Packaging box green printing process based on water-based ink

A technology of water-based ink and packaging box, which is applied in packaging, transportation and packaging, and the manufacture of rigid/semi-rigid containers. It can solve the problems of poor water resistance of printing ink, inconvenient practical application, and poor printing effect, and achieve excellent water resistance. , high practicability, excellent printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

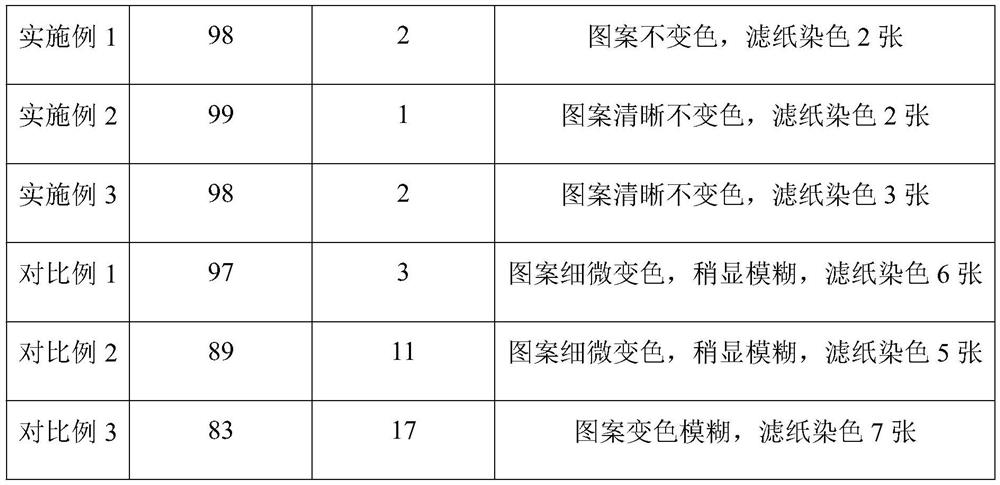

Embodiment 1

[0034] A kind of packing box green printing technology based on water-based ink, comprises the following steps:

[0035] (1) Take dopamine hydrochloride, polyethylenimine and Tris-HCl and mix evenly, the pH is 8.5, soak the packing box substrate and soak and deposit for 2 hours, take it out and wash and dry to obtain the pretreated substrate; dopamine hydrochloride The concentration of the product is 2g / L; the mass ratio of dopamine hydrochloride and polyethyleneimine is 2:1;

[0036] (2) Take 0.2g of silicon dioxide and 90mL of toluene, mix and ultrasonically disperse for 20min, add 0.2g of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate and 10mL of toluene mixed solution under argon atmosphere, 70 Stir and react at ℃ for 5 hours, collect by centrifugation, wash and dry to obtain filler silica;

[0037] Take 100g of tung oil, 14.3g of ethylene glycol and 0.6g of zinc acetate, raise the temperature to 120°C under nitrogen, react for 9h, collect the product, wash with ...

Embodiment 2

[0045] A kind of packing box green printing technology based on water-based ink, comprises the following steps:

[0046] (1) Take dopamine hydrochloride, polyethylenimine and Tris-HCl and mix evenly, pH is 8.5, soak and impregnate and deposit the packing box substrate for 2.5h, take it out and wash and dry to obtain the pretreated substrate; dopamine hydrochloride The concentration of salt is 2g / L; the mass ratio of dopamine hydrochloride and polyethyleneimine is 2:1;

[0047] (2) Take 0.2g of silicon dioxide and 90mL of toluene, mix and ultrasonically disperse for 25min, add 0.2g of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate and 10mL of toluene mixed solution under argon atmosphere, 72 Stir and react at ℃ for 4.5 hours, collect by centrifugation, wash and dry to obtain filler silica;

[0048] Take 100g of tung oil, 14.3g of ethylene glycol and 0.6g of zinc acetate, raise the temperature to 125°C under nitrogen, react for 8.5h, collect the product, wash with deio...

Embodiment 3

[0056] A kind of packing box green printing technology based on water-based ink, comprises the following steps:

[0057] (1) Take dopamine hydrochloride, polyethyleneimine and Tris-HCl and mix evenly, the pH is 8.5, soak and soak the base material of the packaging box for 3 hours, wash and dry after taking it out, and obtain the pretreated base material; dopamine hydrochloride The concentration of the product is 2g / L; the mass ratio of dopamine hydrochloride and polyethyleneimine is 2:1;

[0058] (2) Take 0.2g of silicon dioxide and 90mL of toluene, mix and ultrasonically disperse for 30min, add 0.2g of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate and 10mL of toluene mixed solution under argon atmosphere, 75 Stir and react at ℃ for 4 hours, collect by centrifugation, wash and dry to obtain filler silica;

[0059] Take 100g of tung oil, 14.3g of ethylene glycol and 0.6g of zinc acetate, raise the temperature to 130°C under nitrogen, react for 9h, collect the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com