Patents

Literature

41results about How to "Affect the printing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

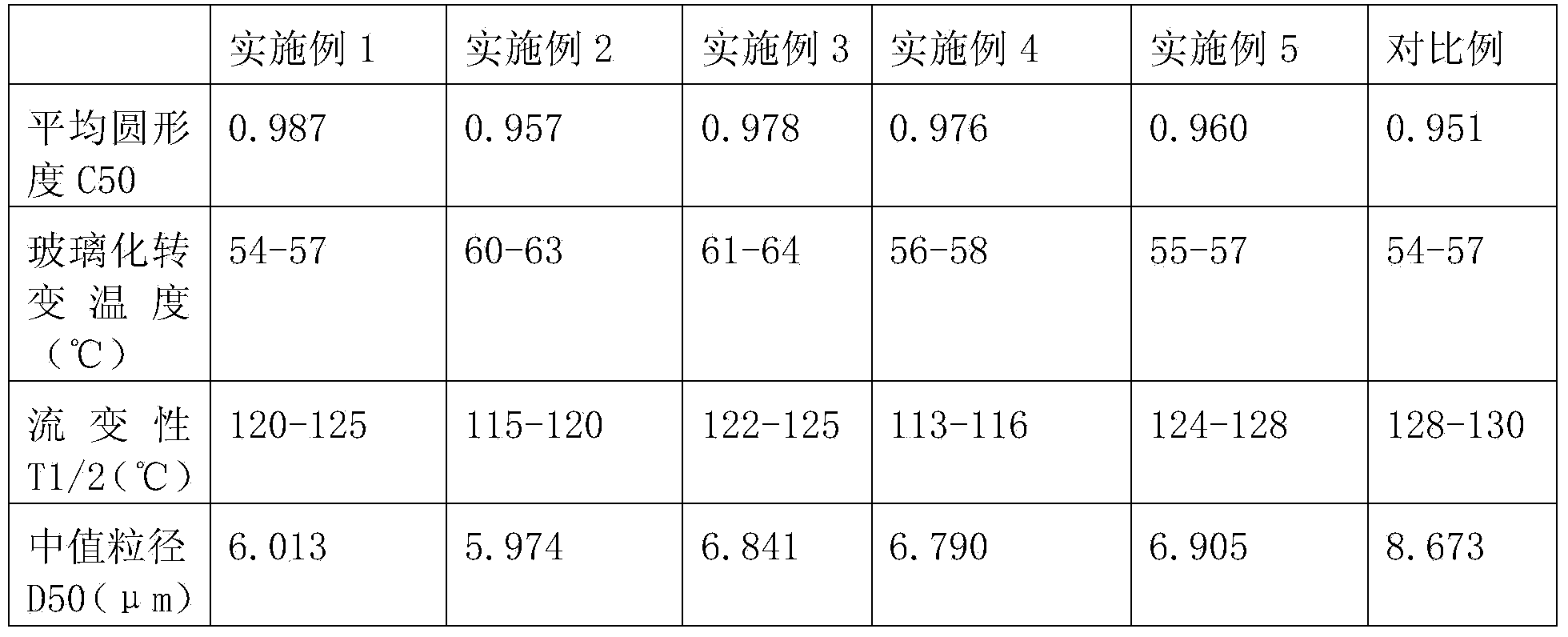

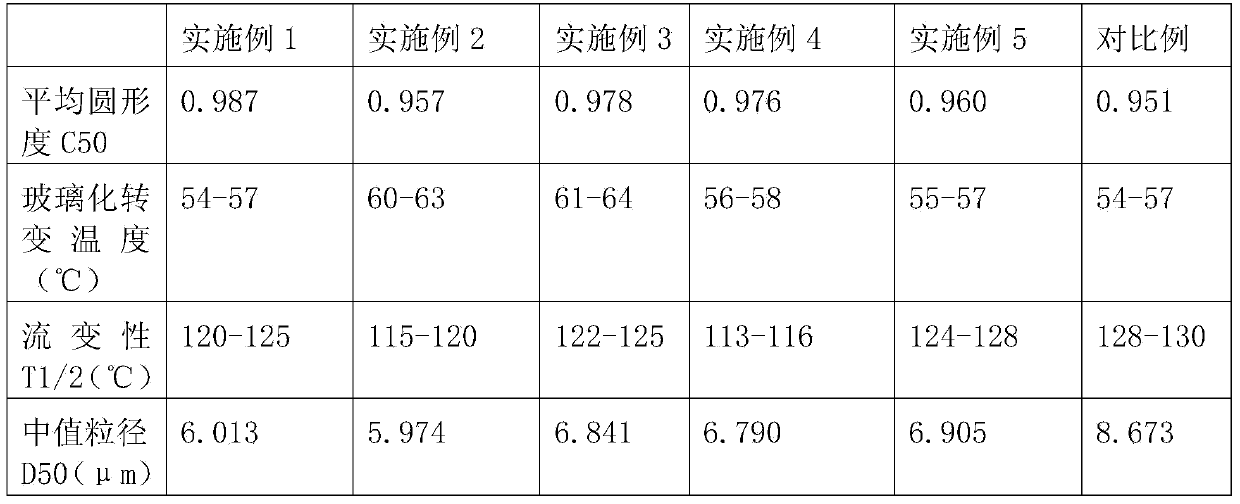

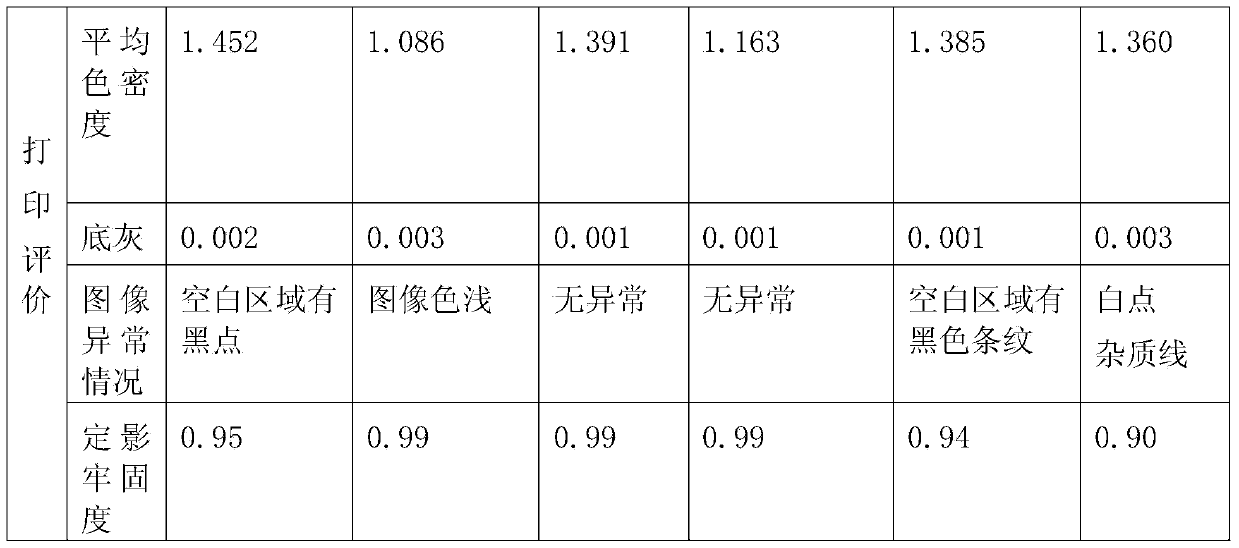

Modified carbon black, and preparation method and application thereof in preparation of black chemical powdered ink

ActiveCN103642281AImprove hydrophilicityGood dispersionInorganic pigment treatmentDevelopersWater bathsModified carbon

The invention provides preparation methods of modified carbon black and black chemical powdered ink. The preparation method of the carbon black comprises the following steps: (1) adding 5 to 30 parts by weight of carbon black to 100 to 500 parts by volume of concentrated acid; uniformly agitating; and controlling the temperature to be 30 to 70 DEG C to react for 2 to 6 hours; (2) adding 15 to 50 parts by weight of strong oxidant to the mixed solution obtained in step (1), and reacting for 1 to 3 hours in a water bath at 30 DEG C; and (3) agitating the mixed solution obtained in step (2), slowly adding deionized water, diluting, performing reduced-pressure suction filtration, and washing to obtain the modified carbon black. The black chemical powdered ink is prepared through such modified carbon black. Due to the adoption of the preparation methods, the problems of the prior art that the carbon black has poor wettability and is instable in an aqueous medium to further cause that the powdered ink is non-uniform in particle distribution and excessively wide in particle size, can be solved.

Owner:鼎龙(宁波)新材料有限公司

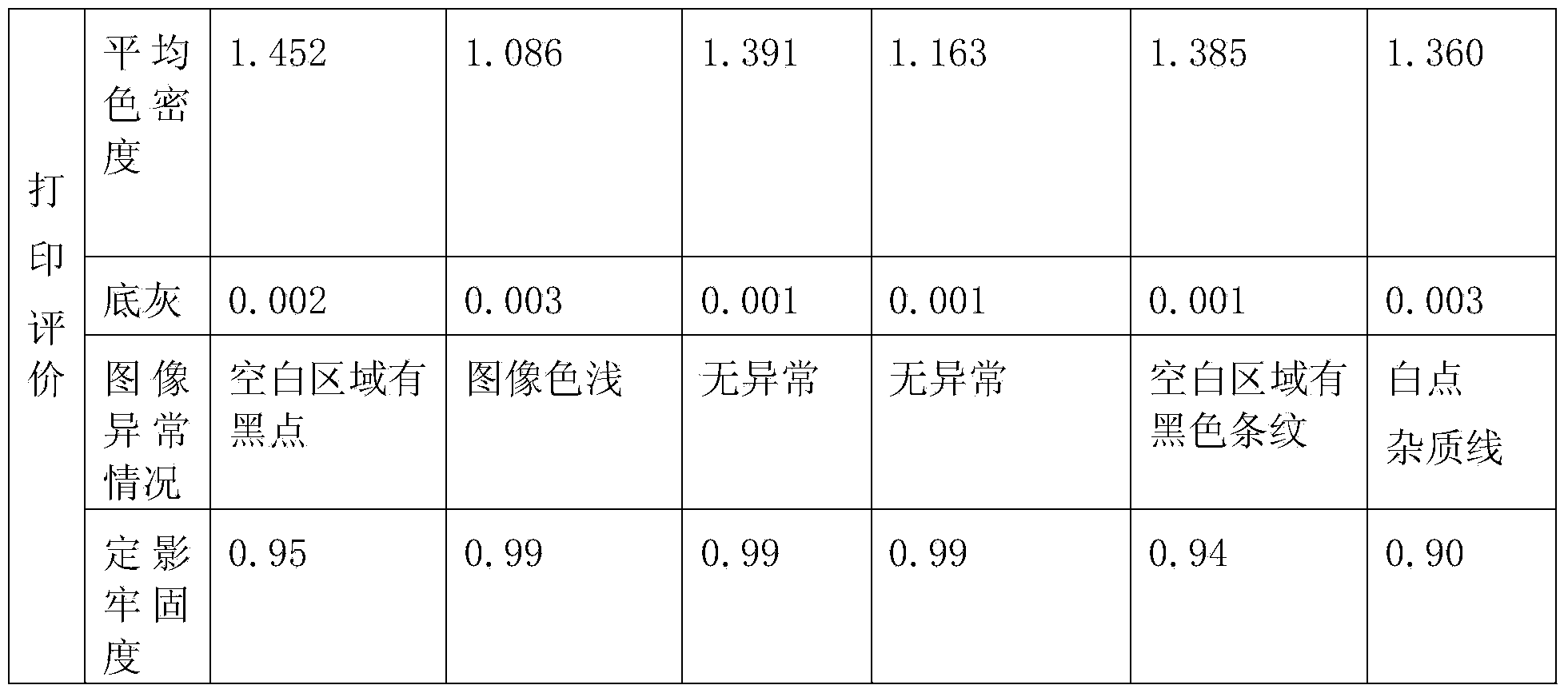

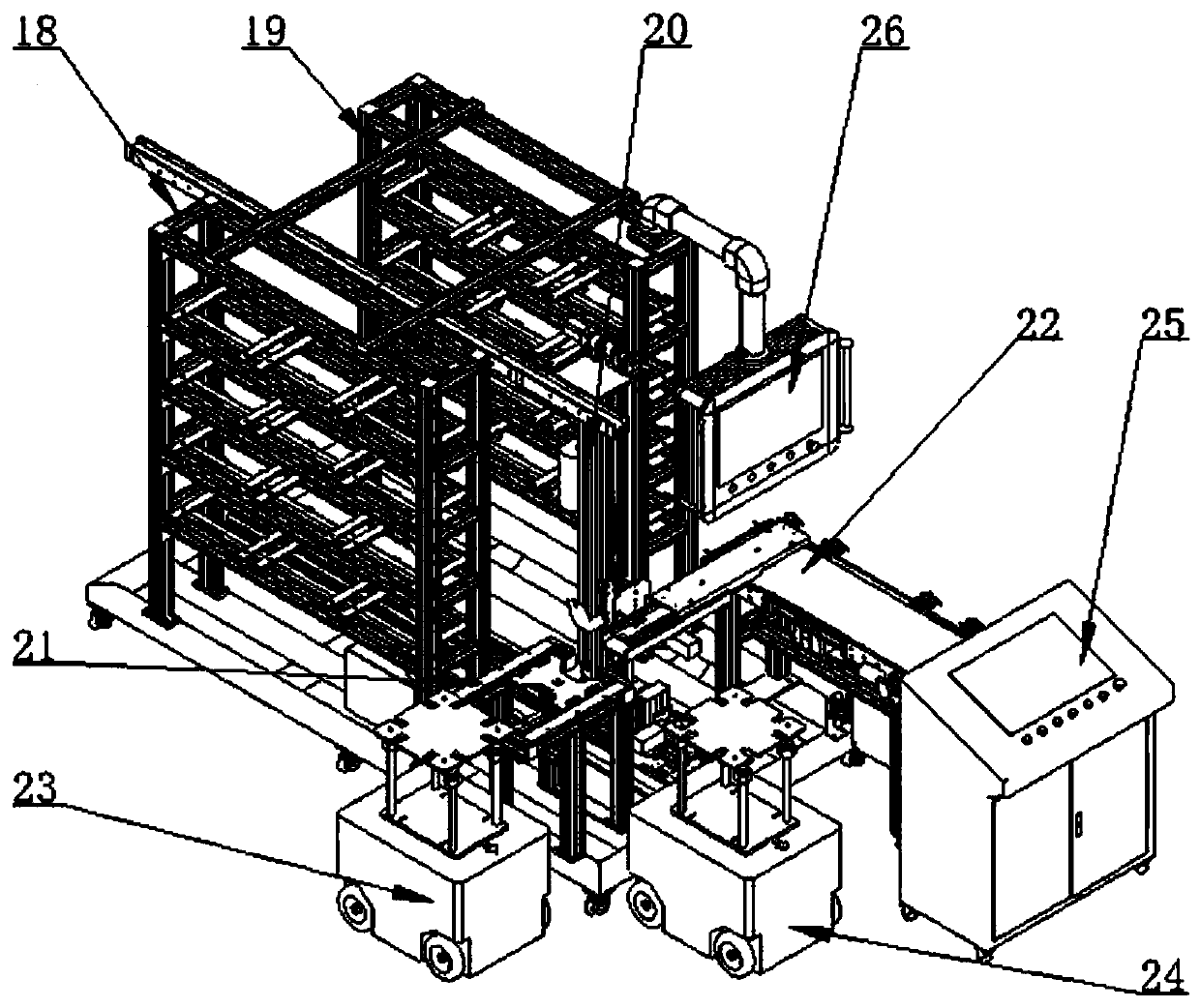

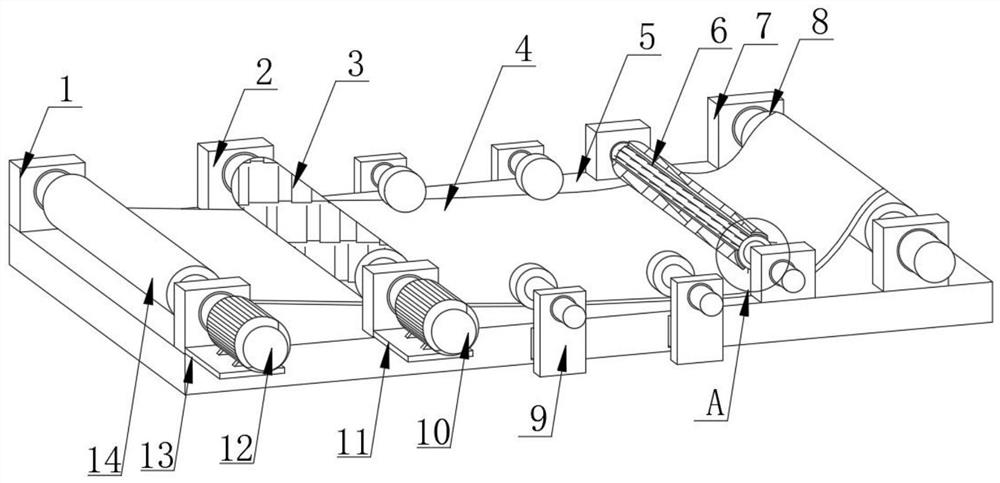

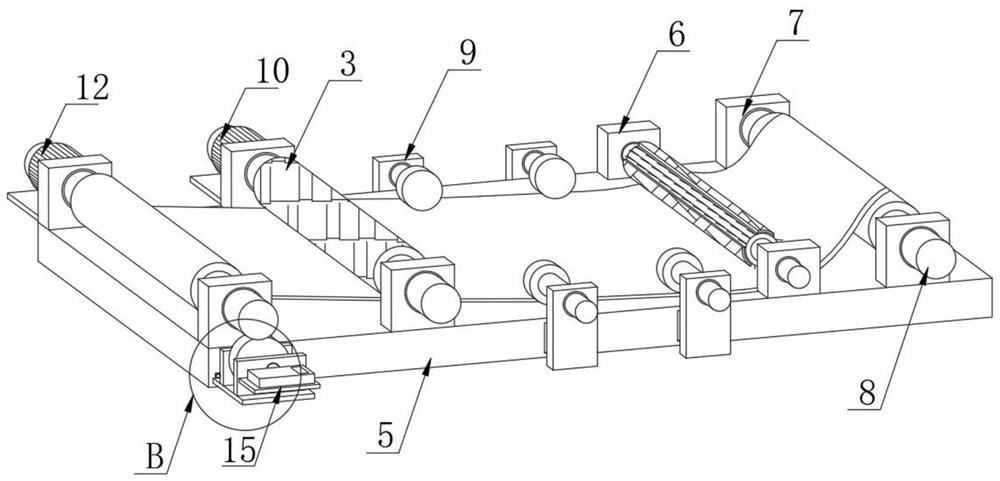

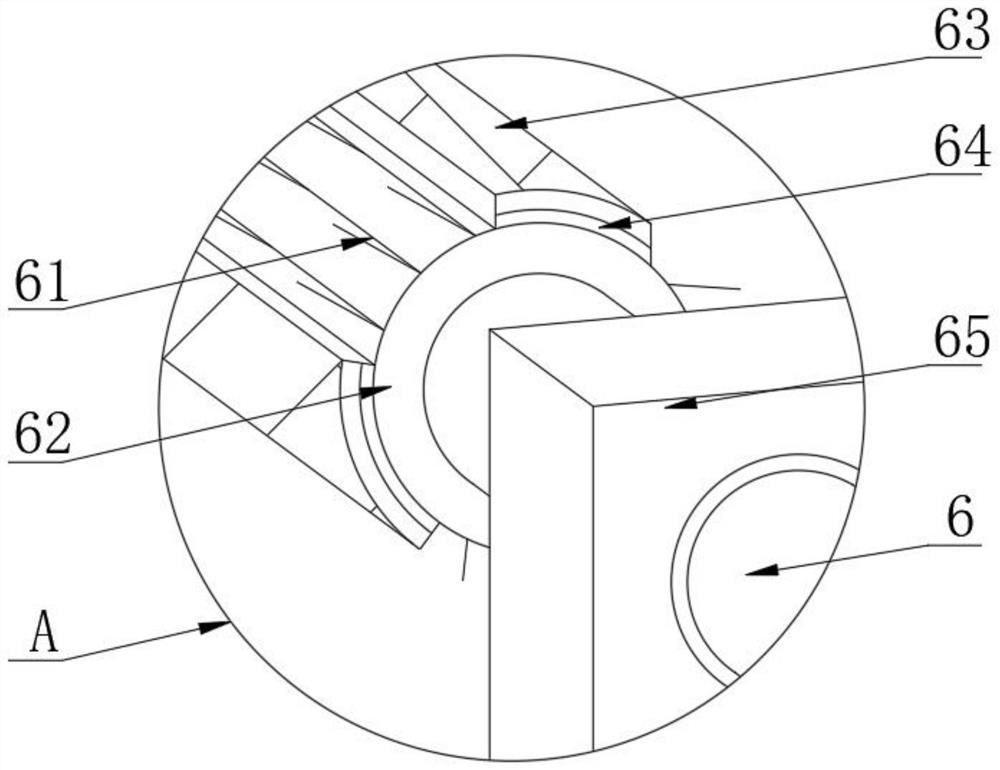

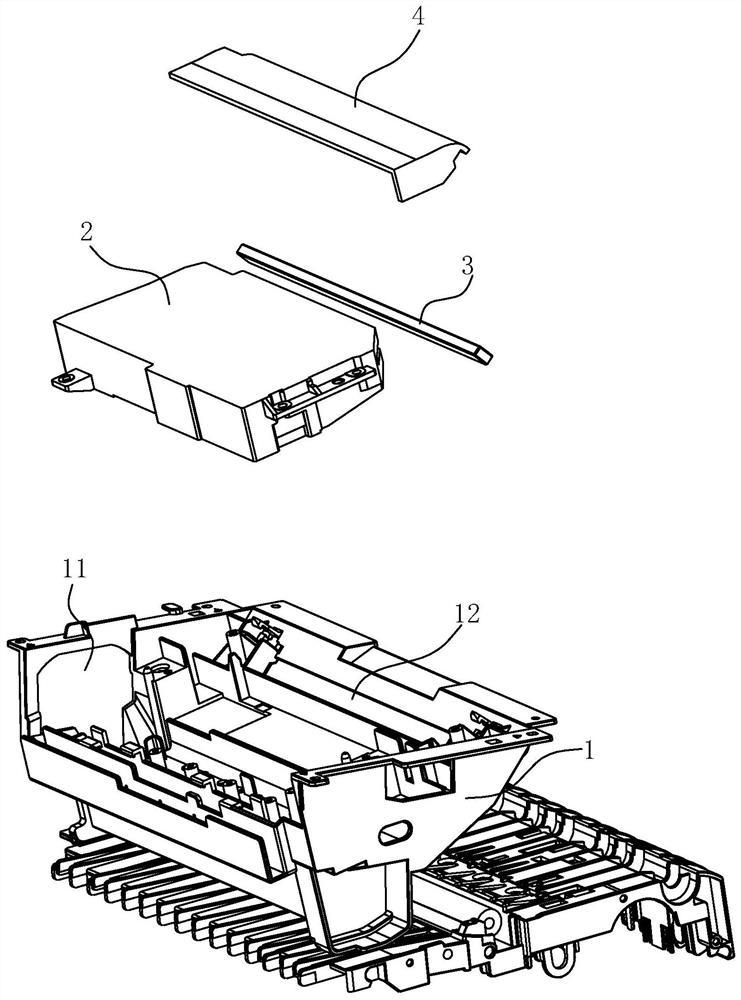

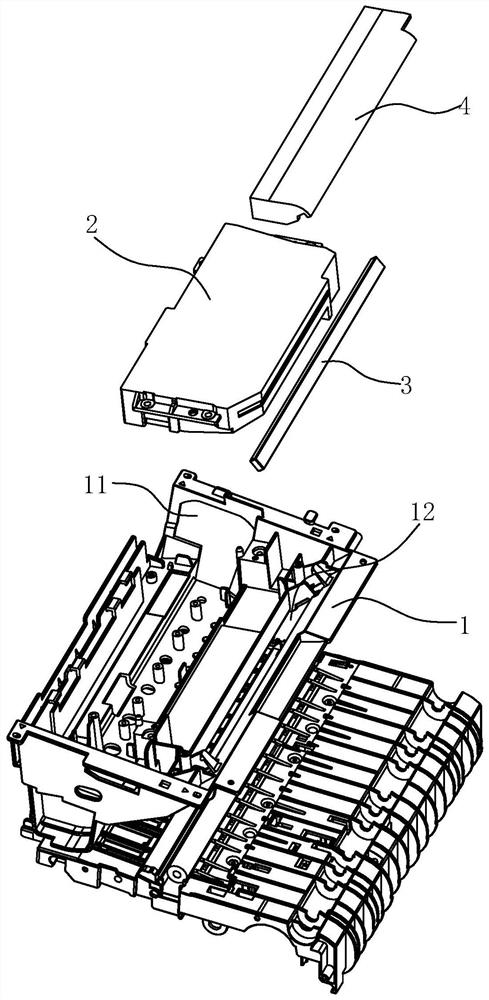

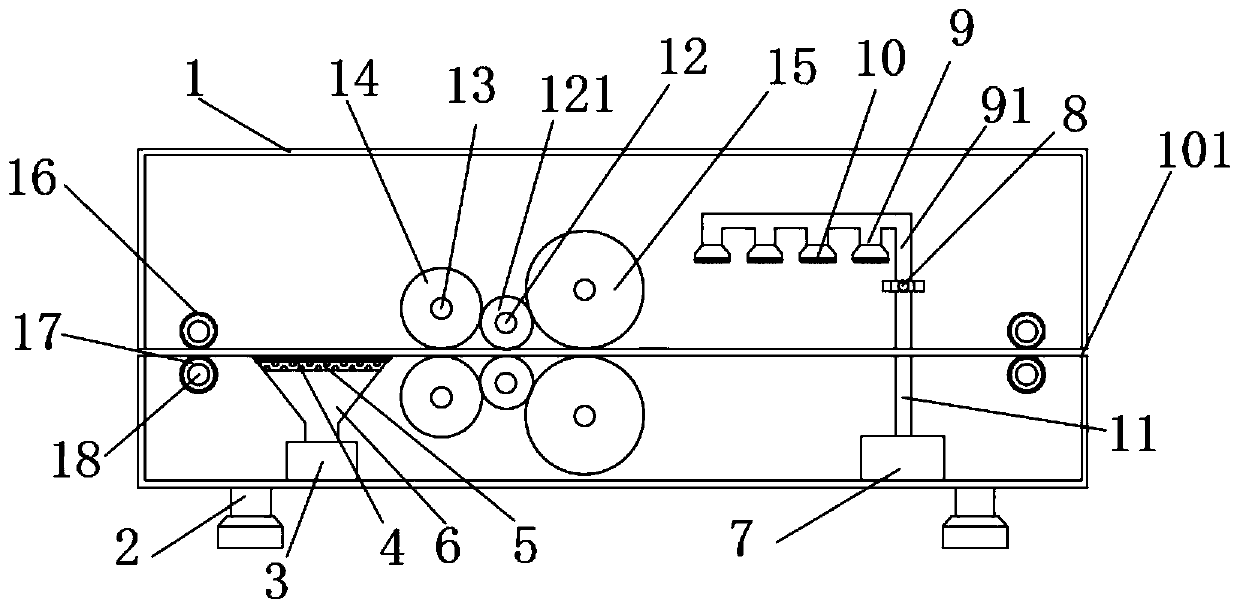

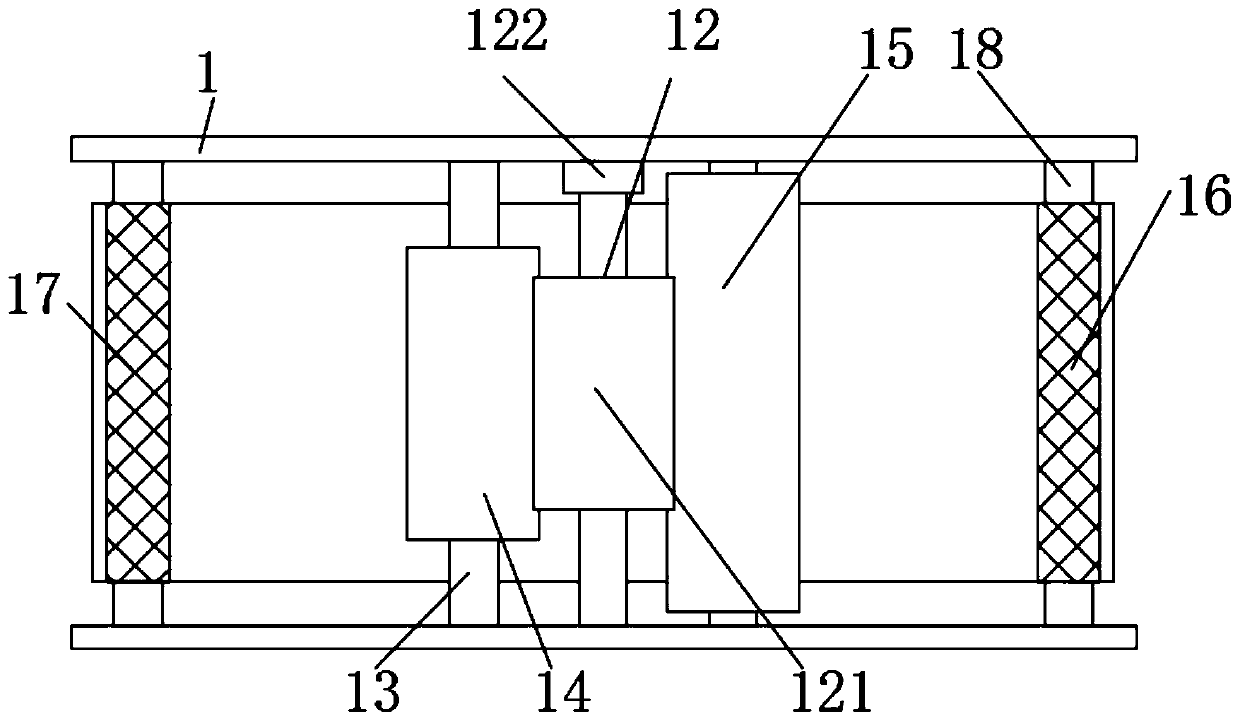

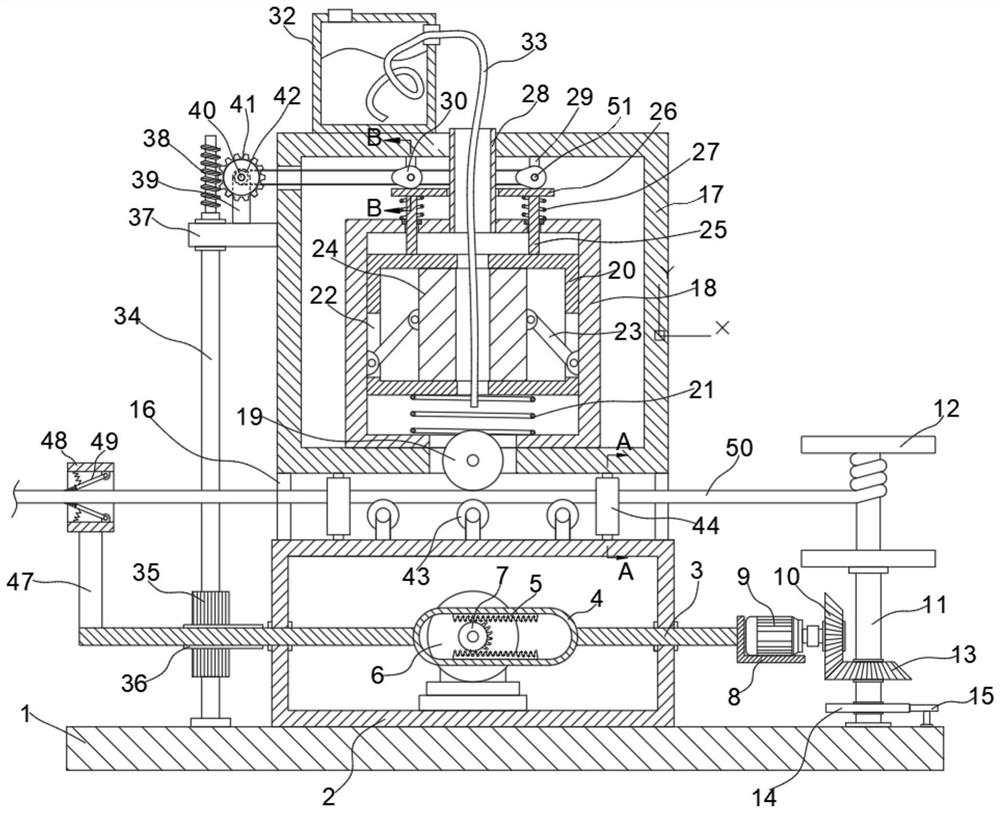

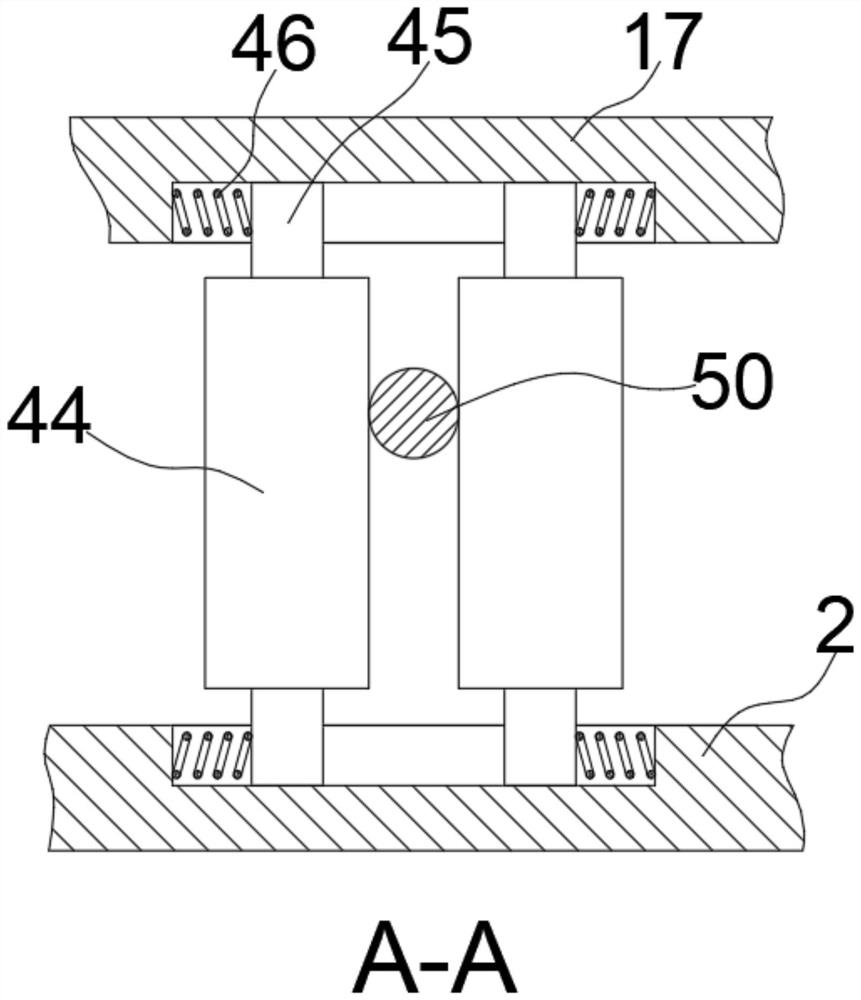

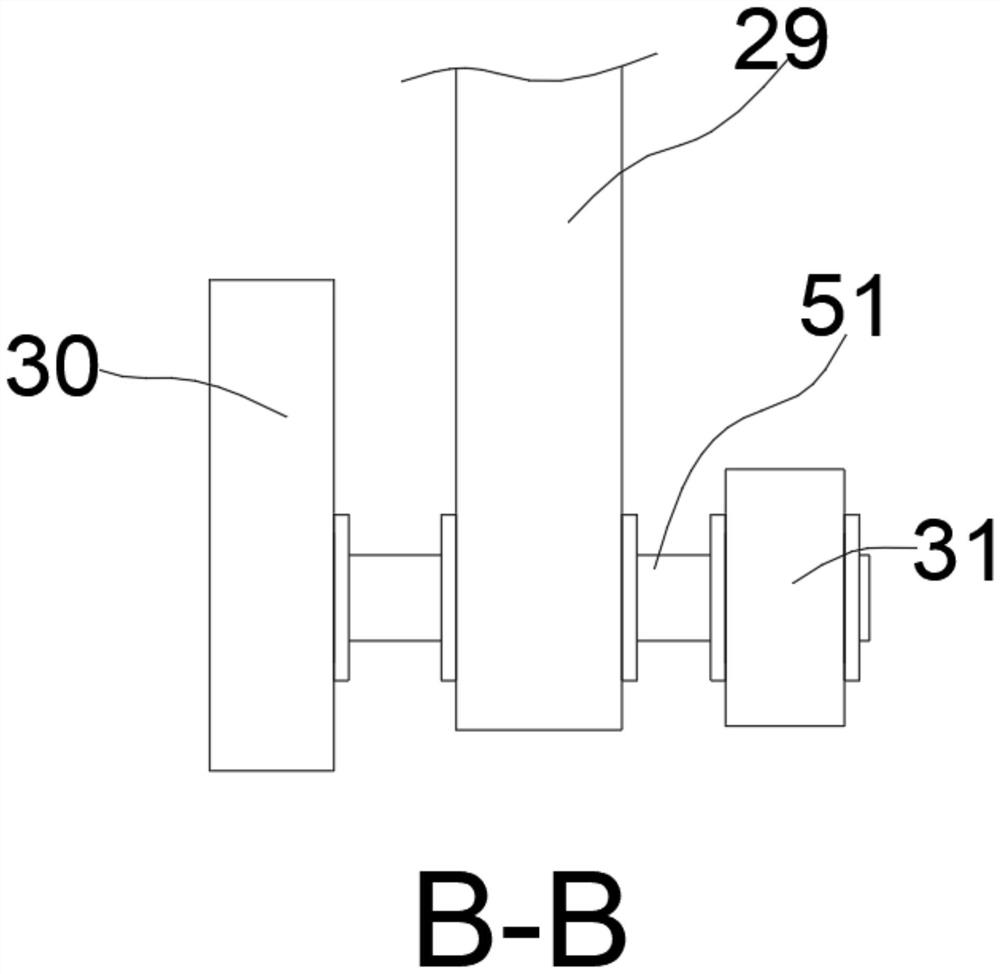

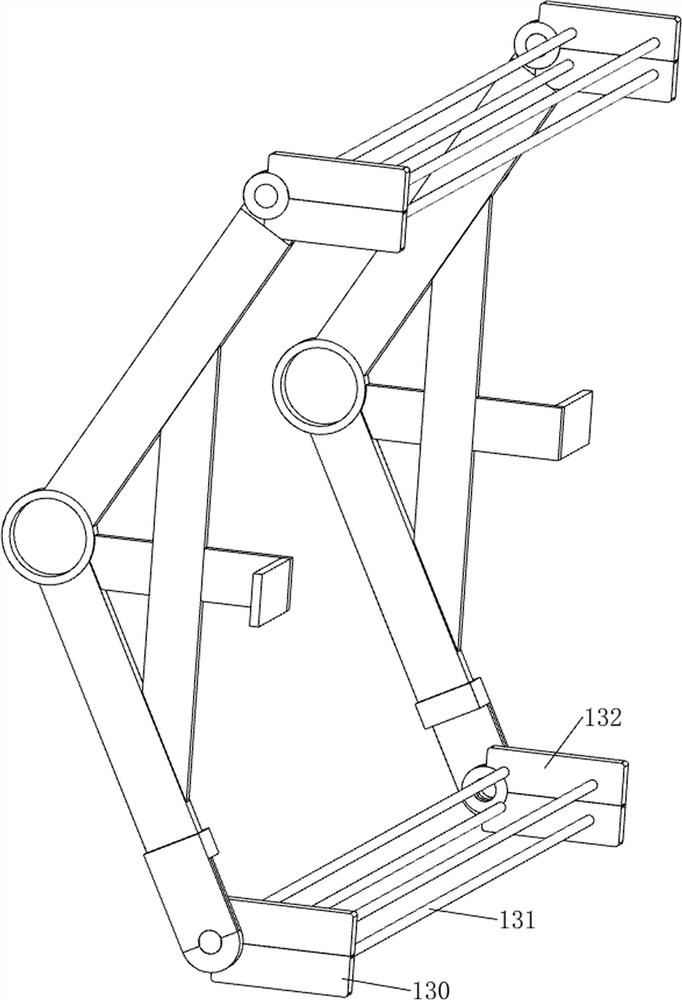

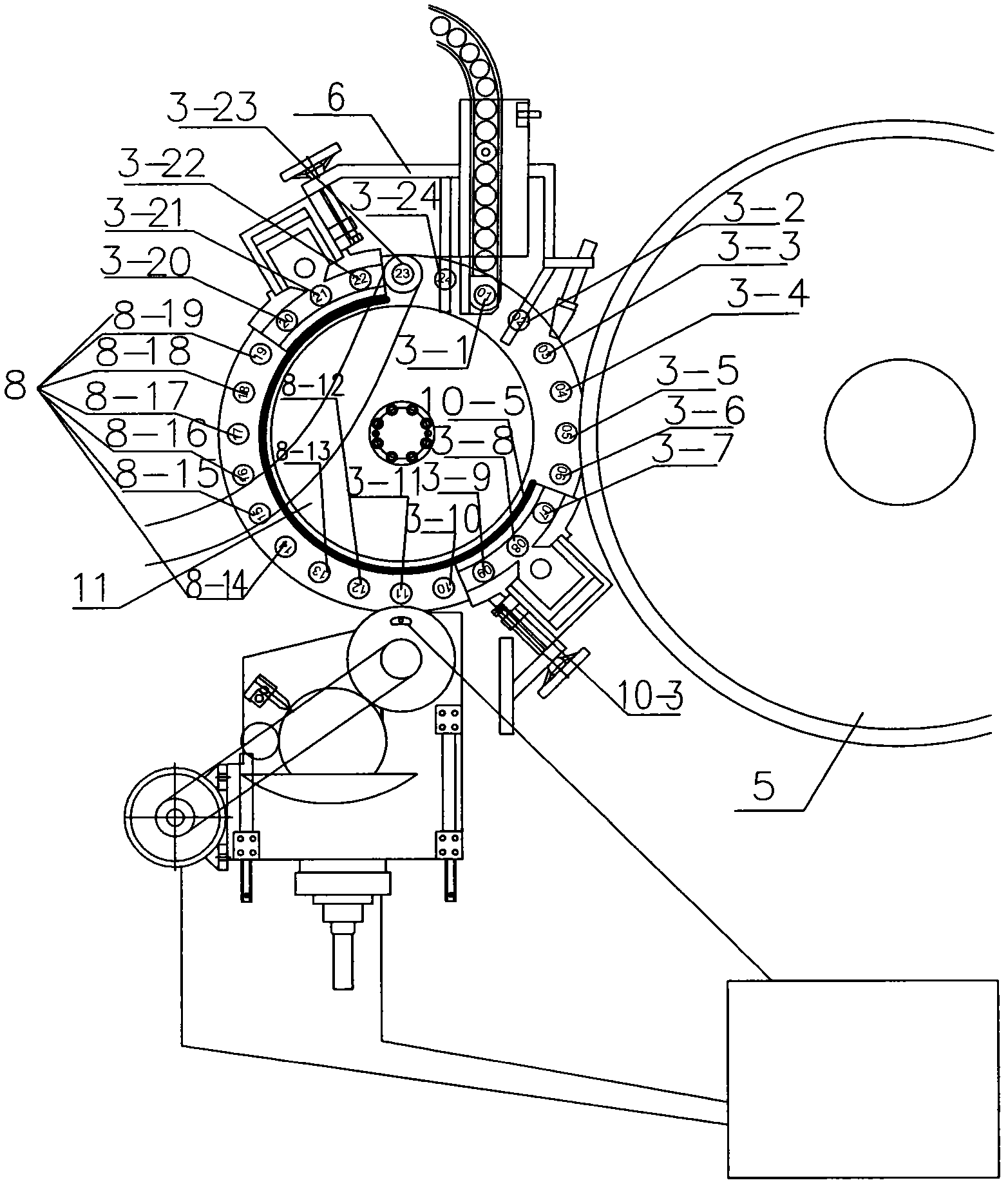

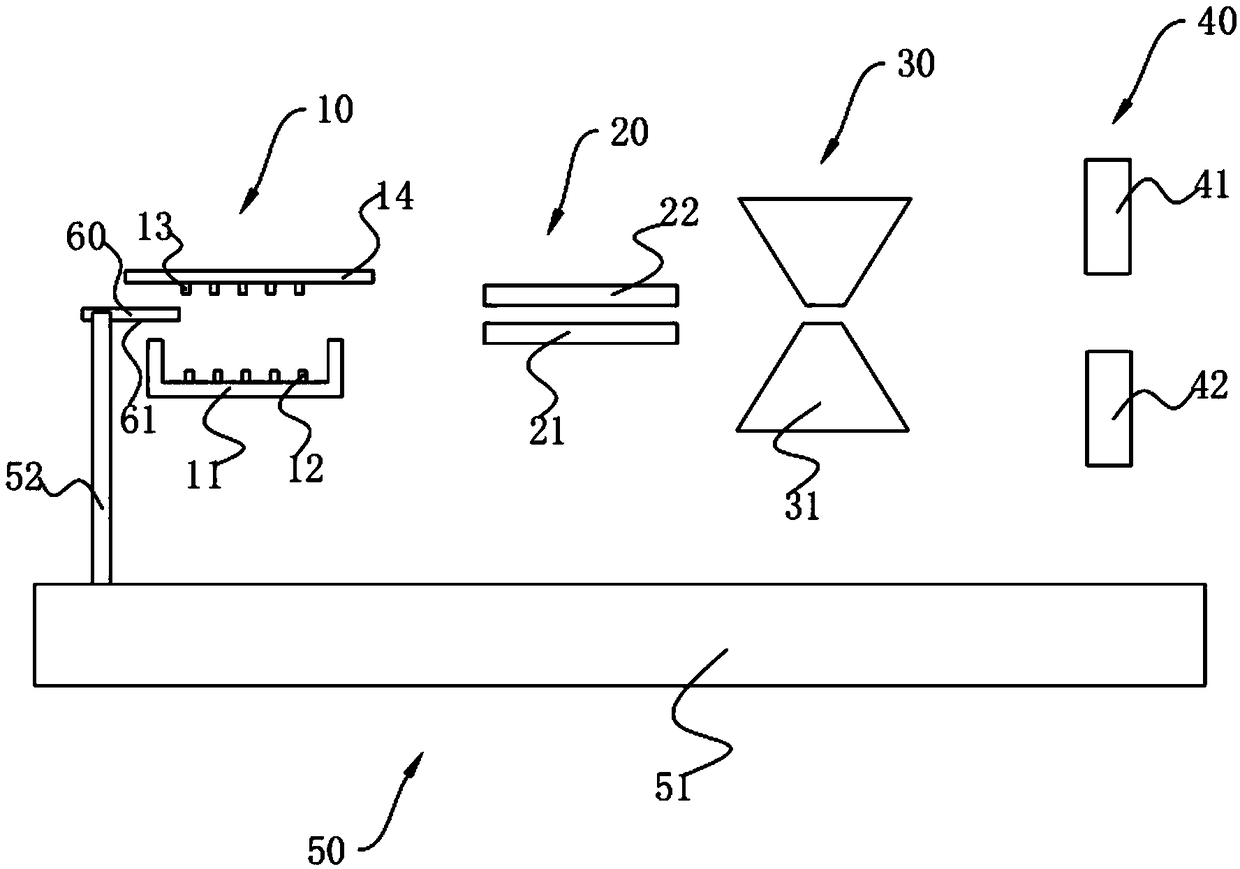

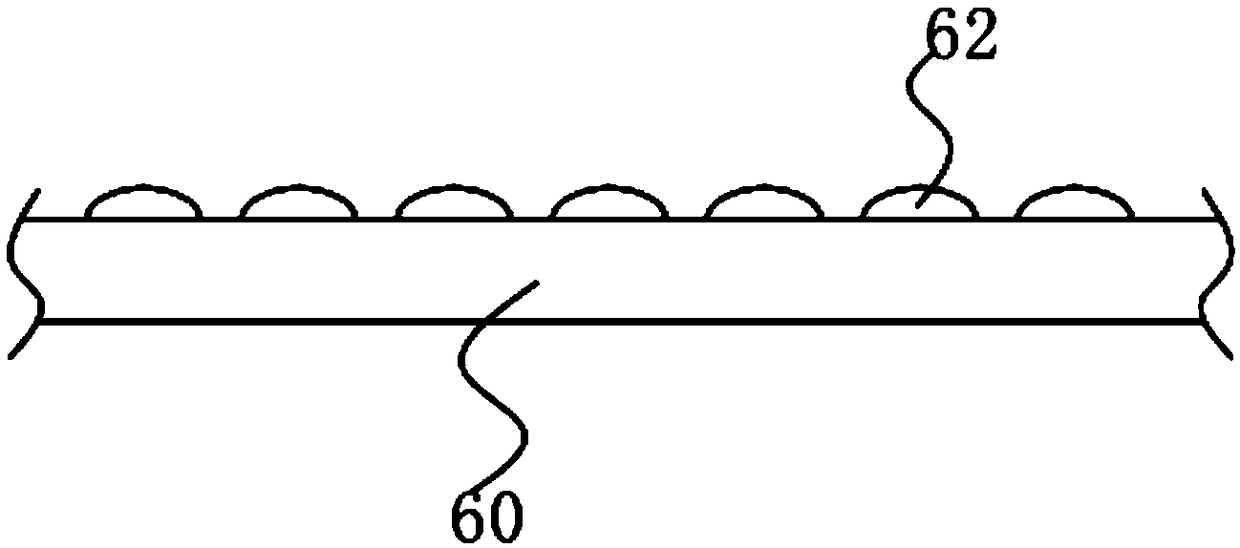

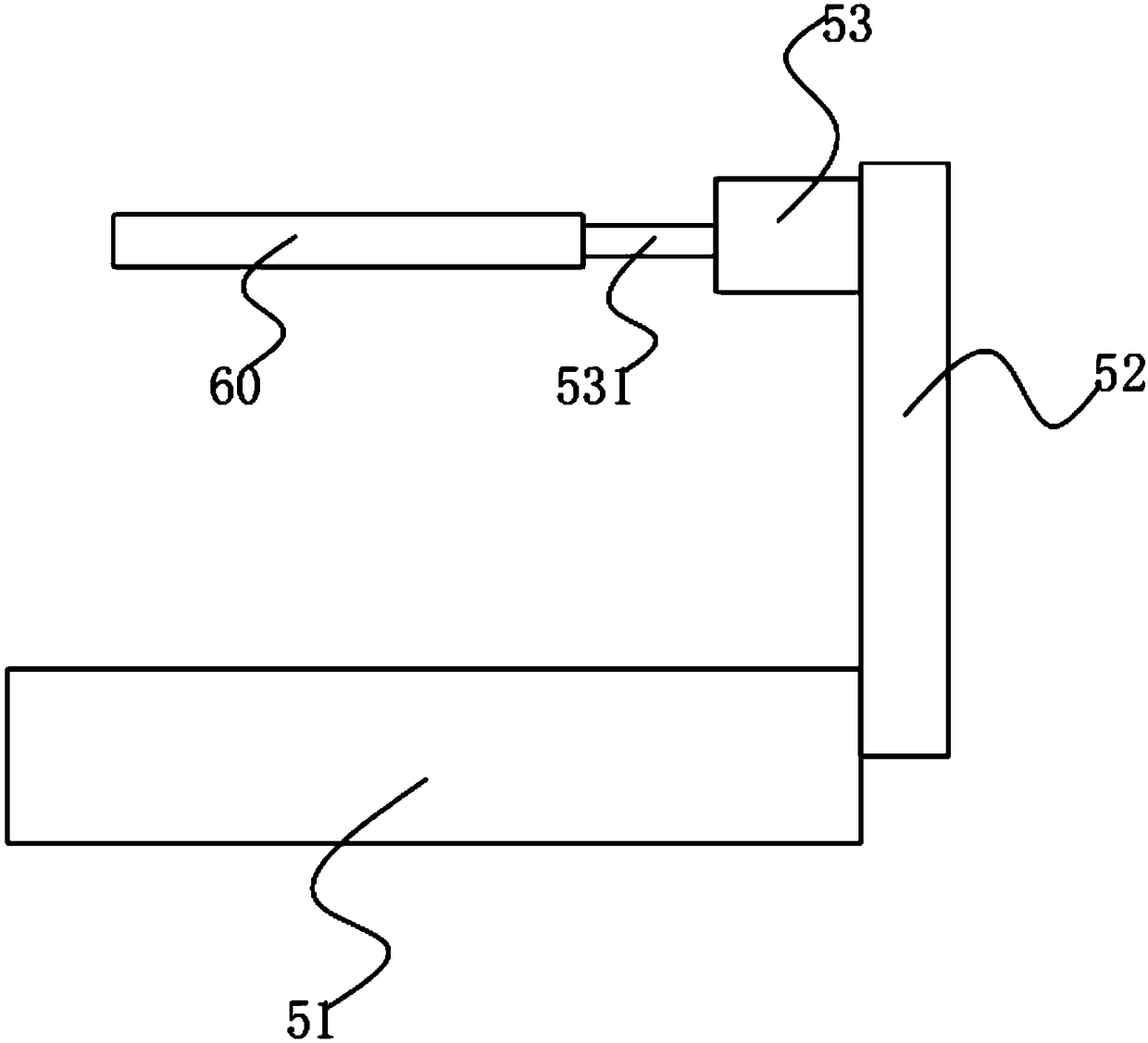

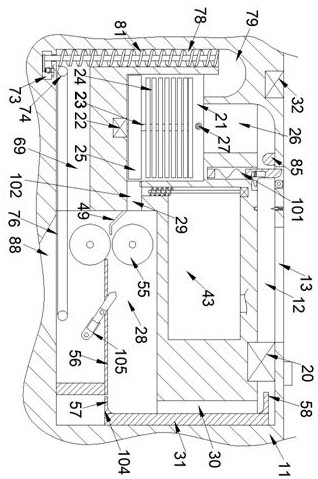

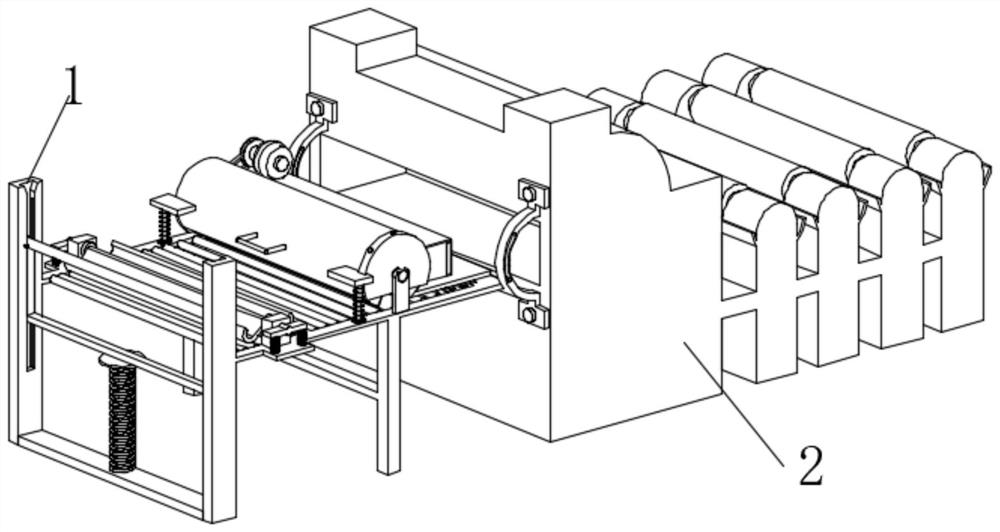

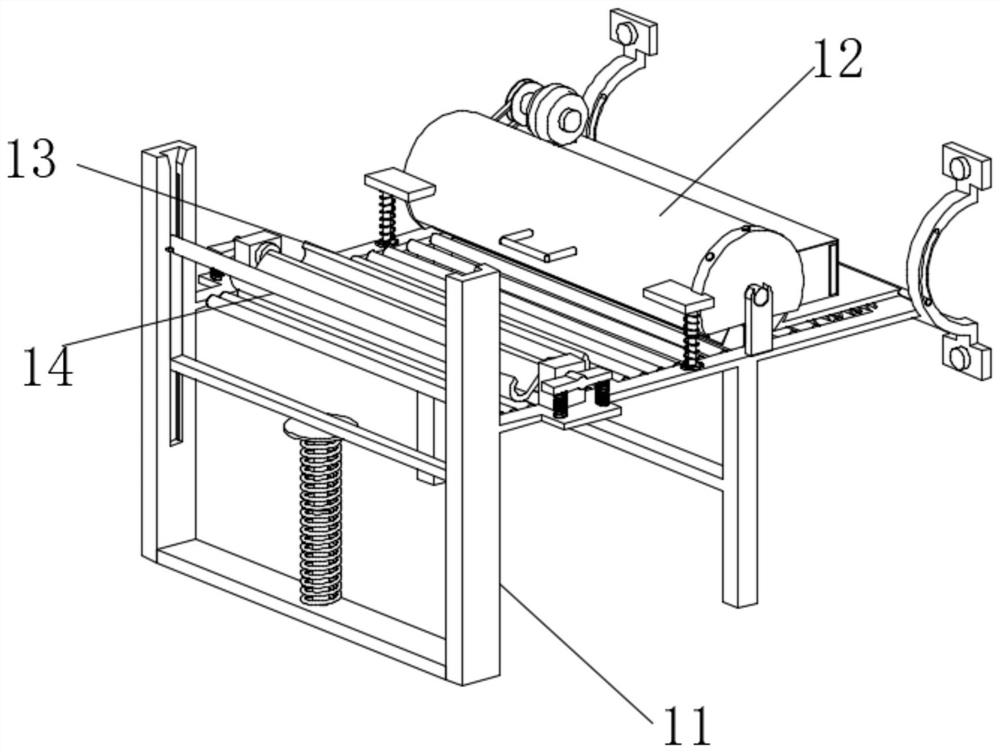

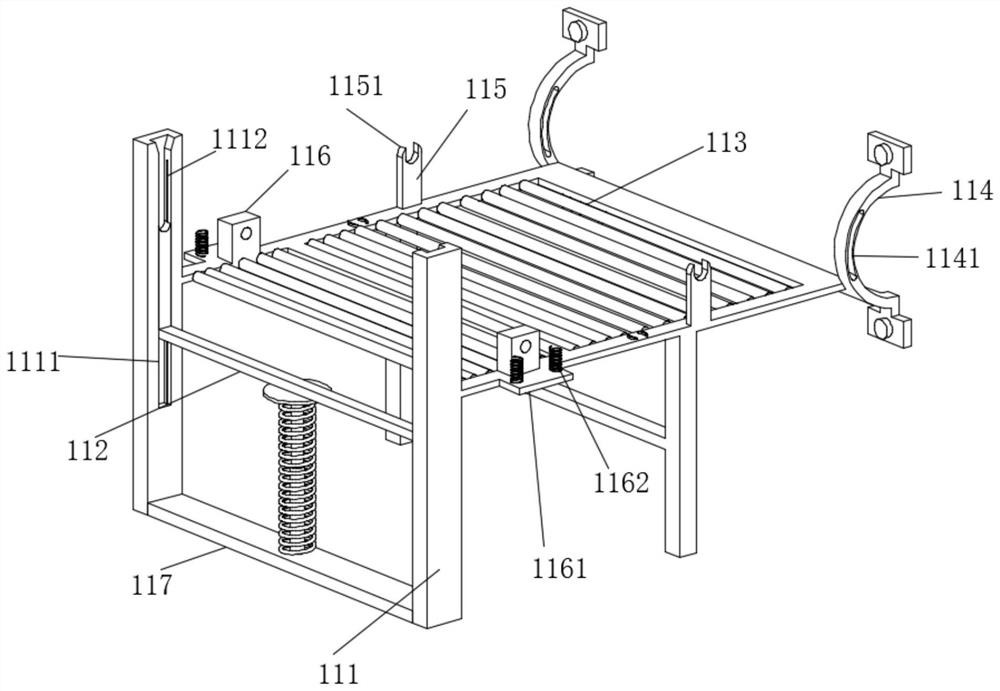

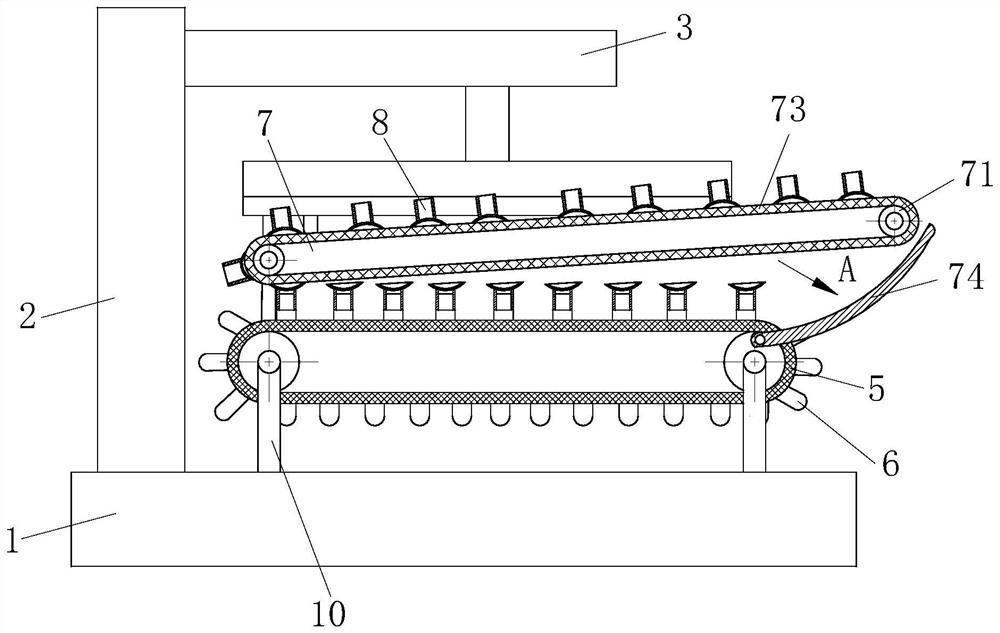

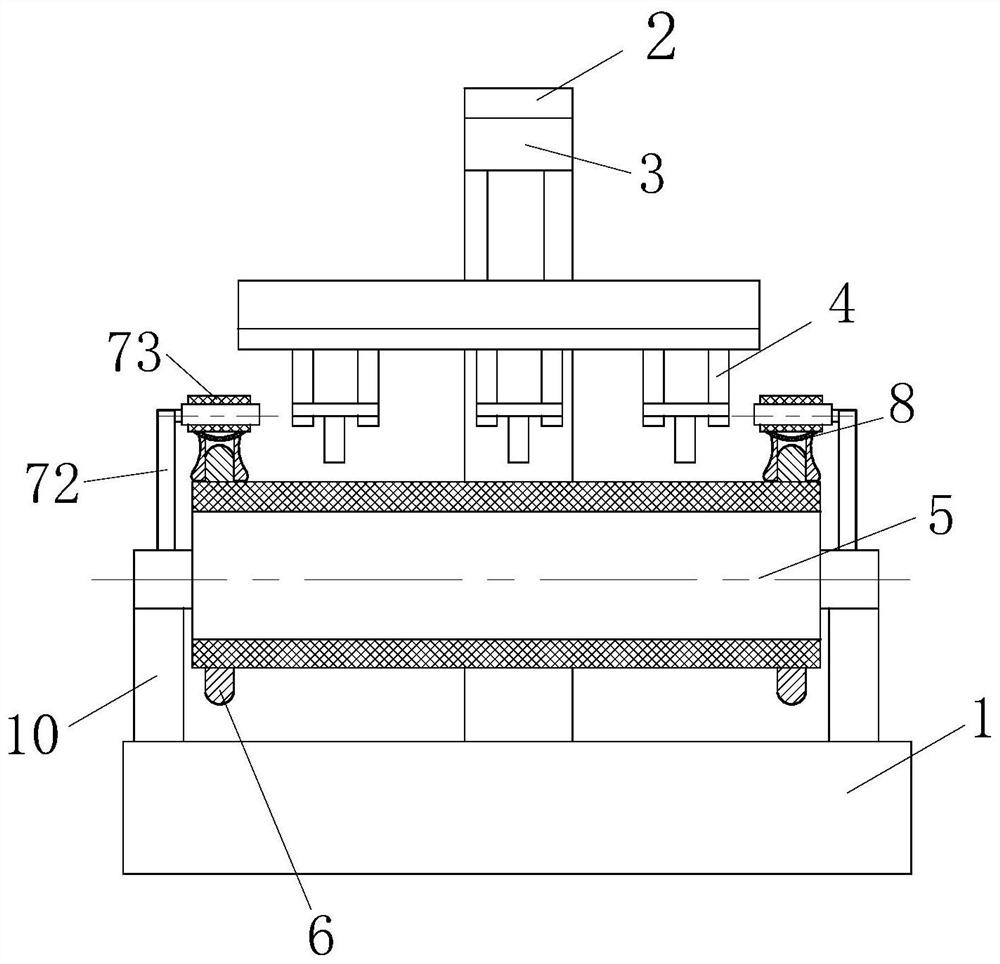

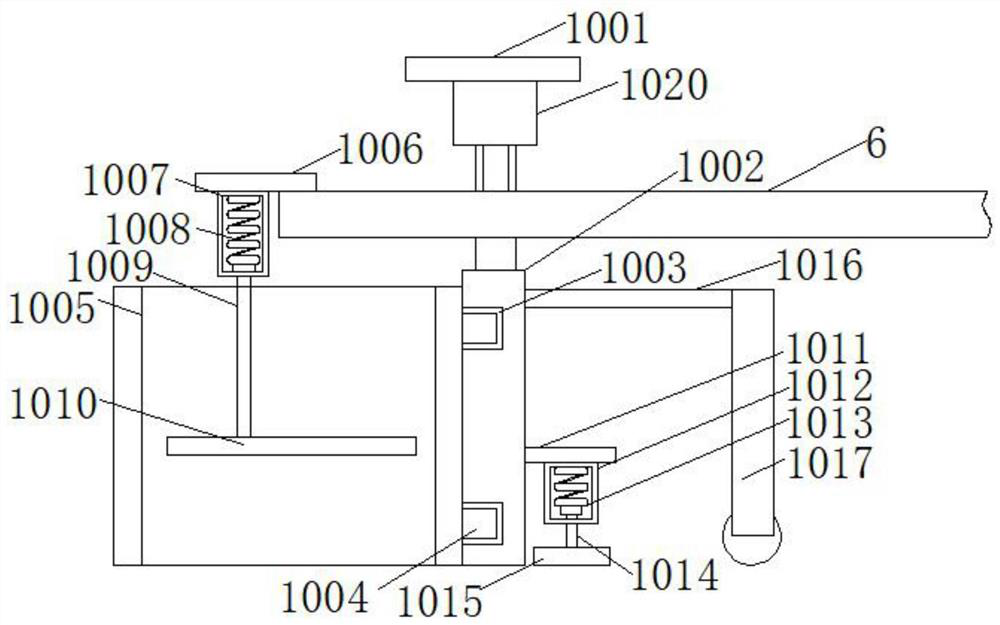

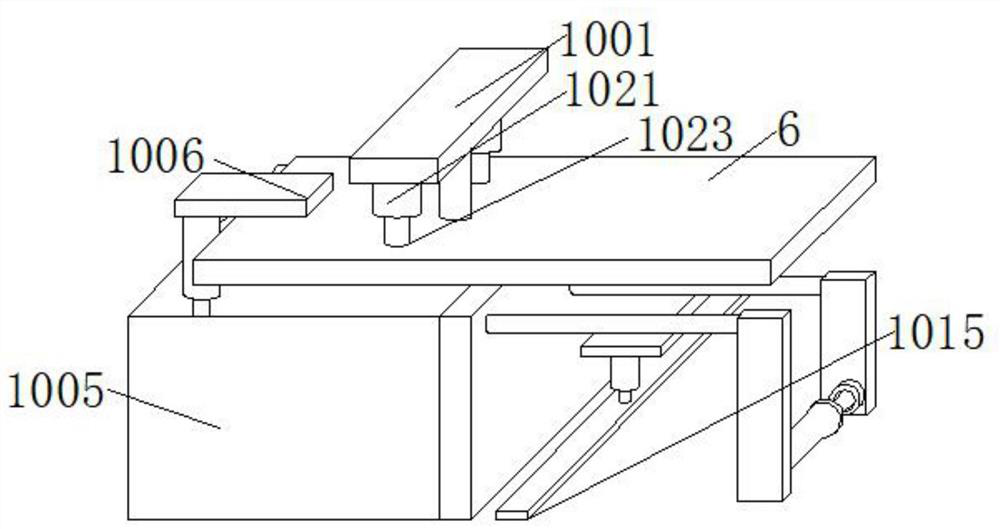

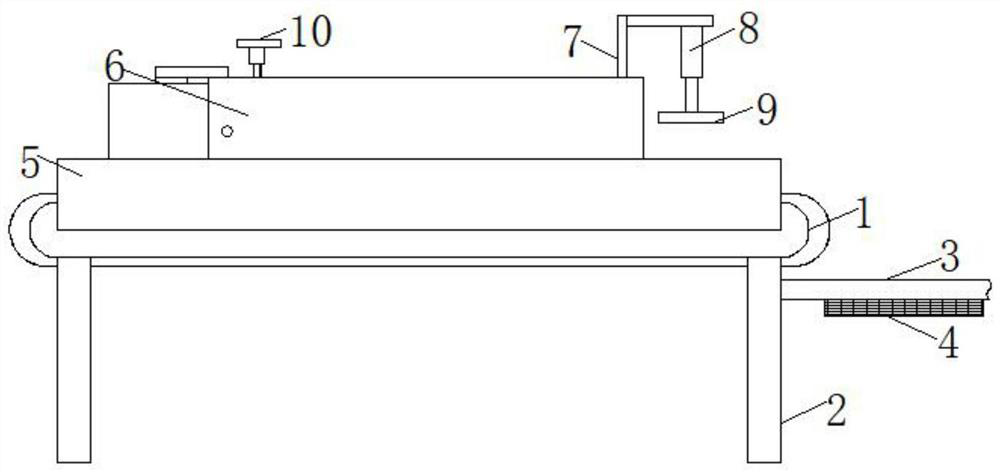

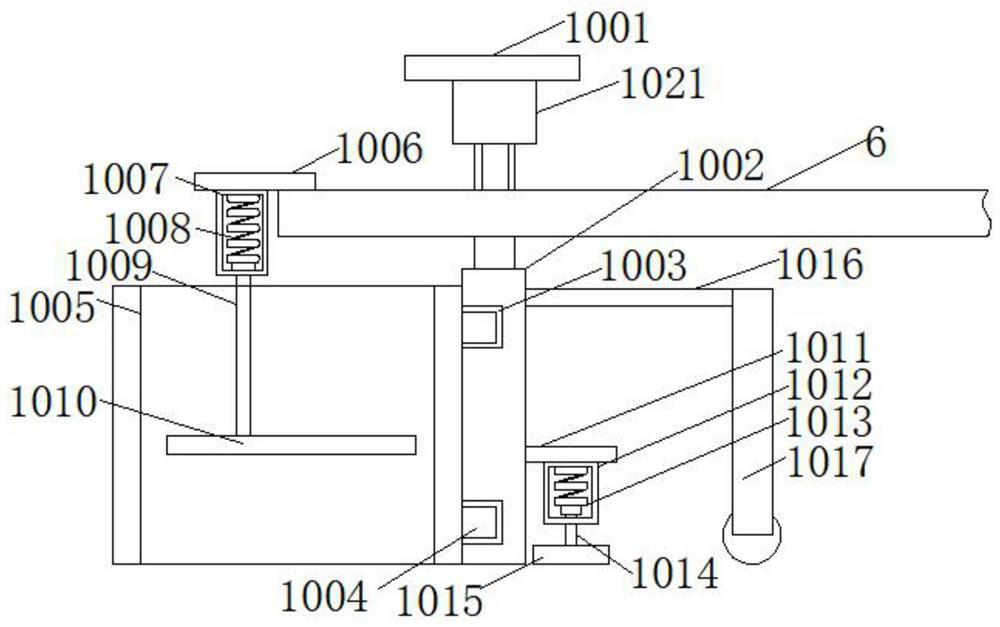

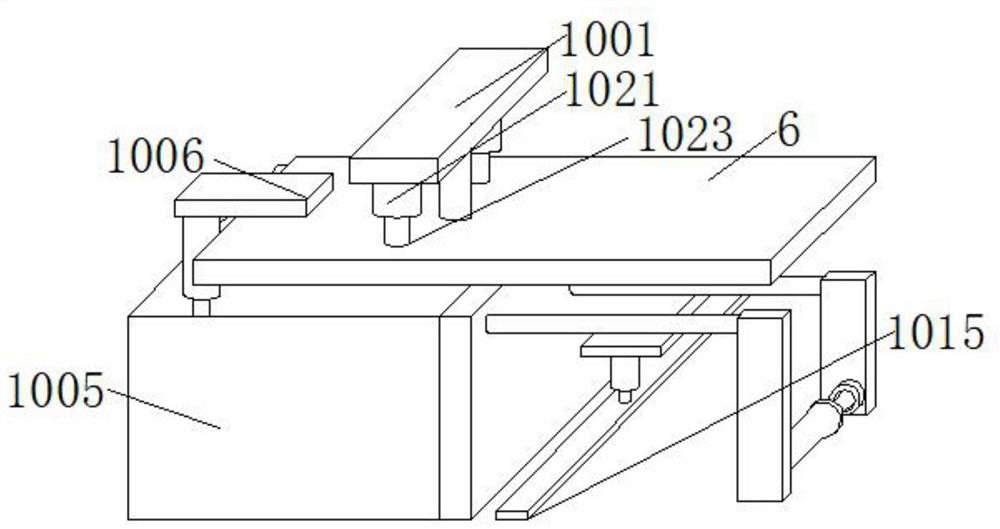

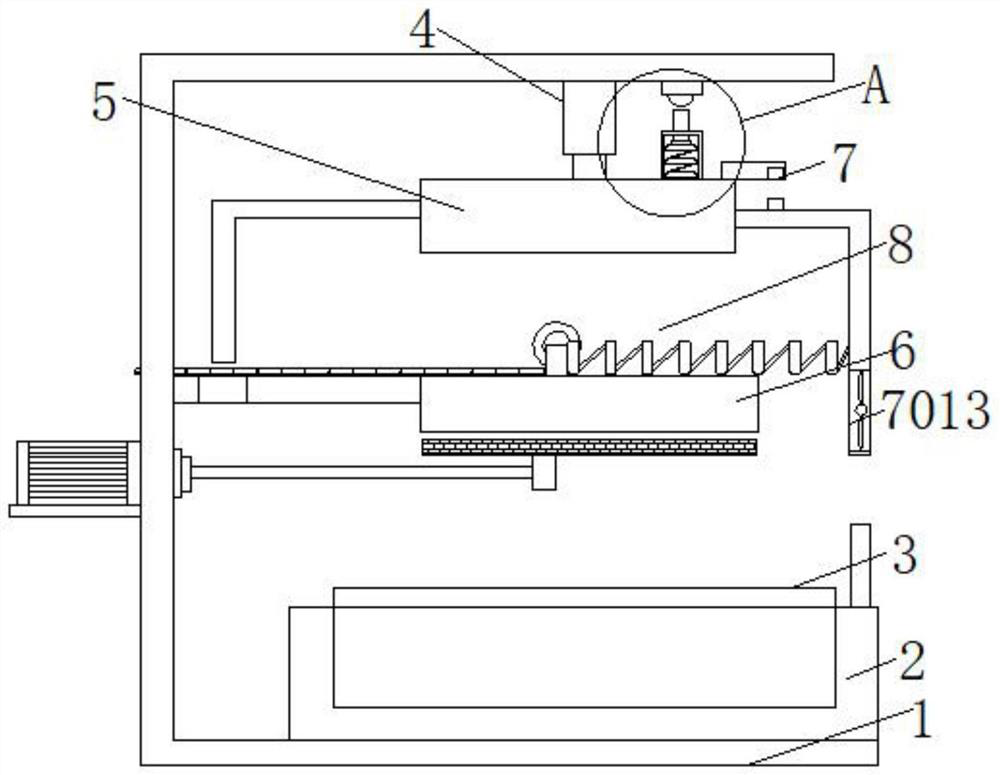

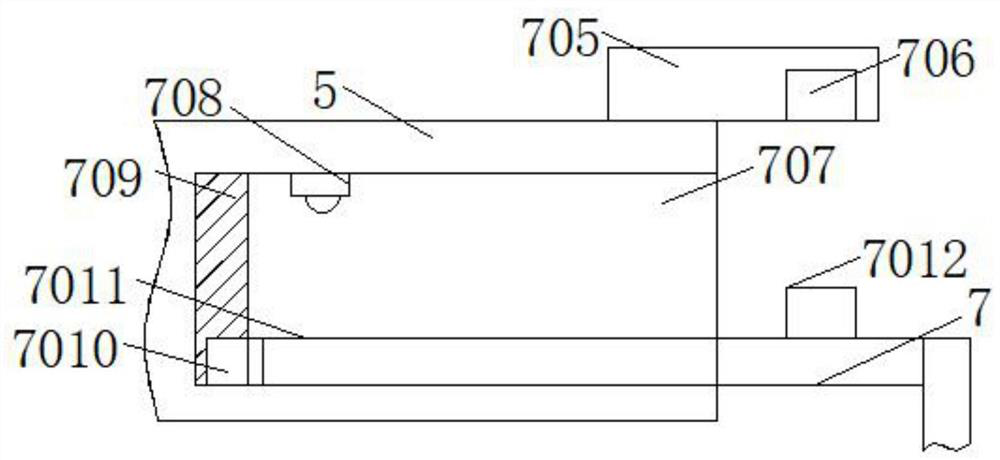

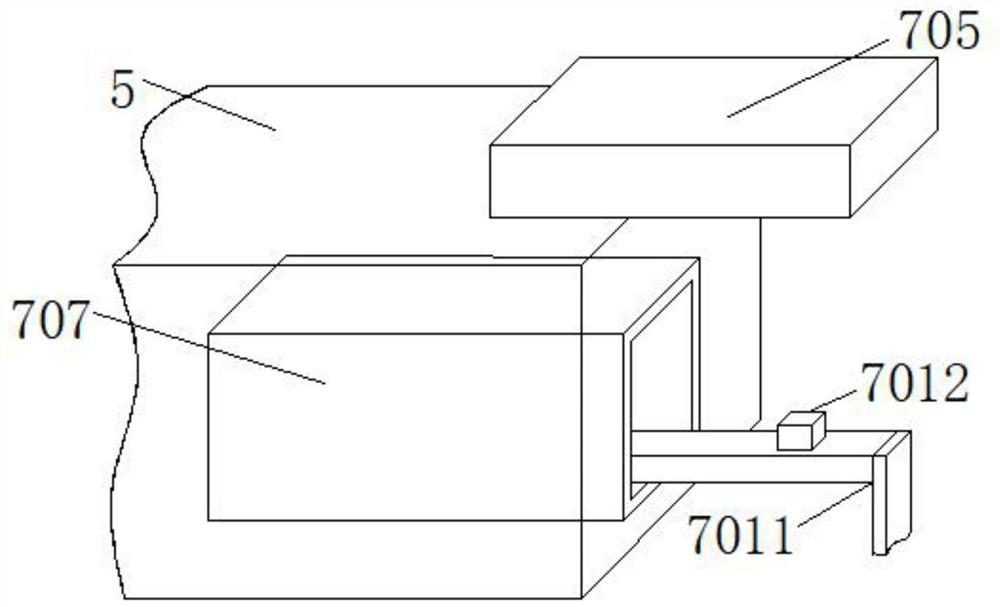

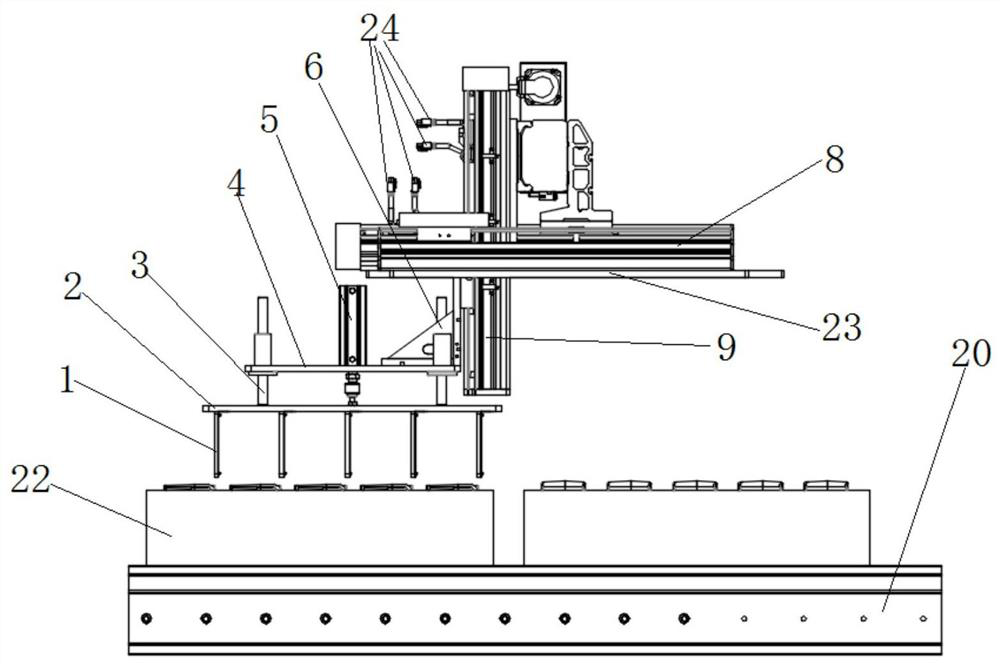

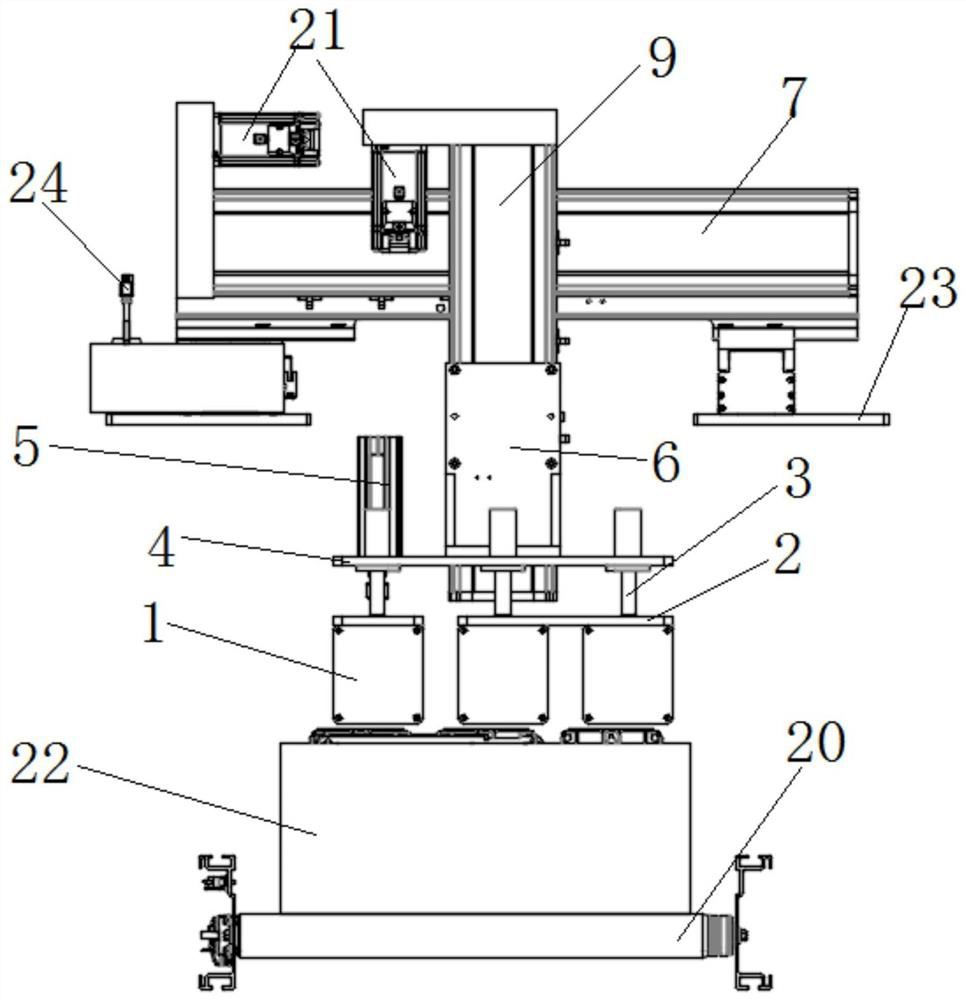

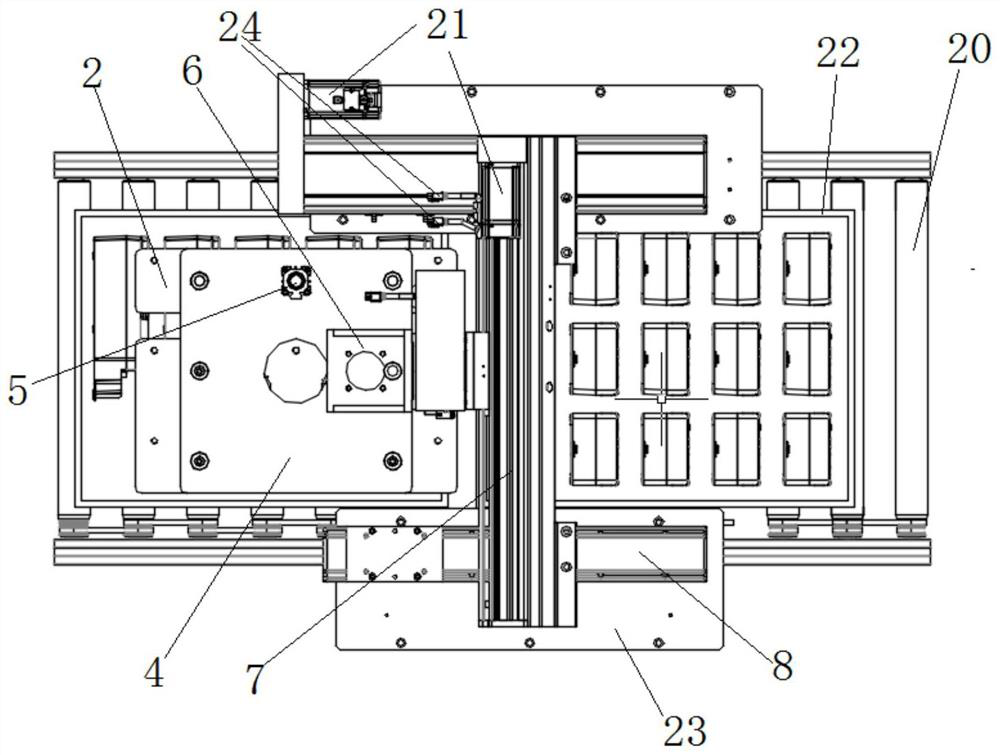

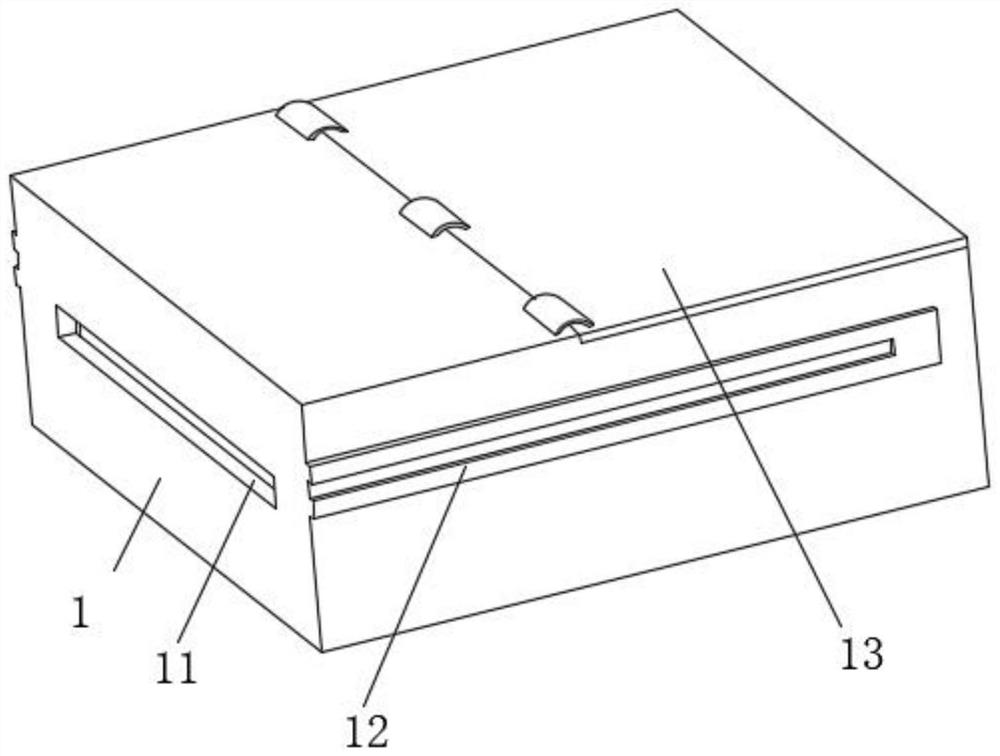

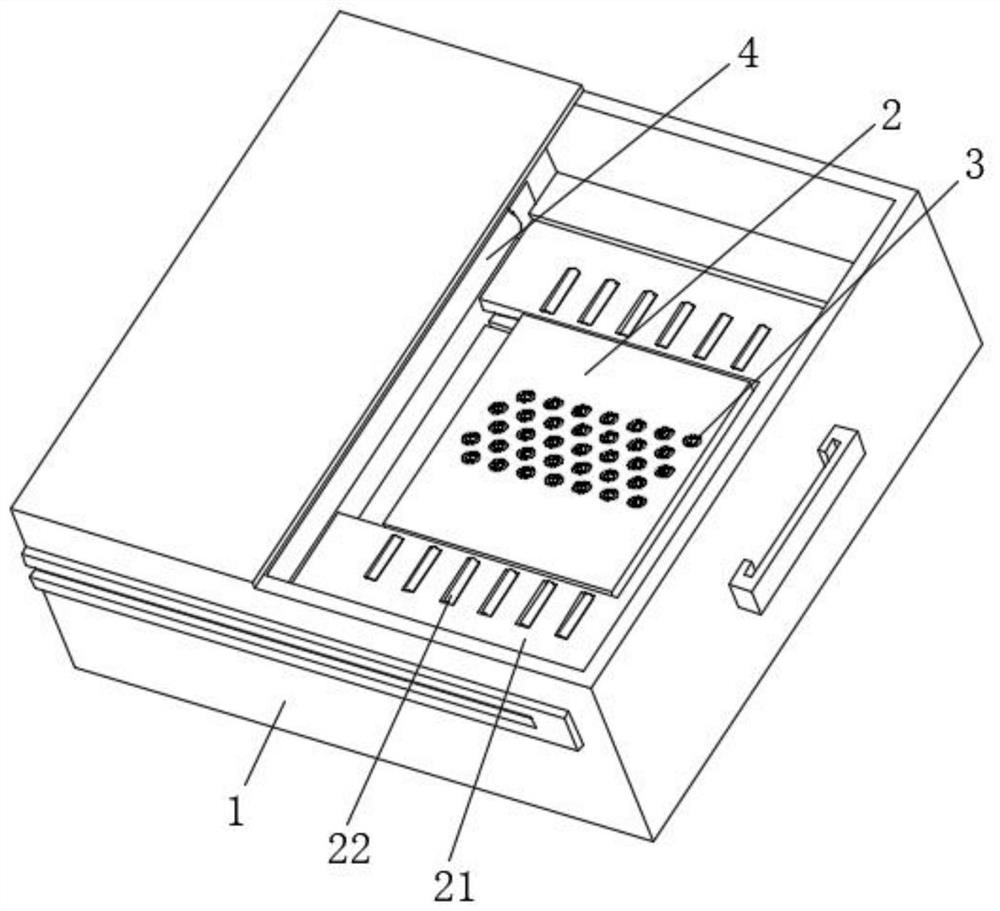

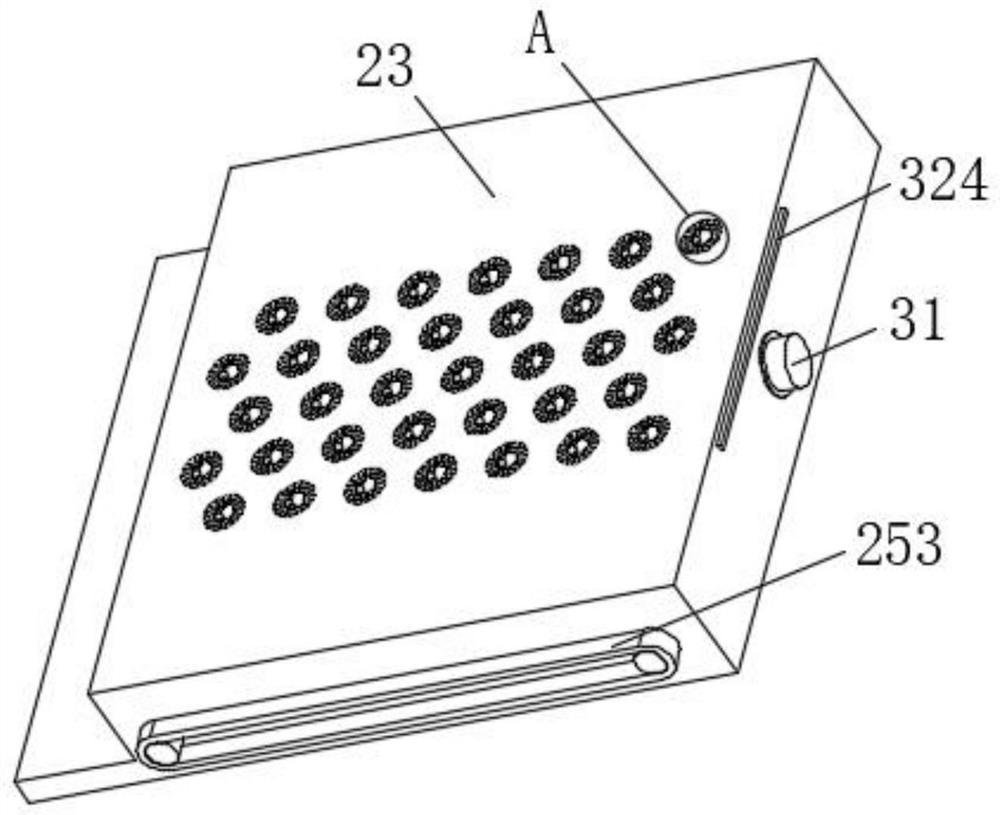

Intelligent manufacturing technology and application production training system

ActiveCN110449577AReduce processing timeIncrease productivityAdditive manufacturing apparatusCeramic shaping apparatusProduction lineManufacturing technology

The invention relates to an intelligent manufacturing technology and application production training system. The invention aims to provide intelligent flexible production line type production and a training technical scheme of photo frame products and solve the problems that a traditional production is dispersing in process, high in labor force, low in production efficiency and insufficient in quality guarantee. According to the system, equipment has an intuitive functions of product output and detection, industrial field application is truly represented, and external interfaces are arranged for facilitating expansion and upgrade of the equipment; construction combination is reasonable, and control is precise, so that application of intelligent manufacturing technology is fully embodied; and meanwhile, a raw material tray and a finished product tray are jointly used for conveying photo frame assemblies, to-be-dissembled photo frame assemblies are placed on the two different trays according to differences of machining processes, and corresponding machining treatment can be respectively carried out before final assembly, in this way, machining time in the production line is saved, and production efficiency is improved.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE +1

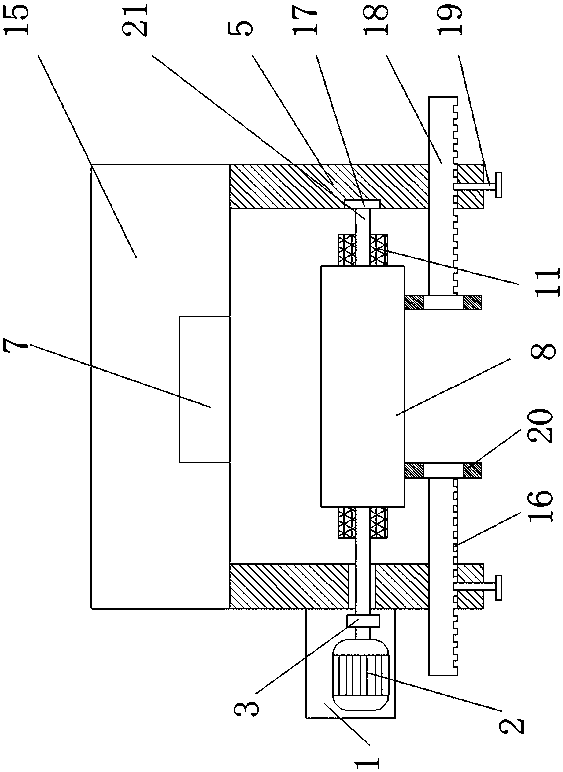

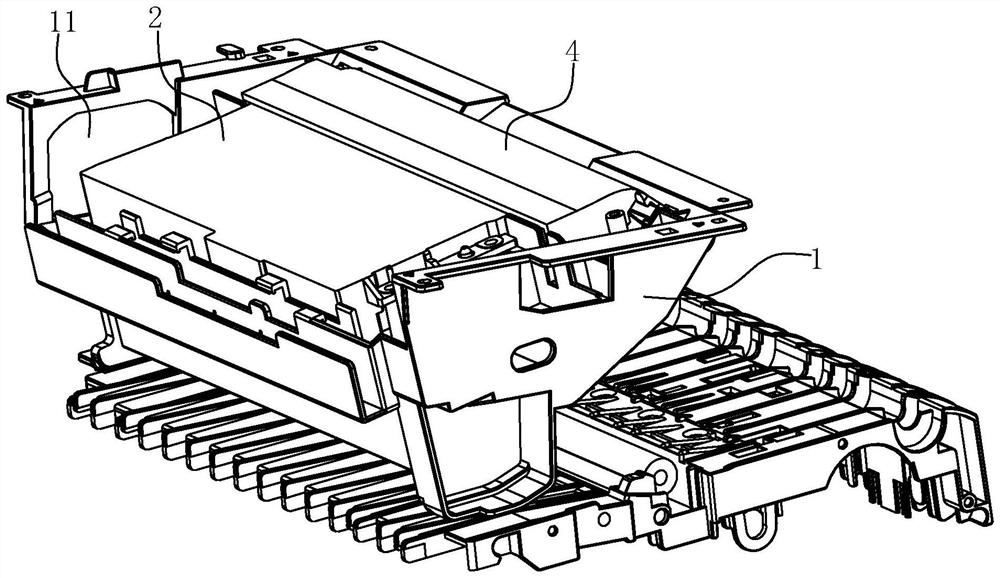

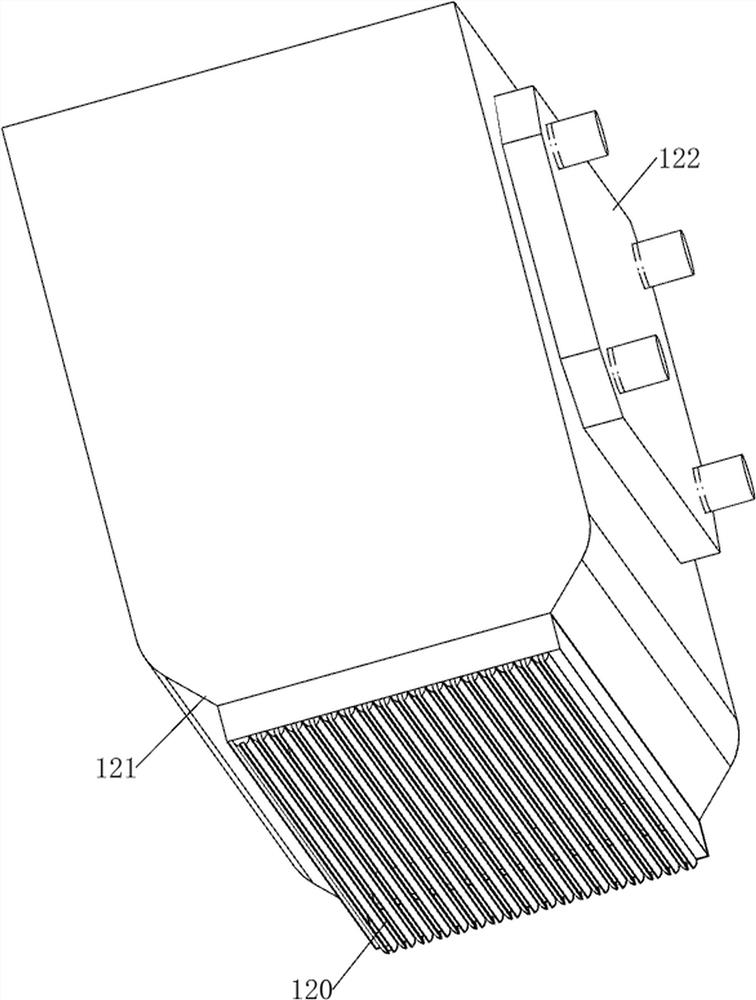

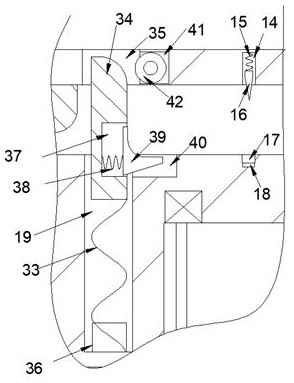

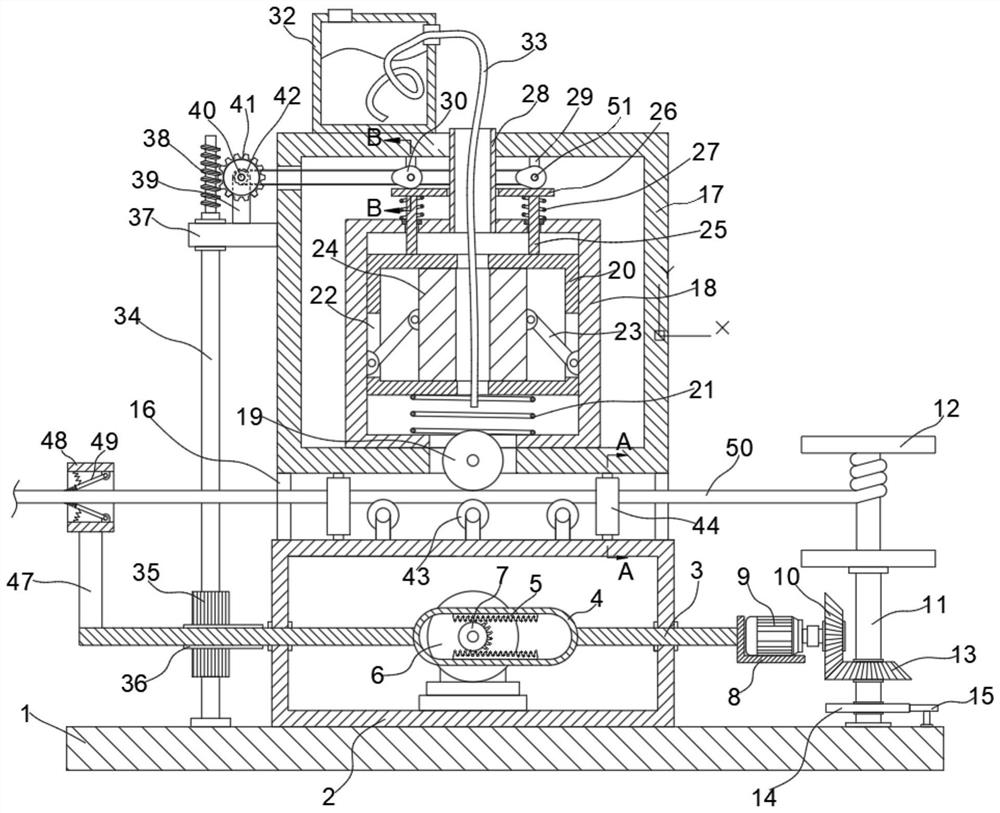

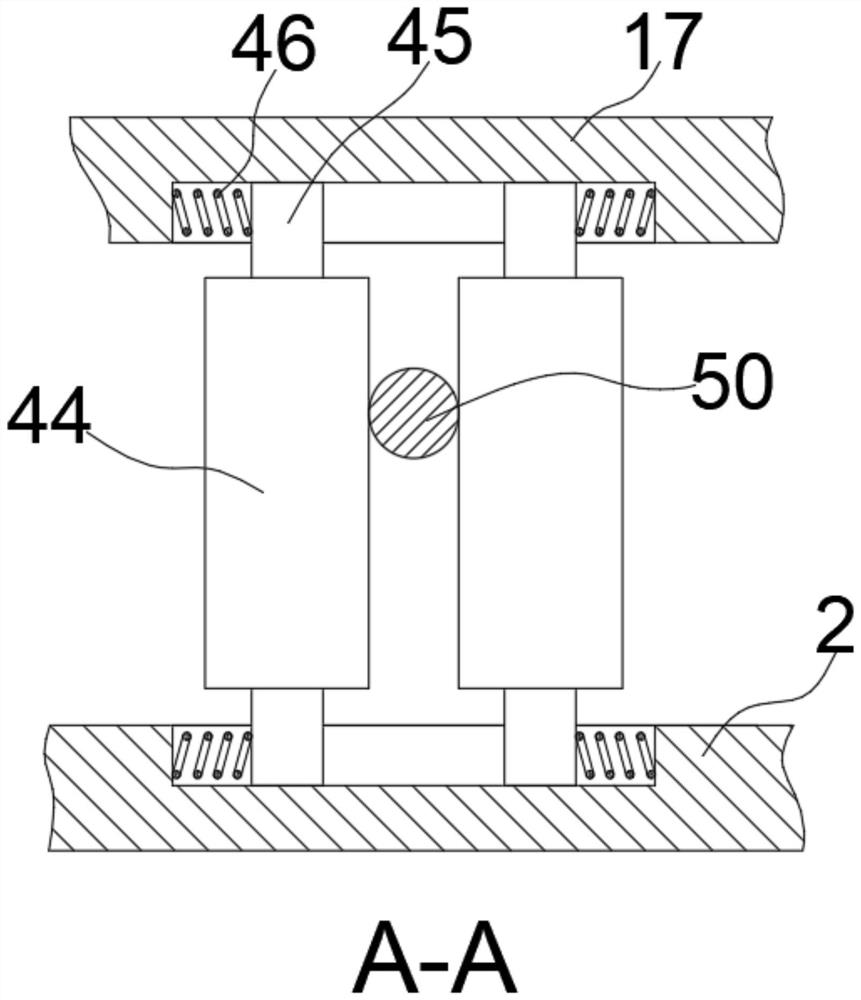

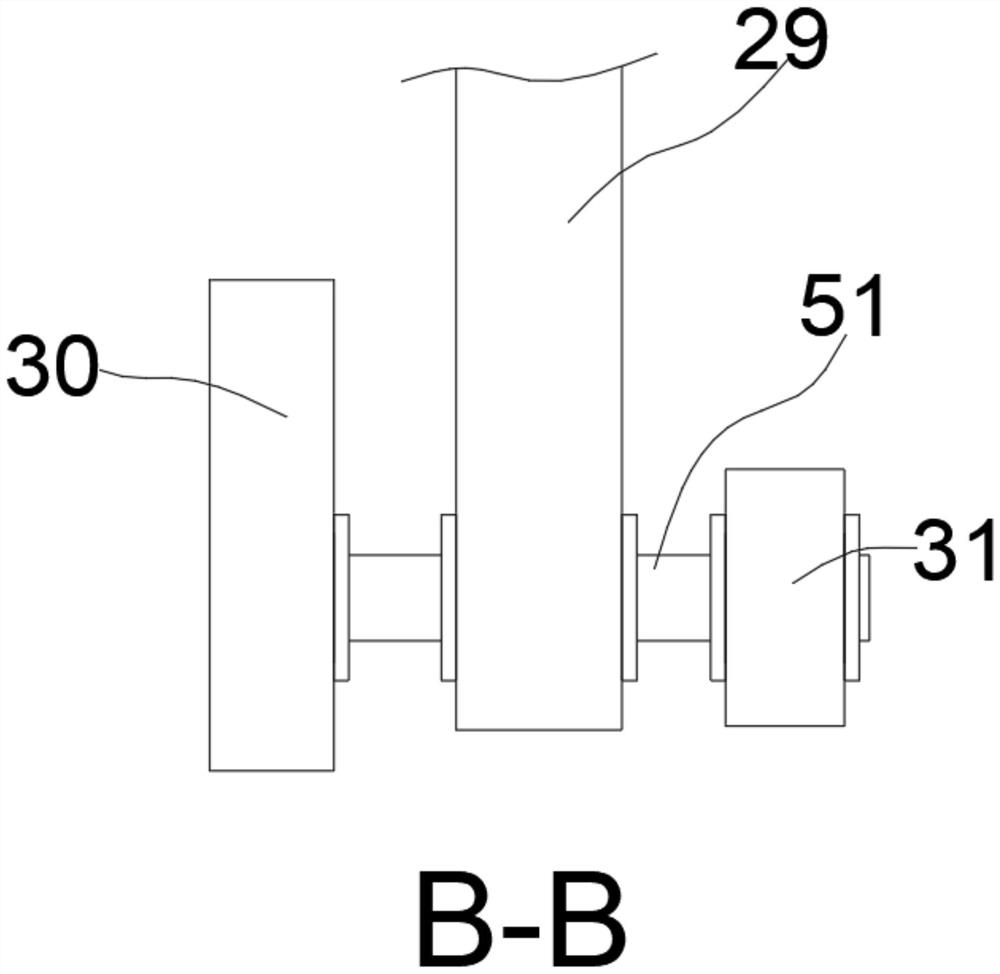

Material collecting pressing roller device of printing machine

PendingCN108608722AAvoid accumulationEasy to printCylinder pressesPlaten pressesSurface mountingEngineering

The invention discloses a material collecting pressing roller device of a printing machine. The material collecting pressing roller device comprises a supporting table and a machine body. Supporting plates are fixed to the two ends of the machine body, a first rotary shaft rod is arranged above the machine body, a first belt wheel is fixed to the left end of the first rotary shaft rod, a second rotary shaft rod is fixed to the right end of a second belt wheel, and the right end of the second rotary shaft rod penetrates through the supporting plates. The upper surface of a driving pressing roller makes contact with a driven pressing roller, the two ends of a third rotary shaft rod penetrate through the supporting plates, a buffer spring is arranged between the second rotary shaft rod and the third rotary shaft rod, the edge of a rotary wheel makes contact with the driven pressing roller, positioning holes are formed in the surface of a positioning rod, and a printing box is mounted on the upper surface of a top plate. According to the pressing roller device of the printing machine, the problems that impurities are accumulated on the surface of rubber of the rubber-covered rollers, the microporosity of the surfaces of the rubber-covered rollers is lost, the surfaces of the rubber-covered rollers are glazed, and finally serious harm is caused to printing are solved.

Owner:YANCHENG XIEHE MACHINERY

Polypropylene panel allowing writing and production technology thereof

The invention provides a polypropylene panel allowing writing and a production technology thereof. The polypropylene panel allowing writing comprises a coating layer which is formed by coating of polypropylene sheet materials and ink composition; the ink composition is formed by the following components, by weight, 100 parts of PP (Propene Polymer) ink, 10 to 20 parts of flatting agent, 40 to 60 parts of thinning agent, 1 to 5 parts of curing agent, 1 to 3 pars of coupling agent, 3 to 5 parts of dimethy lpolysiloxane, 3 to 5 parts of mica powders and 2 to 5 parts of antioxidant; the coating layer on the surface of the polypropylene panel allowing writing is produced through the screen printing process. According to the polypropylene panel allowing writing, the purpose of achieving changing the smooth performance on the polypropylene surface is achieved due to coating of the coating layer on the polypropylene surface, so that writing can be performed on the polypropylene surface and handwriting is not easy to erase.

Owner:义乌市祥胜文化用品有限公司

Printing device suitable for textile fabrics

InactiveCN111761929AAffect the printing effectEasy to cleanRotary pressesOther printing apparatusTextile printerStructural engineering

The invention relates to the technical field of fabric printing, and discloses a printing device suitable for textile fabrics. A cleaning component is fixedly installed at the side of the upper surface of a worktable close to a third fixing seat; a second fixing seat is fixedly installed at the side of the upper surface of the worktable close to the first fixing seat; an auxiliary limiting component is arranged at the side of the upper surface of the worktable close to the second fixing seat; and a measuring component is installed at the back surface of the worktable and at the lower surfaceof a winding roller. By arranging the cleaning component, the surface of a fabric passing through a cleaning roller can be effectively cleaned, thereby preventing contamination on the surface of the fabric; by arranging the auxiliary limiting component, a limiting wheel can achieve an auxiliary pressing effect on the fabric at the lower surface of the limiting wheel, so that wrinkling of the fabric can be effectively prevented, and thus losses caused by influences on fabric printing are prevented; and by virtue of the measuring component, the specific length of the fabric can be obtained; andthus the fabric can be conveniently used by people in later period.

Owner:陈紫璇

Anti-fogging printer and printer working method

PendingCN112698557AAffect the printing effectReduced print qualityElectrographic process apparatusLaser transmitterComputer printing

The invention relates to an anti-fogging printer. The anti-fogging printer comprises a printer body, a control circuit board and a laser imaging unit, wherein the control circuit board and the laser imaging unit are arranged in the printer body; the laser imaging unit comprises a support, a laser emitter and a reflector, wherein the laser emitter and the reflector are installed on the support at intervals, the support is provided with an air inlet for air to enter, wherein the air inlet is provided with a fan; the laser emitter and the fan are electrically connected with the control circuit board; the anti-fogging printer further comprises an isolation piece which can isolate the laser emitting part of the laser emitter and the reflector from an air circulation space on the support. The invention further relates to a printer working method. When the printer works, the temperature T in the printer body is detected, whether the fogging risk exists or not is judged according to the temperature T, and then the fan is controlled to work according to a judgment result. According to the anti-fogging printer and the working method thereof, the influence of fogging on a printing effect can be weakened.

Owner:NINGBO DELI KEBEI TECH CO LTD

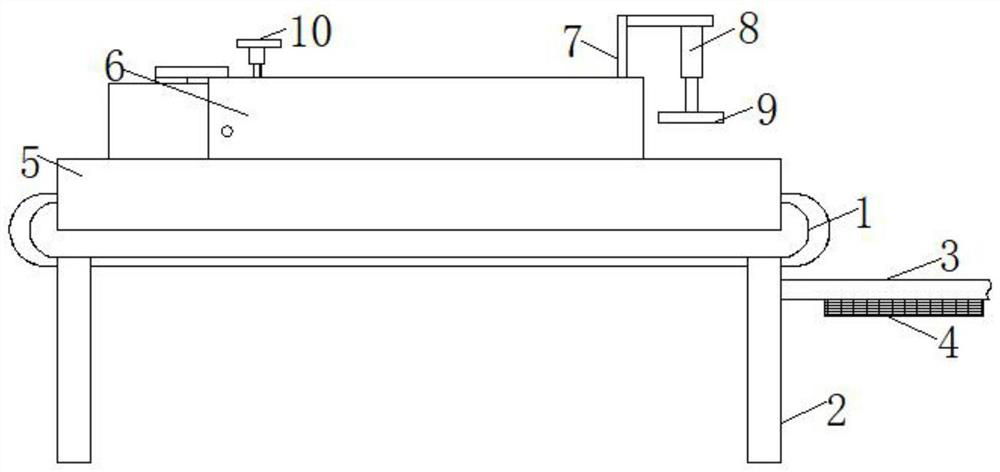

Device for conveying pages through printing machinery

InactiveCN110950118AGuaranteed flatnessQuality improvementArticle feedersPrinting press partsEngineeringPrinting press

Owner:北京点域科技有限公司

Wire and cable surface lettering equipment

ActiveCN112265365APrevent printing from being clear enoughAchieve the effect of replenishing inkFilament handlingCleaning using toolsEngineeringStructural engineering

The invention discloses electric wire and cable surface lettering equipment, the electric wire and cable surface lettering equipment comprises a base, a driving mechanism is arranged at the top of thebase, an ink adding mechanism is arranged at the top of the driving mechanism, a cleaning mechanism is arranged on one side of the driving mechanism, a winding mechanism is arranged at the top, awayfrom the cleaning mechanism, of the base, and a transmission mechanism is arranged between the ink adding mechanism and the driving mechanism. According to the electric wire and cable surface lettering equipment, by arranging the driving mechanism, the ink adding mechanism, the cleaning mechanism and the winding mechanism, the surface of a cable can be cleaned, lettering can be conducted on the cable while winding is conducted, meanwhile, ink can be continuously supplemented to a lettering wheel, and the situation that lettering is not clear due to the fact that the ink of the lettering wheelis too little is prevented.

Owner:安徽扬子线缆有限公司

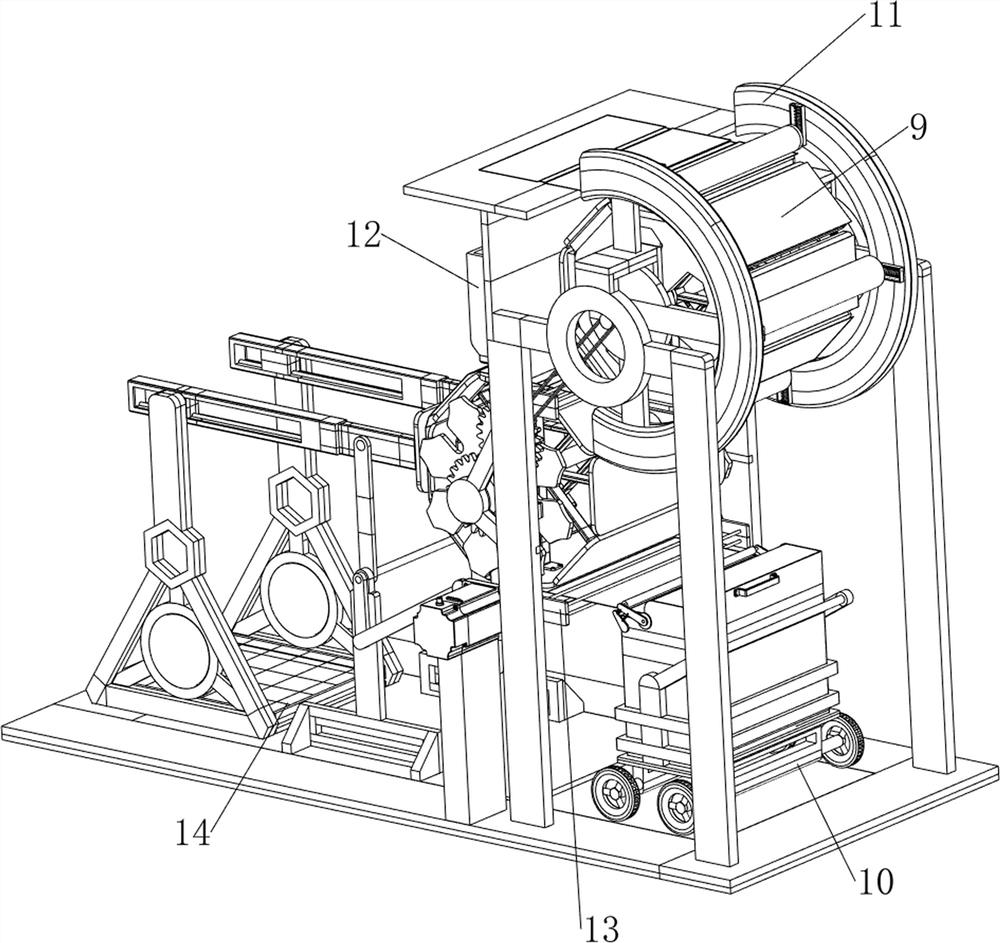

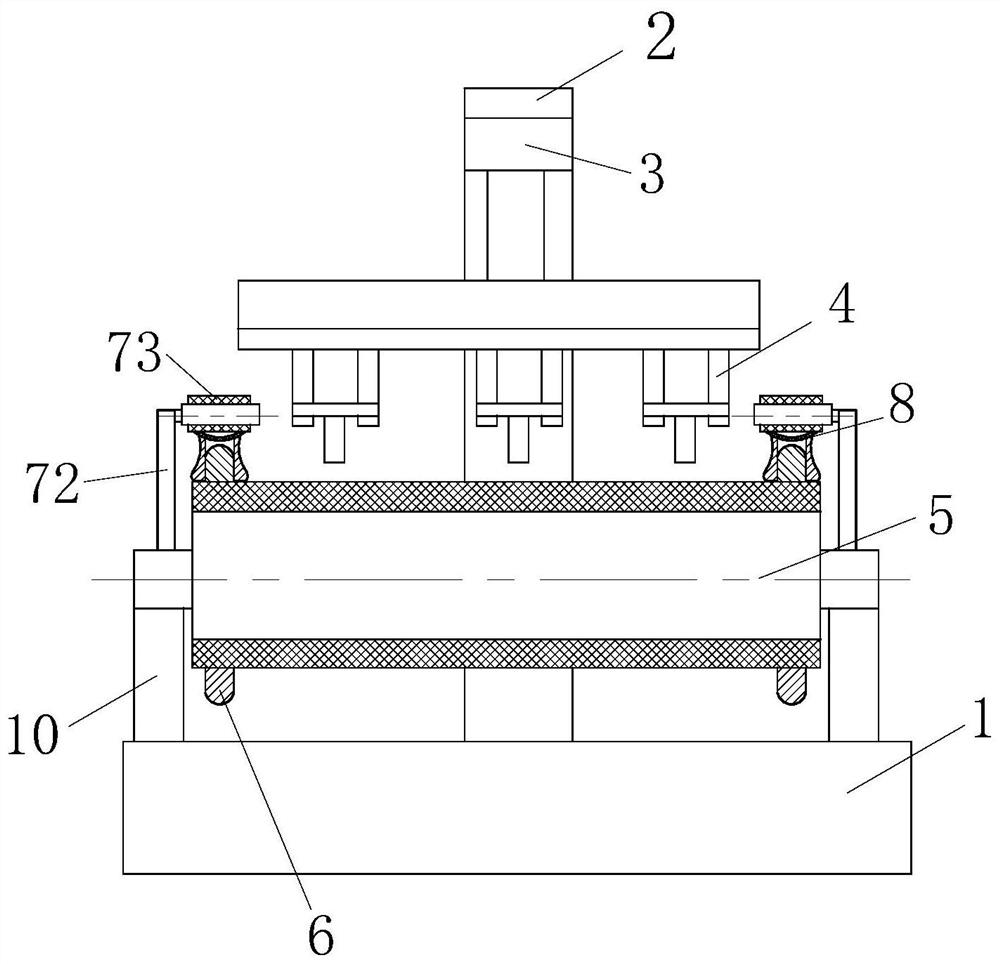

Printing equipment for intelligent manufacturing

PendingCN112937104AAutomatic fast printingEasy to useRotary pressesConveyor partsElectric machinerySmart manufacturing

The invention relates to printing equipment, in particular to printing equipment for intelligent manufacturing. The printing equipment for the intelligent manufacturing which is relatively rapid and convenient in printing and intermittently replenishes ink is provided. The printing equipment for the intelligent manufacturing comprises a supporting plate, first dosage form blocks, a rotating shaft, second dosage form blocks and a first material bearing plate, wherein a motor is arranged on the supporting plate, the first dosage form blocks are arranged on an output shaft of the motor and the supporting plate, the first dosage form blocks are rotationally connected to the supporting plate, the rotating shaft is rotationally arranged on the supporting plate, the second dosage form blocks are symmetrically arranged on the rotating shaft, and the first material bearing plate is arranged on the rotating shaft. According to the printing equipment, through cooperation of the first dosage form blocks, the second dosage form blocks, the first material bearing plate, the rotating shaft, a connecting rod and a movable plate, objects can be automatically and rapidly printed, and the effect of convenient use is achieved.

Owner:莫锦儿

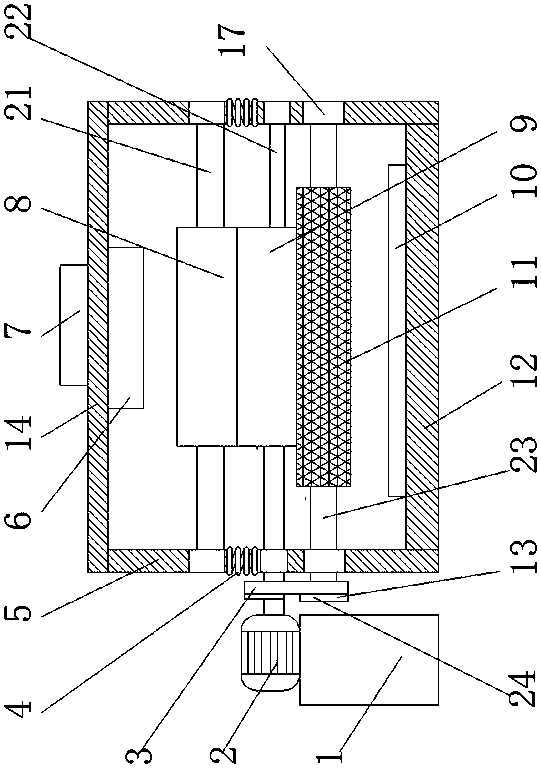

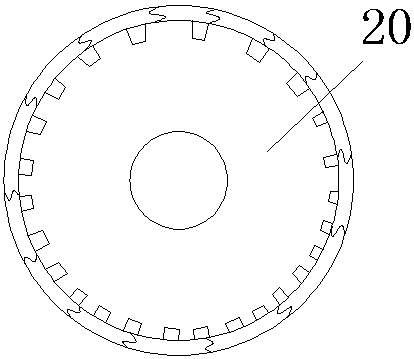

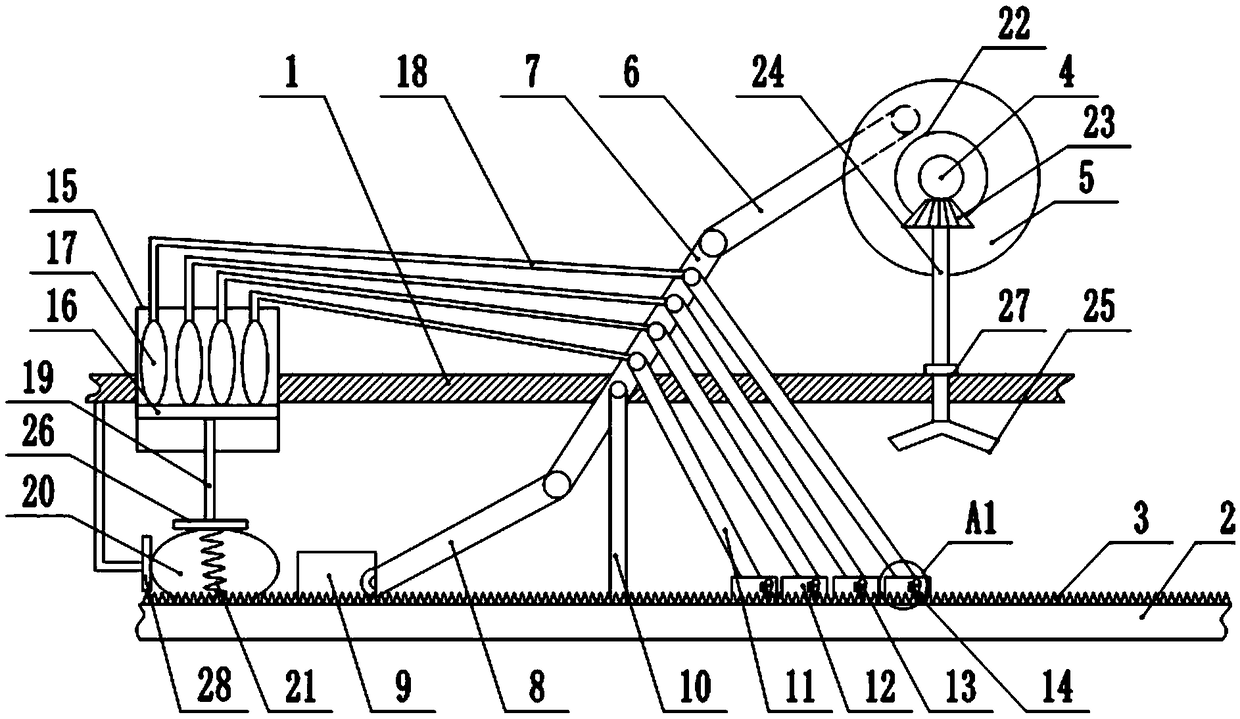

Printing device

InactiveCN108621544ALess printingSolve the defects that cannot meet the gradient printingPrinting press partsDrive shaftSlide plate

The invention relates to a printing device. The printing device comprises a rack, a support table and a driving shaft, wherein a conveying belt is arranged on the support table, engaged teeth are uniformly distributed on the conveying belt, a driving disc is coaxially and fixedly connected to the driving shaft, a first pull rod is rotatably connected to the driving disc, a driving rod is rotatablyconnected to the first pull rod, a second pull rod is connected to the driving rod, a sliding block is hinged to the second pull rod, a support rod is rotatably connected to the middle of the drivingrod, a plurality of printing tubes are rotatably connected to the driving rod, printing plates are removably connected to the bottom ends of the printing tubes, the printing plates are abutted with the conveying belt, driving teeth are connected to the printing plates, and limiting blocks are arranged on the printing plates; an ink box is arranged on the rack, a sliding plate is in sliding connection to the interior of the ink box, an elastic ink bag is arranged in the ink box, and a guide tube is connected between the elastic ink bag and an ink inlet; and a push rod is fixedly connected to the sliding plate, an air bag is fixedly connected to the support table on the bottom end of the push rod, and a support spring is arranged in the air bag. According to the printing device, the requirements of gradient printing and multicolor mixed printing of paper are satisfied.

Owner:重庆再现广告有限公司

Polypropylene panel allowing writing and production technology thereof

The invention provides a polypropylene writable plate and its preparation process. The polypropylene writable plate comprises a polypropylene sheet and a coating formed by coating an ink composition. The ink composition consists of the following parts by weight: Component composition: 100 parts of PP ink, 10-20 parts of matting agent, 40-60 parts of thinner, 1-5 parts of curing agent, 1-3 parts of coupling agent, 3-5 parts of polydimethylsiloxane, mica Powder 3~5 parts, antioxidant 2~5 parts. The coating on the surface of polypropylene writable board is prepared by screen printing process. After coating a layer of coating on the surface of polypropylene, the purpose of changing the smoothness of the surface of polypropylene can be achieved, so that it can be processed on the surface of polypropylene. Writing, and the handwriting after writing is not easy to be erased.

Owner:义乌市祥胜文化用品有限公司

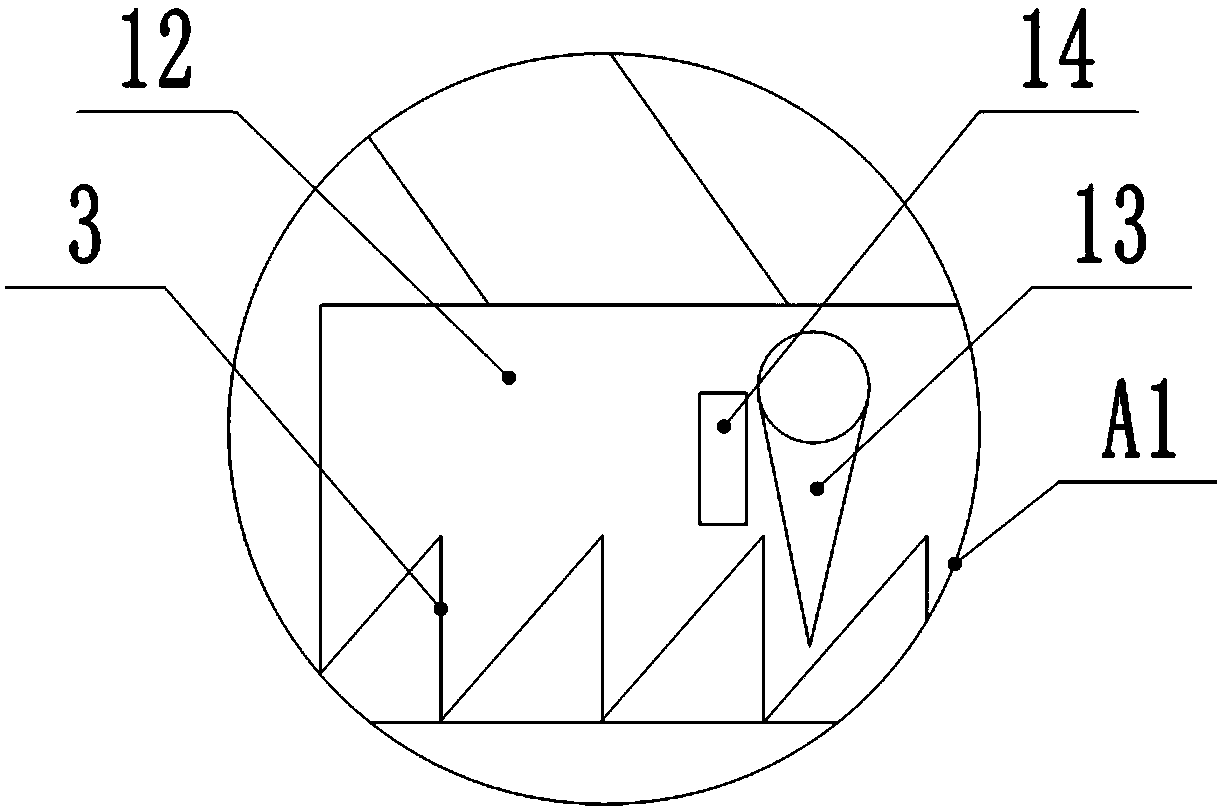

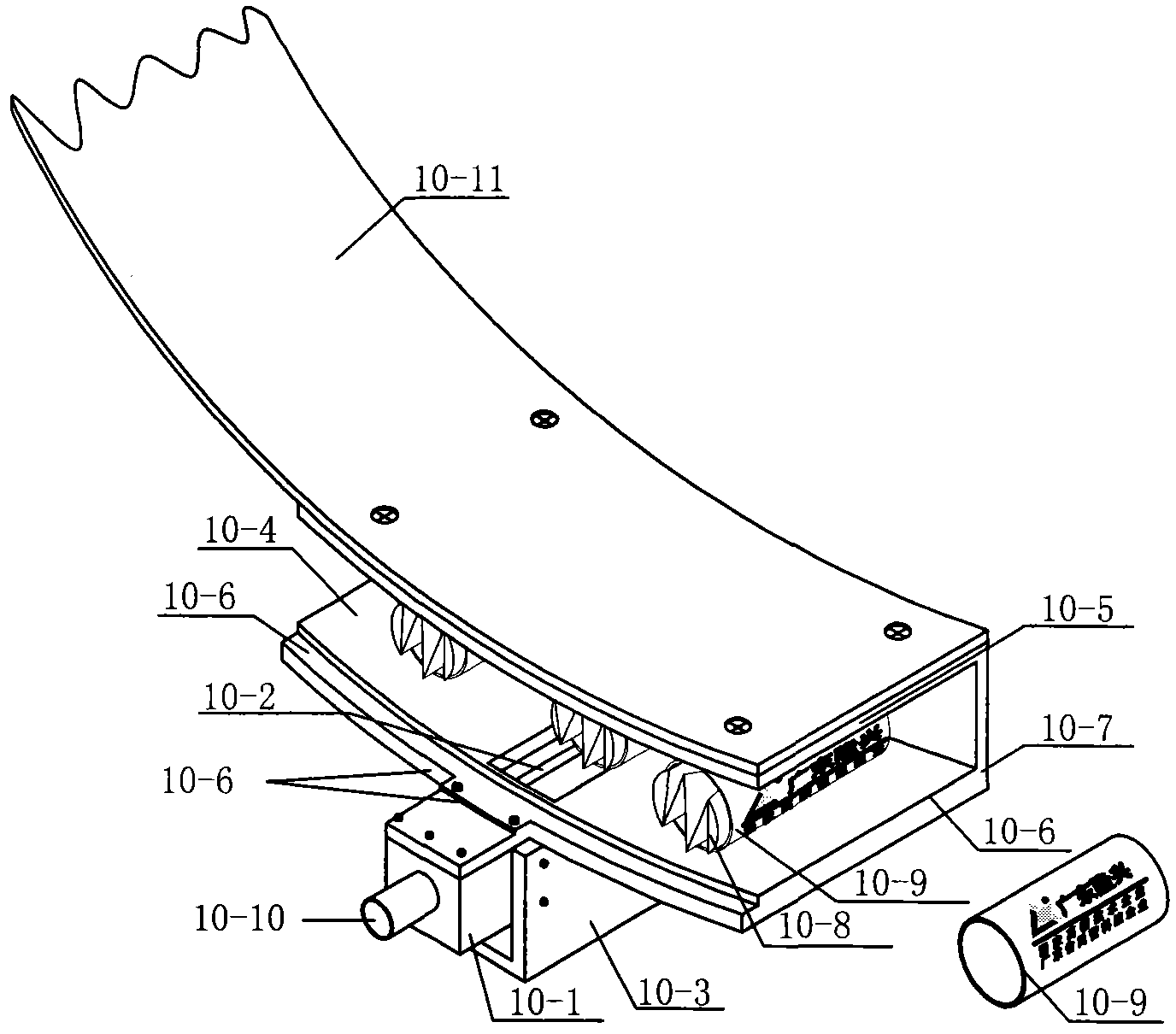

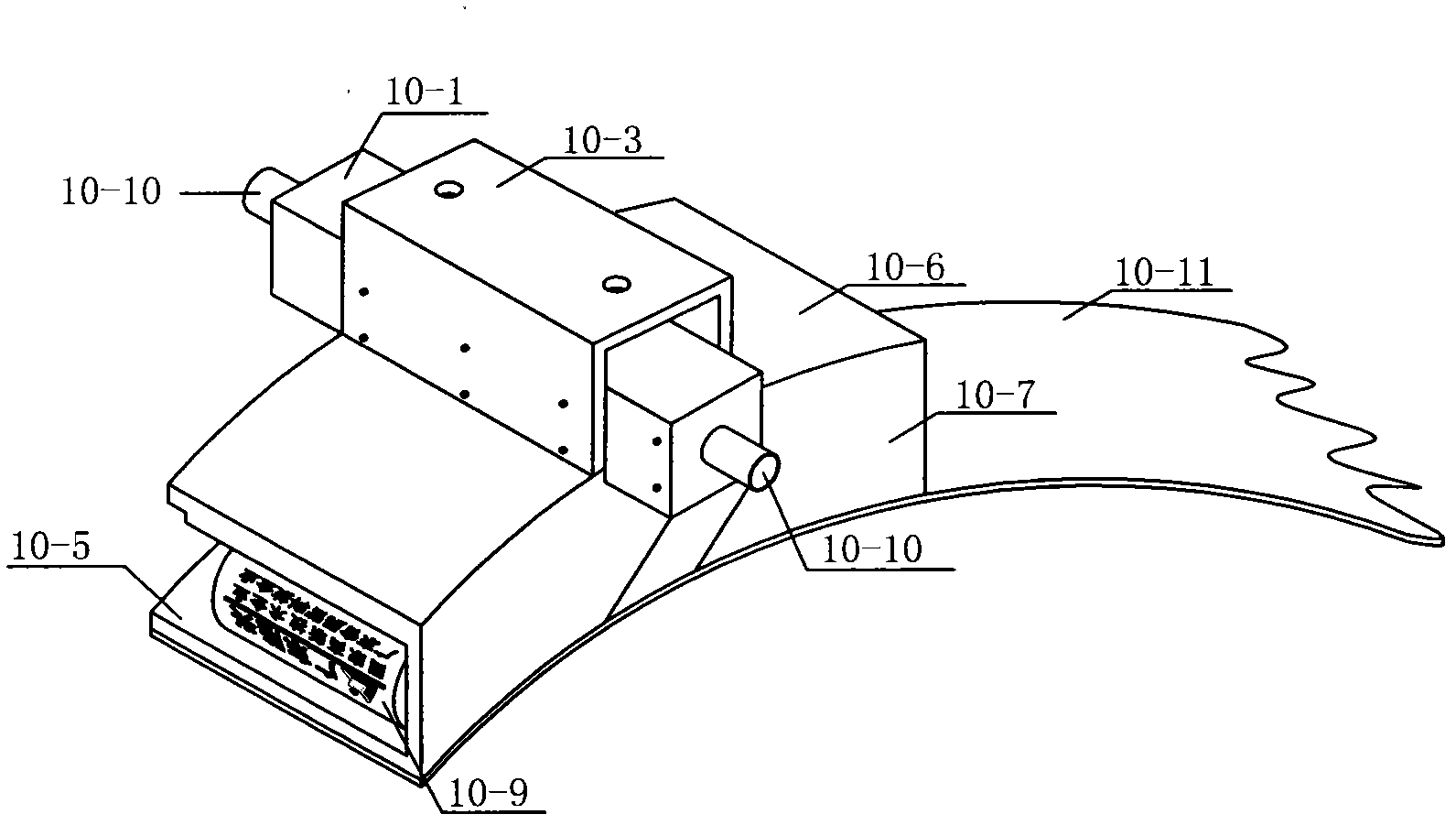

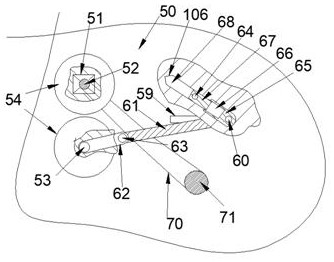

Curved surface printing multi-station function location determining method and shading device

ActiveCN102616041AMulti run timePrinting effect is not affectedOther printing apparatusPrinting press partsUV curingEffect light

The invention relates to a curved surface printing multi-station function location determining method and a shading device. The curved surface printing multi-station function location determining method and the shading device are characterized in that a lighting trap supporting frame, a lamp box and a lighting trap device are provided; the lamp box is fixed on the lighting trap supporting frame; and the UV lighting trap device consists of a lighting trap inside arc-shaped plate, a lighting trap outside arc-shaped plate and a lighting trap bottom arc-shaped plate, and the three plates form a shading arc-shaped channel with the two sides and the front side opened and the rear side fully closed. According to the length of the shading arc-shaped channel, the operation shading station refers to that more than one station distance is covered with the left side and the right side of the curing station serving as a core, and the distance between the lighting station and the curing station is prolonged to the maximum degree after lighting, so that other function stations can be assembled, the method and the device are convenient to operate, the UV curing light is covered, and high printing quality and good lighting effect are achieved.

Owner:GUANGDONG LONGXING PACKAGING IND

Transfer printing plate cleaning device

InactiveCN108906735AAvoid strandedAffect the printing effectDrying gas arrangementsCleaning using toolsMegasonic cleaningTransfer printing

The invention provides a transfer printing plate cleaning device which comprises a spraying mechanism, a wiping mechanism, an ultrasonic cleaning mechanism, an air blowing mechanism and a conveying mechanism. The spraying mechanism comprises a spraying groove and a spraying component. The wiping mechanism comprises a wiping part. The spraying component comprises first spray heads, the first sprayheads are arranged in the vertical direction, and the wiping part is arranged transversely. Suspension cleaning is changed into flat cleaning, and liquid is prevented from staying at the bottom of a transfer printing plate; meanwhile, through combination of the wiping mechanism, the ultrasonic cleaning mechanism and the air blowing mechanism, and a better cleaning effect and drying effect are achieved; and the situation that the liquid is left on the transfer printing plate to influence the effect of subsequent PI liquid printing is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A phonetic braille conversion machine and its conversion method

ActiveCN113229616BInstant reuseAffect the printing effectTypewritersFurniture partsComputer printingEngineering

Owner:浙江音置声学科技有限公司

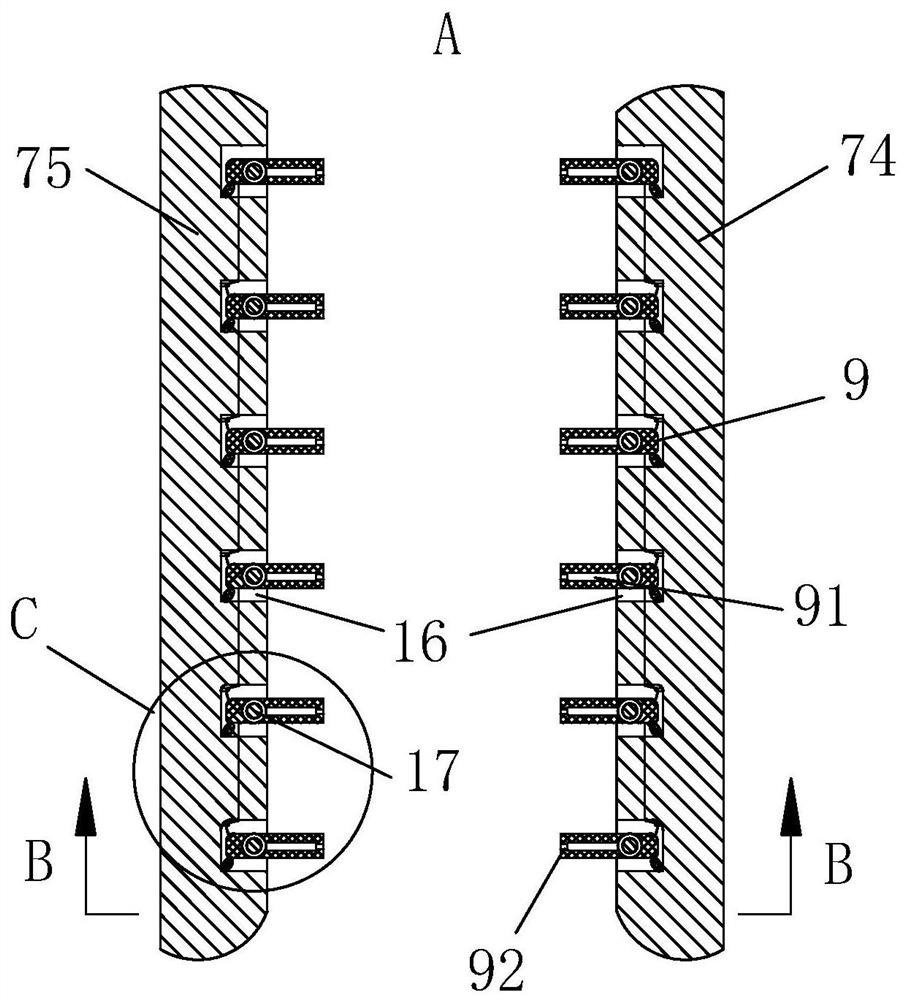

Textile printing protection device based on multiple buffering

ActiveCN112721424AEasy to cover pressureEasy to moveRotary pressesOther printing apparatusTextile printerMechanical engineering

The invention relates to the technical field of textile printing protection, in particular to a textile printing protection device based on multiple buffering. The textile printing protection device comprises a buffer protection device, a printing device is arranged on one side of the buffer protection device, the buffer protection device comprises a fixing device, a cleaning device is arranged at the position, close to one side, of the upper side of the fixing device, a covering and pressing device is arranged at the end, away from the cleaning device, of the upper side of the fixing device, and a cloth shaft is arranged on one side of the covering and pressing device; and the cleaning device comprises a cleaning shell, a rotary ash removing device is arranged in one side of the cleaning shell, an end sleeve fixing device is arranged on one side of the cleaning shell, and the covering and pressing device comprises a cylindrical covering and pressing shaft. The textile printing protection device mainly solves the problems that when cloth is fed, cloth at cloth rolls is not buffered, the cloth vibrates when the cloth moves, printed patterns incline when a printing machine prints the cloth, and printing is inaccurate.

Owner:江苏欧皇纺织科技有限公司

A digital inkjet cloth printing machine

ActiveCN109733076BPlay a fixed roleAffect the printing effectTypewritersOther printing apparatusTextile printerEngineering

Owner:桐乡市桐深数码科技股份有限公司

Matte artificial grass yarn for mark printing and preparation method thereof

PendingCN112921445AStrong chemical stabilityStrong mechanical propertiesElectroconductive/antistatic filament manufactureGround pavingsYarnTextile printer

The invention relates to a matte artificial grass yarn for mark printing. The matte artificial grass yarn comprises the following components in parts by mass of 30-50 parts of polyethylene; 1-4 parts of color master batch; 0.1 to 1.5 parts of an anti-aging auxiliary agent; 2 to 6 parts of matt master batch; 10 to 30 parts of a polar functional material; 5-30 parts of an antistatic auxiliary agent; and 0.1 to 0.5 part of a processing aid.

Owner:江蘇聯創人造草坪股ふん有限公司

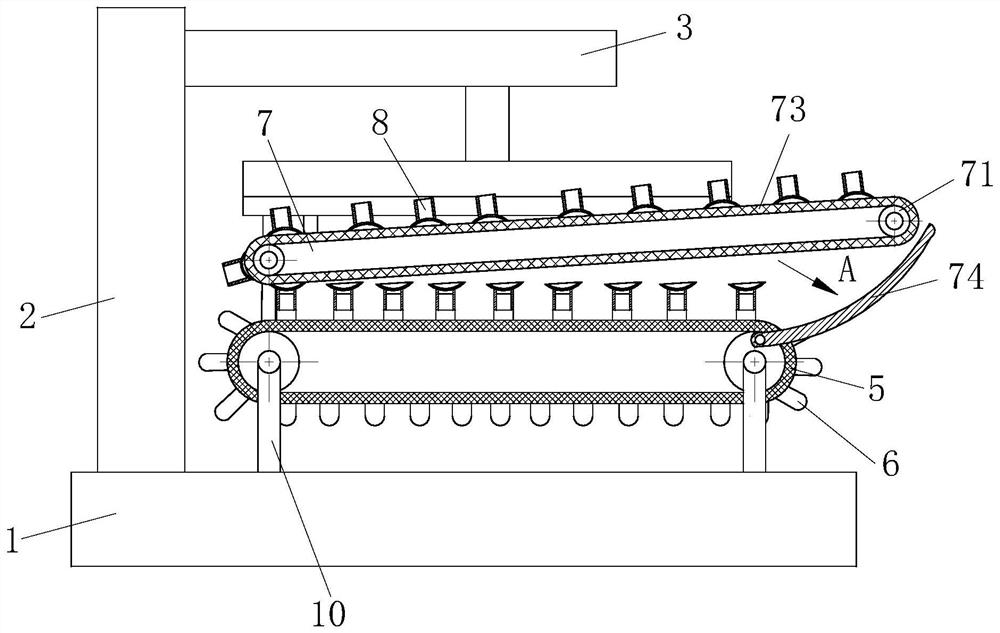

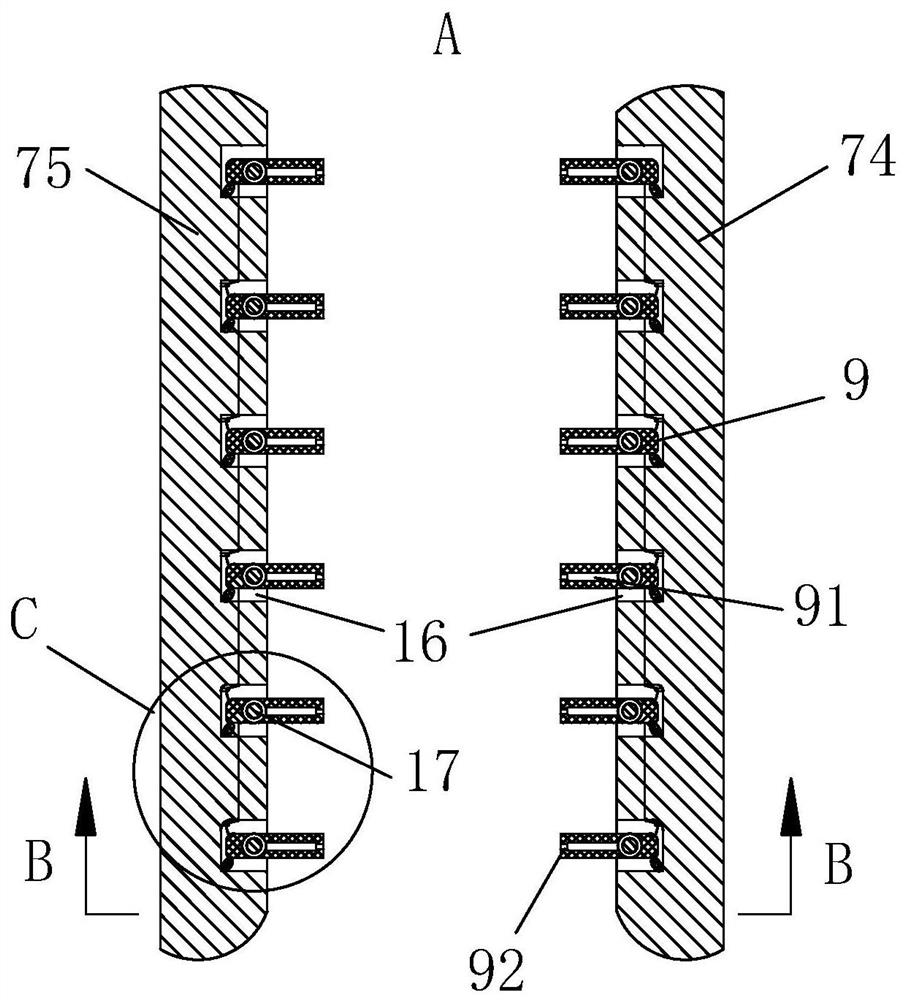

A digital inkjet cloth printing process

ActiveCN109881512BPlay a fixed roleAffect the printing effectDyeing processTextile printerPolymer science

The invention belongs to the technical field of cloth printing, specifically a digital inkjet cloth printing process, which includes the following steps: S1, placing the cloth in the printing equipment; S2, placing the cloth conveyor belt in the printing equipment and the The smooth rubber conveyor belt above carries the cloth synchronously; S3, during the cloth conveying process in S2, the inkjet sprays the ink on the cloth under the control of the inkjet control system; S4, prints the ink after S3 The cloth is sent to the dryer for drying; S5, the cloth dried in S4 is rolled into a roll. This process can fix the elastic fabric through the combination of multiple fixed needles and fixed sleeves evenly arranged on the fabric conveyor belt, and at the same time prevent the elastic fabric from being stretched due to the excessive conveying force of the fabric conveyor belt, which will affect the inkjet. The printing effect of the machine on elastic fabrics.

Owner:江苏凤凰通达印刷有限公司

Carton printing equipment facilitating discharging

ActiveCN112590361AEasy to printThe distance is easy to adjustPlaten pressesPrinting press partsCartonStructural engineering

The invention discloses carton printing equipment facilitating discharging. The carton printing equipment comprises a conveying belt, a plurality of supporting columns are fixedly connected to the bottom end of the conveying belt, a fixing plate is fixedly connected to one sides of the supporting columns, a heating plate is installed at the bottom end of the fixing plate, a first supporting plateis installed at the front end and the rear end of the conveying belt, a cover body is installed at the top end of the first supporting plate, an L-shaped rod is fixedly connected to one side of the top end of the cover body, an electric telescopic rod is fixedly connected to the bottom end of the L-shaped rod, a printing plate is installed at the bottom end of the electric telescopic rod, and a processing mechanism is installed in the cover body. According to the carton printing equipment, fourth T-shaped rods are pressed into sleeves, so that sleeve rods in the sleeves can move, a first T-shaped rod can drive a baffle to move up and down, the distance between the baffle and the conveying belt can be conveniently adjusted to be equal to the thickness of a carton, only one carton can pass through the gap between the baffle and the conveying belt at a time, and printing of the carton is facilitated.

Owner:深圳市永润印刷有限公司

A carton printing equipment that is convenient for discharging

ActiveCN112590361BEasy to printThe distance is easy to adjustPlaten pressesPrinting press partsCartonStructural engineering

The invention discloses a carton printing device which is convenient for discharging, which includes a conveyor belt, the bottom end of the conveyor belt is fixedly connected with a plurality of support columns, and one side of the support columns is fixedly connected with a fixed plate, and the bottom end of the fixed plate A heating plate is installed, and the front and rear ends of the conveyor belt are respectively equipped with a first support plate, and a cover is installed on the top of the first support plate, and an L-shaped rod is fixedly connected to one side of the top end of the cover, and the L-shaped rod The bottom end of the electric telescopic rod is fixedly connected with a printed board, and a processing mechanism is installed inside the cover body. In the present invention, by pressing the fourth T-shaped bar to the inside of the sleeve, the sleeve rod inside the sleeve can be moved, so that the first T-shaped bar can drive the baffle to move up and down, which is convenient for adjusting the distance of the baffle The distance between the conveyor belts can be adjusted to the same distance as the thickness of the carton, so that only one carton can pass through at a time, and it is convenient to print on the carton.

Owner:深圳市永润印刷有限公司

A carton printing machine with waste cleaning and collection function

ActiveCN112590360BEasy to openEasy to collect and processPlaten pressesPaper recyclingCartonPrinting press

The invention discloses a carton printing machine with the function of cleaning and collecting wastes. An electric telescopic rod is installed, and the bottom end of the electric telescopic rod is fixedly connected with a printing board, one side of the mounting frame is connected with a base, and the base and the bottom end of the printing board are relatively connected, and one side of the printing board is connected. A multi-function mechanism is installed on the side, and the interior of the multi-function mechanism includes a first switch. In the present invention, through the downward movement of the electric telescopic rod, the printed board and the first L-shaped plate connected to one side thereof can be moved downward, so that the first L-shaped plate can press down the second connecting rod, and the second connecting rod can be squeezed downward. The connecting plate connected by the second connecting rod is turned over and moved, so that the support rod connected at the top end of the connecting plate can open the cover body connected at the top end, and it is convenient to collect and process some wastes on the carton.

Owner:CHONGQING FULING TAIJI PRINTING CO LTD

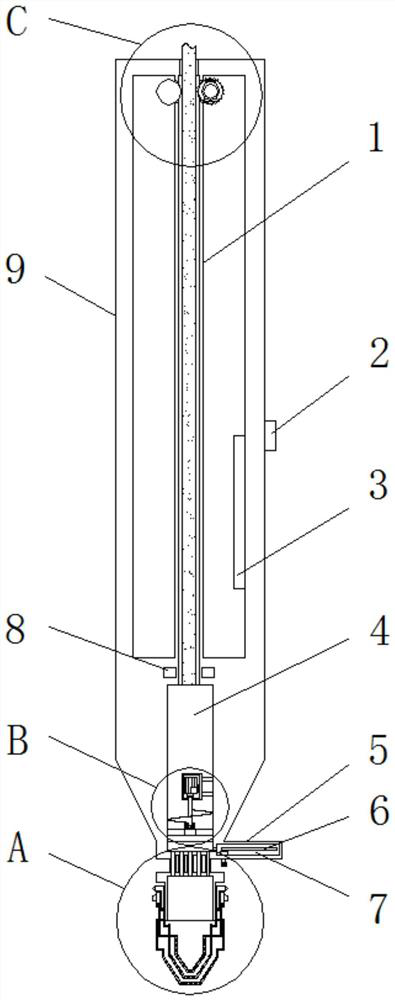

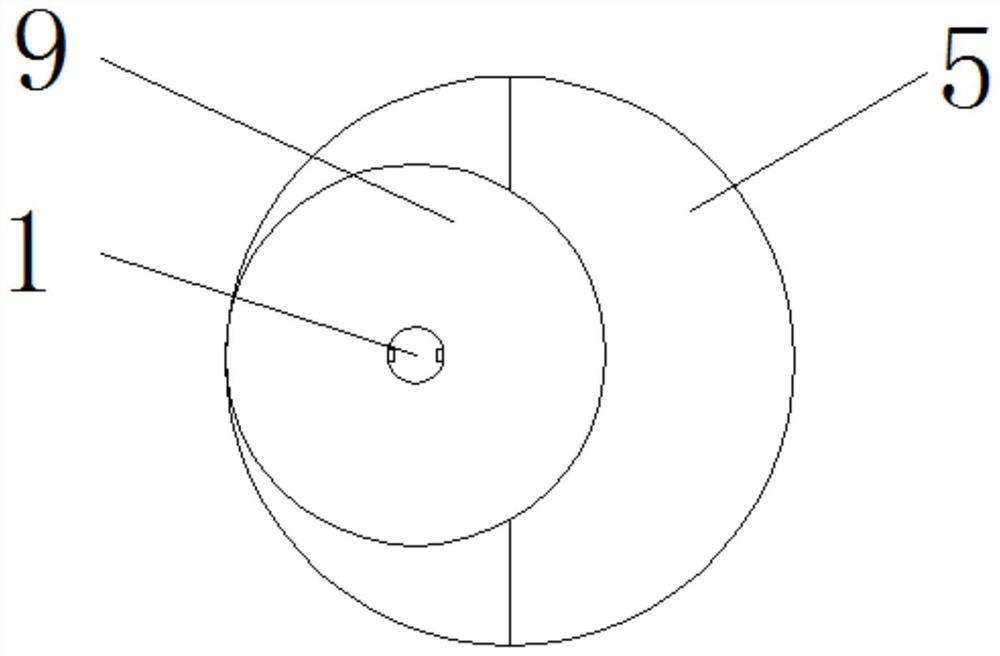

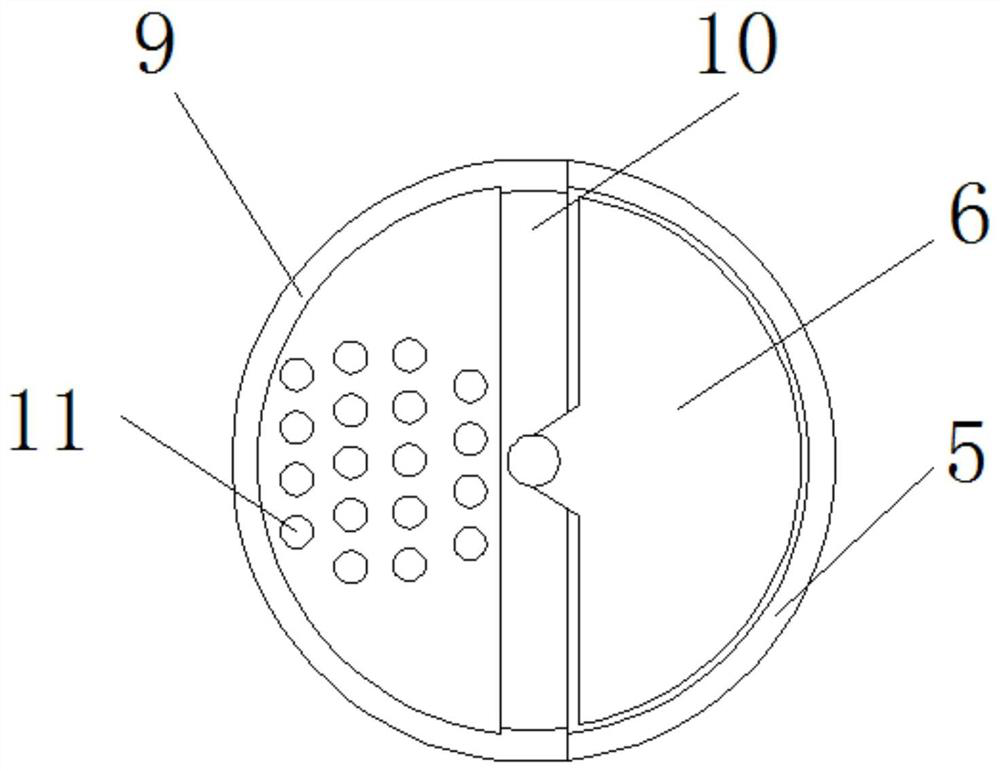

An anti-drawing 3D printing pen with adjustable caliber

ActiveCN109605730BEasy extrusionImprove uniformity3D object support structuresApplying layer meansHot meltPhysics

The invention discloses an anti-wire-drawing 3D printing pen with adjustable diameter. The anti-wire-drawing 3D printing pen with adjustable diameter comprises a material guiding pipe, a hot melt chamber, a pen holder, throat pipes and a pen head. The hot melt chamber is formed in the bottom end of the interior of the pen holder, the material guiding pipe is disposed in the pen holder, the top endof the material guiding pipe extends to the top of the pen holder, the bottom end of the material guiding pipe is in communication with the hot melt chamber, and a heating pipe is arrange in the penholder of the outer side of the end, close to the hot melt chamber, of the material guiding pipe. The throat pipes are evenly spaced between the pen head and the pen holder, so that the surface area of the throat pipes can be utilized to increase the heat dissipation area of materials conveniently without affecting material circulation, and air can circulate between adjacent throat pipes, so thatthe printing pen is driven to move in the process of combining with the use of the printing pen; and the flow of the air between the throat pipes is further increased, the heat dissipation effect is improved, the solidification efficiency of the materials is improved, and the situation that the materials are excessively soft to affect the effect of printing in the process of printing is avoided.

Owner:JIANGNAN UNIV

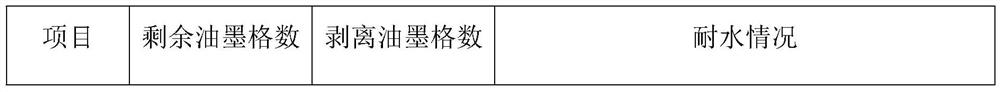

Waterproof printing oil base and preparation method

The invention discloses a waterproof printing oil base and a preparation method thereof, and the waterproof printing oil base comprises the following raw materials by weight: 25 to 45 parts of lignin-modified ethyl acetate, 5 to 10 parts of rosin-modified maleic acid resin, 2 to 5 parts of organic bentonite, 3 to 6 parts of titanium dioxide, 3 to 6 parts of tin oxide, 6 to 10 parts of mussel mucin, 5 to 8 parts of calcium acetate, 15 to 20 parts of an environmentally friendly pigment, 2 to 4 parts of vegetable oil, 10-15 parts of graphite, 2-4 parts of nano-adhesive powder, 3-5 parts of activated clay, 1-2 parts of zirconium dioxide, 2-5 parts of a conductive component, 0.5-1 part of beeswax, 5-10 parts of glyceride, 1-3 parts of an ink enhancer, 1-3 parts of a polymerization inhibitor, 0.5-1 part of a stabilizer, 2-4 parts of a wear aid, 2-4 parts of a water repellent, 1-3 parts of a wetting agent, 1 to 5 parts of a thickener, 3 to 6 parts of a curing agent, 1 to 3 parts of a curing accelerator, 1 to 5 parts of a defoaming agent, and 60 to 80 parts of water.

Owner:安徽华新印务有限公司

Packaging box green printing process based on water-based ink

ActiveCN113668286AImprove water resistanceGood chemical resistanceBox making operationsPaper/cardboardGlycerolPrinting ink

The invention discloses a packaging box green printing process based on water-based ink; the problems that ink selected in a conventional printing process generally adopts water-based polyurethane as a connecting material, but the printing ink prepared from the water-based polyurethane is poor in water resistance and easy to hydrolyze, and the printing effect is greatly influenced are solved; the water-based ink is firstly optimized and modified, a plant-based derivative is introduced into polyurethane, tung oil is eleostearic acid ester of glycerin and contains a conjugated double bond structure, the introduction of the structure can greatly improve the water resistance and chemical resistance of the water-based ink, the comprehensive performance of the water-based ink is improved, and the printing effect is more excellent. The process is reasonable in design and easy to operate, the surface of the packaging box obtained through printing is excellent in water resistance, the water-based ink is excellent in water resistance, abrasion resistance and chemical resistance, the surface printing effect of the packaging box is greatly guaranteed, and high practicability is achieved.

Owner:东莞印想文化科技有限公司

A wire and cable surface printing equipment

ActiveCN112265365BAchieve the effect of replenishing inkEasy to cleanFilament handlingCleaning using toolsStructural engineeringMechanical engineering

Owner:安徽扬子实业有限公司

Electric energy measuring instrument automatic code spraying machine based on RFID identification technology

InactiveCN113807110AAffect the printing effectPlay a protective effectTypewritersSensing by electromagnetic radiationCartonElectricity meter

The invention discloses an electric energy measuring instrument automatic code spraying machine based on RFID identification technology. The electric energy measuring instrument automatic code spraying machine comprises a group reading equipment and a code spraying equipment, the group reading equipment comprises an RFID identification module and a first mobile module, the RFID identification module is connected with the first mobile module, the RFID identification module is provided with a wireless emission module, the code spraying equipment comprises a code spraying module and a second mobile module, the code spraying module is connected with the second mobile module, and a wireless receiving module is arranged on the code spraying module. According to the invention, the reading and code spraying of the related information of the electric energy measuring instrument are realized, so that a worker can directly see the related information of the electricity meters in the businesses of batch new installation and periodic rotation of the electric energy meters without taking out the electricity meters from a carton one by one, the difficulty of sorting the electricity meters by the worker is reduced, the sorting efficiency of the worker is improved, and the operation method effectively avoids the electricity meter distribution error caused by the sorting error, and compared with the manual label pasting and code spraying mode on the meter, the method is more attractive.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO

Paper feeding box for printer

InactiveCN113651145AAffect the printing effectReduce air pressureCleaning using gasesArticle feedersComputer printingIndustrial engineering

Owner:高怀东

Modified carbon black, and preparation method and application thereof in preparation of black chemical powdered ink

ActiveCN103642281BImprove hydrophilicityGood dispersionInorganic pigment treatmentDevelopersModified carbonAqueous medium

Owner:鼎龙(宁波)新材料有限公司

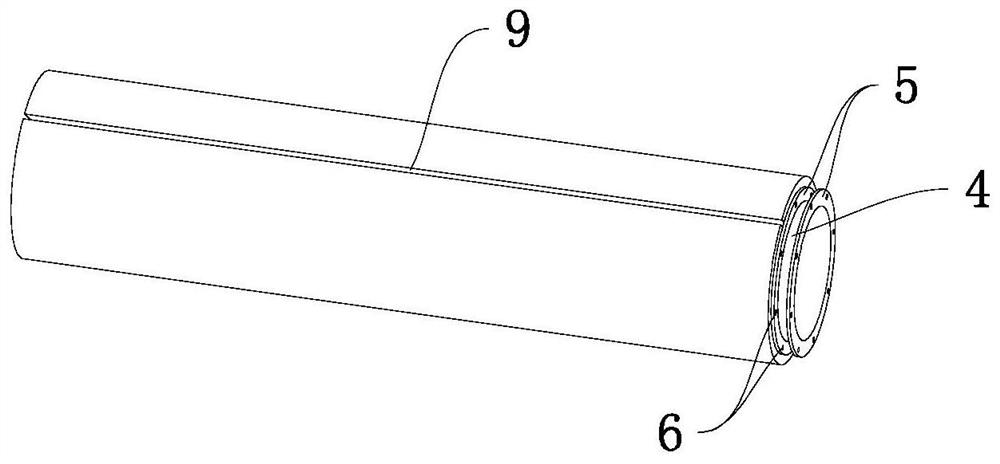

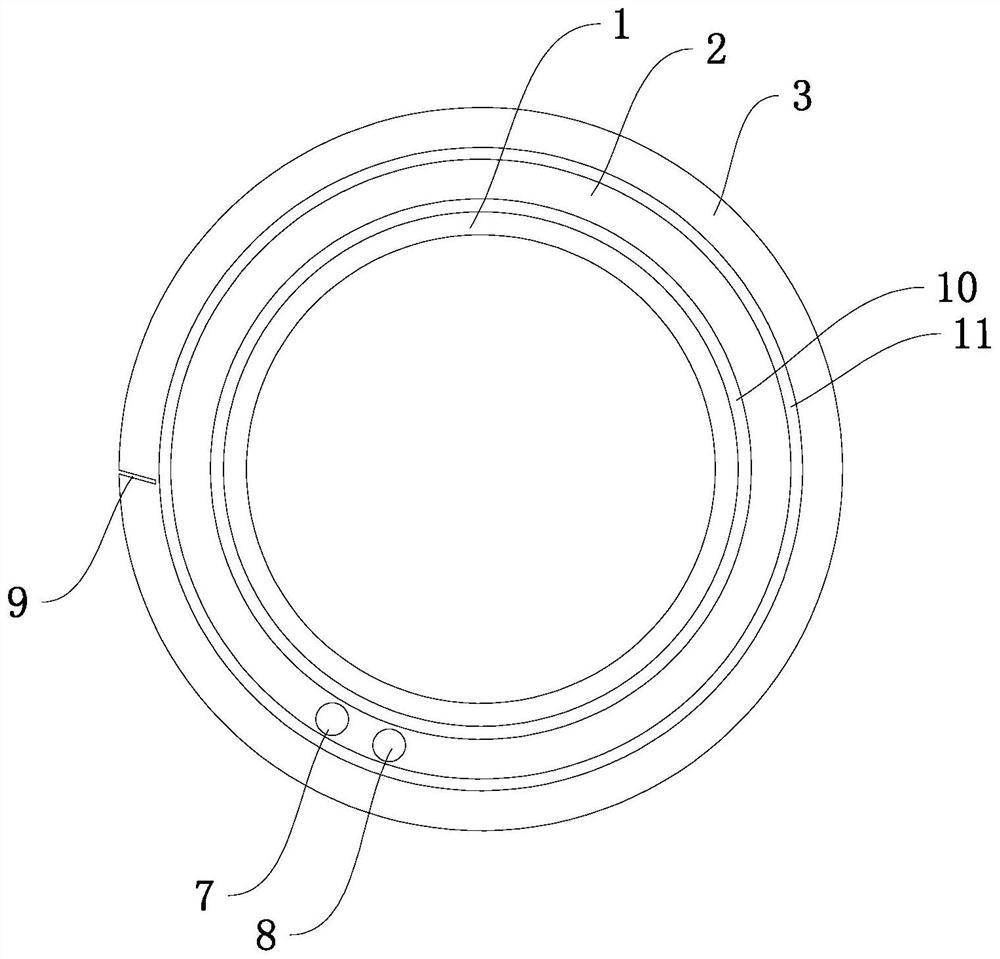

Inflatable sleeve

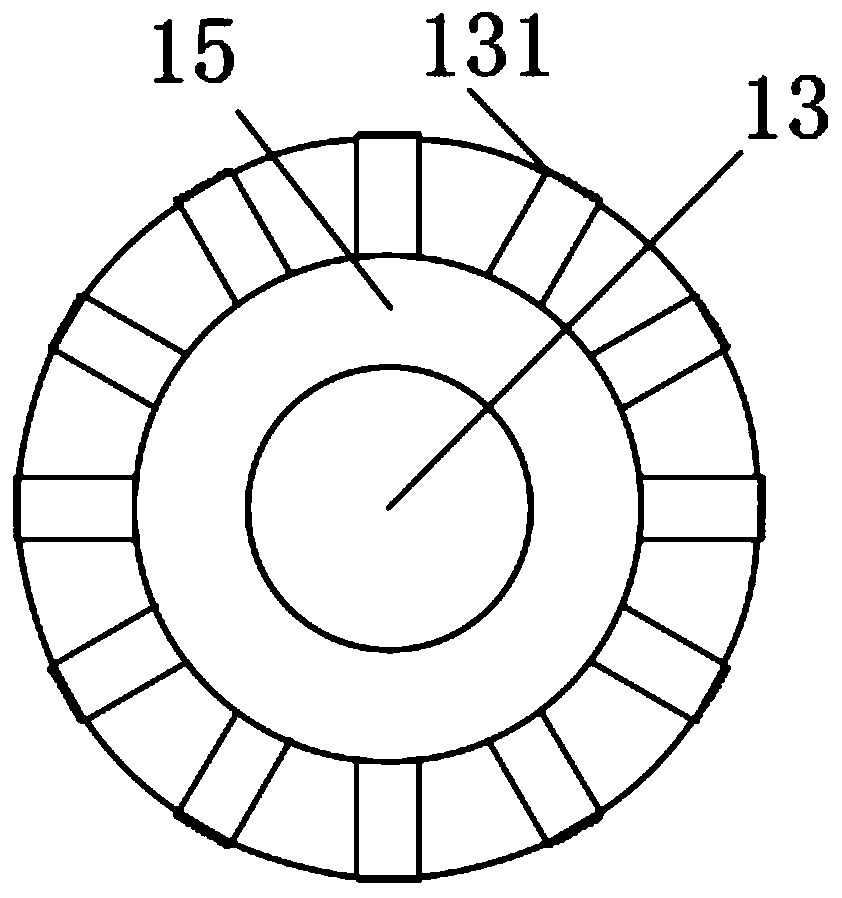

PendingCN112406266ALight in massImprove disassembly efficiencyRotary pressesGlass/slag layered productsPhysicsMechanical engineering

The invention relates to an inflatable sleeve. The wall of the sleeve is of a composite layer structure. The composite layer structure comprises an inflatable layer, a first elastic layer, a filling layer, a second elastic layer and a shaping layer which are sequentially arranged from inside to outside in the radial direction of the sleeve. The inflatable layer can elastically deform under the pressure of an inflatable shaft and is tightly arranged on the inflatable shaft in a sleeving manner. The first elastic layer and the second elastic layer are both light elastic material layers. The filling layer is a light and hard material layer. The shaping layer is a hard material layer. All the adjacent structural layers are connected in a composite manner. The inflatable sleeve has the advantages that the mass is small, the dismounting and mounting efficiency of the sleeve and a mandrel is high, the shaping layer is not prone to deformation, and the printing effect is good.

Owner:上海运成印刷机械配件有限公司

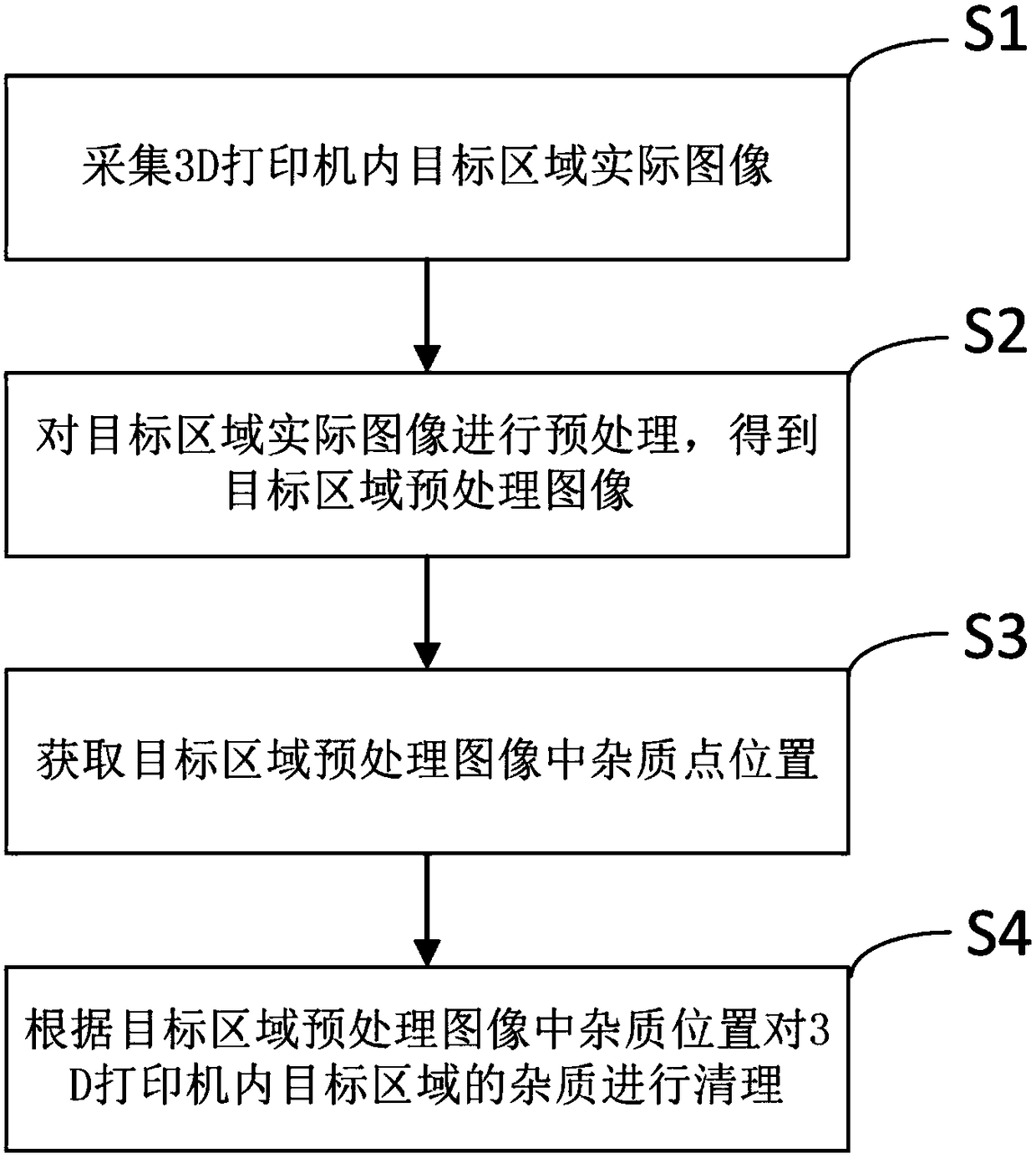

3D printing impurity cleaning method based on image collection

InactiveCN108115937AAffect the printing effectLocation intelligenceAdditive manufacturing apparatus3D object support structuresComputer graphics (images)Pre treatment

The invention discloses a 3D printing impurity cleaning method based on image collection. The method comprises the steps that a target area actual image in a 3D printer is collected and pretreated, and a target area pretreated image is obtained; the impurity point position in the target area pretreated image is obtained; impurities in the target area in the 3D printer are cleaned away according tothe impurity position in the target area pretreated image, and accordingly after the 3D printer finishes the printing task, the positions where impurities are likely to be left in the 3D printer areautomatically cleaned away, automatic and intelligent printer cleaning is achieved, and impurities in the 3D printer are effectively prevented from influencing the printing effect. Meanwhile, due to unmanned operation, manmade operation disturbance is avoided.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com