Inflatable sleeve

An inflatable and sleeve technology, applied in the field of printing rolls, can solve the difficulty in disassembling the steel sleeve and the mandrel, which is time-consuming and labor-intensive, the assembly of the mandrel and the steel sleeve is difficult and labor-intensive, and the disassembly and assembly of the sleeve and the mandrel. Low efficiency and other problems, to achieve the effect of high disassembly and assembly efficiency, light weight, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The application will be described in further detail below in conjunction with the accompanying drawings.

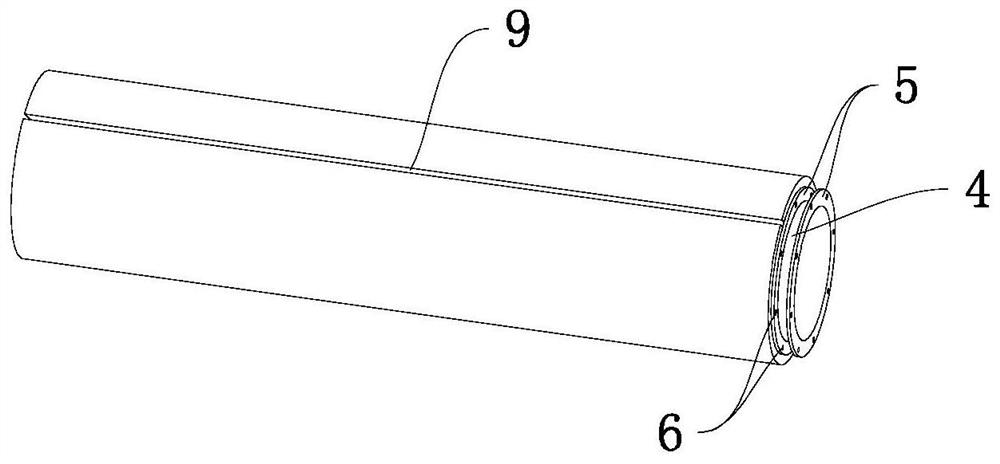

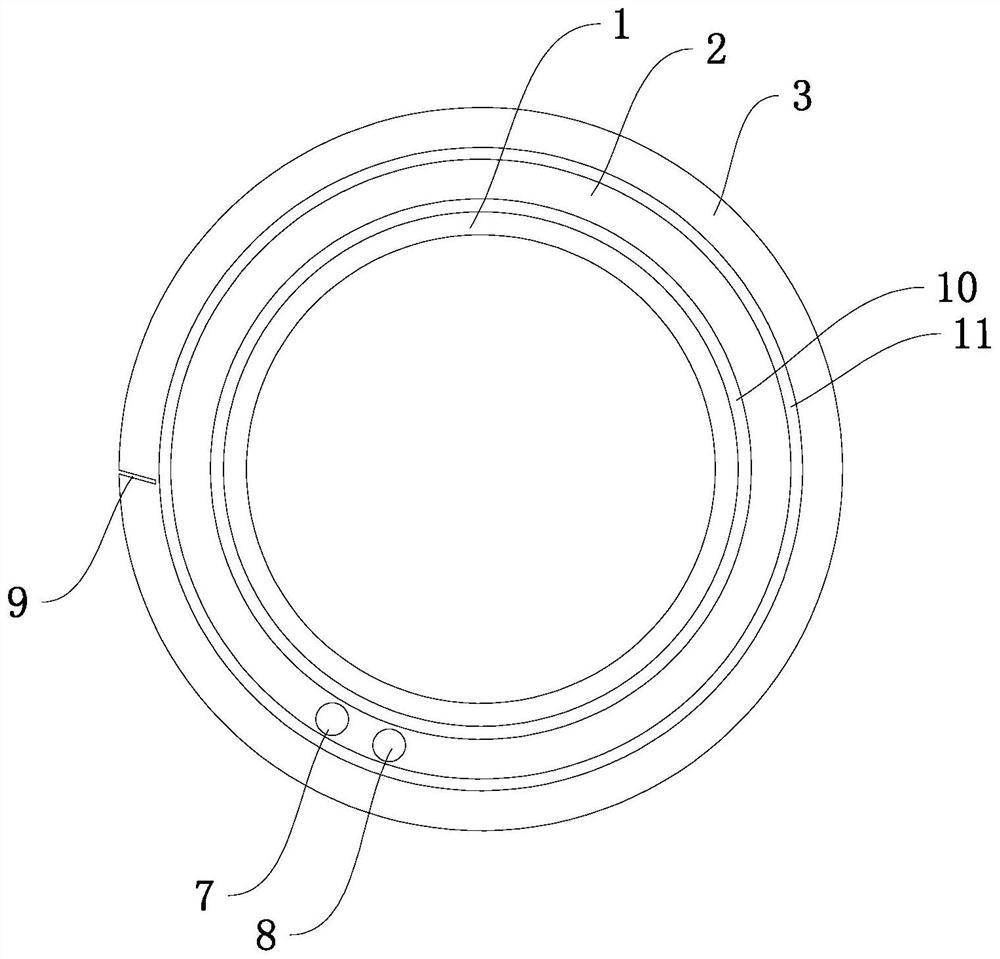

[0028] refer to figure 1 and figure 2 , the embodiment of the present application discloses an inflatable sleeve, the sleeve is an annular tubular structure, and the wall of the sleeve is a composite layer structure. The composite layer structure includes an inflatable layer 1 , a first elastic layer 10 , a filling layer 2 , a second elastic layer 11 , and a shaping layer 3 arranged sequentially from inside to outside along the radial direction of the sleeve. The inflatable layer 1 is a fiber layer made of fiber material. In this embodiment, the inflatable layer 1 is preferably a glass fiber layer, and the glass fiber has relatively high tensile strength and good heat resistance. The air-expansion layer 1 is used for interference fit on the air-expansion shaft. When the air-expansion shaft is inserted into the air-expansion layer 1 of the sleeve, the air-expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com