Intelligent manufacturing technology and application production training system

A technology of intelligent manufacturing and technology, applied in the direction of manufacturing tools, manufacturing auxiliary devices, ceramic molding machines, etc., can solve the problem of non-providance, and achieve the effect of improving production efficiency, enhancing connection strength, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

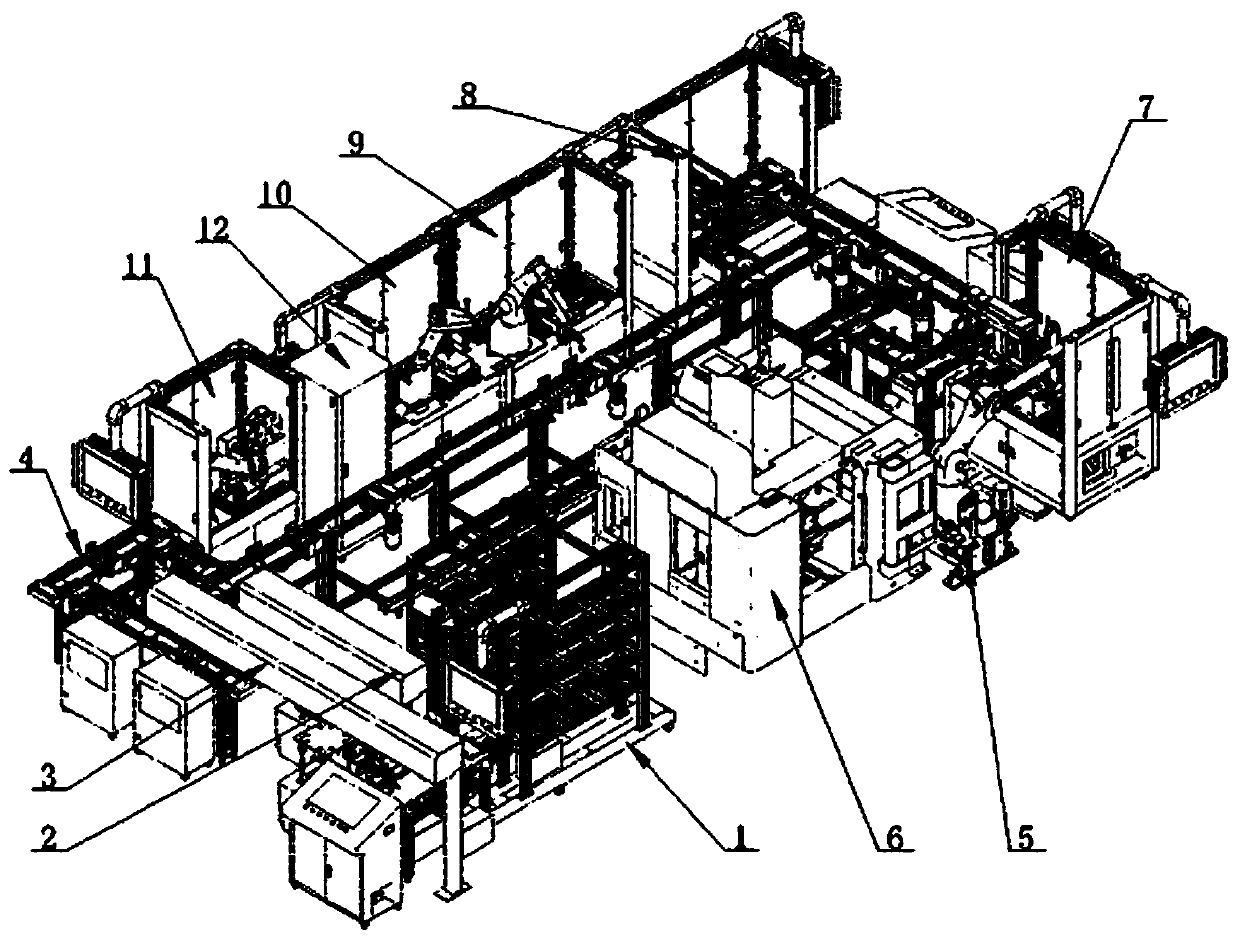

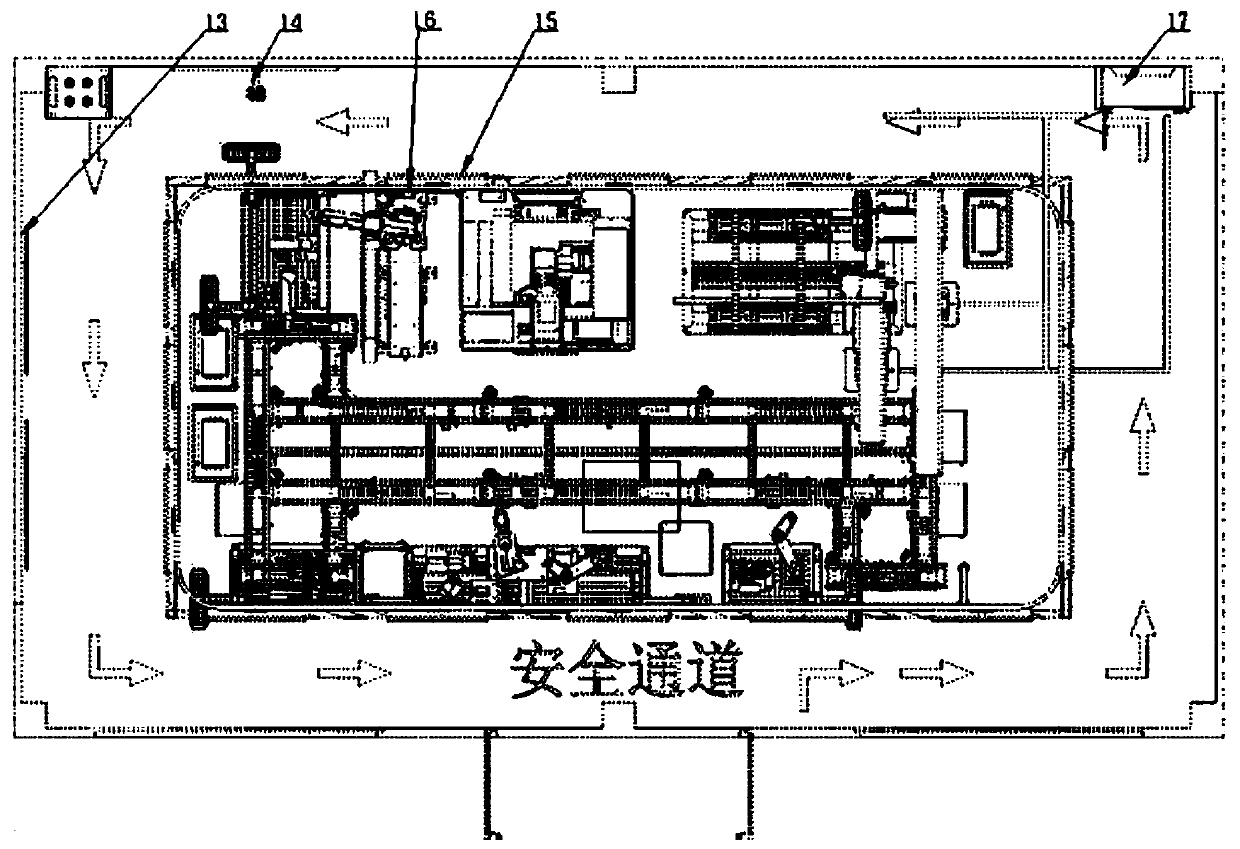

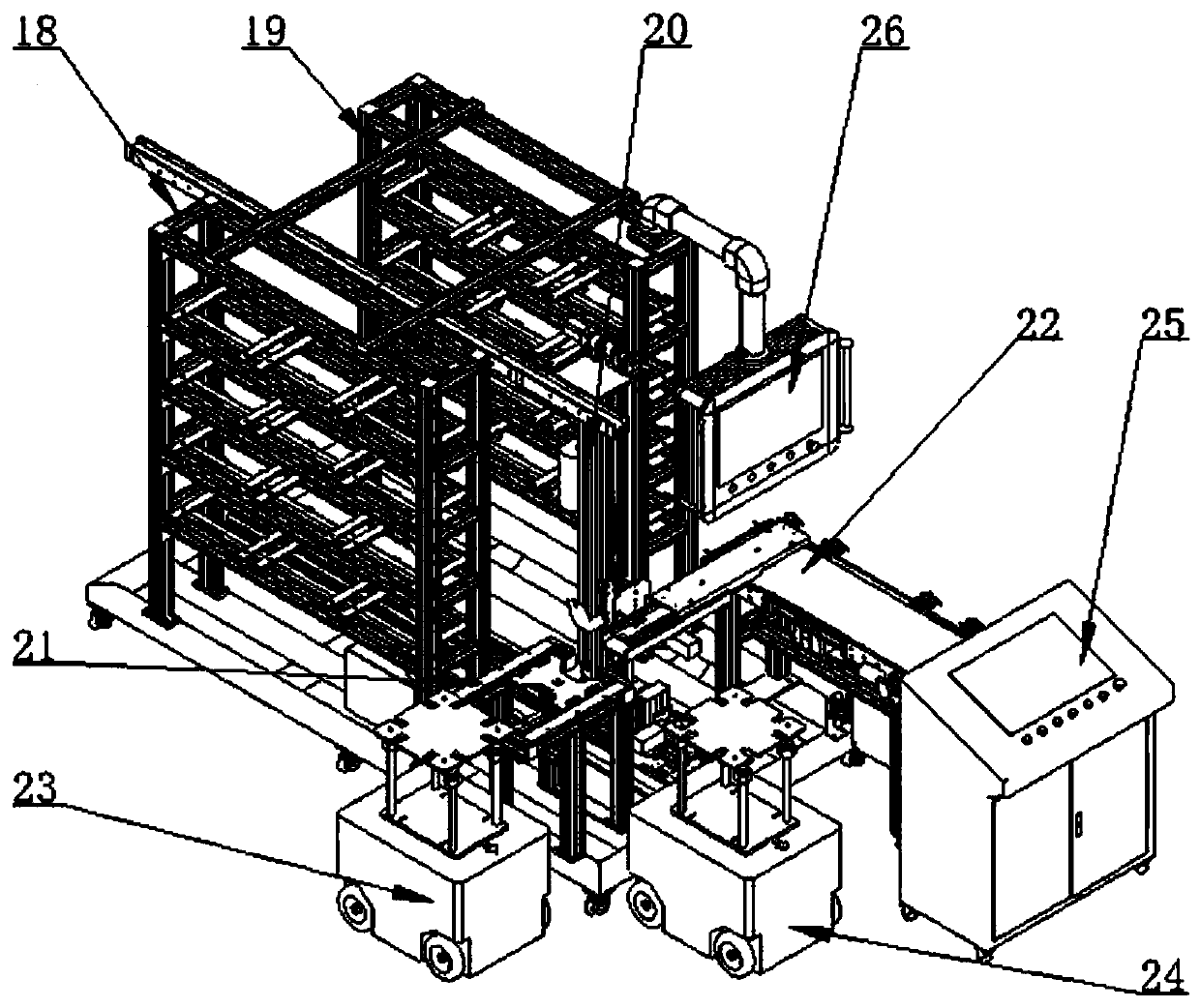

[0058] Such as figure 1 , figure 2As shown, the intelligent manufacturing technology and application production training system includes an automated three-dimensional warehouse (1), a loading manipulator (2), an unloading manipulator (3), an automated conveyor line (4), a seven-axis robot (5 ), CNC machining center (6), marking unit (7), 3D printing unit (8), assembly testing unit (9), packaging unit (10), labeling unit (11), power distribution cabinet (11), MES kanban (13), short-focus projector (14), process kanban (15), safety fence (16), material storage (17), etc. After the equipment is started, the administrator or customer places an order through the MES system. After receiving the order information, the loading manipulator (2) takes the raw material tray (30) from the automated three-dimensional warehouse (1) and places it at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com