A digital inkjet cloth printing machine

A technology of digital inkjet and printing machine, applied in the field of fabric processing, which can solve the problems of color pattern deformation or distortion, and fabric easily stretched or deformed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

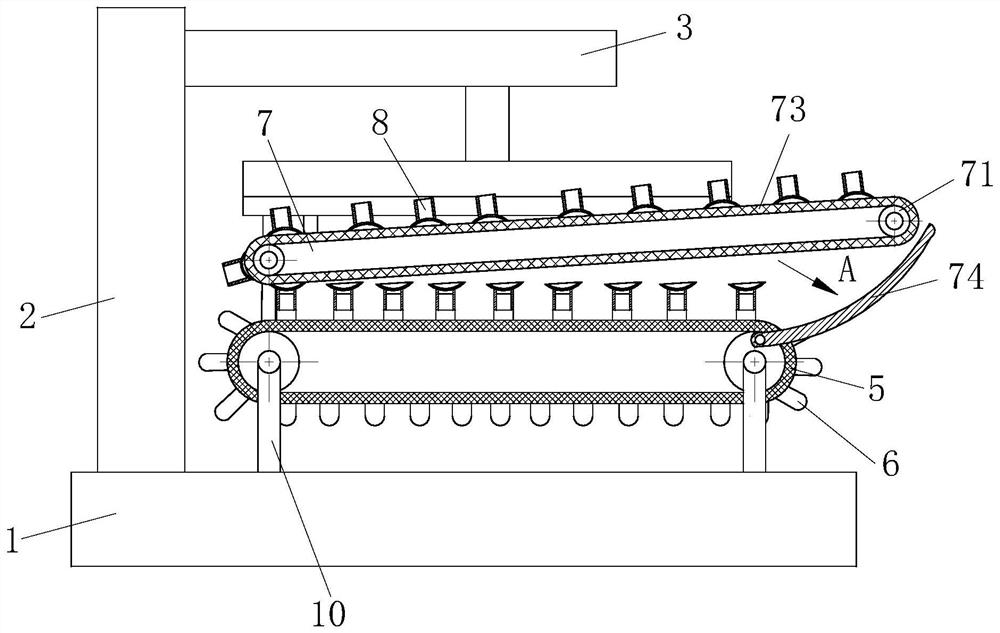

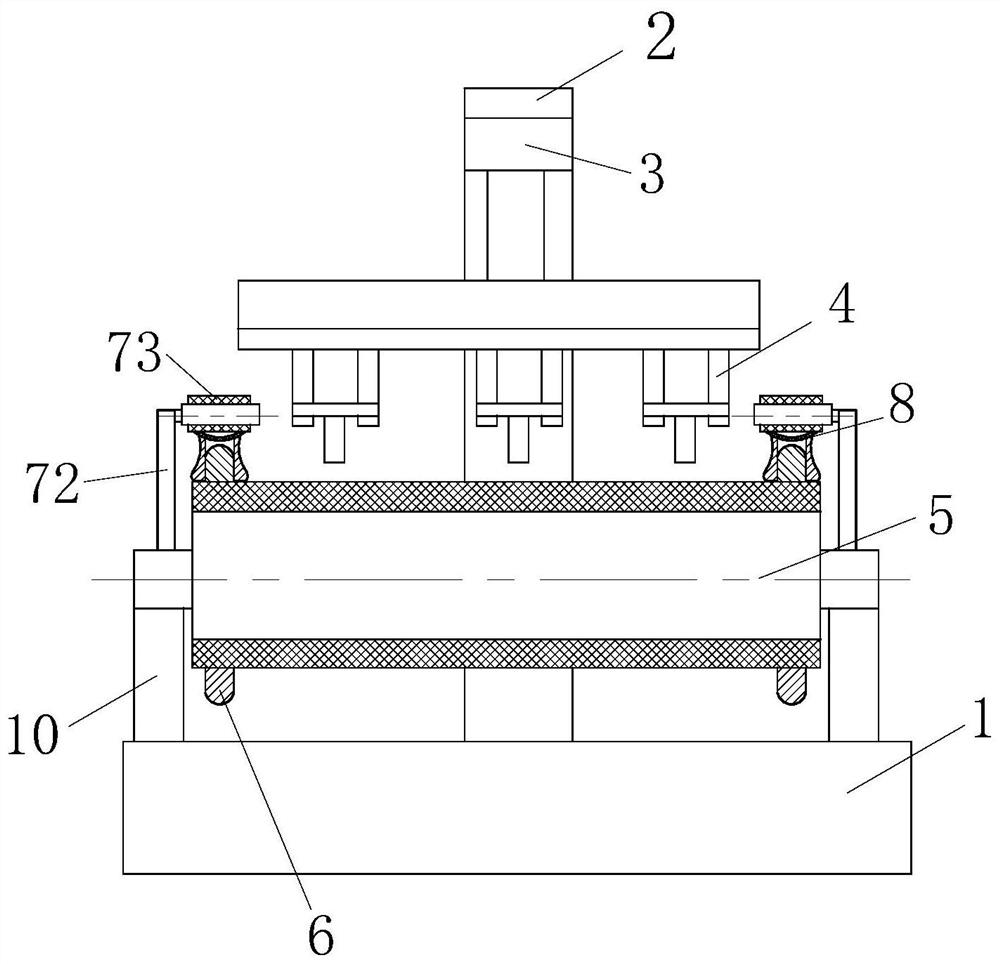

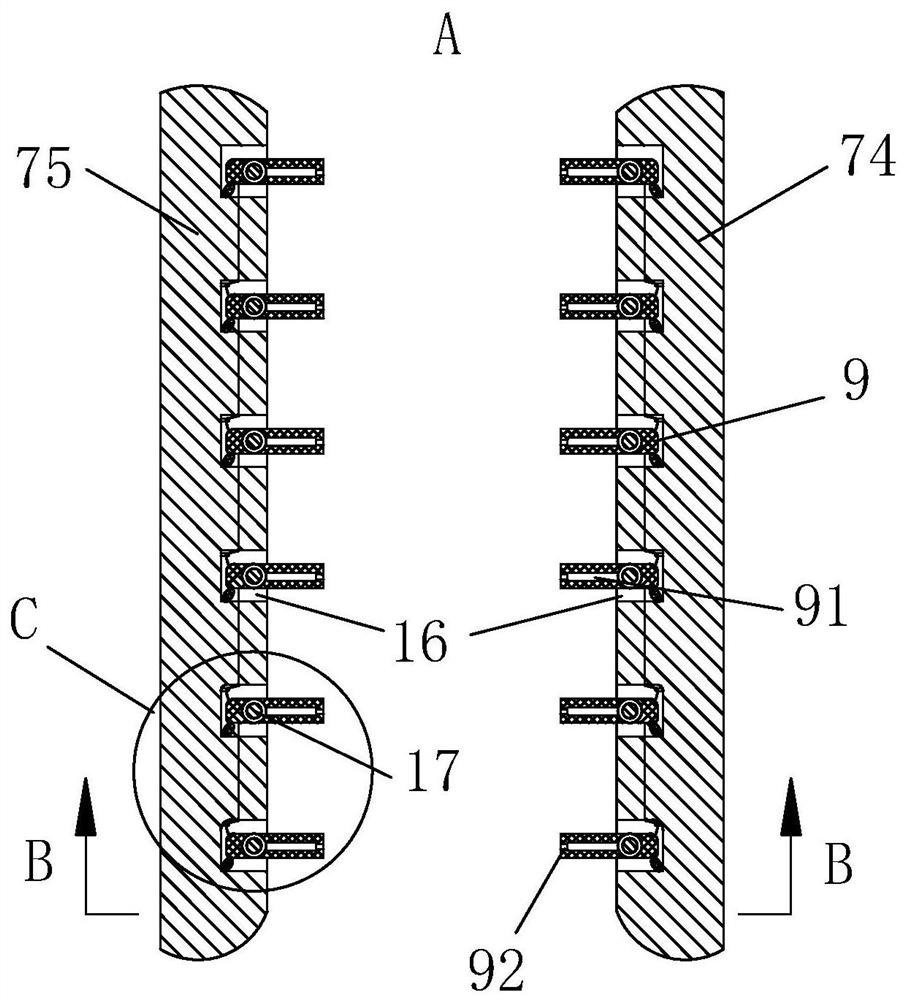

[0024] use Figure 1-Figure 7 A digital inkjet cloth printing machine according to an embodiment of the present invention is described as follows.

[0025] Such as figure 1 with figure 2 As shown, a digital inkjet cloth printing machine according to the present invention includes a support base 1, a support frame 2, a beam arm 3 and an inkjet 4; one side of the support base 1 is fixed with a support frame 2, And the support frame 2 is fixed with a crossbeam arm 3; the bottom end of the crossbeam arm 3 is connected with a heating plate through a connecting column, and the bottom end of the heating plate is provided with an inkjet 4 through a cover plate; the upper end of the support base 1 A cloth conveyor belt 5 is provided through the support rod 10, and fixed pins 6 are evenly arranged on both sides of the outer surface of the cloth conveyor belt 5; an installation pull-out unit 7 is arranged directly above the fixed pin 6, and the pull-out unit 7 is installed A fixed sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com