Light soil construction device

A construction device and lightweight soil technology, which is applied in the processing of building materials, construction, climate change adaptation, etc., can solve the problems of labor consumption, solidification of bubble lightweight soil, waste of bubble lightweight soil, etc., to improve the pouring construction. Efficiency, slow down solidification, reduce waste effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

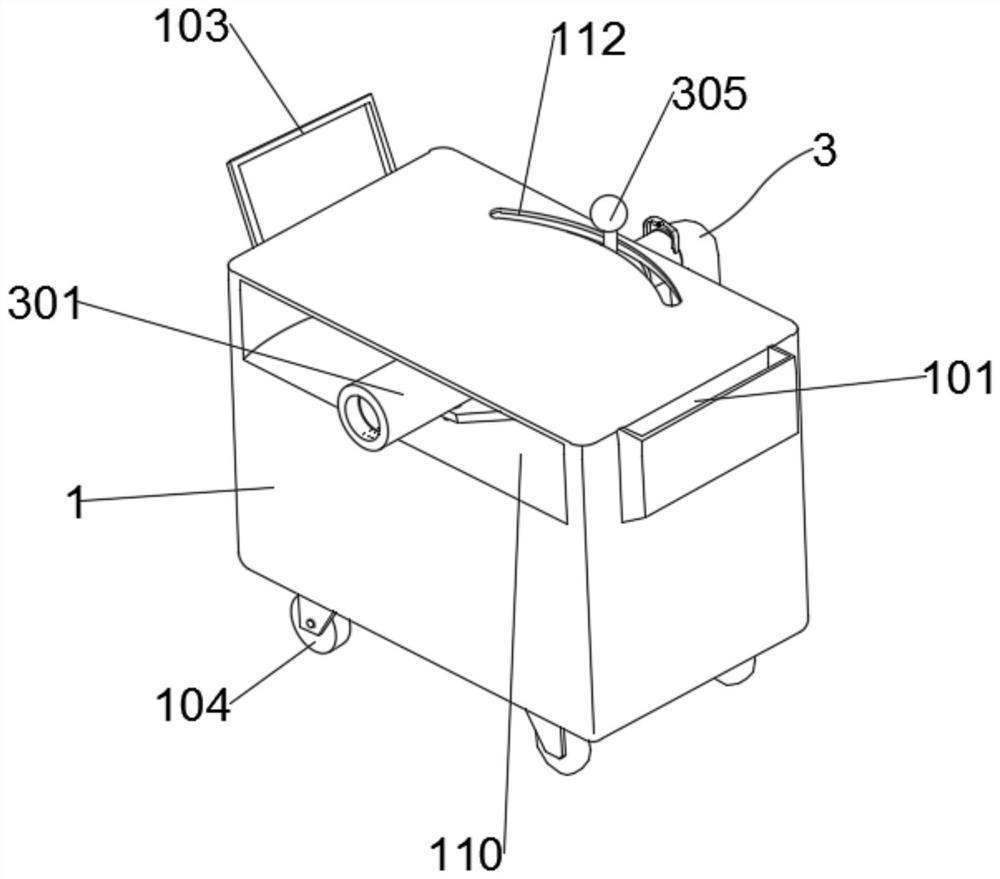

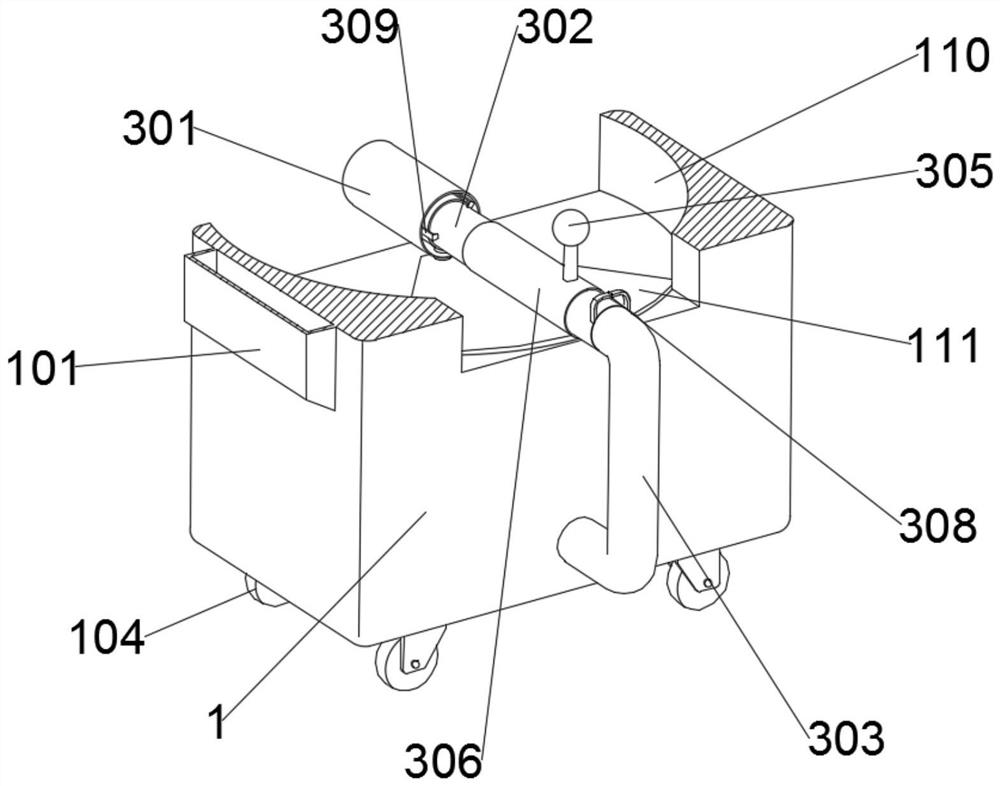

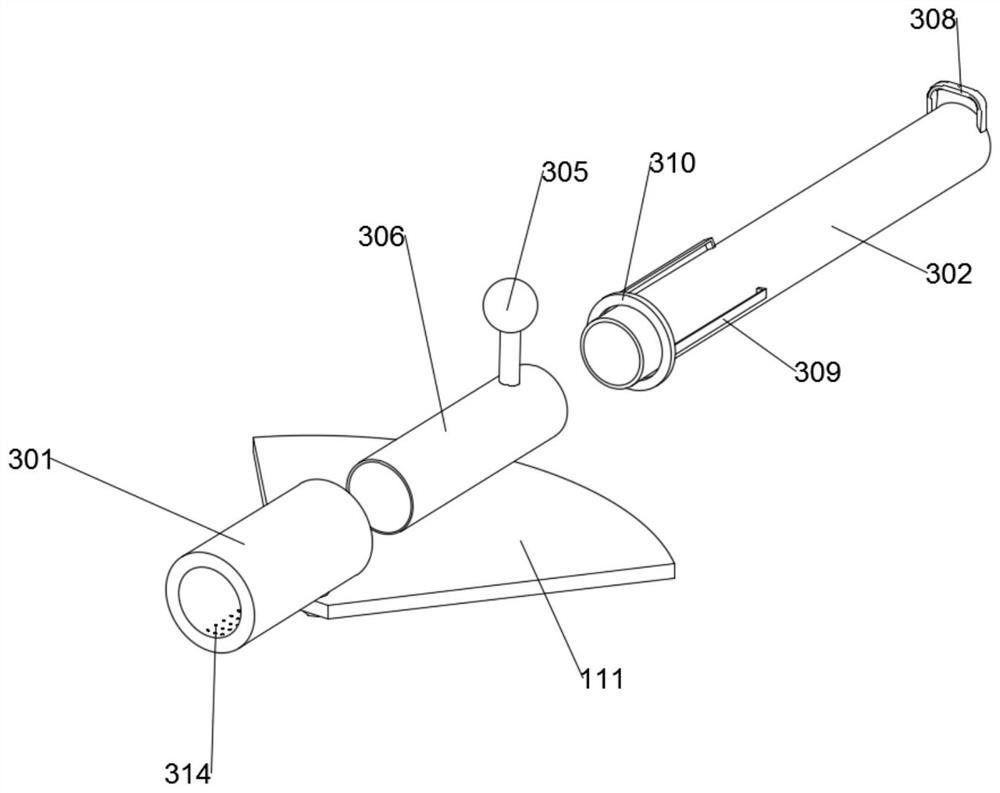

[0030] like Figure 1 to Figure 7 As shown, the present invention provides a lightweight soil construction device, comprising a box body 1 , a feeding mechanism 2 and a discharging mechanism 3 .

[0031] Among them, the box body 1 is used to contain the bubble light soil, and is provided with a feed port 101 and a funnel discharge port 102 on it. The bottom of the box body 1 is provided with a universal wheel 104, and one side wall of the box body 1 is provided with a push handle 103, so that the box body 1 can be shifted according to needs.

[0032] The feeding mechanism 2 includes a screw feeder 202 driven by a motor 201 , the inner wall of the box body 1 is provided with an extrusion cylinder 203 for matching the screw feeder 202...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com