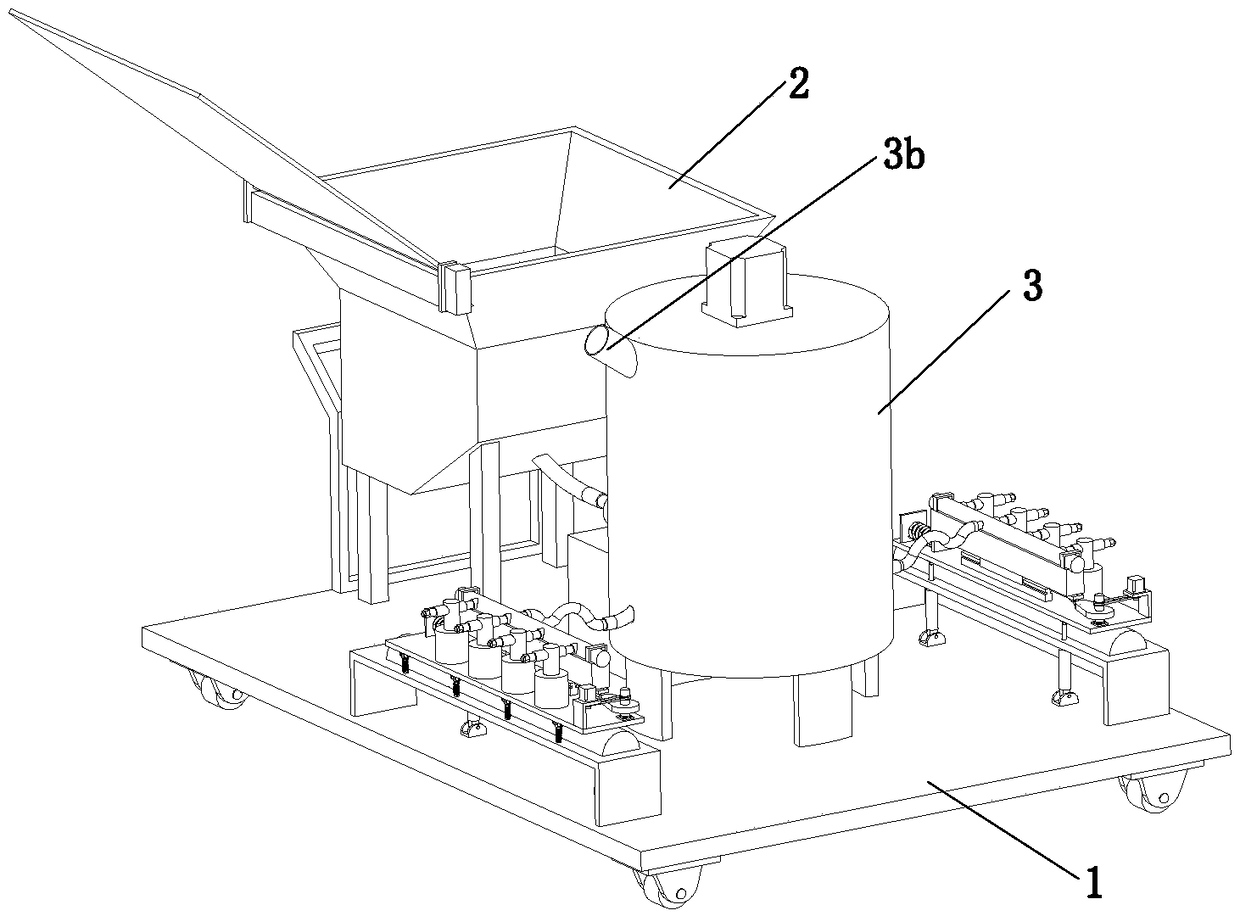

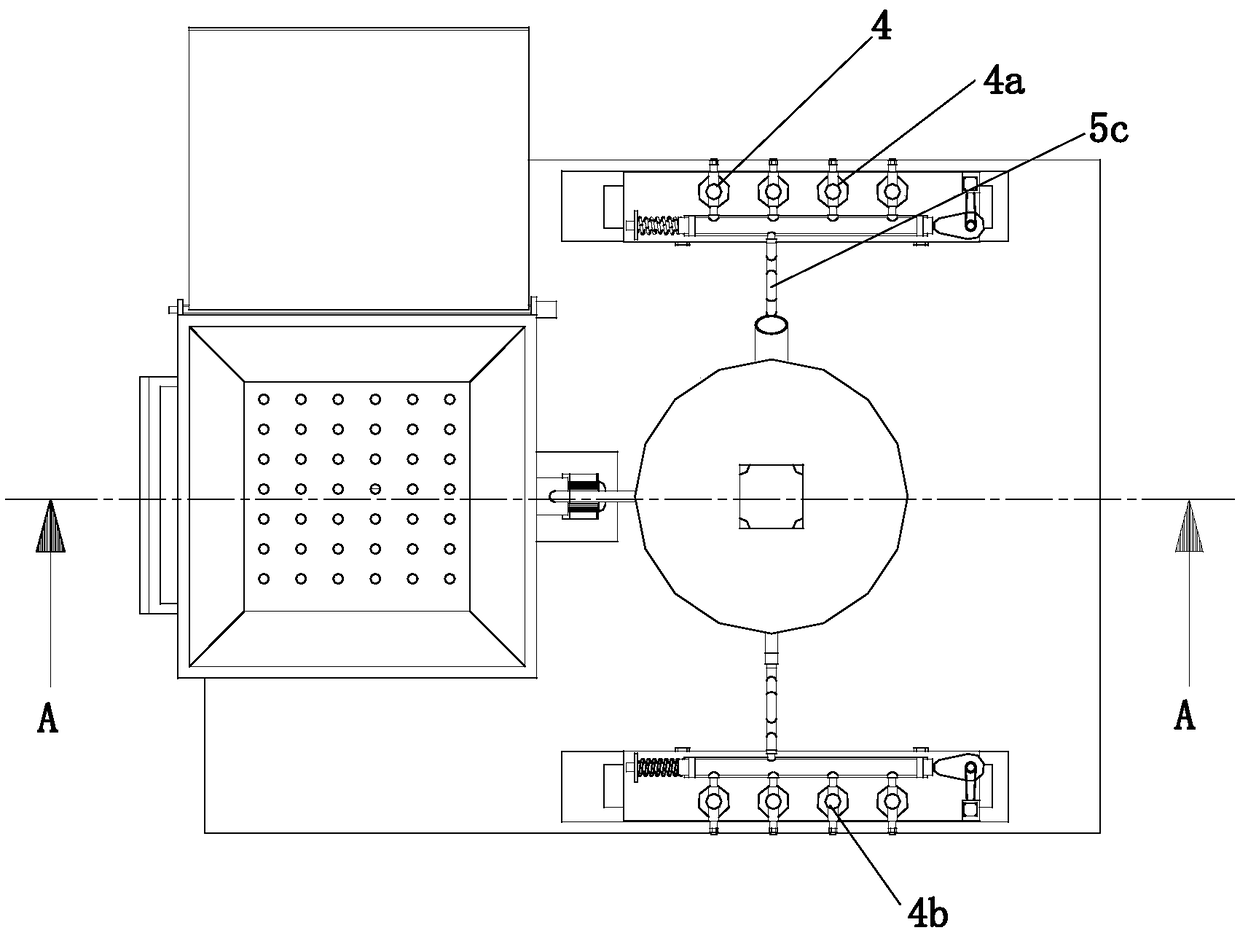

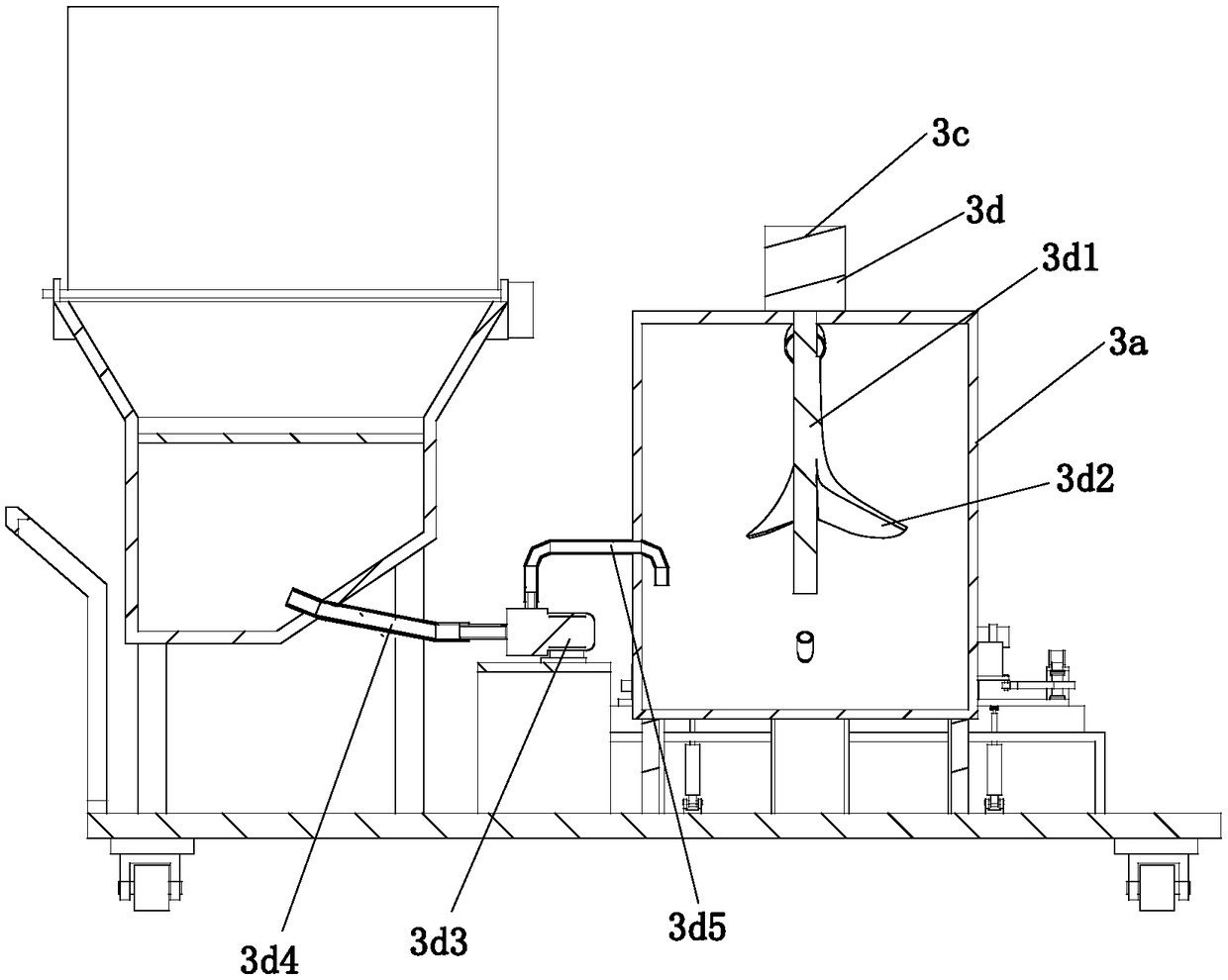

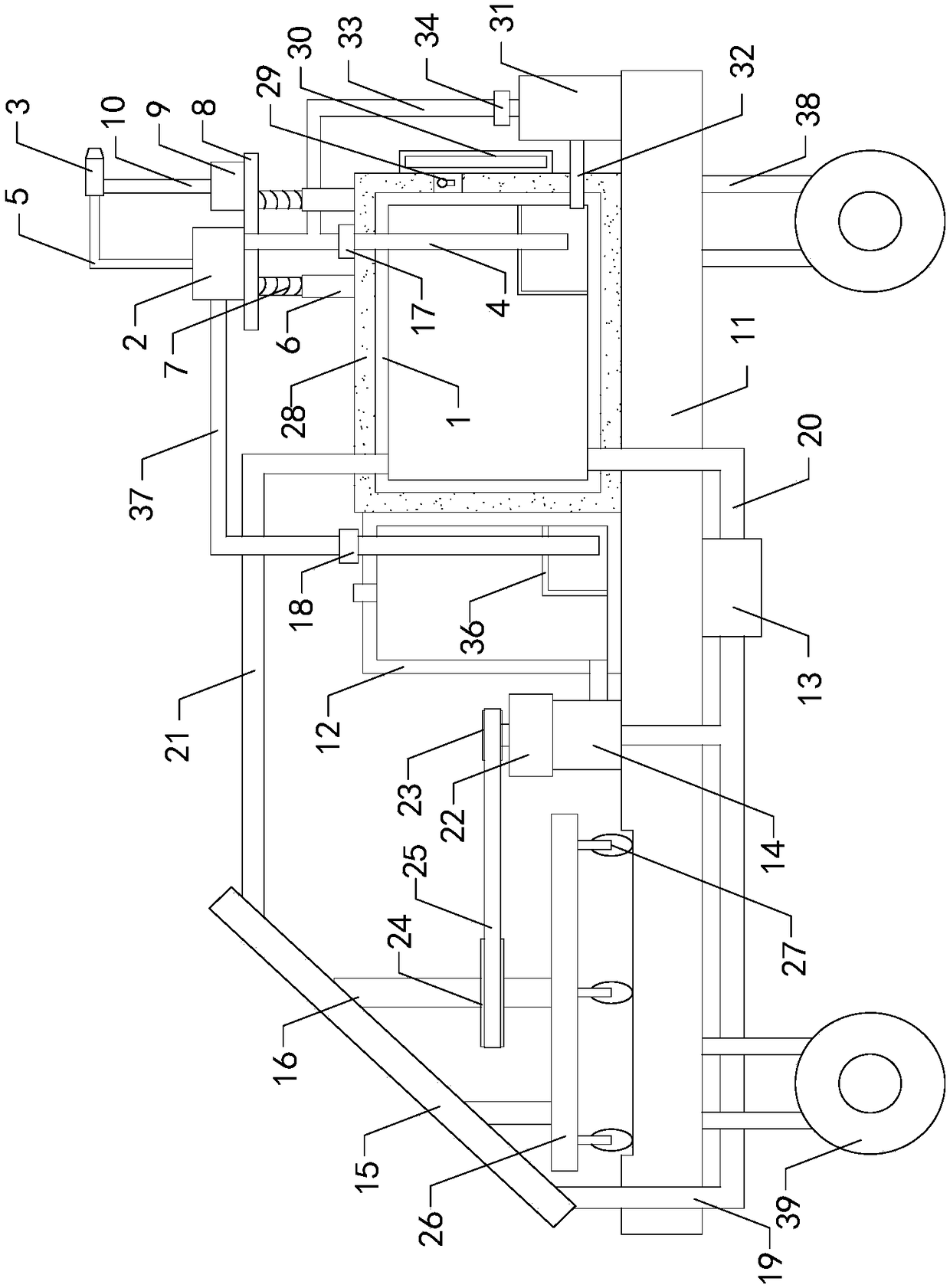

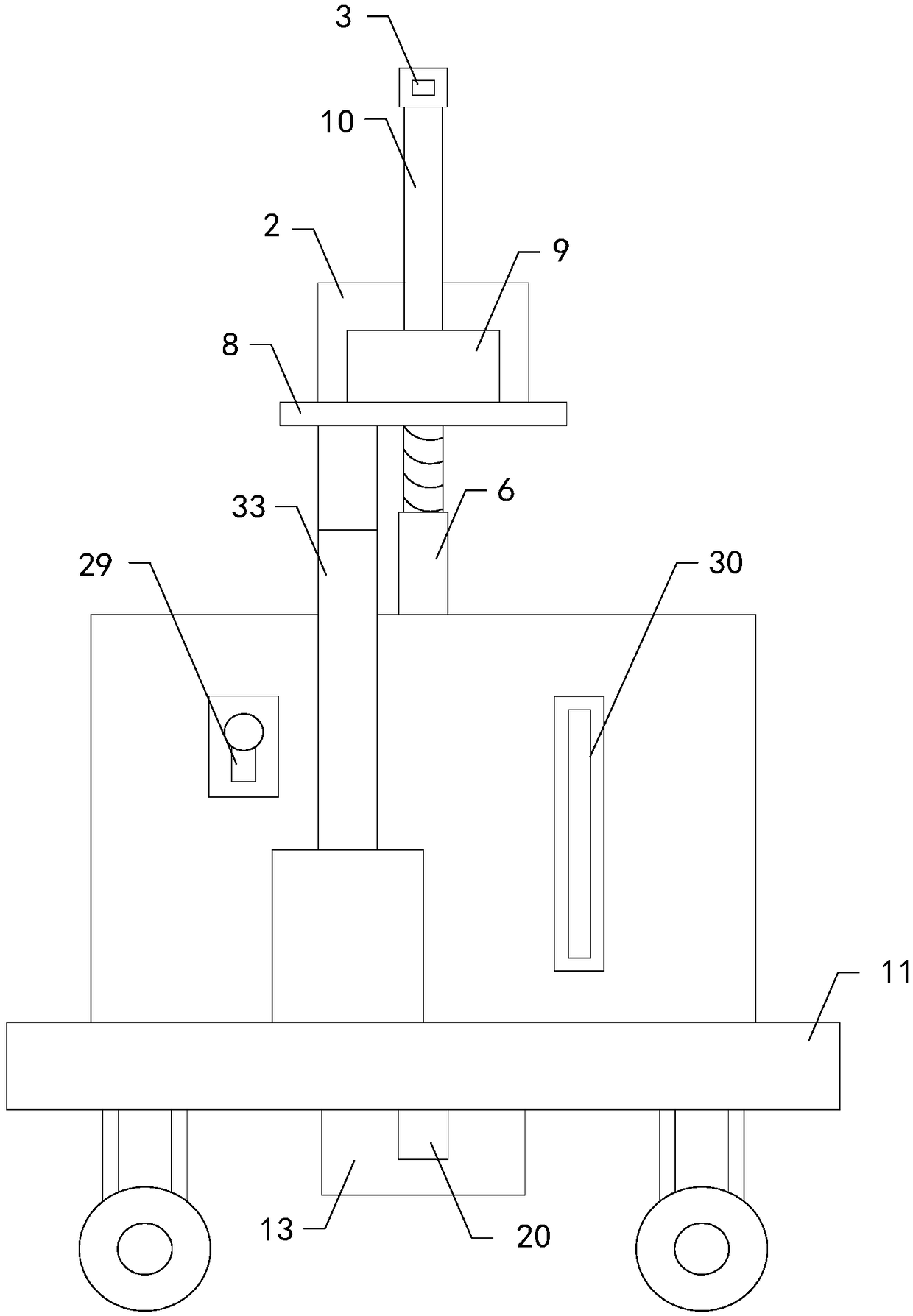

Light soil construction device

ActiveCN114837419AChange spray angleReduce solidificationClimate change adaptationBuilding material handlingElectric machineryEngineering

The light soil construction device comprises a box body, a feeding mechanism and a discharging mechanism, and a feeding port and a funnel discharging port are formed in the box body; the feeding mechanism comprises a screw feeder which is driven by a motor and is sleeved in the extruding barrel, and the feeding end of the extruding barrel is connected with the discharging hole of the funnel; the discharging mechanism comprises a material suction barrel with the lower end hinged to the box body, a hard discharging pipe arranged in the material suction barrel in a sleeved mode and a discharging hose connected to the feeding end of the hard discharging pipe, the hard discharging pipe is sleeved with a guide barrel, a handle is arranged on the guide barrel, a piston is arranged in the material suction barrel, and the discharging hose is connected to the feeding end of the hard discharging pipe. The outer side of the piston is connected to the side wall of the hard discharging pipe, a plurality of excess material feeding ports and excess material discharging ports are formed in the cylinder wall of an inner cylinder of the material suction cylinder in the axial direction, first one-way passing valves are arranged on the excess material feeding ports, second one-way passing valves are arranged on the excess material discharging ports, and the soft soil pouring construction efficiency is improved.

Owner:NANTONG INST OF TECH

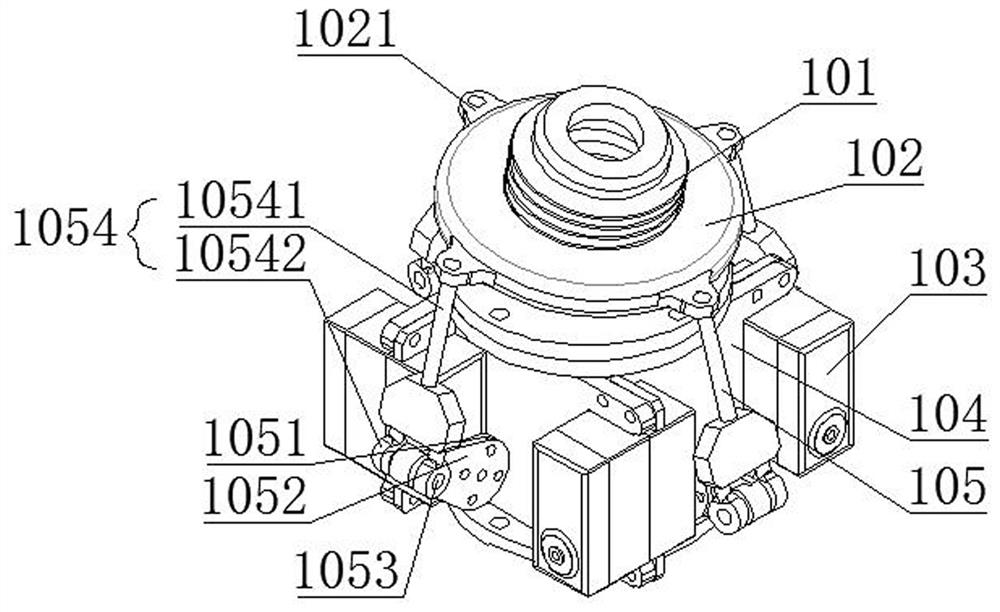

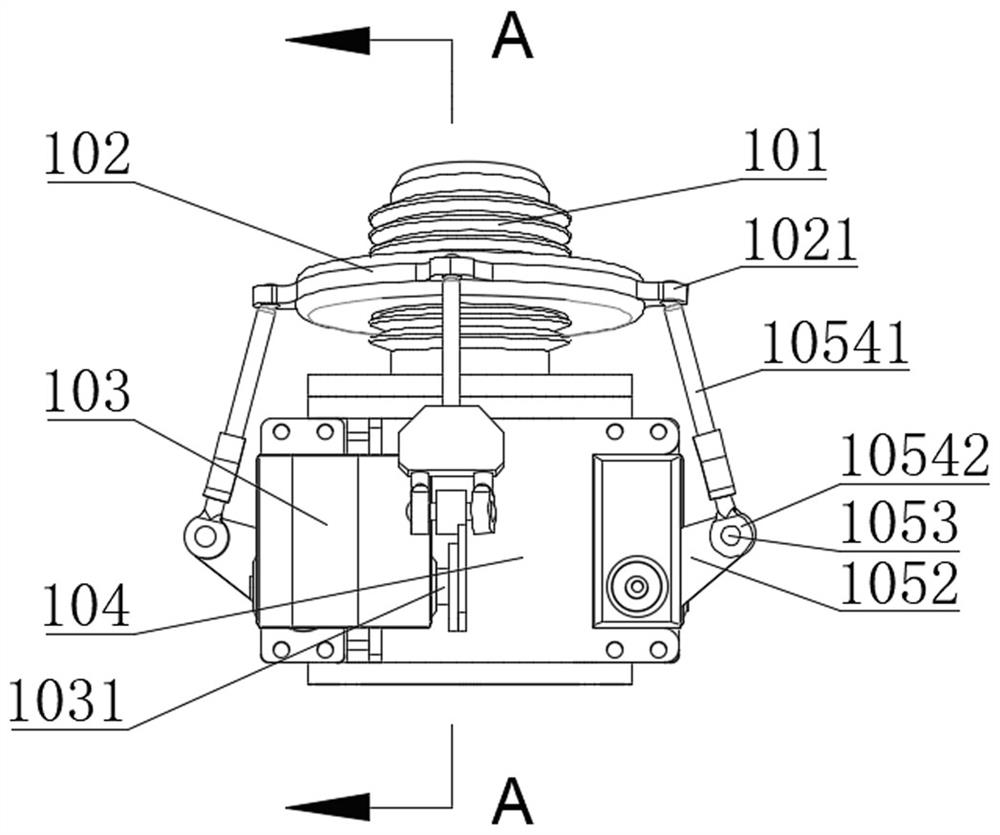

A nozzle orientation vector control structure

The invention provides a nozzle orientation vector control structure, which includes a corrugated nozzle, an amplitude modulation ring and several steering gears; The connection positions are different, and each crank connection mechanism adjusts the height of different connection positions of the amplitude modulation ring, so that the inclination angle of the amplitude modulation ring is variable, and the amplitude modulation ring is clamped outside the corrugated nozzle. In the nozzle azimuth vector control structure, the steering gear drives the connecting crank of the rudder disc to rotate, and the connecting crank of the rudder disc drives the connecting rod to rotate, and then changes the height position of the connecting ear of the amplitude modulation ring connected to the connecting rod. According to the inclination angle of the AM ring, the four steering gears raise or lower the connecting ear of the AM ring according to different height requirements, and the inclination angle of the AM ring changes accordingly. After the inclination angle of the amplitude modulation ring is changed, the bending angle of the corrugated nozzle is also changed, thereby changing the jetting angle of the gas.

Owner:气味王国(山东)科技有限公司

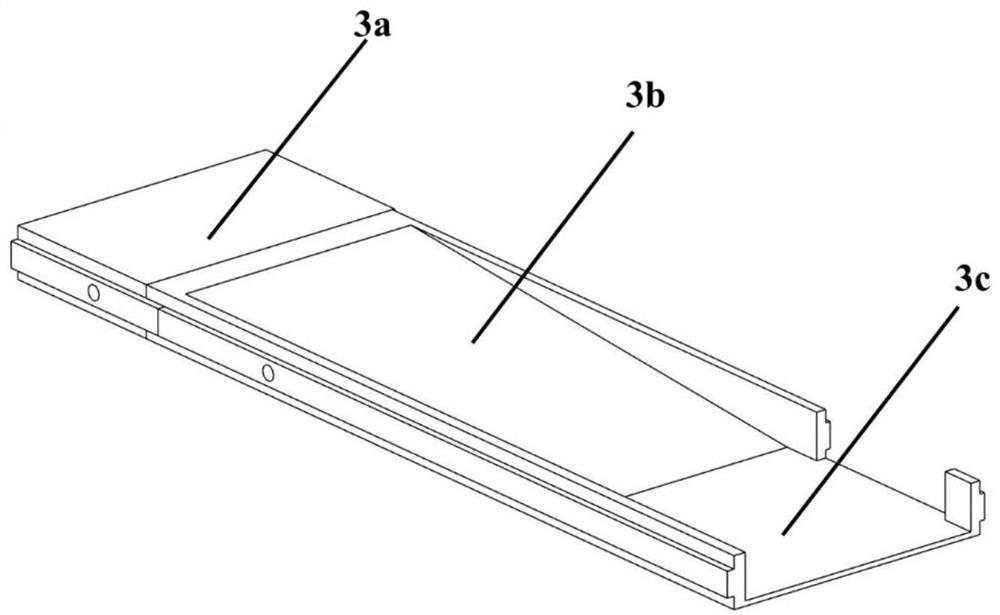

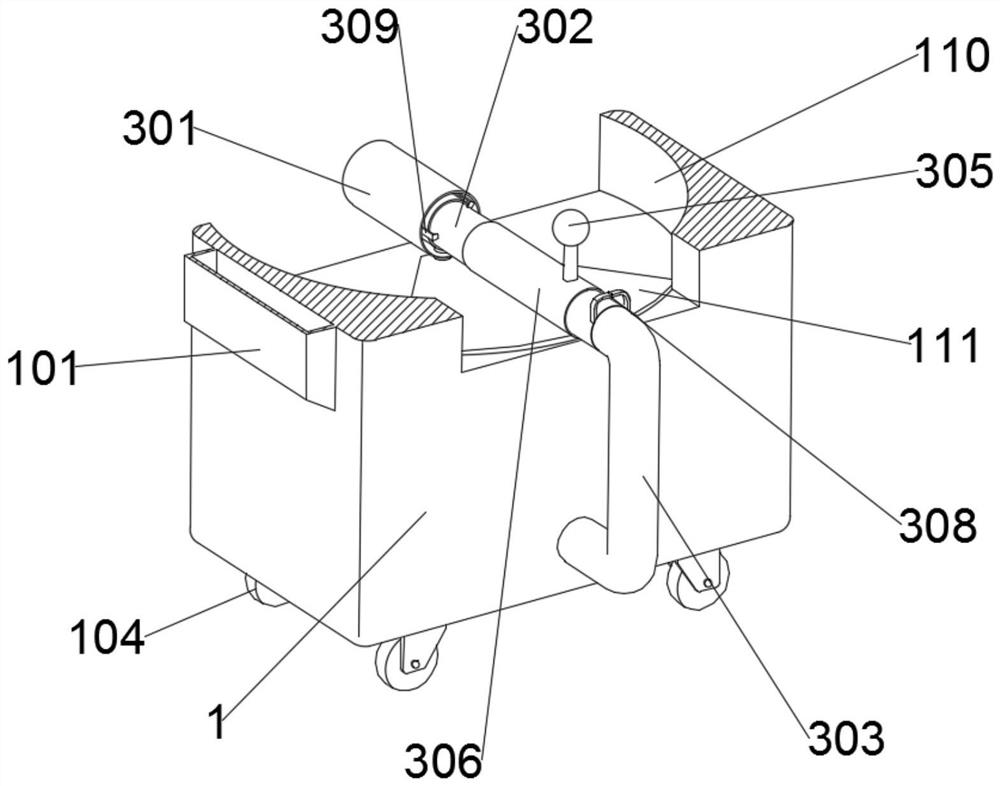

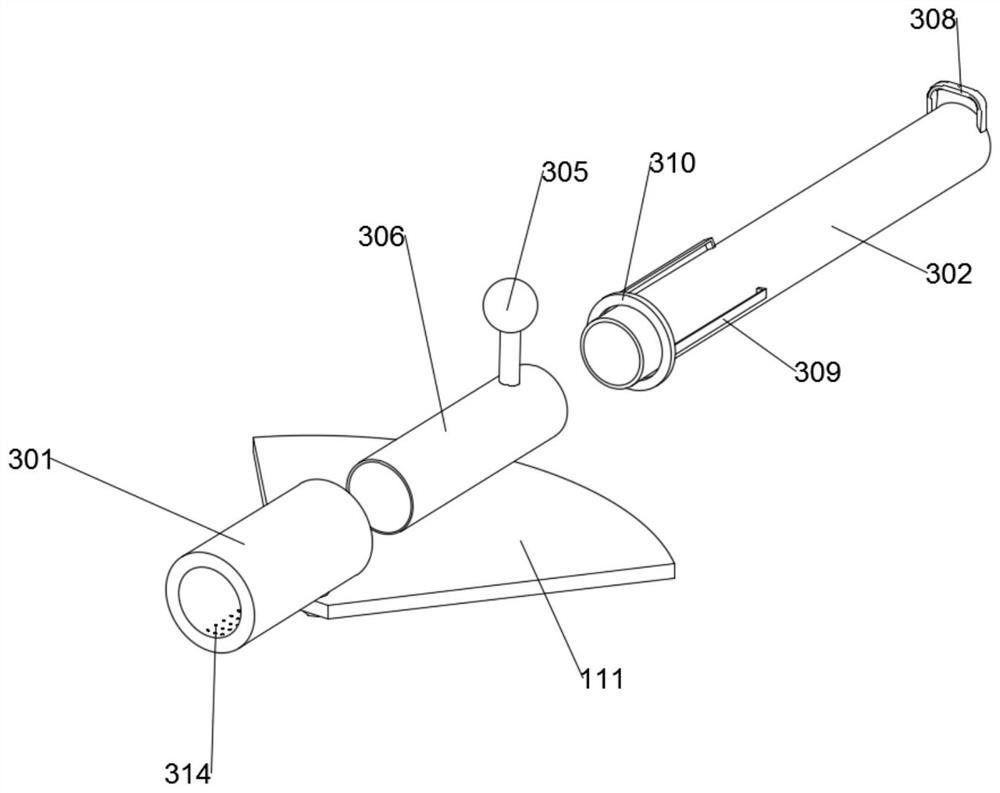

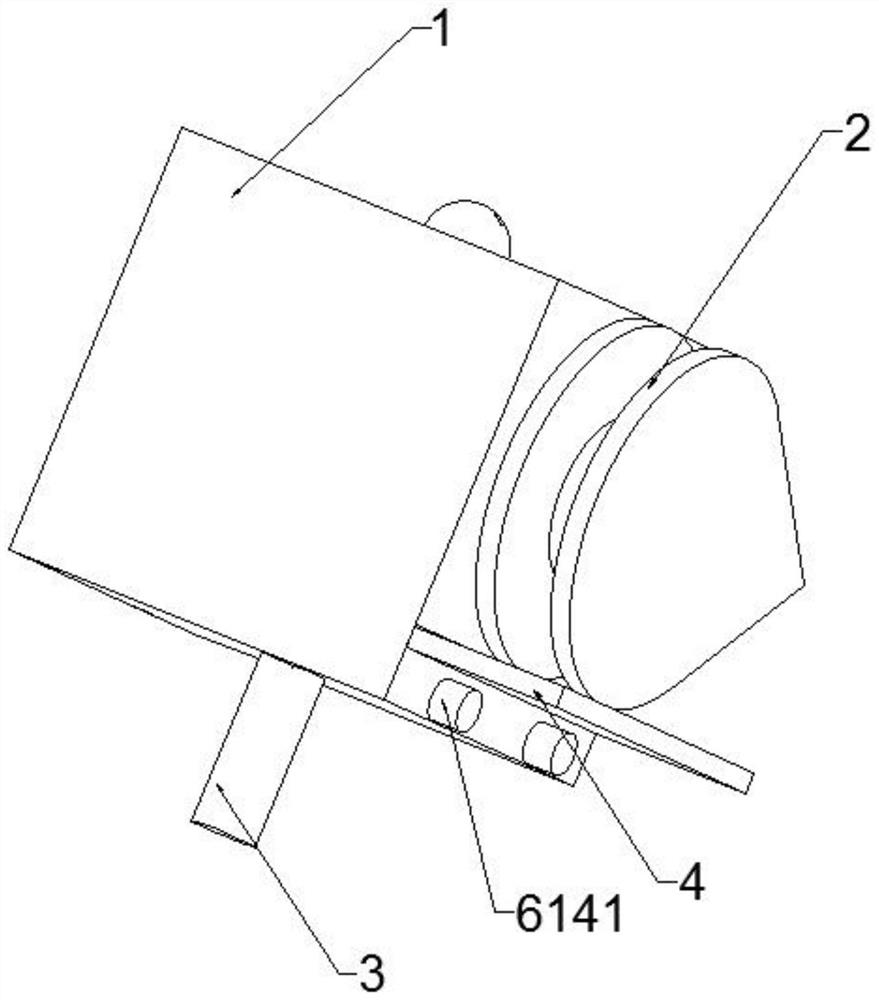

Spray pipe hanging device easy to disassemble and assemble for mixing machine

PendingCN112827422AIncrease contact areaReduce pressureTransportation and packagingSpraying apparatusWire ropePipe

The invention provides a spray pipe hanging device easy to disassemble and assemble for a mixing machine. The device comprises at least one spray pipe which is arranged below a steel wire rope, at least one adjusting part which is arranged on the outer side of the spray pipe and is provided with a plurality of positioning parts matched with nozzles, a connecting plate which is used for fixing the spray pipe and is provided with first kidney-shaped holes extending transversely and matched with the positioning parts so as to enable the transverse position and the water spraying angle of the spray pipe to be adjustably arranged, and a hanging plate which is arranged above the connecting plate. The hanging plate of the spray pipe hanging device easy to disassemble and assemble for a mixing machine can be directly hung on the steel wire rope or directly taken down, disassembly and assembly are convenient, and manpower, time and maintenance cost are effectively reduced. Meanwhile, by rotating or horizontally moving the relative positions of the adjusting part and the connecting plate, the spraying range of the nozzles can be accurately adjusted, and the percent of pass of the product is remarkably increased.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Heating system for paper web movement and drying method thereof

InactiveCN114197237AImprove drying effectIncrease coverageDryer sectionCleaning using gasesProcess engineeringHeating system

The invention relates to a heating system for paper web movement and a drying method thereof. The heating system is characterized by comprising a medium source; a heater; an upper drying device; a lower drying device; the pipeline is used for conveying gas and / or liquid discharged by the medium source, and the gas and / or liquid are / is conveyed to the upper drying device and the lower drying device after passing through the heater; wherein a drying area is formed between the upper drying device and the lower drying device, heating ends are at least arranged at the opposite ends of the upper drying device and the lower drying device, and when paper passes through the drying area, the heating ends heat the paper and dry the paper; the paper drying device has the beneficial effects that the drying efficiency is high, and the two faces of paper can be heated and dried at the same time.

Owner:VINDA PAPER ZHEJIANG

Feeding device capable of automatically adjusting charging proportion and used for concrete additive production

ActiveCN112761571AChange spray angleChange operating statusUnderground chambersDischarging apparatusStructural engineeringSoil horizon

The invention discloses a feeding device capable of automatically adjusting feeding charging proportion and used for concrete additive production. The feeding device comprises a shell, and is characterized in that a drill bit is arranged on the right side of the shell, a collecting plate is arranged below the drill bit, a grounding rod is arranged on the lower portion of the shell, a following spraying mechanism is arranged in the shell, a control mechanism is arranged in the shell, a stone and sand separating mechanism is arranged in the shell, the following spraying mechanism is fixedly installed on the upper portion of the shell, the control mechanism is fixedly installed on the inner wall of the shell, the stone and sand separating mechanism is fixedly installed on the left side of the collecting plate, the following spraying mechanism is connected to the upper portion of the control mechanism through a pipeline, and the stone and sand separating mechanism is connected to the left side of the control mechanism through a pipeline. The feeding device has the characteristics that the charging proportion can be automatically changed according to the soil layer condition, and the concrete spraying angle is changed in real time according to the feeding distance of the drill bit.

Owner:江苏博拓新型建筑材料股份有限公司

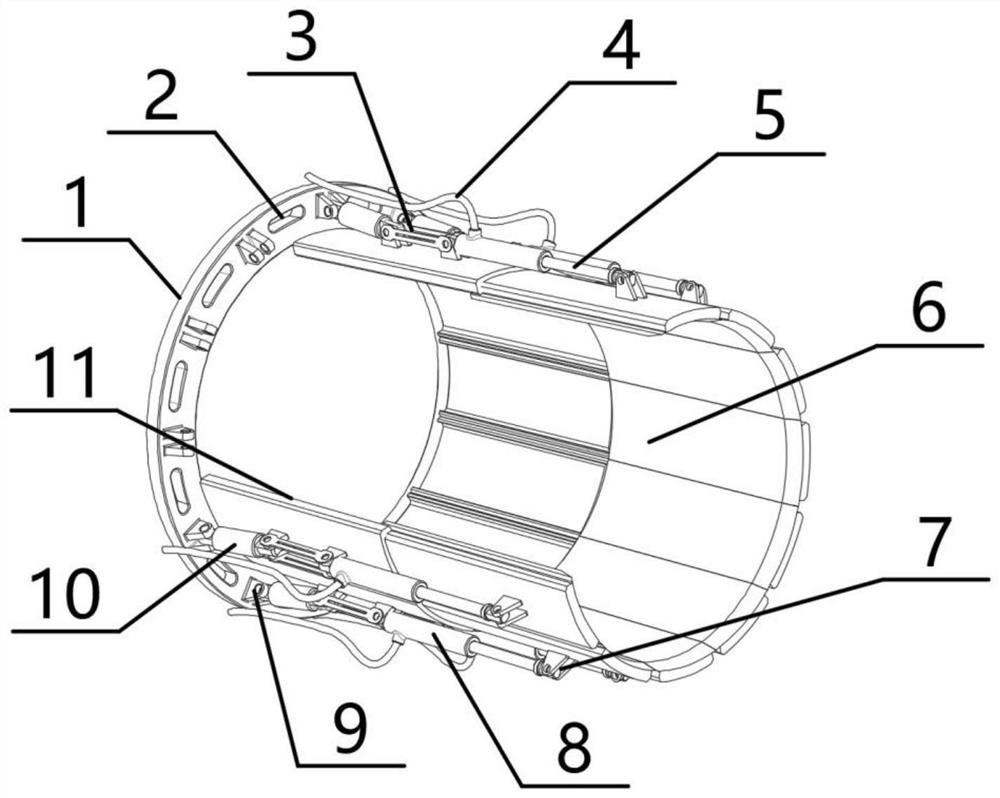

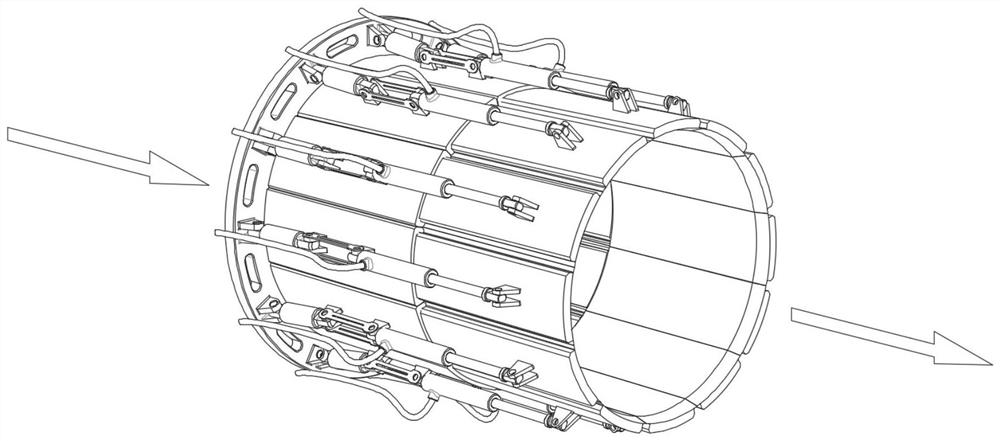

Thrust vectoring nozzle and control method thereof

ActiveCN113250853AChange spray angleOvercoming Complex Control ProblemsJet propulsion plantsJet flowThrust vectoring

The invention discloses a thrust vectoring nozzle and a control method thereof. A plurality of telescopic arm mechanisms with the same structure are arranged in the circumferential direction to form an annular nozzle arm, the telescopic arm mechanisms can stretch out and draw back in the axial direction of an annular base, so that an outlet of the nozzle is in different step shapes, the flowing direction of gas at the outlet of the nozzle is controlled, and then the thrust direction is changed, and a vector propulsion function is realized. Therefore, the jet flow direction of the tail of an aero-engine can be controlled in a 360-degree all-around mode under the condition that the nozzle does not deflect, complex motion control requirements such as torsion do not exist, the equipment structure is simplified, the control mode is simple, the problem of complex control needed for controlling the airflow direction by rotating the nozzle is solved, and the spray angle of the nozzle can be quickly, efficiently and reliably changed.

Owner:HUAZHONG UNIV OF SCI & TECH

Needle valve assembly of fuel injection device

ActiveCN103982350BSimple structureEasy to processFuel injection apparatusMachines/enginesInlet channelReciprocating motion

The invention discloses a needle valve component for a fuel injection device. The needle valve component comprises a valve body (10) and a needle valve (20). The valve body is provided with a valve body end (12), a valve hole (14), an oil inlet channel (16) and an oil injection hole (18). The oil injection hole comprises a first group of oil injection holes (181) and a second group of oil injection holes (182), wherein the first jet angles of the first group of oil injection holes are smaller than the second jet angles of the second group of oil injection holes, and the communicating positions of the first group of oil injection holes and the valve hole are closer to the valve body end than the communicating positions of the second group of oil injection holes and the valve hole. The needle valve can reciprocate in the valve hole and comprises an oil inlet ring groove (26), an oil outlet ring groove (28) and an oil supply channel (24) for communicating the oil inlet ring groove and a first oil outlet ring groove. The first oil outlet ring groove is respectively communicated with the first group of oil injection holes and the second group of oil injection holes, the fuel oil is sprayed at different jet angles so as to adapt to oil-gas mixing under different loads, the oil consumption and discharge under the different conditions are both considered, and the needle valve component has the advantages of simple structure and convenience for processing.

Owner:JIANGSU UNIV +1

Accurate cleaning device for ultrafiltration membrane assembly

PendingCN114558457AChange spray angleNo change in spray positionMembranesSemi-permeable membranesUltrafiltrationMechanical engineering

The invention relates to the technical field of ultrafiltration membrane tools, in particular to a precise cleaning device for an ultrafiltration membrane component, which is characterized in that a supporting slide block is slidably arranged on a supporting slide rail, an adjusting rod is rotatably arranged at the left end of the front side wall of the supporting slide block through a rotating shaft, an adjusting slide block is slidably arranged on an adjusting slide rail, and an adjusting driving part is fixedly arranged on a cleaning seat; the bearing sliding block is slidably arranged on the bearing sliding rail, the rotating shaft is rotationally arranged on the upper side wall of the bearing sliding block through a bearing, and the rotating seat is fixedly arranged at the upper end of the rotating shaft; clamping of a workpiece and arrangement of a spray head are controlled by two independent parts, the spray head is arranged to be of a structure capable of rotating to adjust the angle, after the spray head rotates by the angle, the drop point position of water spraying is not changed, the clamping part of the workpiece is arranged to be of a structure capable of moving and rotating, and then positioning of the workpiece is guaranteed; therefore, accurate positioning of the workpiece during washing is guaranteed.

Owner:湖南时远新材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com