Heating system for paper web movement and drying method thereof

A heating system and paper web technology, which are applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of poor drying effect, low utilization rate of energy consumption, violation of energy conservation and environmental protection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

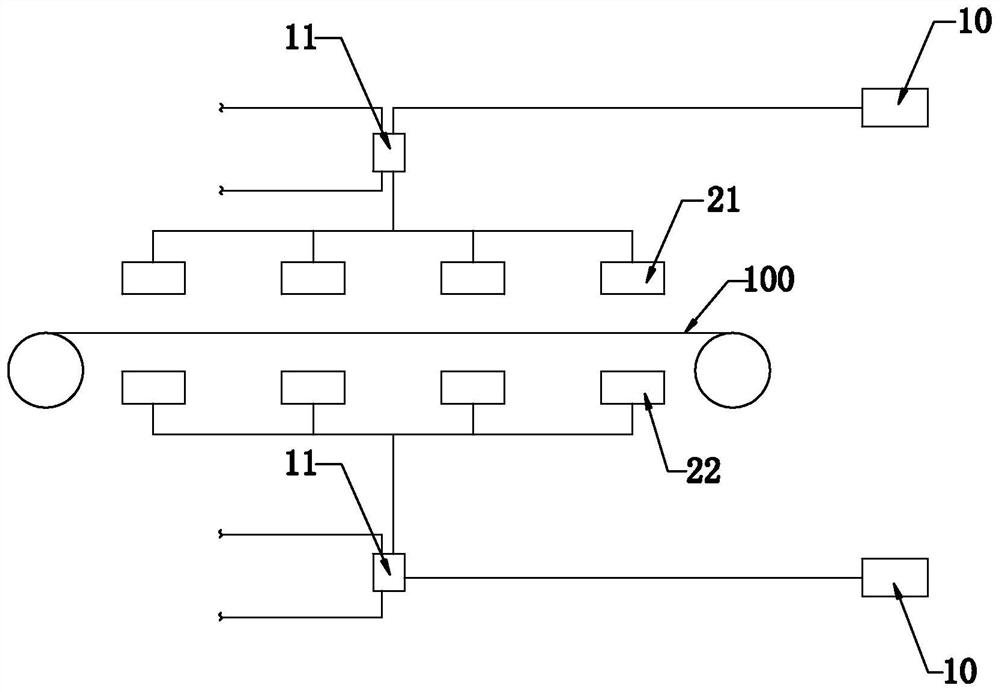

[0090] Such as figure 1 As shown, the present invention discloses a heating system for paper web movement. In a specific embodiment of the present invention, it includes:

[0091] medium source 10;

[0092] Heater 11;

[0093] Upper drying device 21;

[0094] Lower drying device 22;

[0095] The pipeline is used to transmit the gas and / or liquid discharged from the medium source, and send it to the upper drying device 21 and the lower drying device 22 after passing through the heater 11;

[0096] Wherein, a drying zone is formed between the upper drying device 21 and the lower drying device 22, and at least a heating end is provided at the opposite end of the upper drying device 21 and the lower drying device 22, when the paper 100 passes through In the drying zone, the heating end heats the paper 100 and dries the paper 100 .

[0097] In a specific embodiment of the present invention, the upper drying device 21 and the lower drying device 22 may use existing air injectio...

Embodiment 2

[0099] Embodiment 2, the difference with embodiment 1 is that

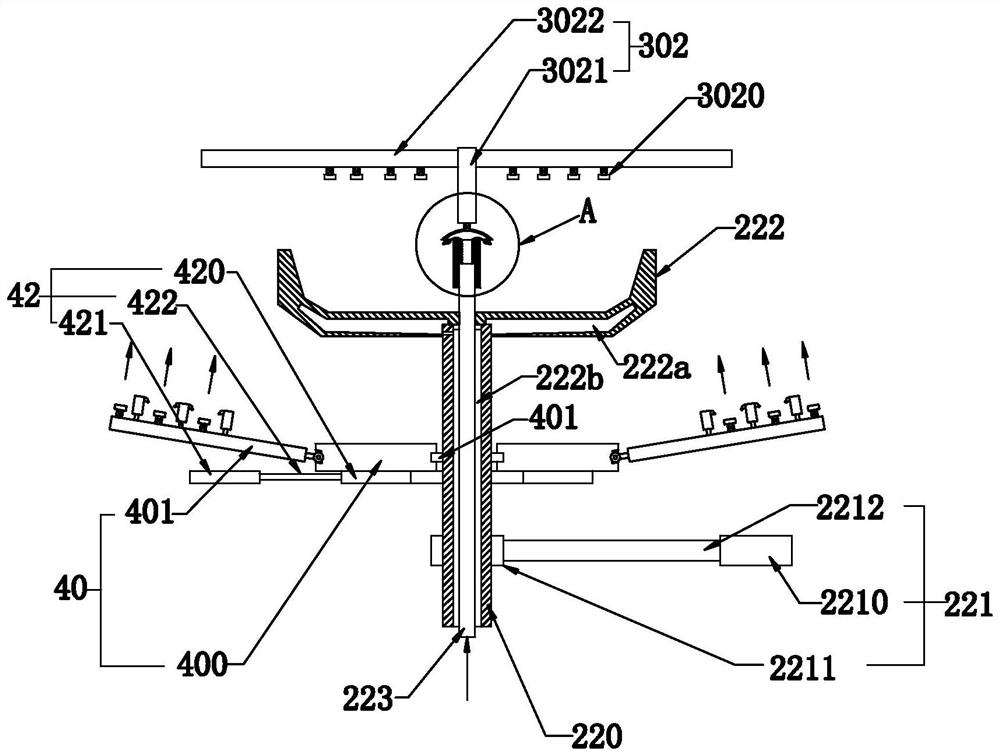

[0100] Such as Figure 2-5 As shown, in a specific embodiment of the present invention: the lower drying device 22 includes:

[0101] lower bracket;

[0102] The rotating shaft 220 is hollow and rotatably mounted on the lower bracket, and can be driven to rotate by the first driving mechanism 221;

[0103] The collection housing 222 is installed on the rotating shaft 220 and is used to collect impurities;

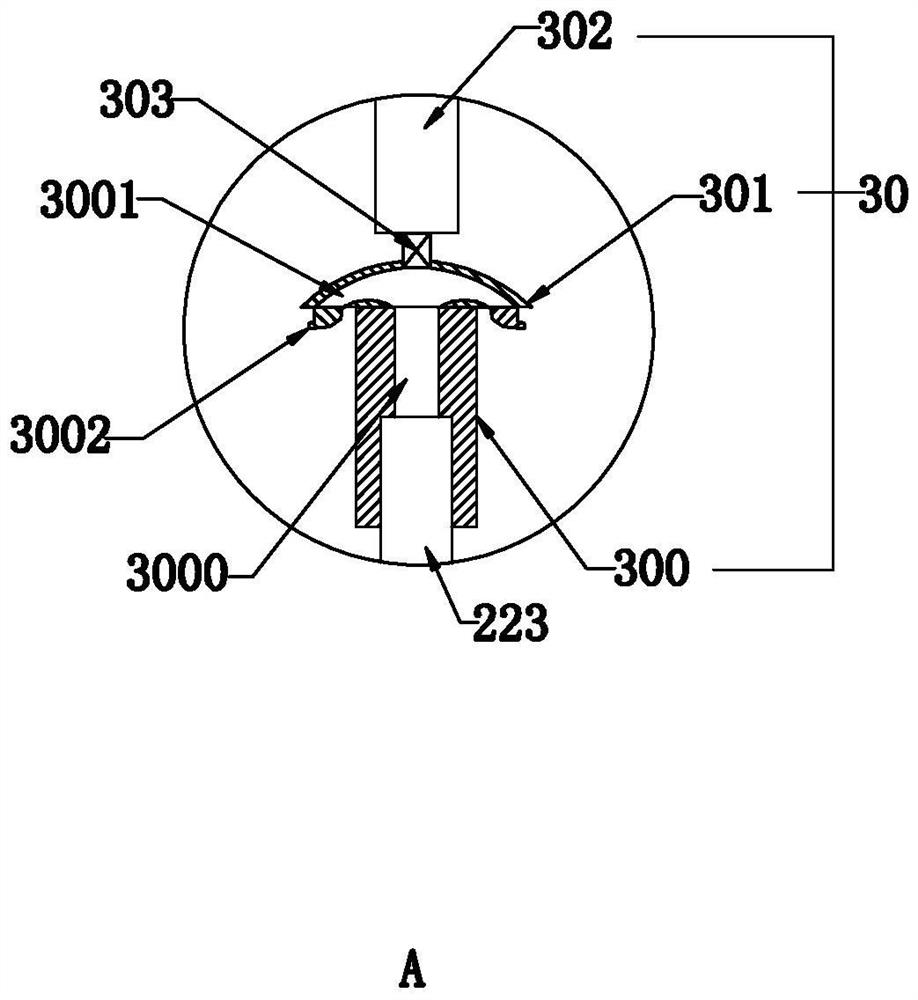

[0104] The first transmission pipe 223 is arranged in the rotating shaft 220, and one end penetrates into the collection housing 222, and the first injection device 30 is arranged at the end;

[0105] Wherein, the inner wall of the collection housing 222 forms a cavity 222a, and the inner wall of the collection housing 222 is provided with a discharge hole communicating with the cavity 222a, the first transmission pipe 223 and the rotating shaft 220 A discharge cavity 222b is formed between them, and the di...

Embodiment 3

[0149] Embodiment 3, the difference with embodiment 2 is:

[0150] Such as Figure 6-8 As shown, in a specific embodiment of the present invention: the upper drying device 21 includes:

[0151] upper bracket;

[0152] The upper air injection device 60 is installed on the upper bracket and can be supplied with air by the heat source;

[0153] Wherein, the upper air injection device 60 at least includes an air injection part 600 and a diffusion part 601, and the diffusion part 601 has at least a hollow area, when the air injection part 600 sends the gas into the hollow area and contacts the inner wall of the hollow area , the divergence of the gas through the hollow area expands the injection angle.

[0154] In a specific embodiment of the present invention: the diffusion part 601 includes:

[0155] The cover body 6010 is rotatably mounted on the upper bracket and can be driven to rotate by a third driving mechanism, and the cover body 6010 has a recessed area 6011;

[0156...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com