A digital inkjet cloth printing process

A printing process, digital inkjet technology, applied in the field of cloth printing, can solve the problems of easy stretching or deformation of the cloth, deformation or distortion of color patterns, etc., so as to improve the printing effect and avoid the effect of excessive elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A kind of digital ink-jet type cloth printing technique described in the present invention, this technique comprises the following steps:

[0031] S1, placing the cloth in the printing device;

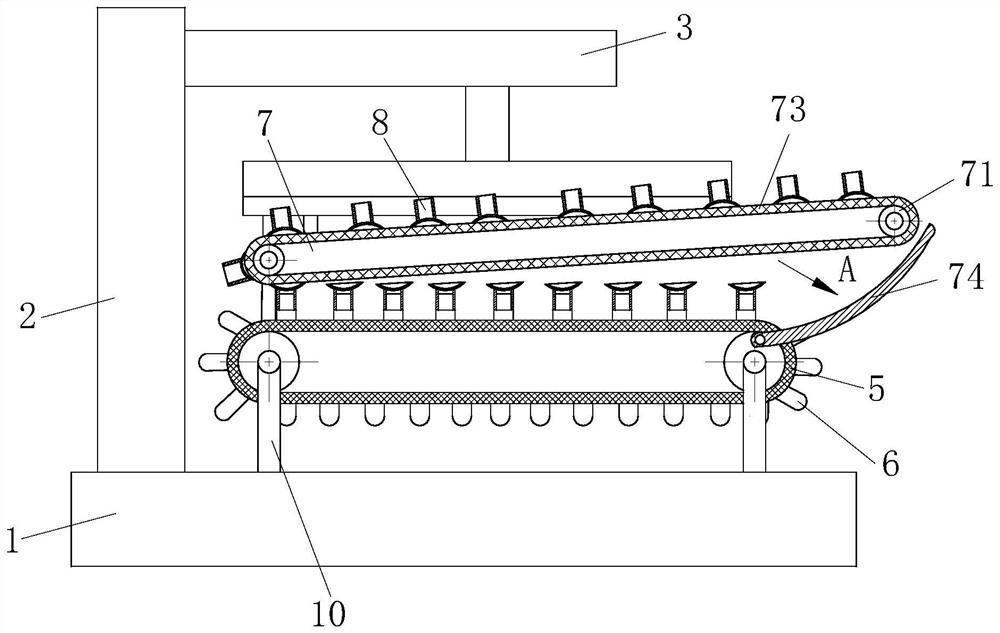

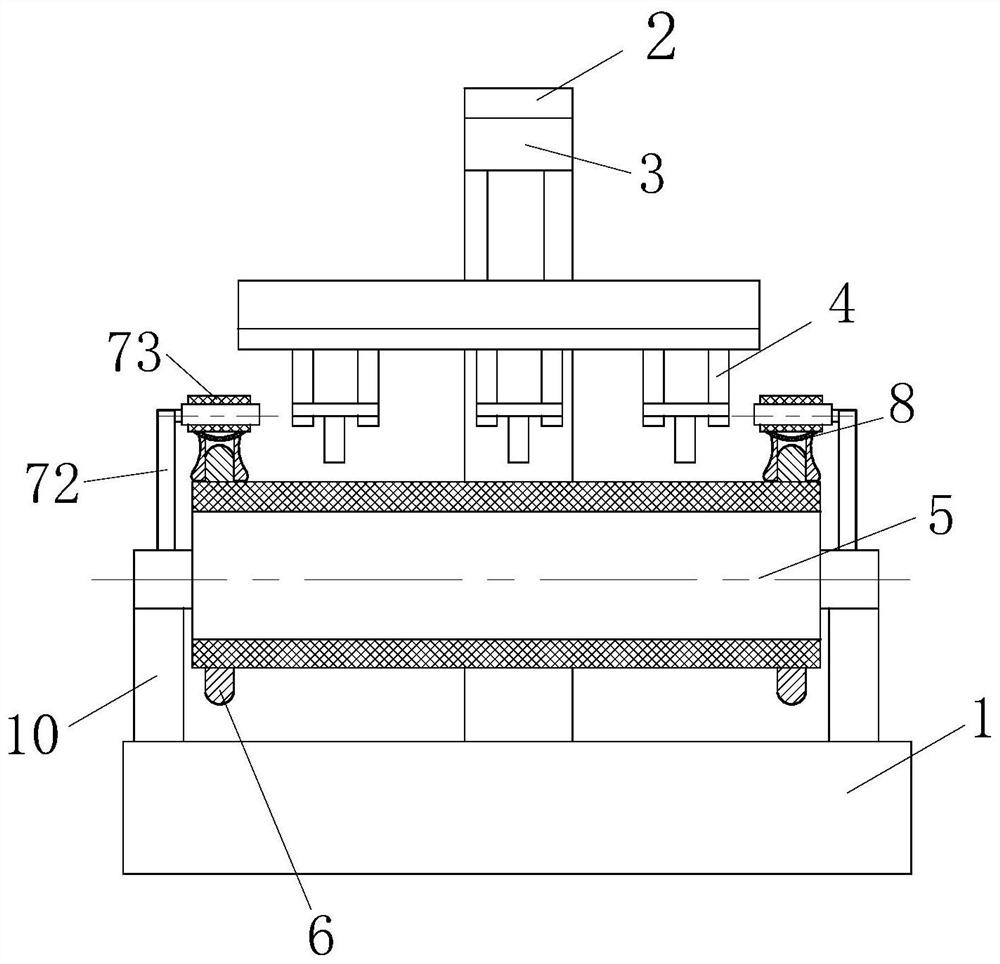

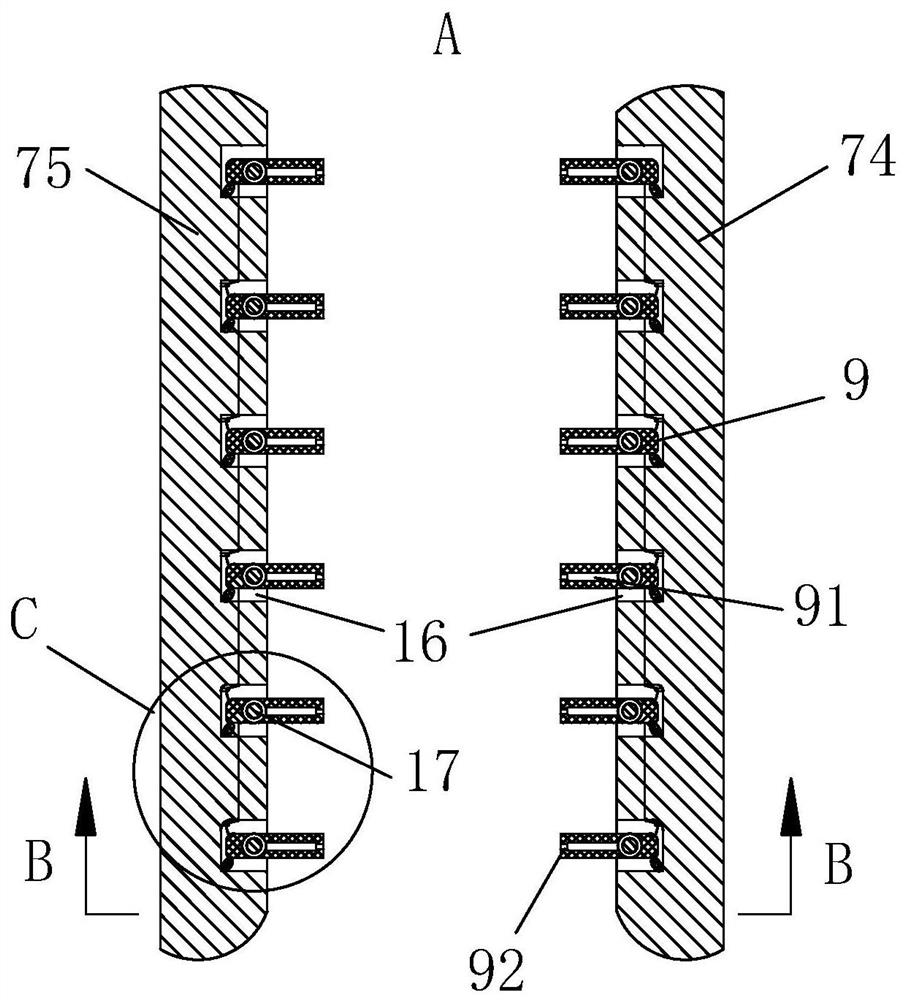

[0032] S2, the cloth conveyor belt 5 in the printing equipment and the smooth rubber conveyor belt 73 above it carry out synchronous delivery of the cloth;

[0033] S3, during the process of conveying the cloth in S2, the inkjet 4 sprays ink on the cloth under the control of the inkjet control system;

[0034] S4, sending the cloth printed in S3 to the dryer for drying;

[0035] S5, making the cloth roll after drying in S4 into a roll;

[0036] Such as figure 1 with figure 2 Shown, wherein, the printing equipment that adopts in this method comprises support base 1, support frame 2, beam arm 3 and inkjet 4; One side of described support base 1 is fixed with support frame 2, and is fixed on the support frame 2 There is a crossbeam arm 3; the bottom end of the crossbeam arm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com