A nozzle steering mechanism and a plastic tank cleaning device using the nozzle steering mechanism

A technology of steering mechanism and nozzle, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, large waste of water resources, poor cleaning effect, etc., and achieve good high-pressure flushing effect , High degree of automation, guarantee comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

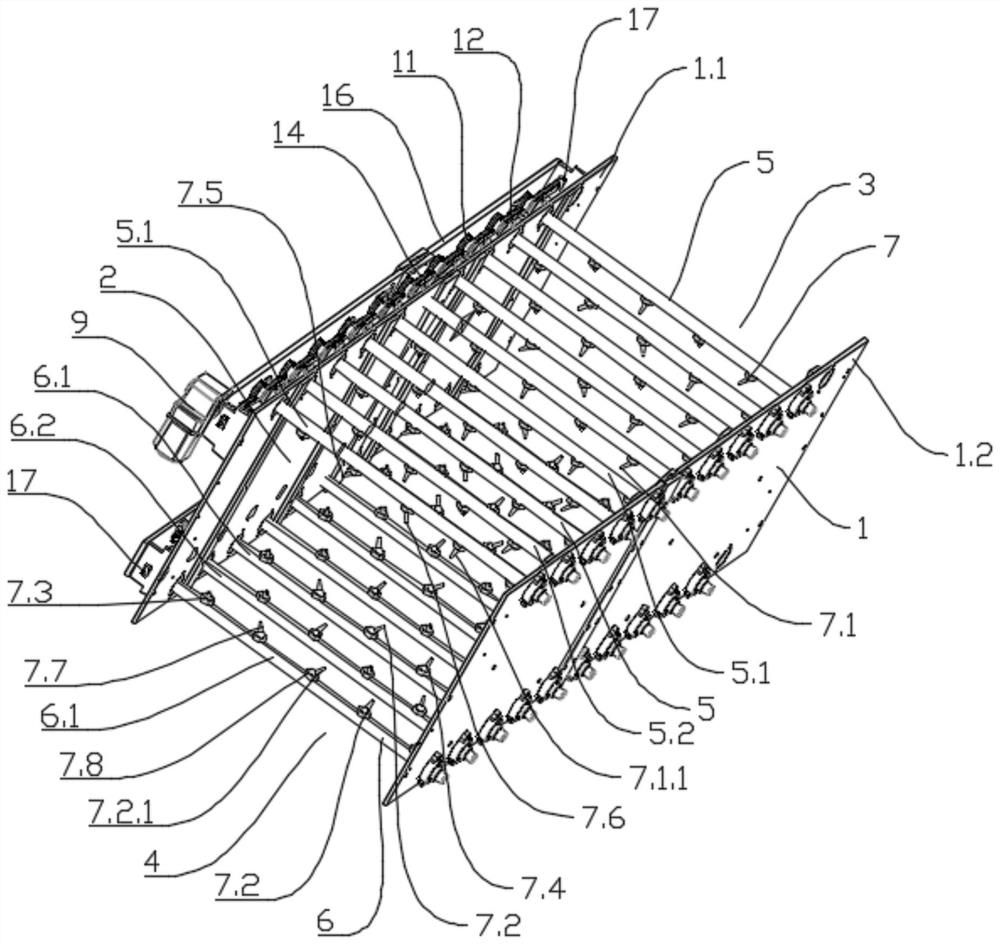

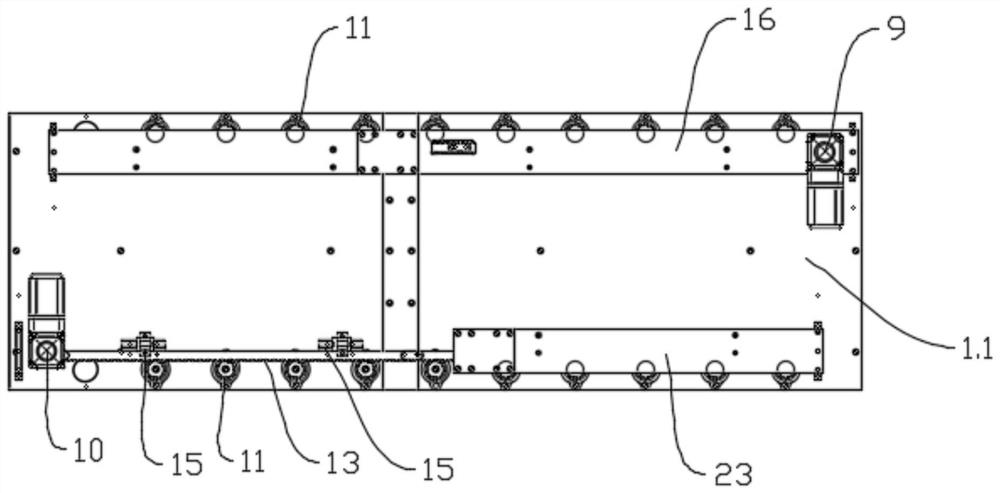

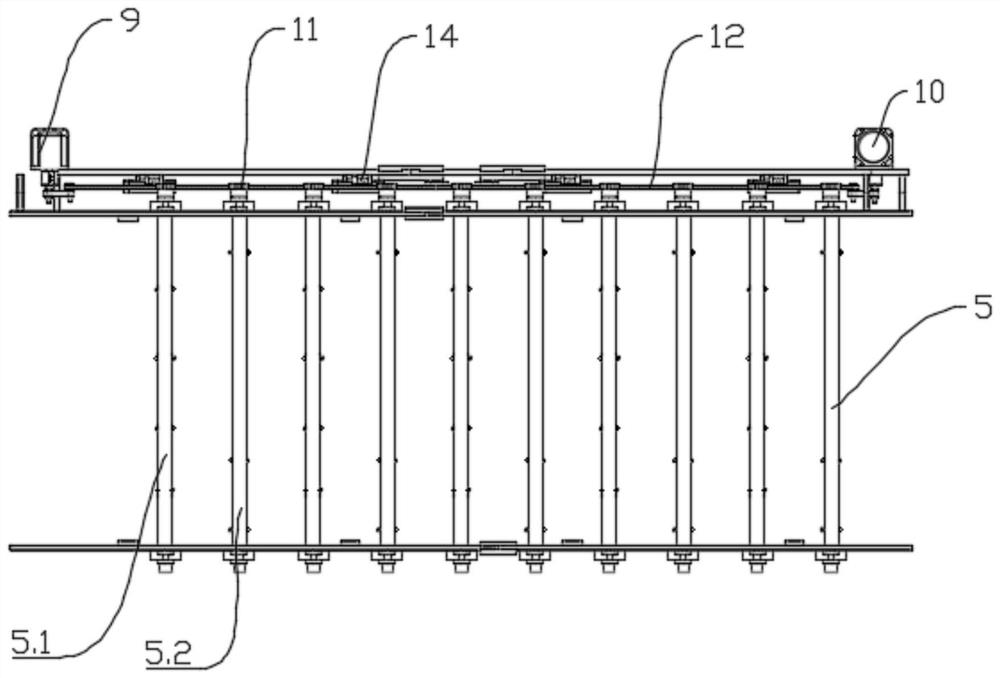

[0043] Such as Figure 1-Figure 7 As shown, this embodiment provides a nozzle steering mechanism, which includes a mounting frame 1, and the mounting frame 1 is provided with an upper installation position, a lower installation position below the upper installation position, and a cleaning device between the upper installation position and the lower installation position. Area 2, cleaning area 2 is provided with inlet end 3 and outlet end 4, and the upper installation position is provided with a plurality of rotating shafts 15, and the lower installation position is provided with a plurality of rotating shafts 26, a plurality of rotating shafts 5 and 6 They are all arranged side by side in the direction from the inlet end 3 to the outlet end 4. The first rotating shaft 5 and the second rotating shaft 6 are rotationally connected with the installation frame 1, and the first rotating shaft 5 and the second rotating shaft 6 are provided with a nozzle 7. The nozzles of 7 are all t...

Embodiment 2

[0049] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0050] Such as Figure 1-Figure 7 As shown, the nozzle 7 set on the rotating shaft 5 is the nozzle 1 7.1, the nozzle 7 provided on the rotating shaft 6 is the nozzle 2 7.2, and the nozzle 7.1 is evenly arranged in multiples along the length direction of the rotating shaft 5. Two nozzles 7.2 are evenly arranged in multiples along the length direction of the rotating shaft two 6 .

[0051] Nozzle 1 7.1 and Nozzle 2 7.2 adopt a uniformly arranged structure, which can achieve thorough cleaning of each surface of the glue tank.

[0052] Specifically, in this embodiment, there are 4 nozzles 1 7.1 on the first rotation axis 5, and 4 nozzles 2 7.2 on the rotation axis 2 6.

Embodiment 3

[0054] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 2.

[0055] Such as Figure 1-Figure 7 As shown, the upper mounting position and the lower mounting position are intersected with odd-numbered rotating shaft positions and even-numbered rotating shaft positions, and the rotating shaft one 5 and rotating shaft two 6 installed on the odd-numbered rotating shaft positions are respectively odd-numbered rotating shaft 1 5.1 and odd-numbered rotating shaft Two 6.1, the first rotating shaft 5 and the second rotating shaft 6 installed on the even rotating shaft positions are the first even rotating shaft 5.2 and the second even rotating shaft 6.2;

[0056] Rotating shaft 1 5 and rotating shaft 2 6 are intersected with odd-numbered installation positions and even-numbered installation positions. Nozzle 1 7.1 is installed on the odd-numbered installation positions of odd-numbered rotational shaft 1 5.1 and on the even-numbered installation pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com