Modified carbon black, and preparation method and application thereof in preparation of black chemical powdered ink

A modified, carbon black technology, applied in chemical instruments and methods, optics, electrography, etc., can solve the problems of poor dispersibility, wide particle size distribution, poor carbon black wettability, etc., to improve dispersibility and stability, The effect of improving utilization and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

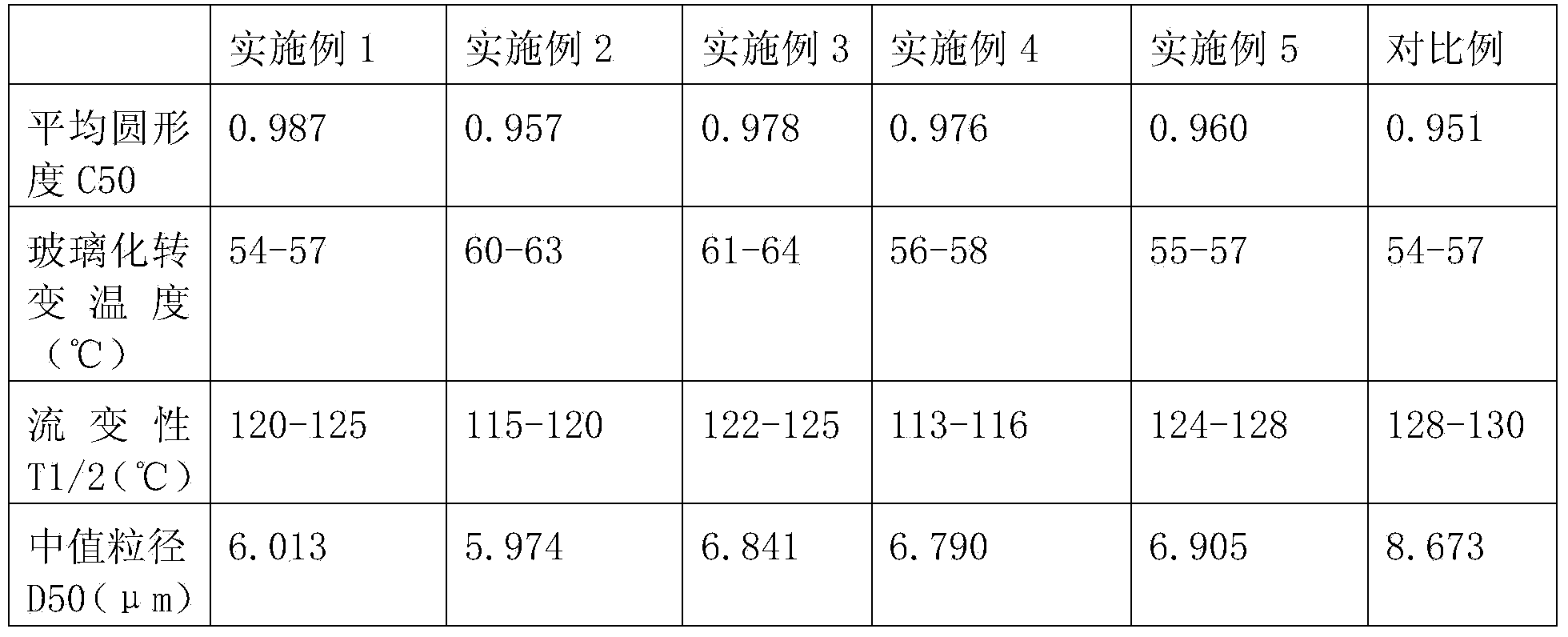

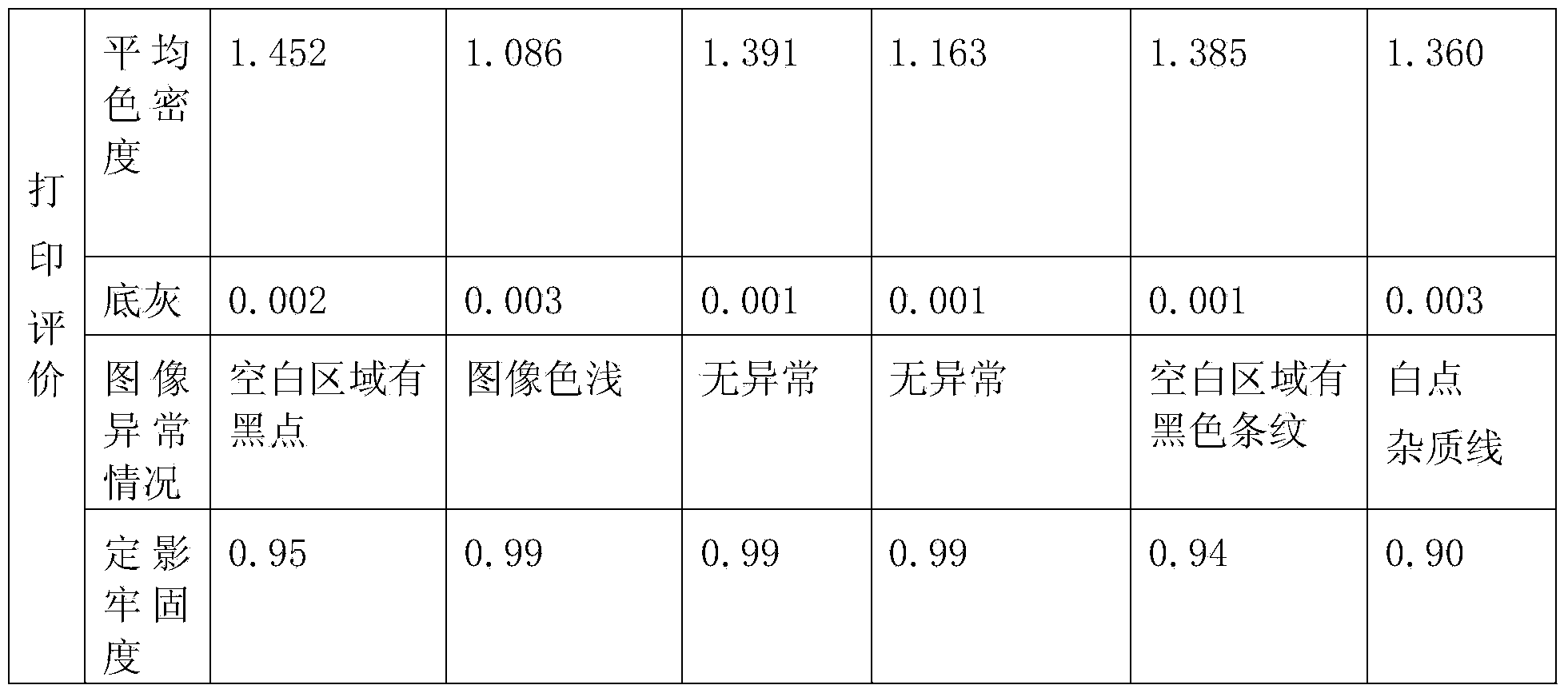

Examples

Embodiment 1

[0046] The modified carbon black described in the present embodiment is prepared through the following steps:

[0047] (1) Add 5kg of carbon black to 100L of concentrated sulfuric acid, stir at a speed of 200r / min, stir evenly, control the temperature at 30°C, and react for 2h;

[0048] (2) Take 7kg of strong oxidant hydrogen peroxide and 8kg of potassium permanganate, 15kg in total, and add it to the mixed solution obtained in step (1), and react in a water bath at 25°C for 1 hour;

[0049] (3) Stir the mixed solution obtained in step (2) at a speed of 200 r / min, slowly add deionized water to dilute, filter under reduced pressure, and wash to obtain the modified carbon black.

[0050] The method for preparing black chemical toner with the prepared modified carbon black comprises the following steps:

[0051] (1) Take 1.8kg of sodium lauryl sulfate and 1.8kg of sodium cetyl sulfate, and make a total of 3.6kg of the above surfactants into a deionized aqueous solution with a co...

Embodiment 2

[0057] The modified carbon black described in the present embodiment is prepared through the following steps:

[0058] (1) Add 6kg of carbon black to 100L of concentrated nitric acid, stir at a speed of 300r / min, stir evenly, control the temperature at 70°C, and react for 6h;

[0059] (2) Take 5kg of strong oxidant potassium dichromate and 5kg of potassium hypochlorite, 10kg in total, and add it to the mixed solution obtained in step (1), and react in a water bath at 35°C for 3h;

[0060] (3) Stir the mixed solution obtained in step (2) at a speed of 300 r / min, slowly add deionized water to dilute, filter under reduced pressure, and wash to obtain the modified carbon black.

[0061] The method for preparing black chemical toner with the prepared modified carbon black comprises the following steps:

[0062] (1) Get 2kg of the surfactant laurylamine hydrochloride and 2kg of stearyl amine hydrochloride to make a deionized aqueous solution with a concentration of 15wt%; get 6kg o...

Embodiment 3

[0068] The modified carbon black described in the present embodiment is prepared through the following steps:

[0069] (1) Add 17.5kg of carbon black to 300L of concentrated hydrochloric acid, stir at a speed of 300r / min, stir evenly, control the temperature at 70°C, and react for 4h;

[0070] (2) Take 10kg of strong oxidizing agent potassium hypochlorite and 25kg of potassium persulfate, 35kg in total, and add it to the mixed solution obtained in step (1), and react in a water bath at 30°C for 2 hours;

[0071] (3) Stir the mixed solution obtained in step (2) at a speed of 400 r / min, slowly add deionized water to dilute, filter under reduced pressure, and wash to obtain the modified carbon black.

[0072] The method for preparing black chemical toner with prepared carbon black comprises the steps:

[0073] (1) Take the mixture of the surfactant lauryl sulfonate 3kg, aliphatic amide sulfate 3kg, sodium dodecylbenzenesulfonate 3kg and polyoxyethylene alkyl ether 3kg to make a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com