Printing device suitable for textile fabrics

A technology for textile fabrics and printing, applied in printing devices, printing, printing machines, etc., can solve the problems of wrinkling, loss, and pollution of fabrics, and achieve the effect of ease of use and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

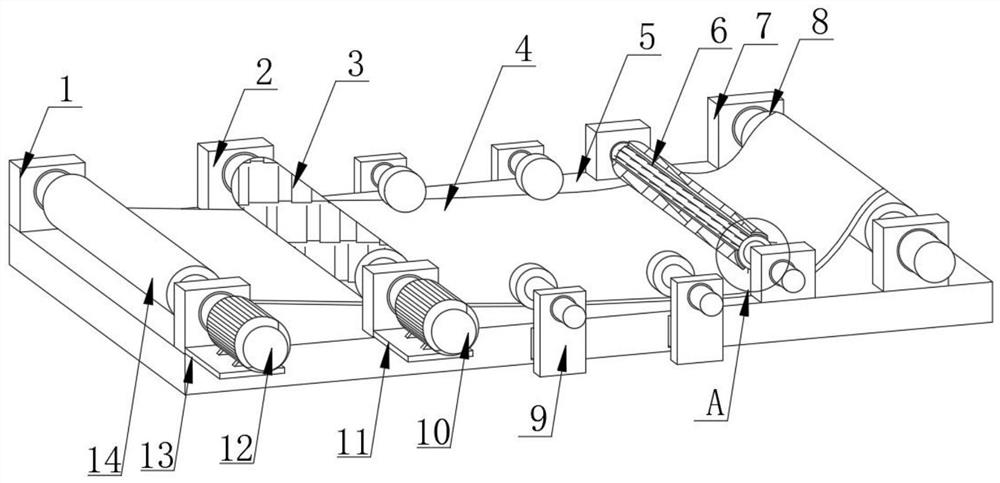

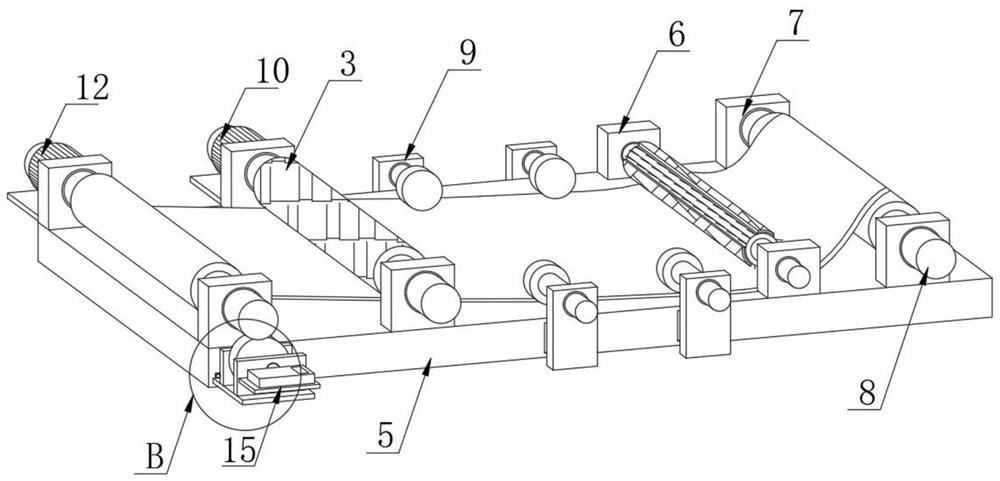

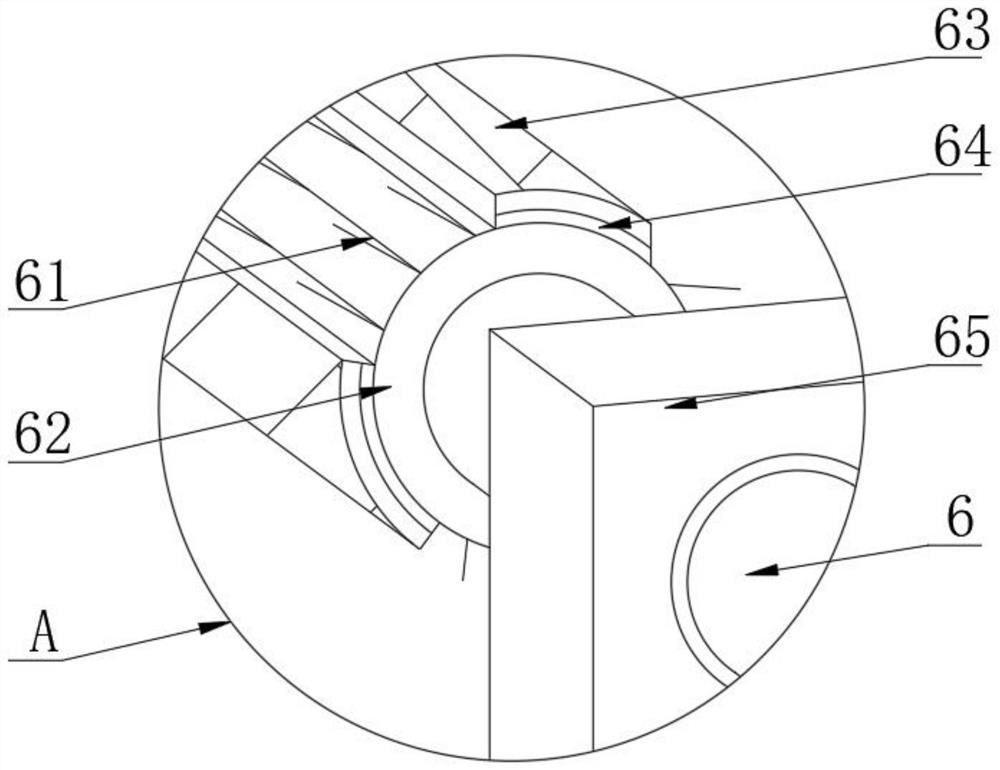

[0025] see Figure 1-6 , in an embodiment of the present invention, a printing device suitable for textile fabrics includes a workbench 5, the upper surface of the workbench 5 is fixedly installed with a first fixing seat 1 and a third fixing seat 7 respectively from left to right, the first The inside of fixed seat 1 is installed with winding roller 14 through, and one end of winding roller 14 is connected to the driving end of second motor 12, and second motor 12 is fixedly installed on the upper surface of second connecting seat 13, and the third fixed seat 7 The inner rotation of the unwinding roller 8 is installed, and the outer surface of the unwinding roller 8 is wound with a fabric 4, and the upper surface of the workbench 5 is fixed on the side close to the third fixed seat 7. The cleaning assembly 6 is fixedly installed, and the cleaning assembly 6 includes a cleaning brush 61 , cleaning roller 62, cleaning cotton 63, viscose layer 64 and fixed plate 65, the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com