High-speed wire coating device and method

A technology for equipment and equipment operation, which is applied in coatings, textiles and papermaking, and devices for coating liquids on surfaces, etc. It can solve problems such as restrictions, easy blockage of devices, and increased speed of cord travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

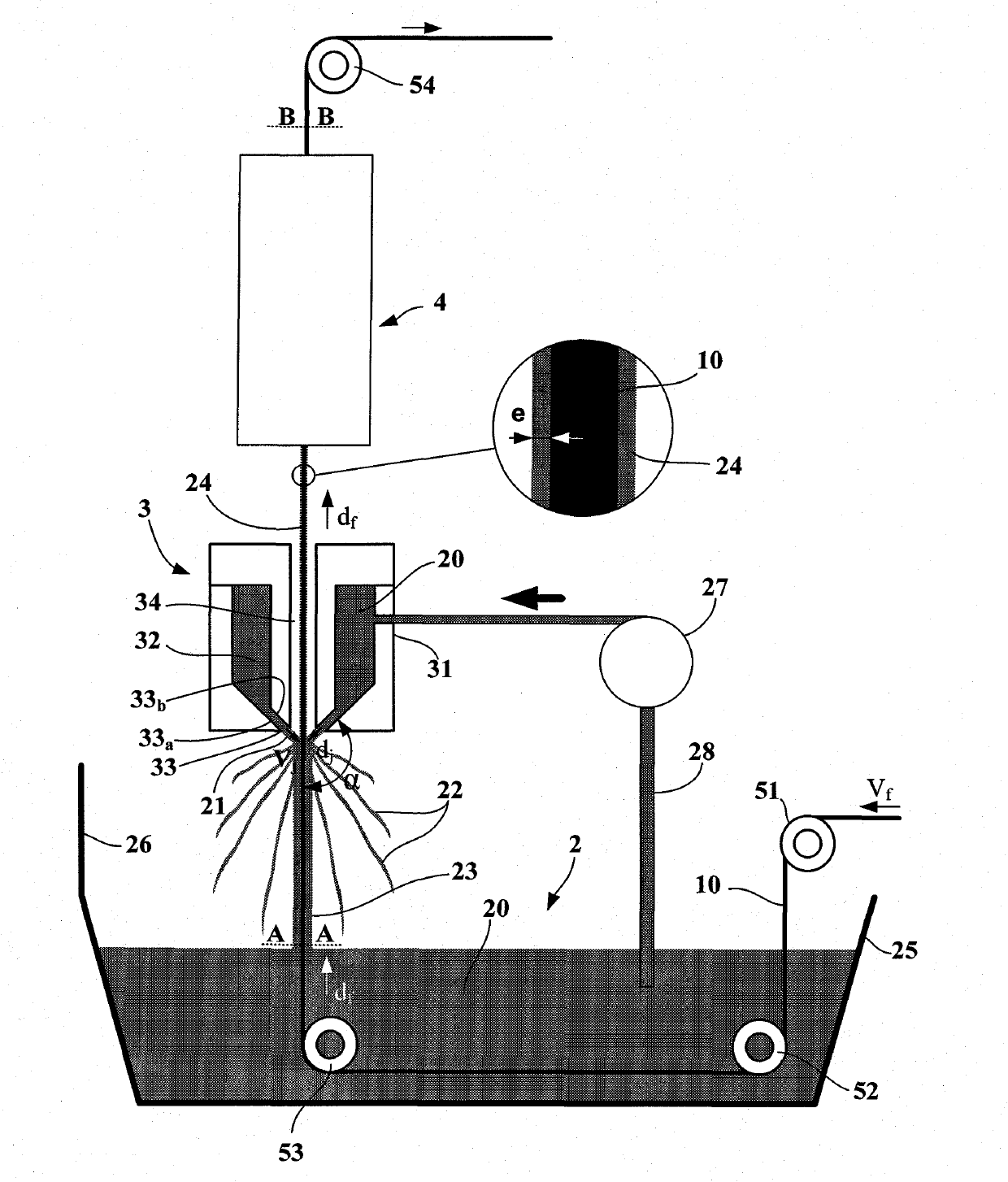

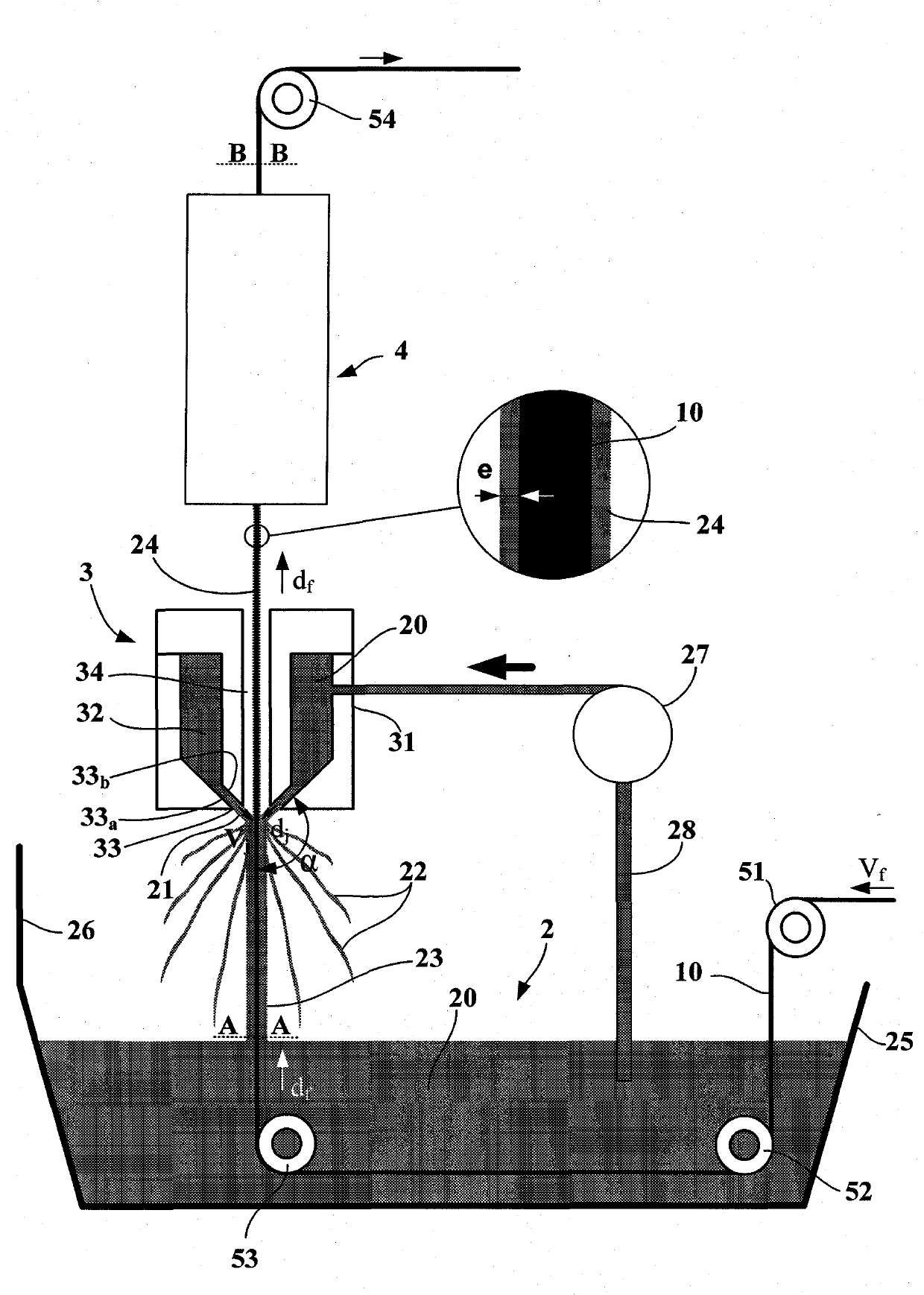

[0022] The device on which this description is based comprises impregnation means 2, drainage means 3, treatment means and means formed by turning pulleys, which enable the cord 10 to be impregnated from the inlet (51) to the outlet (54) of the device Travels between devices (52, 53) and through impregnation devices (52, 53).

[0023] The impregnation device 2 is formed, for example, by a tank 25 containing the treatment liquid 20 . The treatment liquid may be a solute dissolved in a solvent or an organic composition capable of curing under the action of a heat or energy source such as laser light or ultraviolet radiation.

[0024] A drive means (not shown), such as a motorized pulley, drives the continuous cord 10 through the tank 25 from a cord source (not shown). cord at speed V f Move down through processing equipment. On leaving the plant, the cords can be repackaged for subsequent manufacturing steps, or they can be integrated directly into the material to be reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com